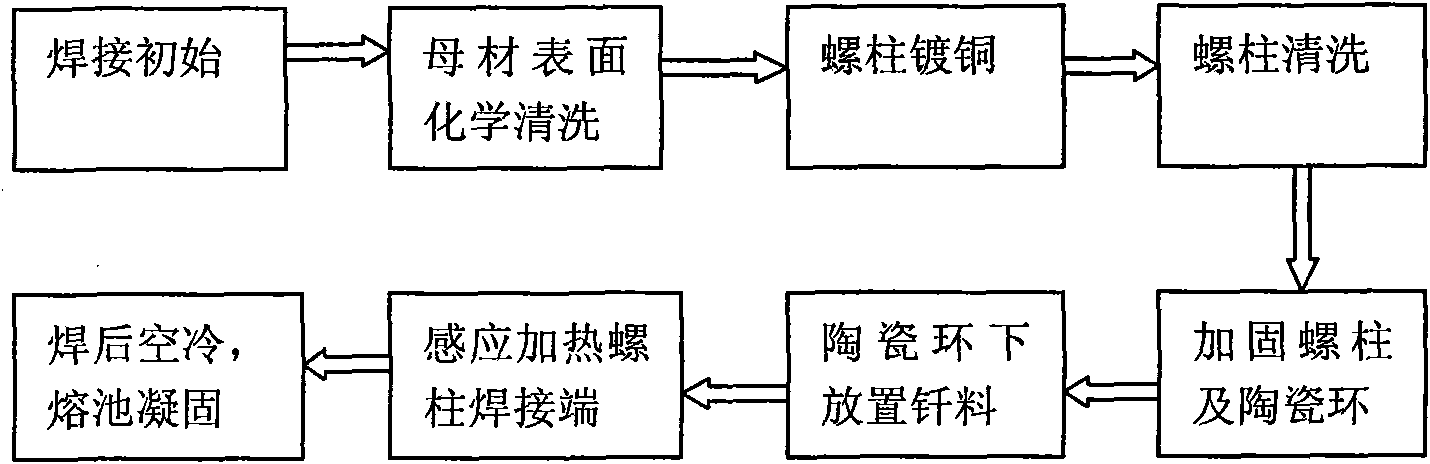

Method of pre-copper-plated induction welding-brazing of aluminum-steel stud bolt

A pre-plating copper and soldering technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve problems such as difficult implementation, poor quality of welds, and low recurrence rate of welded parts, and achieve Efficiency improvement, good weld quality, and the effect of realizing welding automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

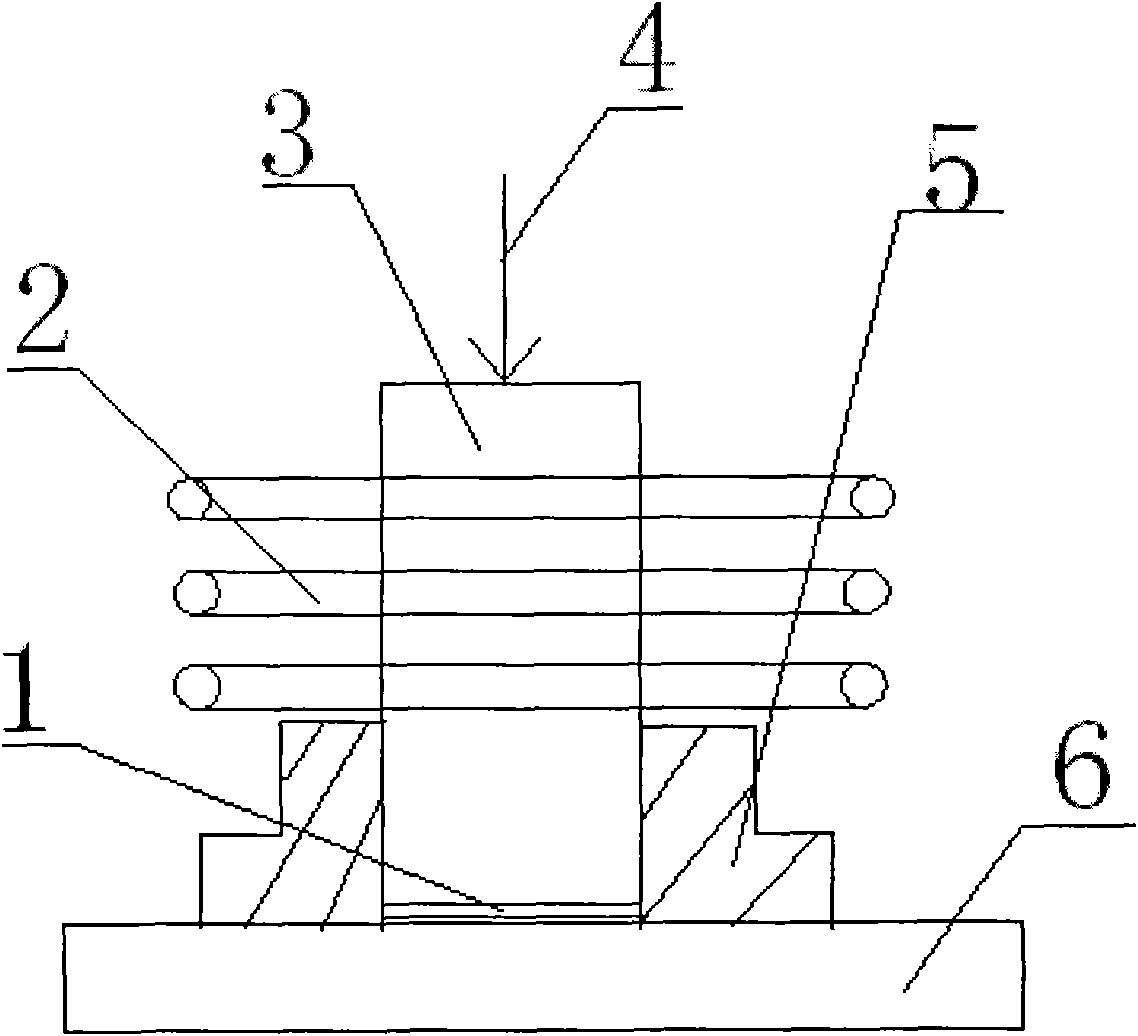

[0029] Combine figure 1 with figure 2 Take a copper-plated steel stud with a diameter of 16mm and a height of 48mm as an example. First, chemically clean the surface of the aluminum base metal and the solder before welding. The specific cleaning process is: etch the surface of the aluminum base metal with 8% NaOH solution for 10 minutes, the solder for 5 minutes, and the solution temperature is 40 ℃. The mixed solution of nitric acid and hydrofluoric acid etches the surface of the aluminum base metal for 5 minutes, and the brazing filler metal for 3 minutes (the mixture ratio is: 10L of nitric acid solution with a concentration of 58%, and 0.3L of hydrofluoric acid solution with a concentration of 46%). Finally, the surface of the aluminum base material is cleaned with alcohol and dried quickly, and then a layer of fluoride flux K is applied to the surface of the base material 3 AlF 6 -K 3 AlF 4 , Fix the copper-plated steel stud on the surface of the aluminum base material wi...

Embodiment 2

[0031] Combine figure 1 with figure 2 Take a copper-plated steel stud with a diameter of 27mm and a height of 52mm as an example. First, chemically clean the surface of the aluminum base metal and the solder before welding. The specific cleaning process is: etch the surface of the aluminum base metal with a 10% NaOH solution for 10 minutes, the solder for 5 minutes, and the solution temperature is 50°C. The mixed solution of nitric acid and hydrofluoric acid etches the surface of the aluminum base metal for 6 minutes, and the brazing filler metal for 3 minutes (the mixture ratio is: 10L of nitric acid solution with a concentration of 61%, and 0.3L of hydrofluoric acid solution with a concentration of 50%). Finally, the surface of the aluminum base material is cleaned with alcohol and dried quickly, and then a layer of fluoride flux K is applied to the surface of the base material 3 AlF 6 -K 3 AlF 4 , Fix the copper-plated steel stud on the surface of the aluminum base material...

Embodiment 3

[0033] Combine figure 1 with figure 2 Take a copper-plated steel stud with a diameter of 30mm and a height of 52mm as an example. First, chemically clean the surface of the aluminum base metal and the brazing filler metal before welding. The specific cleaning process is: etch the surface of the aluminum base metal with 11% NaOH solution for 12 minutes, the brazing filler metal for 6 minutes, and the solution temperature is 60 ℃. The mixed solution of nitric acid and hydrofluoric acid etches the surface of the aluminum base metal for 7 minutes, and the brazing material for 4 minutes (the ratio of the mixed solution is: 10L nitric acid solution with a concentration of 64%, and 0.3L hydrofluoric acid solution with a concentration of 55%). After cleaning, blow After drying, apply a layer of fluoride flux K on the surface of the base material 3 AlF 6 -K 3 AlF 4 , Fix the copper-plated steel stud on the surface of the aluminum base material with a clamp, and put a ceramic ring match...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com