A production method of low inclusion clean steel

A production method and technology for cleaning steel, applied in the field of metal materials, can solve the problems of low level of steel equipment, poor quality awareness, low technical level, etc., and achieve the effects of saving process costs, improving production efficiency, and reducing the generation of inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

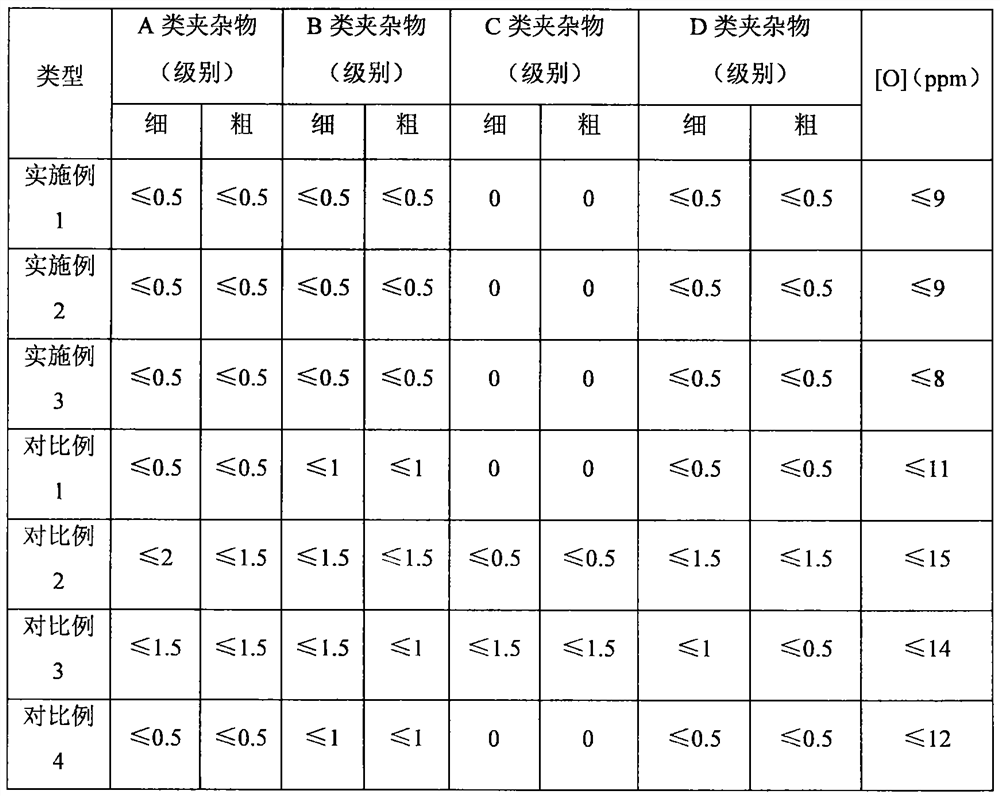

Examples

Embodiment 1

[0049] The production method of low-inclusion clean steel is characterized in that the steel composition is C 0.012%, Si 0.15%, Mn 0.85%, P 0.001%, S 0.001%, Nb 0.045%, Ti 0.01%, Al 0.002% , Cr1.85%, Mo 0.65%, Ni 2.55%, Cu 0.15%, W 0.005%, Zr 0.0001%, Ta 0.0001%, rare earth La+Y 0.0001%, La:Y mass ratio is 2:1, B 0.0001% , N 0.0025%, the balance is Fe and unavoidable impurity elements.

[0050] The process route includes: ratio preparation → hot metal pretreatment desulfurization → converter smelting → LF refining → RH refining → continuous casting → rolling → coiling; the specific steps are as follows:

[0051] (1) Desulfurization by KR molten iron pretreatment: slag removal to ensure that the thickness of the slag layer on the liquid surface is ≤15mm, the oxygen blowing time is 14-18min, the oxygen supply intensity is 10000-13000m3 / h, the S content of the molten iron before treatment is ≤0.03%, and the injection particle size Granular magnesium with a particle size of 1.2-1...

Embodiment 2

[0059] The production method of low-inclusion clean steel is characterized in that: the steel composition is C0.013%, Si 0.16%, Mn0.86%, P 0.003%, S 0.002%, Nb 0.05%, Ti 0.011%, Al 0.003%, Cr 1.9%, Mo 0.7%, Ni 2.6%, Cu 0.17%, W 0.006%, Zr 0.0002%, Ta 0.002%, rare earth La+Y 0.0002%, La:Y mass ratio is 2:1, B 0.0003%, N 0.004 %, the balance is Fe and unavoidable impurity elements.

[0060] The process route includes: ratio preparation → hot metal pretreatment desulfurization → converter smelting → LF refining → RH refining → continuous casting → rolling → coiling; the specific steps are as follows:

[0061] (1) Desulfurization by KR molten iron pretreatment: slag removal to ensure that the thickness of the slag layer on the liquid surface is ≤15mm, the oxygen blowing time is 14-18min, the oxygen supply intensity is 10000-13000m3 / h, the S content of the molten iron before treatment is ≤0.03%, and the injection particle size Granular magnesium with a particle size of 1.2-1.5 cm ...

Embodiment 3

[0069]The production method of low inclusion clean steel is characterized in that: C0.015%, Si 0.18%, Mn 0.88%, P0.005%, S 0.005%, Nb 0.055%, Ti 0.012%, Al 0.004%, Cr 1.95%, Mo 0.75%, Ni2.65%, Cu 0.19%, W 0.008%, Zr 0.0004%, Ta 0.005%, rare earth La+Y0.0005%, La:Y mass ratio is 2:1, B 0.0005%, N 0.005% , the balance being Fe and unavoidable impurity elements.

[0070] The process route includes: ratio preparation → hot metal pretreatment desulfurization → converter smelting → LF refining → RH refining → continuous casting → rolling → coiling; the specific steps are as follows:

[0071] (1) Desulfurization by KR molten iron pretreatment: slag removal to ensure that the thickness of the slag layer on the liquid surface is ≤15mm, the oxygen blowing time is 14-18min, the oxygen supply intensity is 10000-13000m3 / h, the S content of the molten iron before treatment is ≤0.03%, and the injection particle size Granular magnesium with a particle size of 1.2-1.5 cm and lime powder with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com