Automatic mechanical arm for welding

A robotic arm and automatic welding technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as low production efficiency, poor product quality, and easy fatigue, and achieve increased productivity, improved stability, The effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

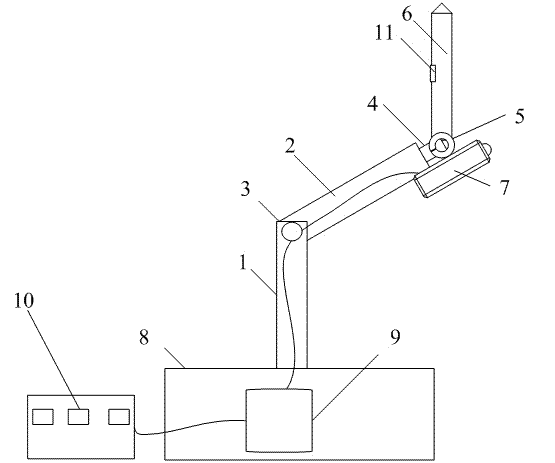

[0007] An automatic welding mechanical arm, comprising: a base 8, a mechanical arm, and a welding torch 6. The mechanical arm is composed of two rigid rod bodies. Free movement, the end of the rigid rod body 2 is connected with the wrist 4, the wrist 4 has a wrist swivel joint 5, the wrist swivel joint 5 is provided with a servo motor driver 8, the wrist swivel joint 5 is connected to the welding torch 6 through the flange, and the welding torch 6 is provided with The feeding port 11 and the base 9 are provided with a PLC controller 10 , and the output end of the PLC controller 9 is connected with the servo motor driver 7 . The input end of the PLC controller 9 is connected with the man-machine interface 7 .

[0008] Combined with the automatic welding water tray nozzle device with application number 201210140887.5, it provides a device that fixes and rotates the welding parts through welding points. During the welding process, since the welding parts rotate with the welding a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com