Manifold welding machine

A welding machine and manifold technology, used in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of uncertain connection speed, decreased welding seam strength, large impact, etc., to achieve automatic welding and uniform welding seam. Smooth, lower product cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawings and embodiments.

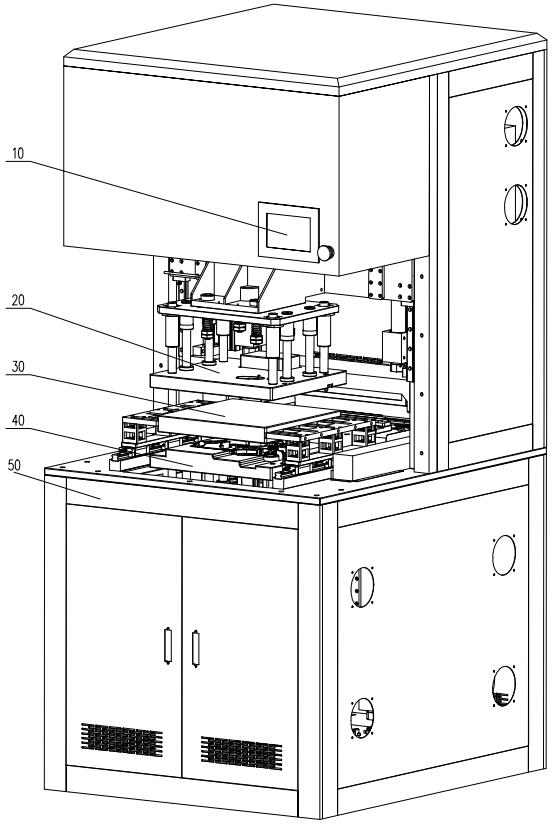

[0044] Such as Figure 1-11 As shown, a manifold welding machine includes a control system 10 , a driving and positioning mechanism 20 for the upper part of the manifold, a driving mechanism 30 for the hot melt plate, a driving and positioning mechanism 40 for the lower part of the manifold, and a frame 50 .

[0045] The control system 10 , the upper manifold driving and positioning mechanism 20 , the hot melt plate driving mechanism 30 , and the manifold lower driving and positioning mechanism 40 are all arranged on the frame 50 .

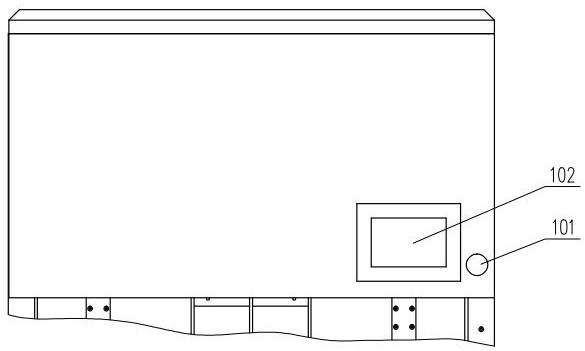

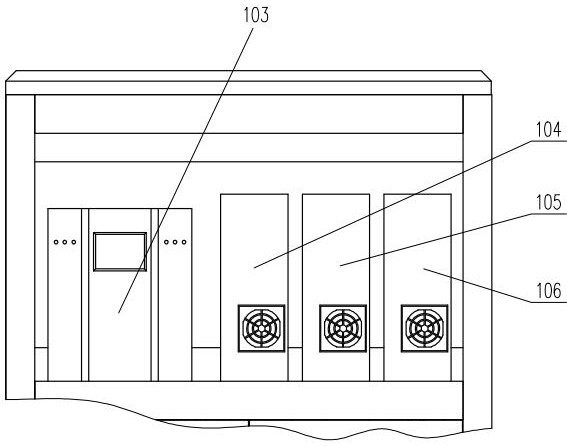

[0046] Such as figure 2 , 3 As shown, the above-mentioned control system 10 includes an emergency button 101, an operation display screen 102, a PLC controller 103, a servo motor driver 104 on the upper part of the manifold, a servo motor driver 105 on the hot melt plate and a servo motor driver 106 on the lower part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com