High-strength and ductility steel plate for coal mine machinery and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

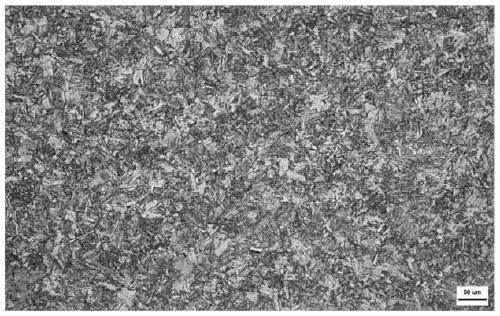

Image

Examples

Embodiment Construction

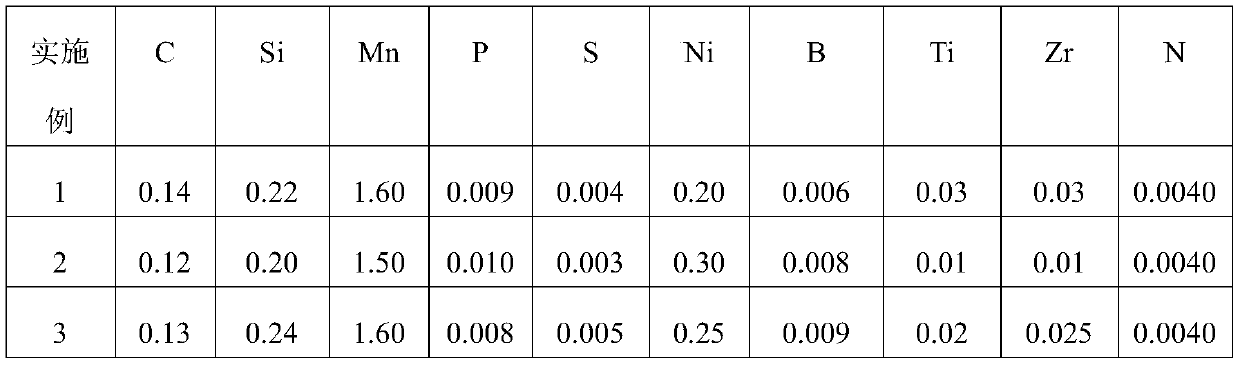

[0023] A high-strength and tough steel plate for coal mine machinery, its chemical composition and mass percentage are as follows: C: 0.12% to 0.14%, Si: 0.20% to 0.25%, Mn: 1.5% to 1.6%, P≤0.010%, S≤0.005% , Ni: 0.2% to 0.3%, B: 0.006% to 0.009%, Ti: 0.01% to 0.03%, Zr: 0.01% to 0.03%, N≤0.005%, and the balance is iron Fe and unavoidable impurities.

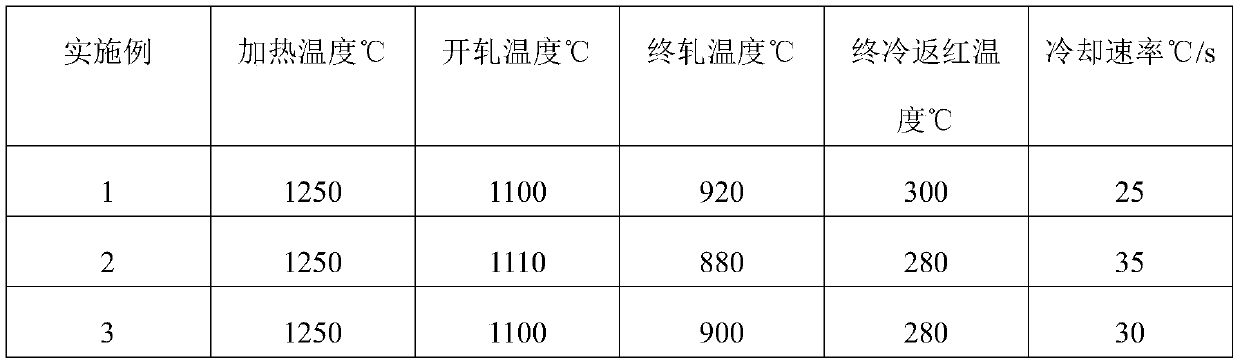

[0024] The preparation method of the above-mentioned steel plate: converter smelting→LF furnace refining→RH vacuum treatment→continuous casting→slab heating→hot rolling→laminar flow cooling→off-line stack cooling, wherein the thickness of the casting slab is 250mm, and the casting slab is heated to 1250°C , one-stage rolling is carried out on a thick plate rolling mill, the starting rolling temperature is 1100°C, and the final rolling temperature is 880-920°C. After rolling, the steel plate is cooled to ≤300°C at a cooling rate of 25-30°C / s, and then the steel plate The off-line pile is cold.

[0025] Below in conjunction with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com