A production line for producing electric ignition head brackets

An electric ignition head and production line technology, applied in the field of electric ignition head production and the production line of electric ignition head brackets, can solve problems such as high labor intensity, affecting product performance, unstable welding quality, etc., and achieve welding speed and quality improvement, High product quality stability, good drug head consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

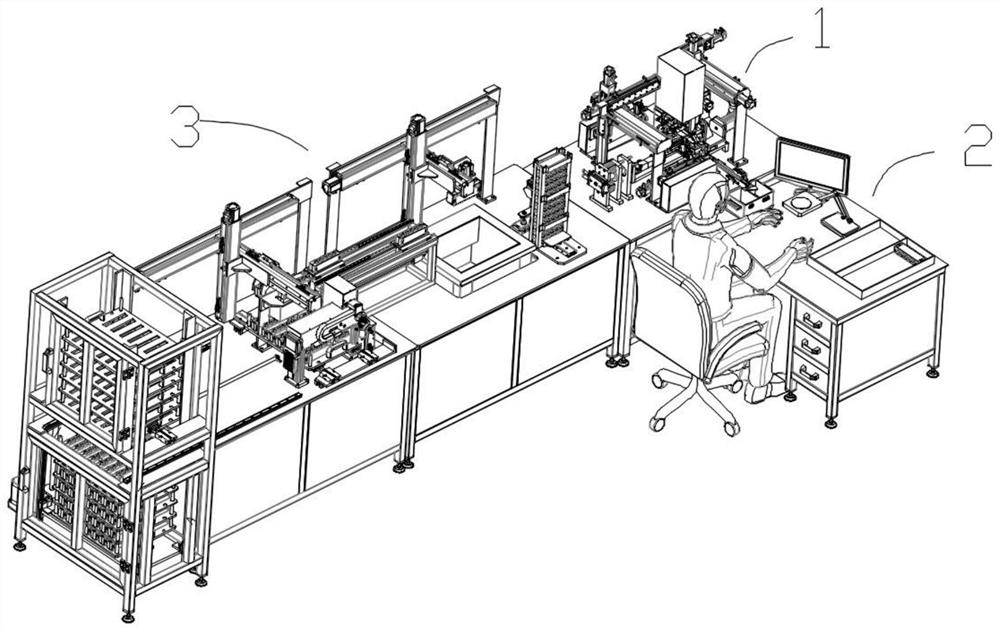

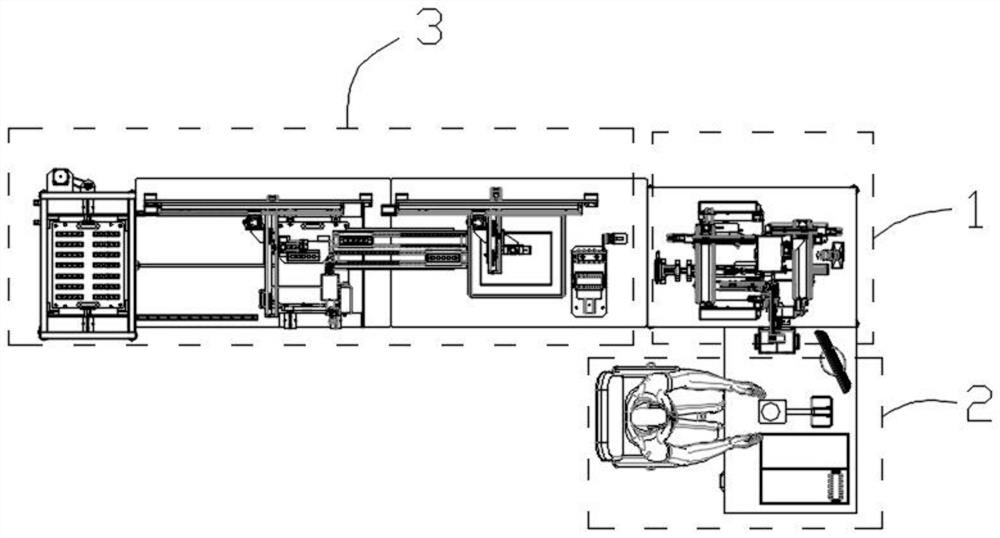

[0055] like Figures 1 to 23 As shown, this embodiment provides a production line for producing an electric ignition head bracket, including an automatic welding system 1 for welding foot wires and bridge wires on the toothed piece, and manual assistance for loading the welded toothed piece into a tooling. System 2. An automatic dipping and molding system for realizing the electric ignition head bracket formed by the tooth-shaped tablet in the tooling. 3. A control system for controlling the automatic welding system 1 and the automatic dipping and molding system 3. The automatic welding system 1 and The automatic medicine dipping and forming system 3 is electrically connected with the control system.

[0056] The control system adopts the upper computer and the SCADA system based on PLC control.

[0057] The artificial assistance system is mainly composed of a manual operation platform, a host computer, and a manual auxiliary processing bridge wire device. Manually take out ...

Embodiment 2

[0059] This embodiment is further optimized on the basis of implementation 1, specifically:

[0060] The automatic welding system 1 includes a welding frame 1-1, a feeding and turning mechanism 1-6 installed on the welding frame 1-1 for pushing and turning the toothed sheet, and a foot for actively outputting the foot wire. Wire constant tension wire feeder 1-7, bridge wire constant tension wire feeder 1-2 for actively outputting bridge wire, wire pulling mechanism 1-5 for pulling and cutting foot wire and bridge wire, and foot wire Laser welding system 1-4 for welding the toothed sheet with bridge wire, toothed sheet shearing machine 1-3 for cutting the welded toothed sheet to form an electric ignition head, and toothed sheet shearing machine 1-3 The matching electric ignition head down-line mechanism 1-8, the resistance detection system 1-10 for detecting the resistance of the tooth-shaped sheet, and the smoke and dust processing device 1-9 for processing the smoke and dust....

Embodiment 3

[0073] This embodiment is further optimized on the basis of implementation 1 or 2, specifically:

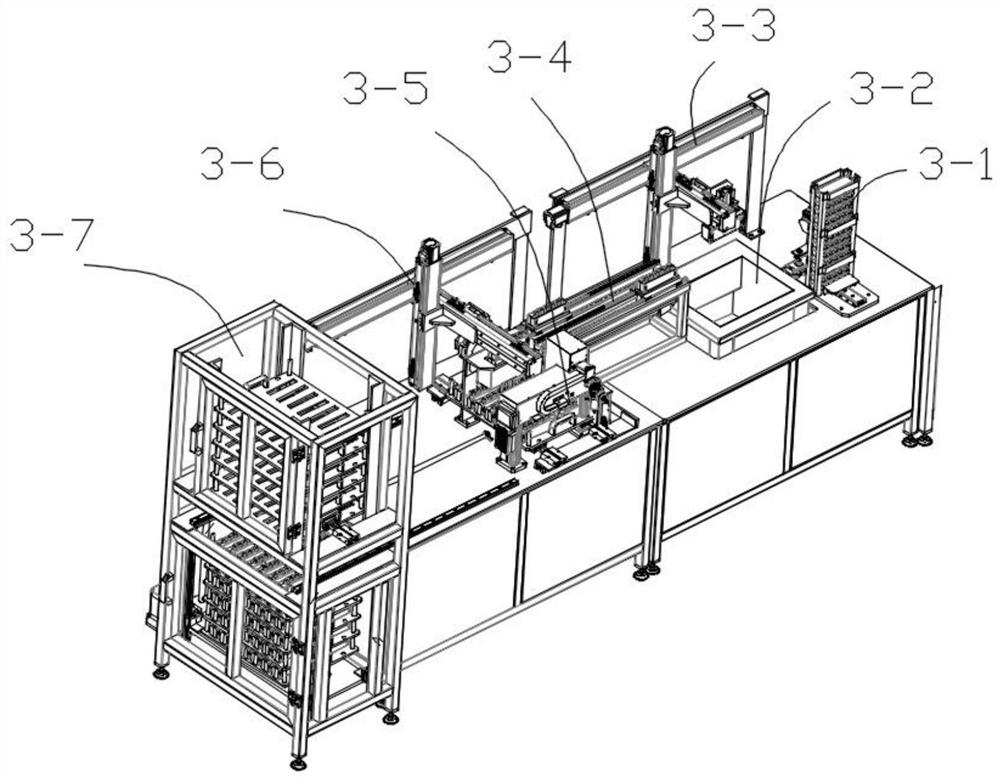

[0074] The automatic drug-dipping molding system 3 includes an installation table and a tooling feeding mechanism 3-1, a cleaning tank 3-2, a transport mechanism A3-3, a transport mechanism B3-4, and a drug-dipping plastic mechanism 3, which are sequentially arranged on the mounting table. -5. Handling mechanism C3-6 and automatic drying rack 3-7.

[0075] The medicine-dipping plastic mechanism 3-5 includes a medicine-dipping mold assembly 3-5.2, a liftable drying mechanism 3-5.3 arranged under the medicine-dipping mold assembly 3-5.2, and a side of the medicine-dipping mold assembly 3-5.2. Glue dispenser 3-5.1 for pouring medicine into medicine-dipping mold assembly 3-5.2, described medicine-dipping mold assembly 3-5.2 includes mounting bracket, a mold that can be opened and closed on the mounting bracket, and a stripper that drives the opening and closing of the mold. Molded c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com