High-toughness and low-yield-ratio quenched and tempered steel plate used in low-temperature environment and manufacturing method of high-toughness and low-yield-ratio quenched and tempered steel plate

A quenched and tempered steel plate, low-temperature environment technology, applied in the chemical industry, can solve the problems of low production efficiency, low control level of steel plate thickness precision, etc., achieve deterioration of welding performance, promote fine and multi-orientation distribution, improve strength, toughness and anisotropy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with specific examples.

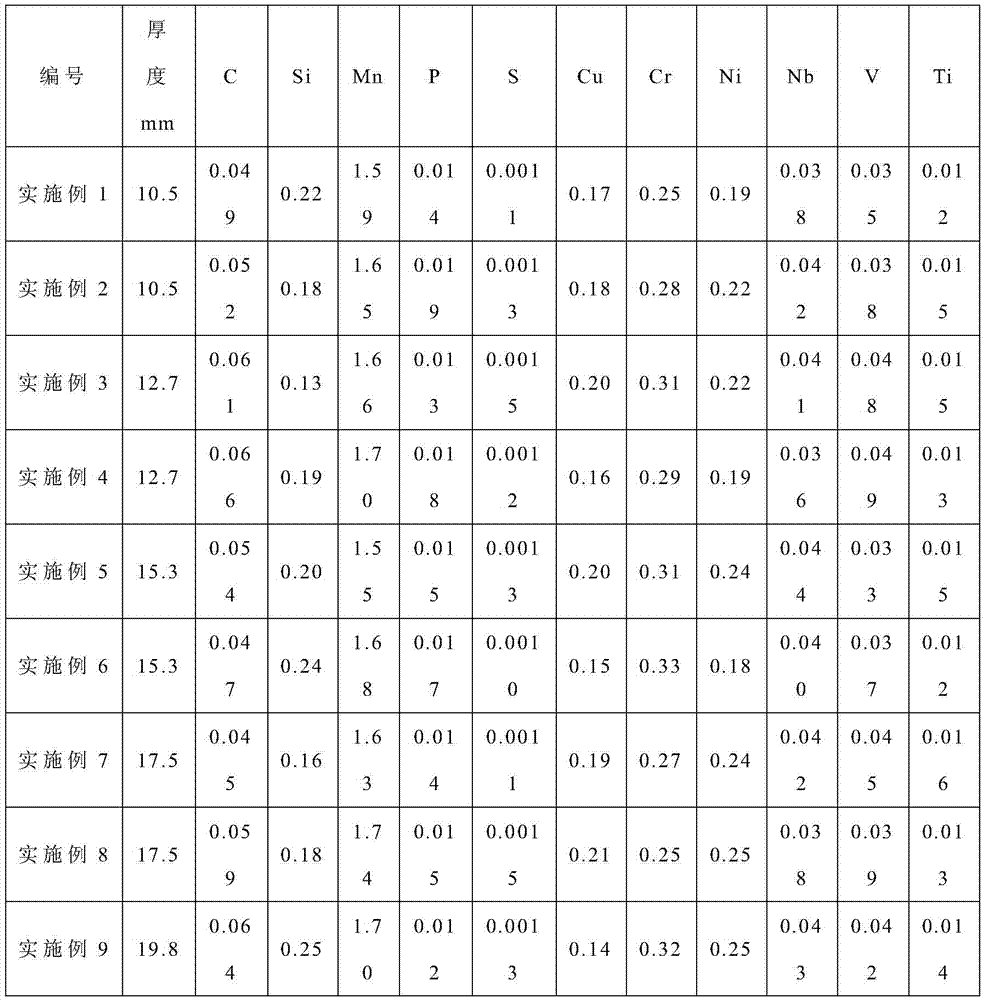

[0034] Table 1 is the value list of each embodiment of the present invention and comparative examples;

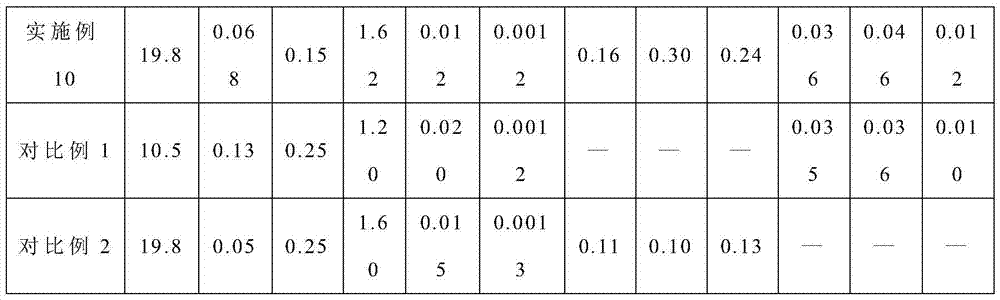

[0035] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

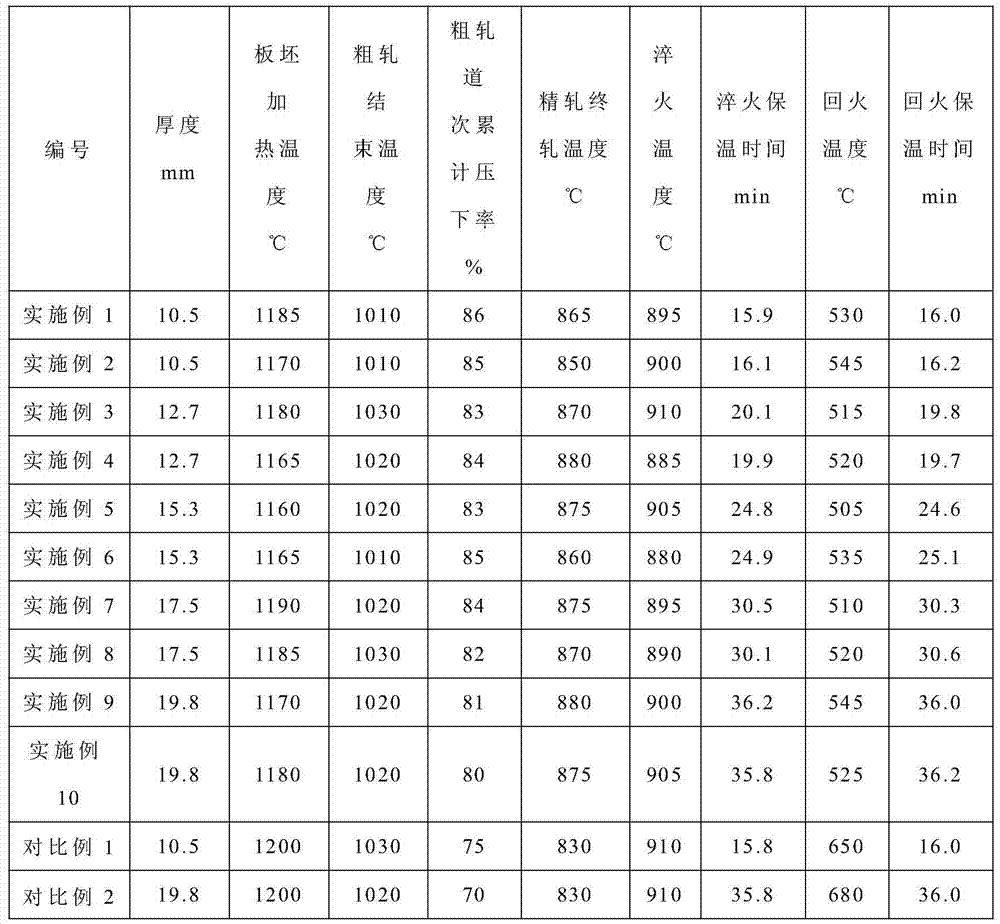

[0036] Table 3 is each embodiment of the present invention and comparative example mechanical property detection situation list;

[0037] Each embodiment of the present invention is produced according to the following steps:

[0038] (1) The reheating temperature of the slab is 1160-1190°C, the finishing temperature of the rough rolling is 1010-1030°C, the cumulative reduction rate in the rough rolling stage is ≥80%, the finishing rolling temperature is 850-880°C, and the steel coil is cooled The method is air cooling.

[0039] (2) The hot-rolled steel coil is flattened into a hot-rolled steel plate, which is quenched and tempered to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com