Patents

Literature

59results about How to "Eliminate overheating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

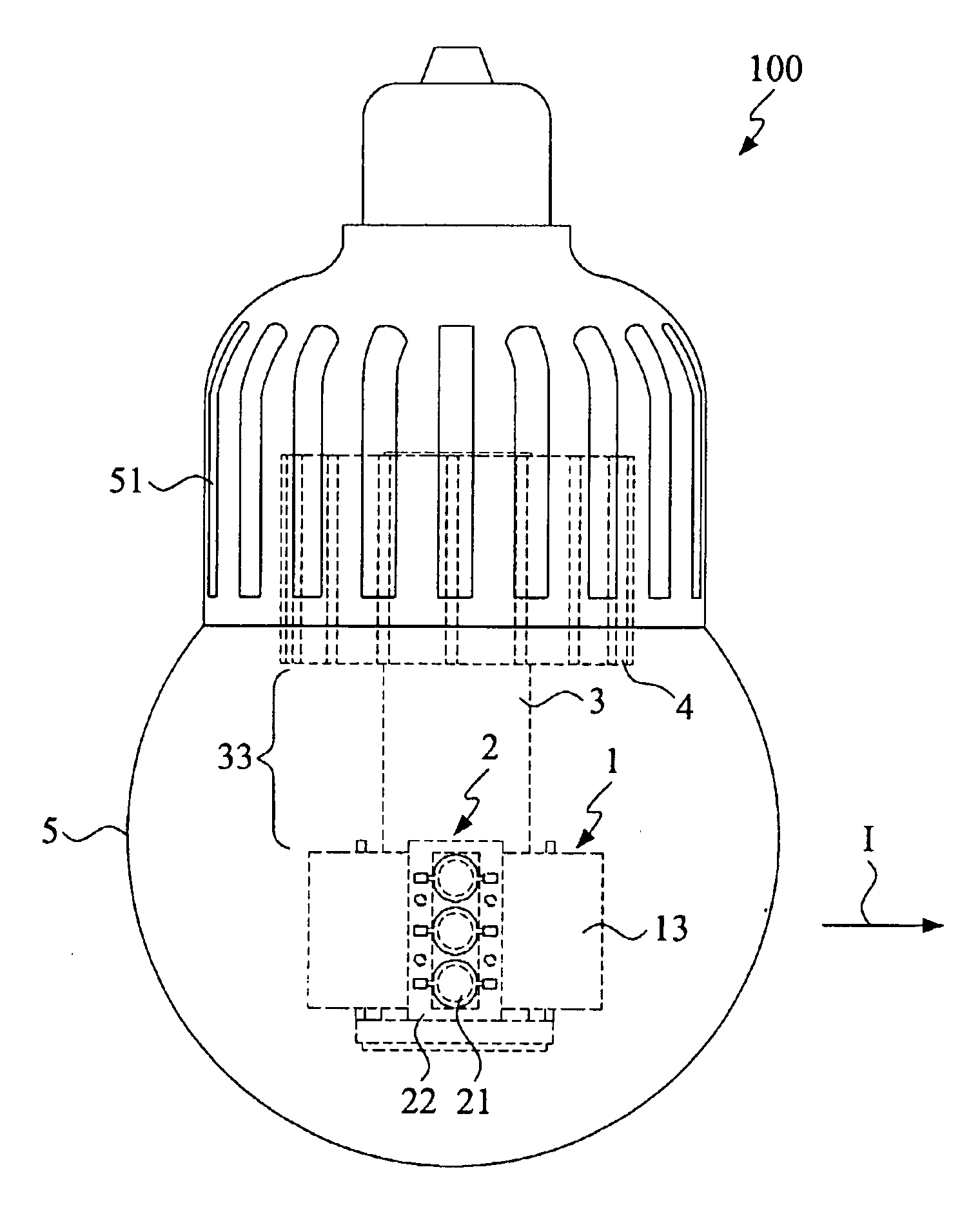

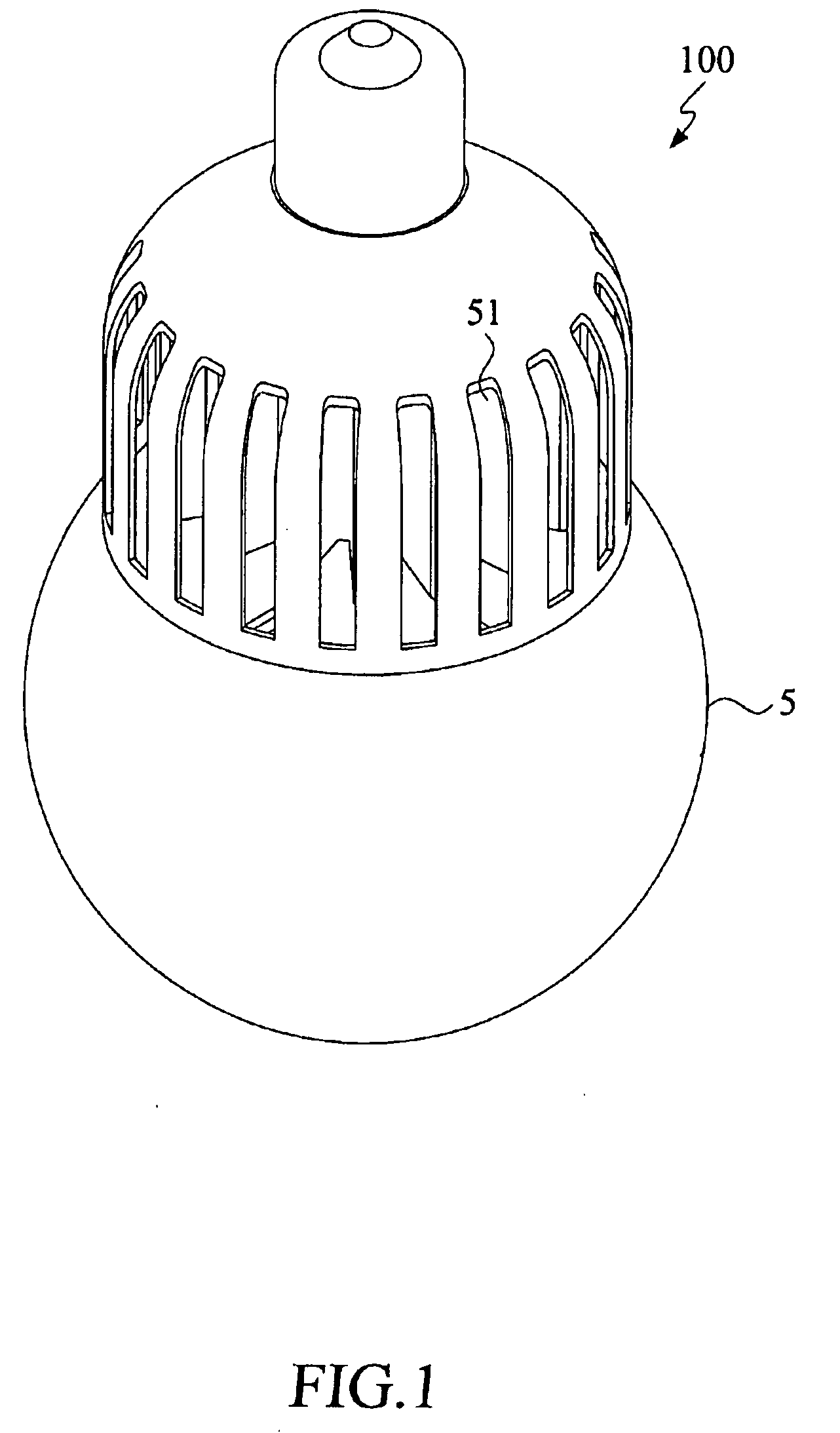

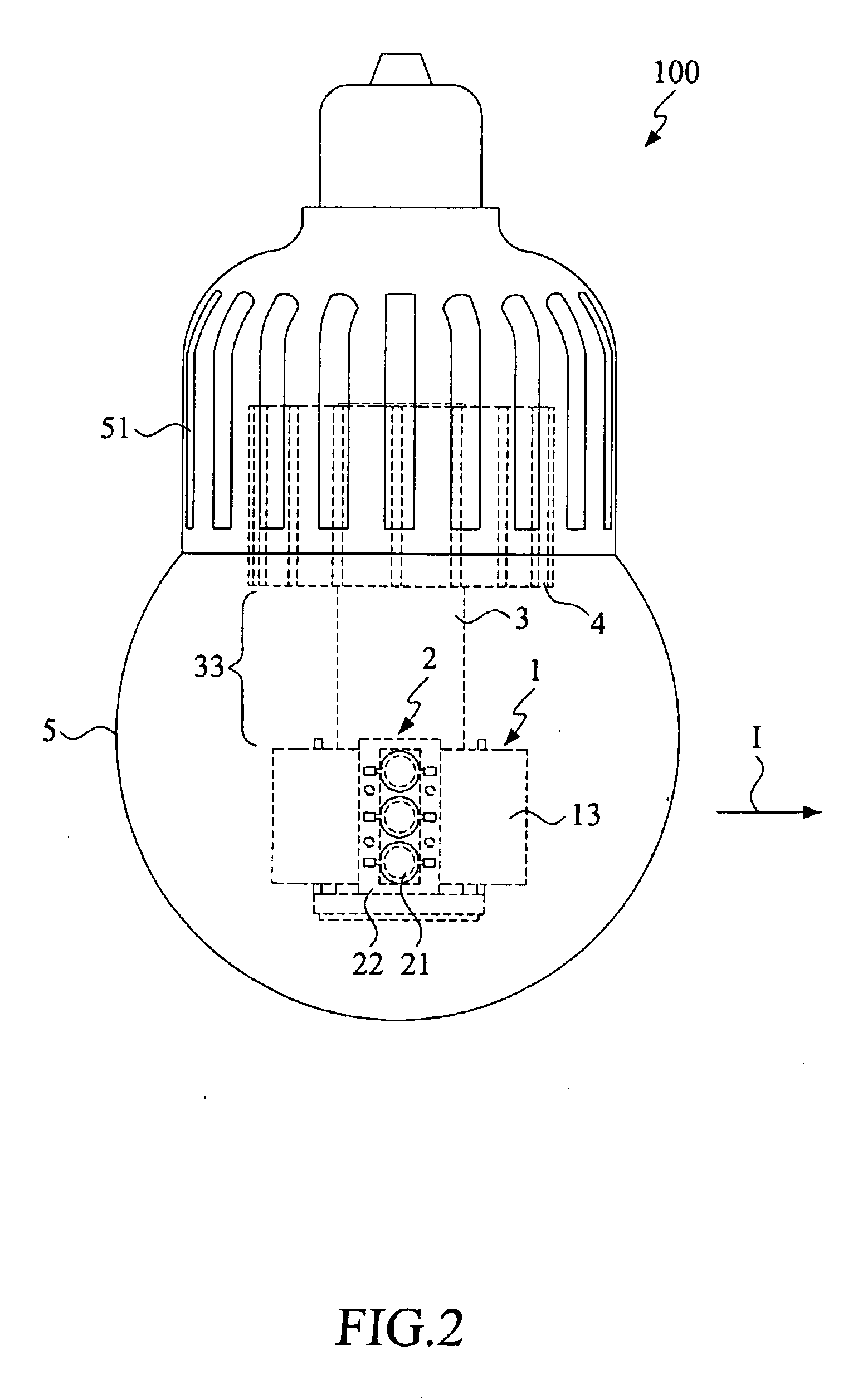

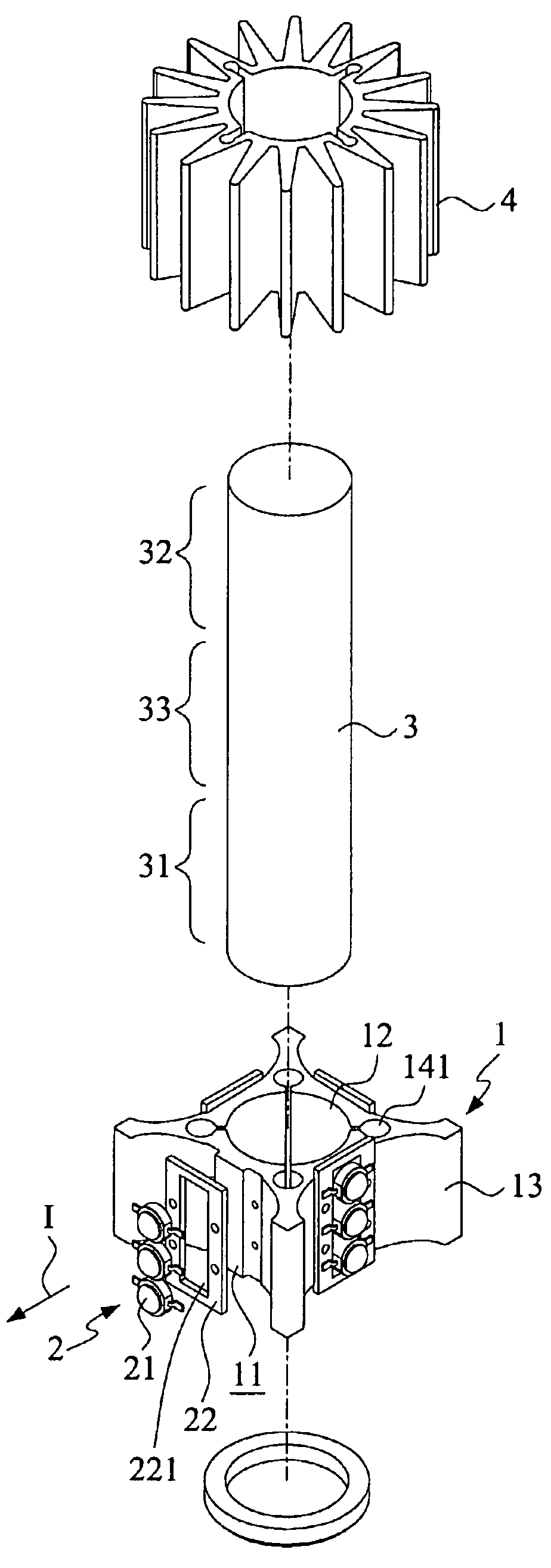

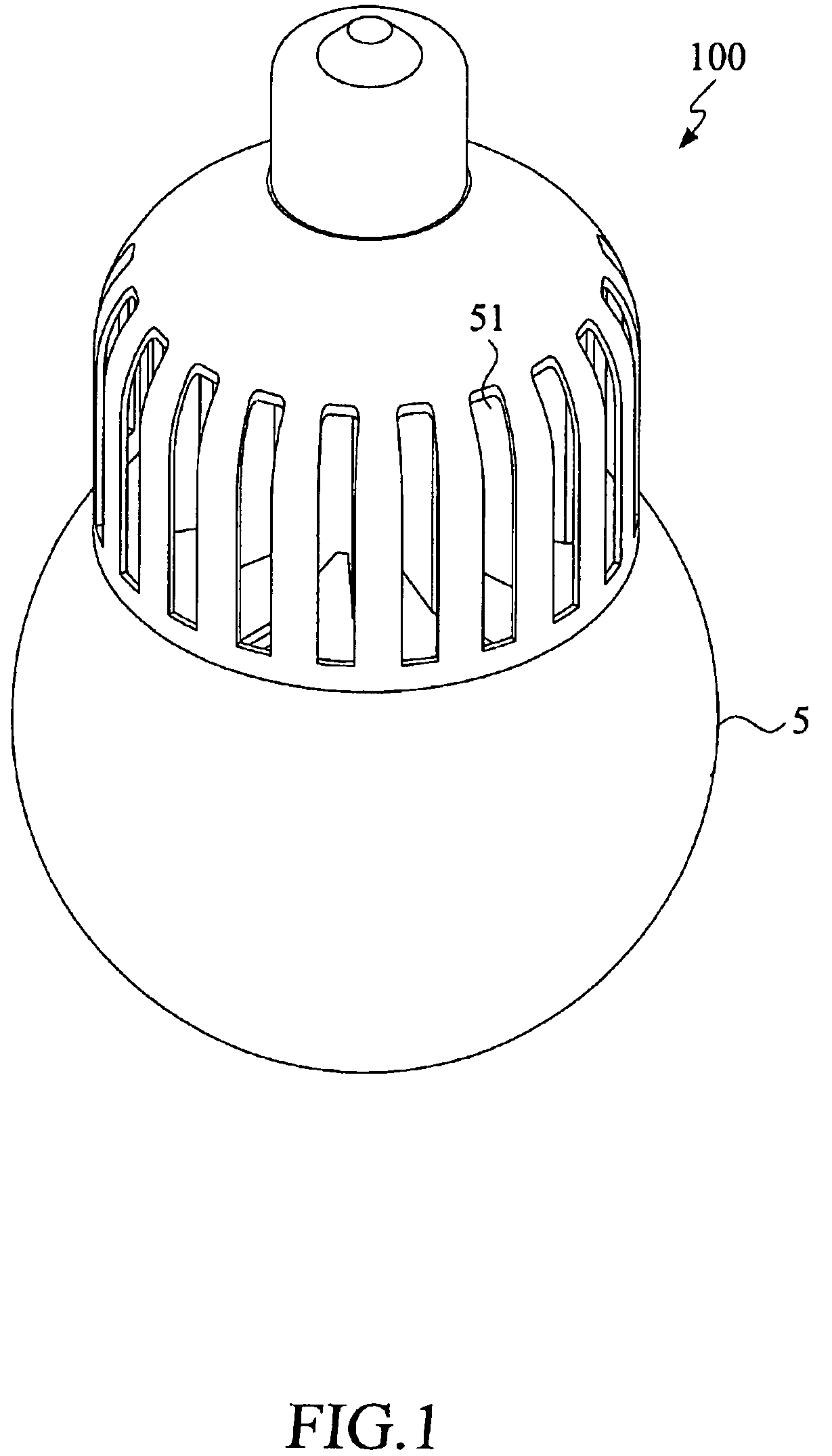

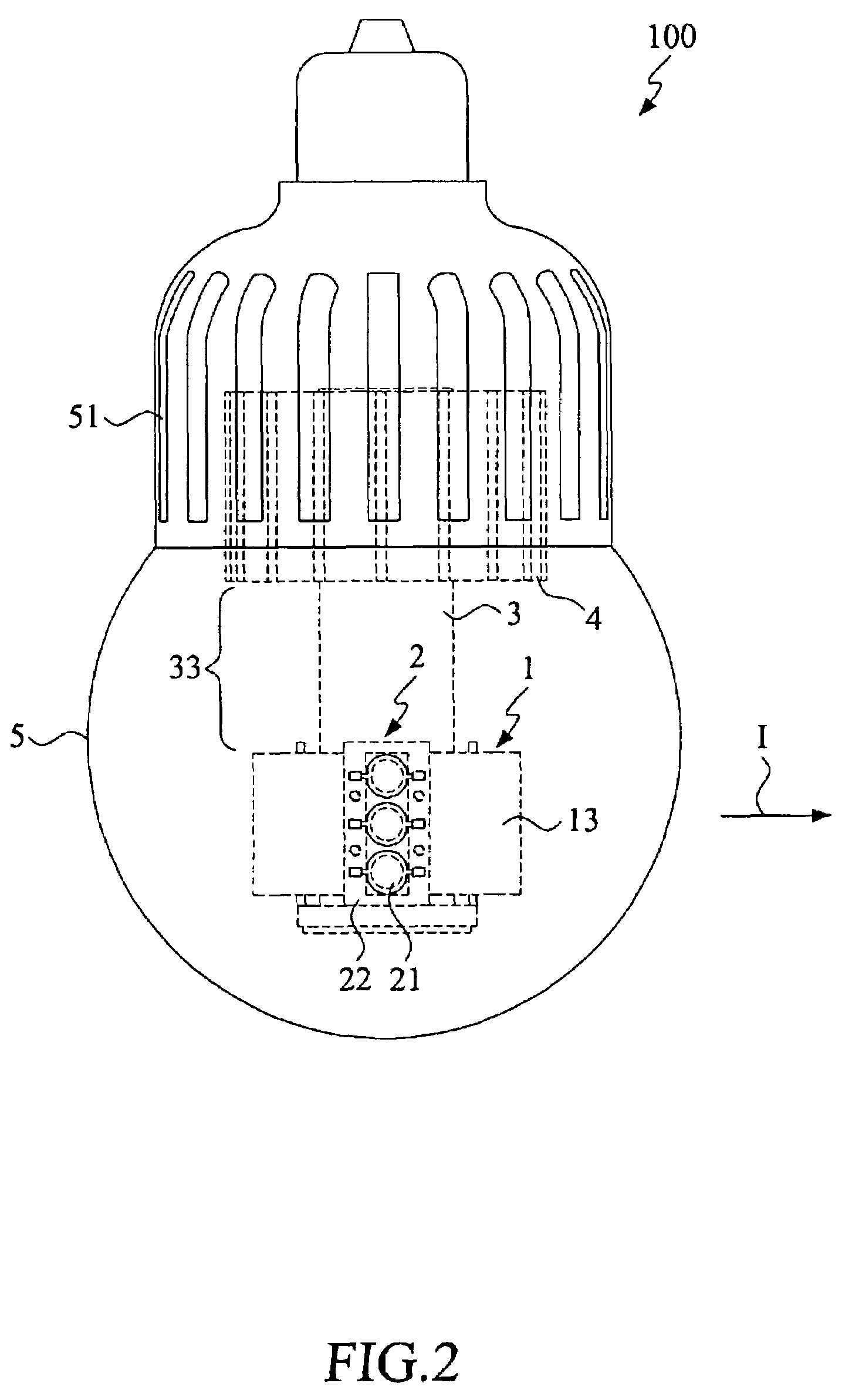

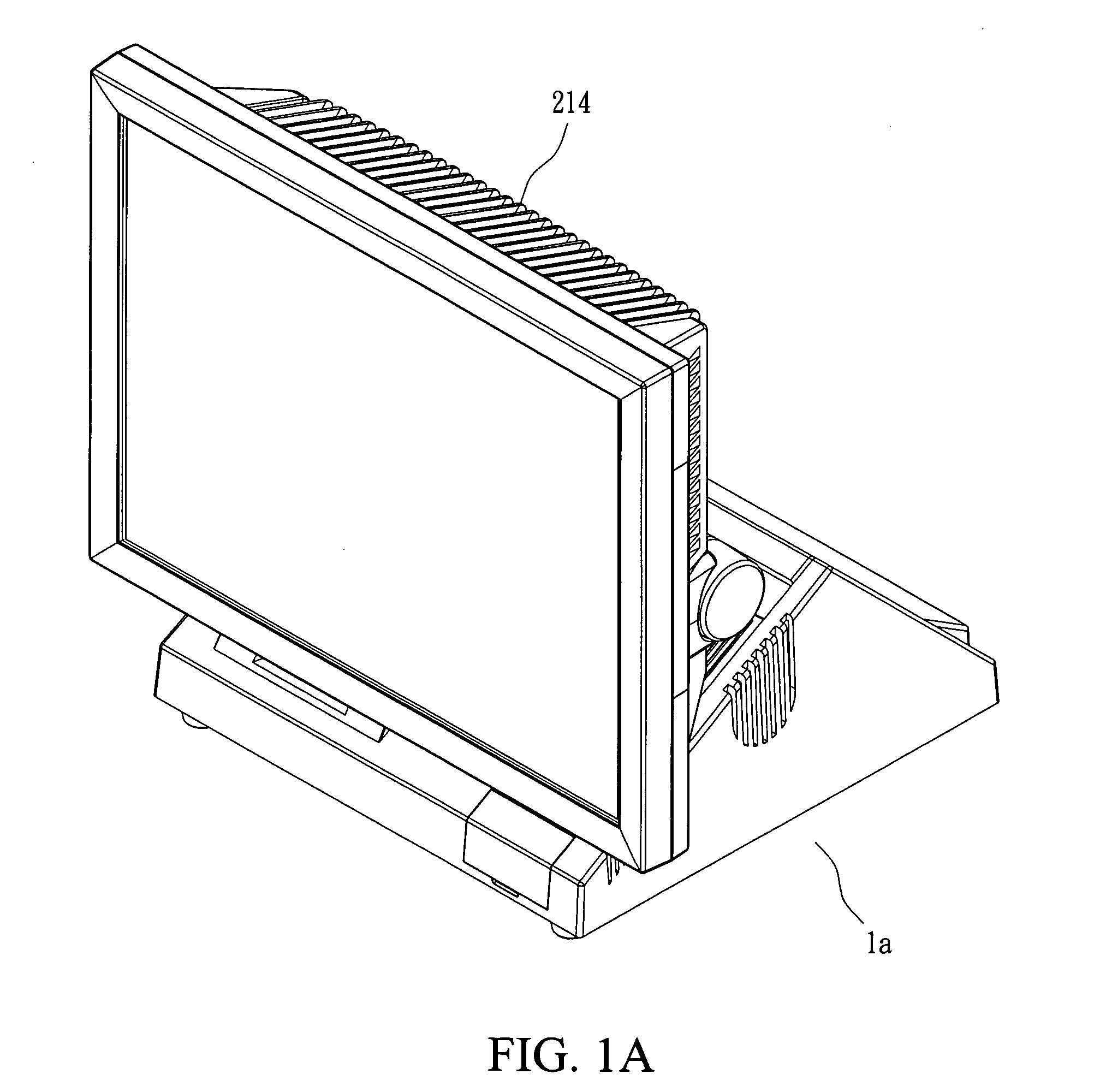

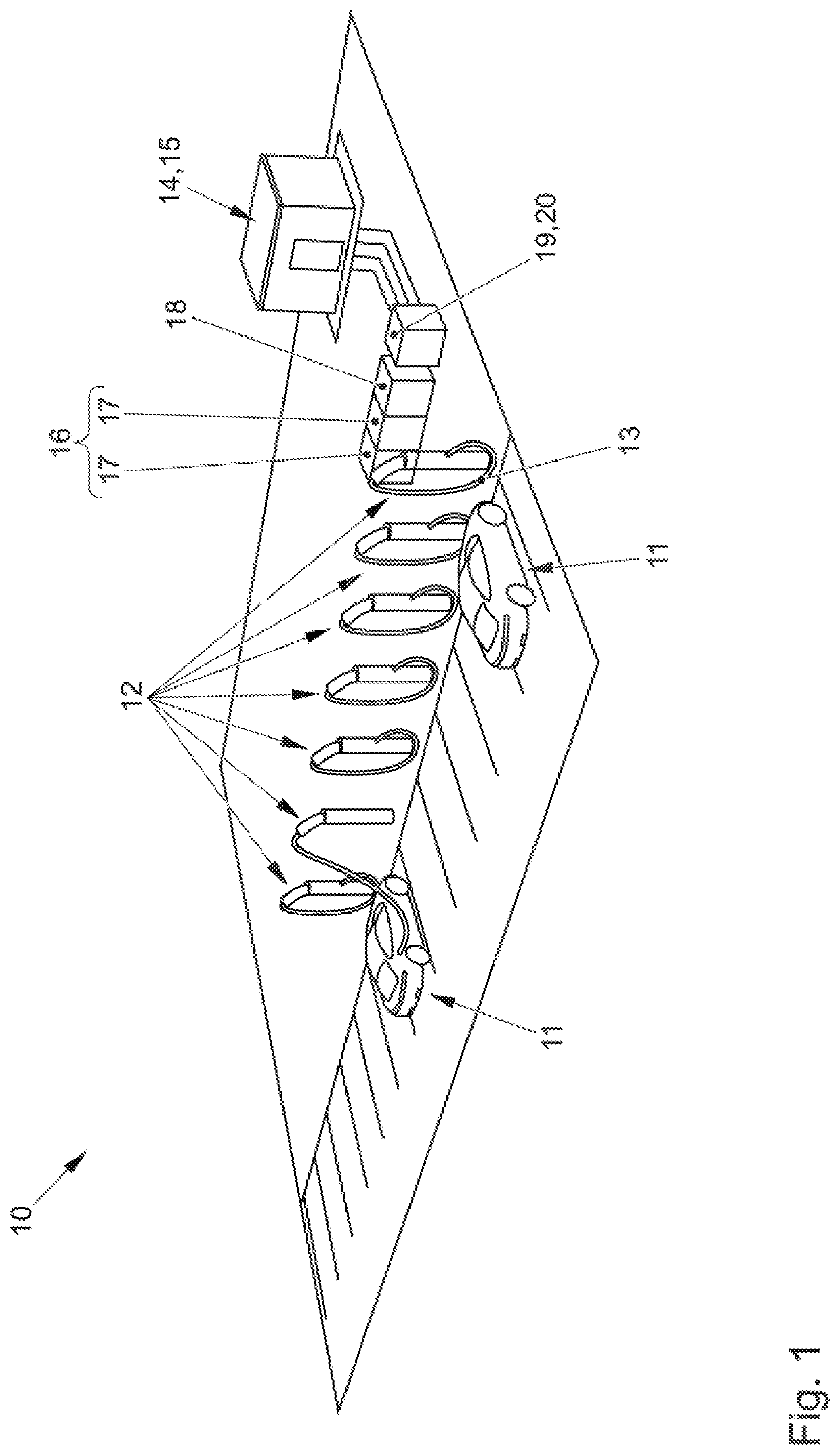

High power LED lighting assembly incorporated with a heat dissipation module with heat pipe

InactiveUS20080253125A1Reduce power consumptionIncrease powerPoint-like light sourceLighting heating/cooling arrangementsThermal energyWorking fluid

A high power light emitting diode (LED) lighting assembly incorporated with heat dissipation module is provided. The LED lighting assembly includes a heat exchange base, at least one LED array, at least one heat pipe and a heat dissipation module. The heat exchange base includes at least one LED configuration plan for mounting of the LED array and at least a hollow part for insertion of the heat pipe. The LED array is arranged at a predetermined projecting angle at the LED configuration plane. The heat pipe includes a heated section, a cooling section and a conducting section, and contains a working fluid therein. The heat exchange base is mounted to the heated section and the heat dissipation module is mounted to the cooling section. The thermal energy generated by the LEDs is conducted from the heat exchange base to the heated section of the heat pipe, whereby allowing the working fluid in the heat pipe to be heated and vaporized, and flows, from the conducting section to the cooling section for dissipation at the heat dissipation module.

Owner:TAMKANG UNIVERSITY

High power LED lighting assembly incorporated with a heat dissipation module with heat pipe

InactiveUS7581856B2Reduce power consumptionIncrease powerPoint-like light sourceLighting heating/cooling arrangementsThermal energyWorking fluid

A high power light emitting diode (LED) lighting assembly incorporated with heat dissipation module is provided. The LED lighting assembly includes a heat exchange base, at least one LED array, at least one heat pipe and a heat dissipation module. The heat exchange base includes at least one LED configuration plan for mounting of the LED array and at least a hollow part for insertion of the heat pipe. The LED array is arranged at a predetermined projecting angle at the LED configuration plane. The heat pipe includes a heated section, a cooling section and a conducting section, and contains a working fluid therein. The heat exchange base is mounted to the heated section and the heat dissipation module is mounted to the cooling section. The thermal energy generated by the LEDs is conducted from the heat exchange base to the heated section of the heat pipe, whereby allowing the working fluid in the heat pipe to be heated and vaporized, and flows, from the conducting section to the cooling section for dissipation at the heat dissipation module.

Owner:TAMKANG UNIVERSITY

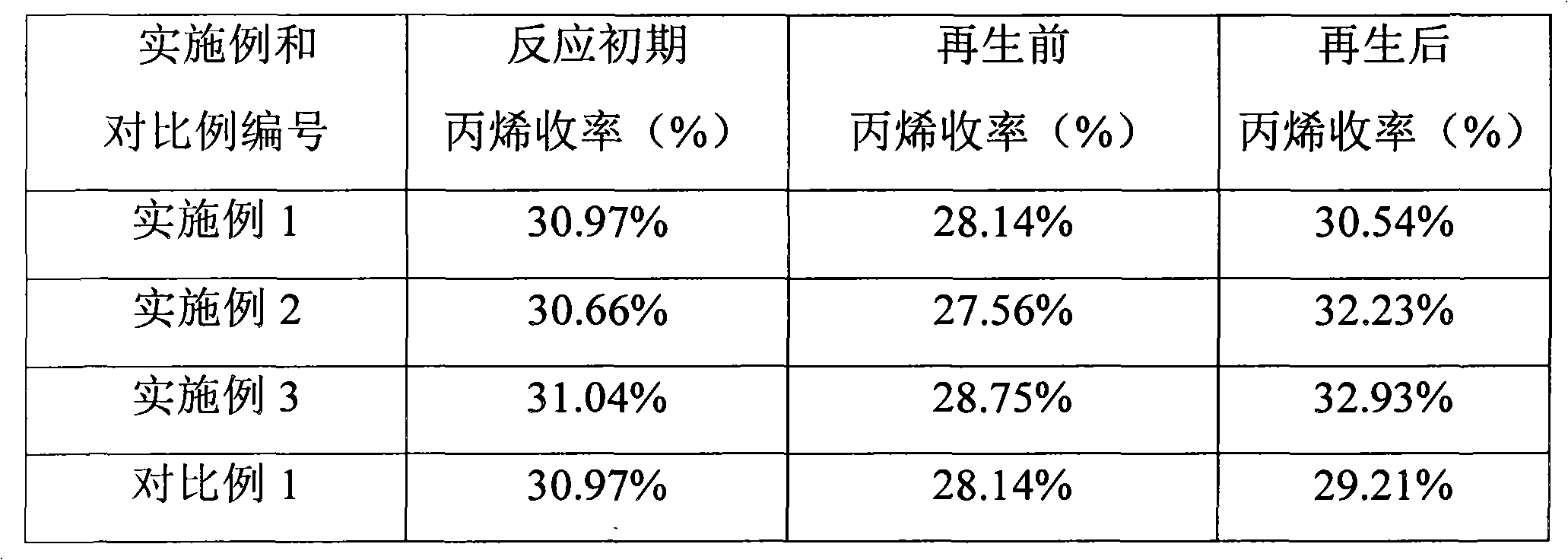

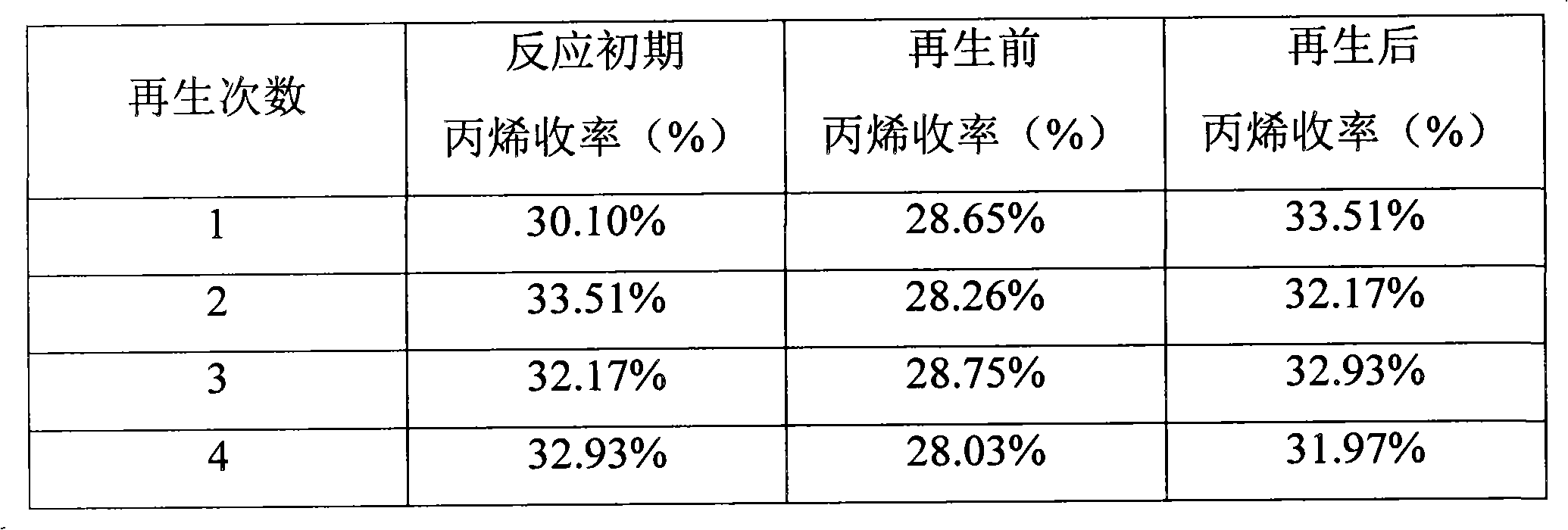

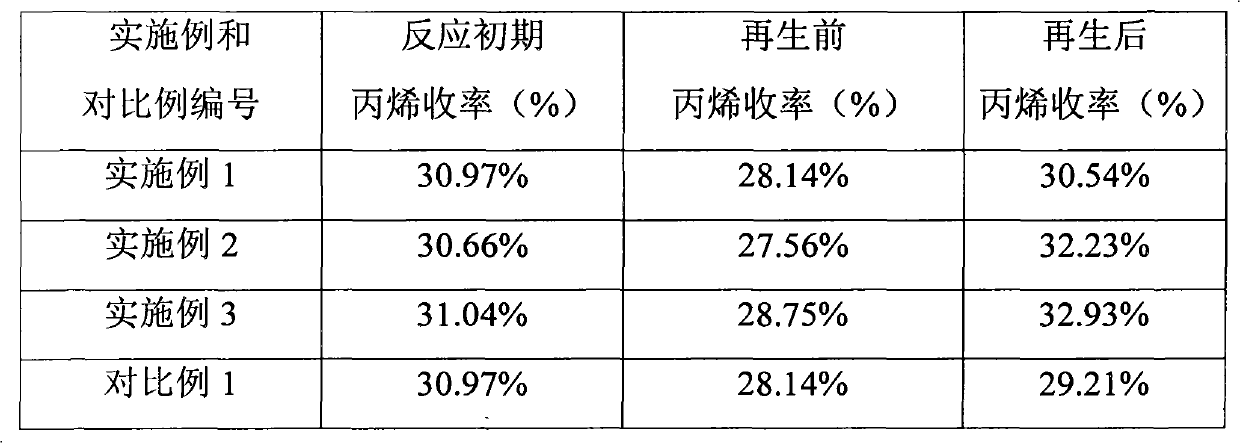

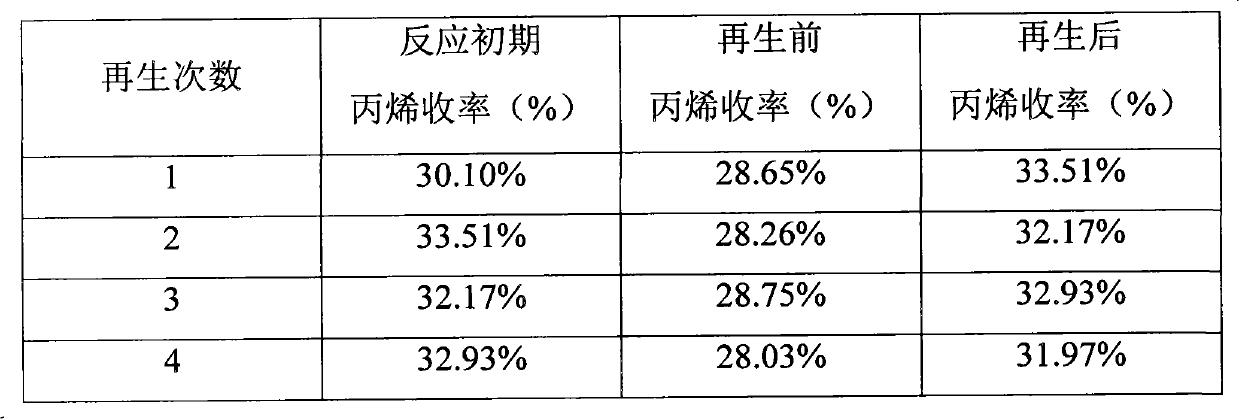

Regeneration method of molecular sieve catalyst

ActiveCN102836743AEfficient regenerationNo overheatingMolecular sieve catalystsMolecular sieveCarbon deposit

The invention provides a regeneration method of a molecular sieve catalyst, comprising the following steps: roasting a molecular sieve catalyst to be regenerated at 300-750 DEG C to decomposing the carbon deposit in the molecular sieve catalyst to be regenerated into CO2, wherein the roasting step is characterized in that: in the presence of oxygen-containing gas, the molecular sieve catalyst to be regenerated is subject to roasting of multiple stages at a constant temperature, the roasting of multiple stages comprises a first roasting stage and roasting stages after the first roasting stage, the roasting temperature of any one roasting stage after the first roasting stage is 5-70 DEG C higher than that of the adjacent former roasting stage, and the roasting time of each roasting stage is long enough to generate no CO2 when roasting is conducted under the roasting condition of the roasting stage. According to the invention, the performance of the regenerated molecular sieve catalyst is recovered and even better than the performance of a fresh catalyst, thus good regeneration effect can be achieved by using the method disclosed herein.

Owner:CHINA PETROLEUM & CHEM CORP +1

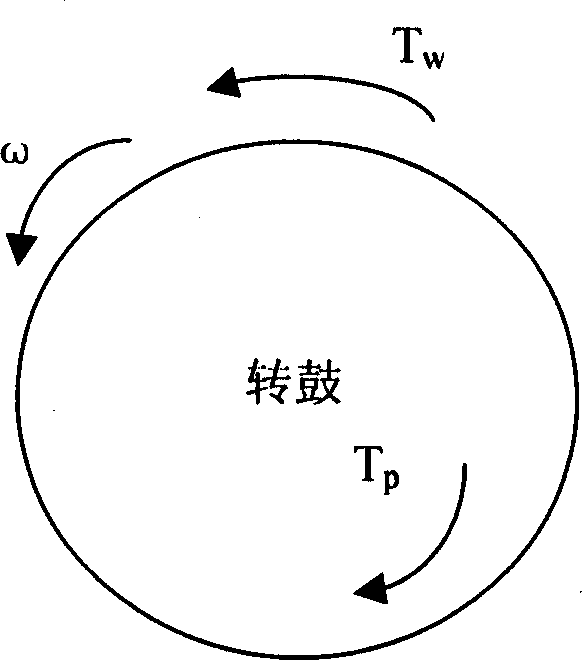

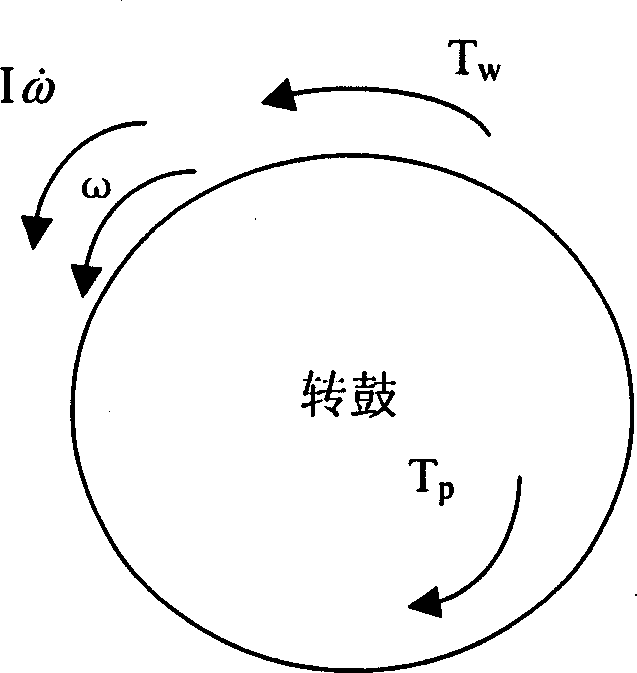

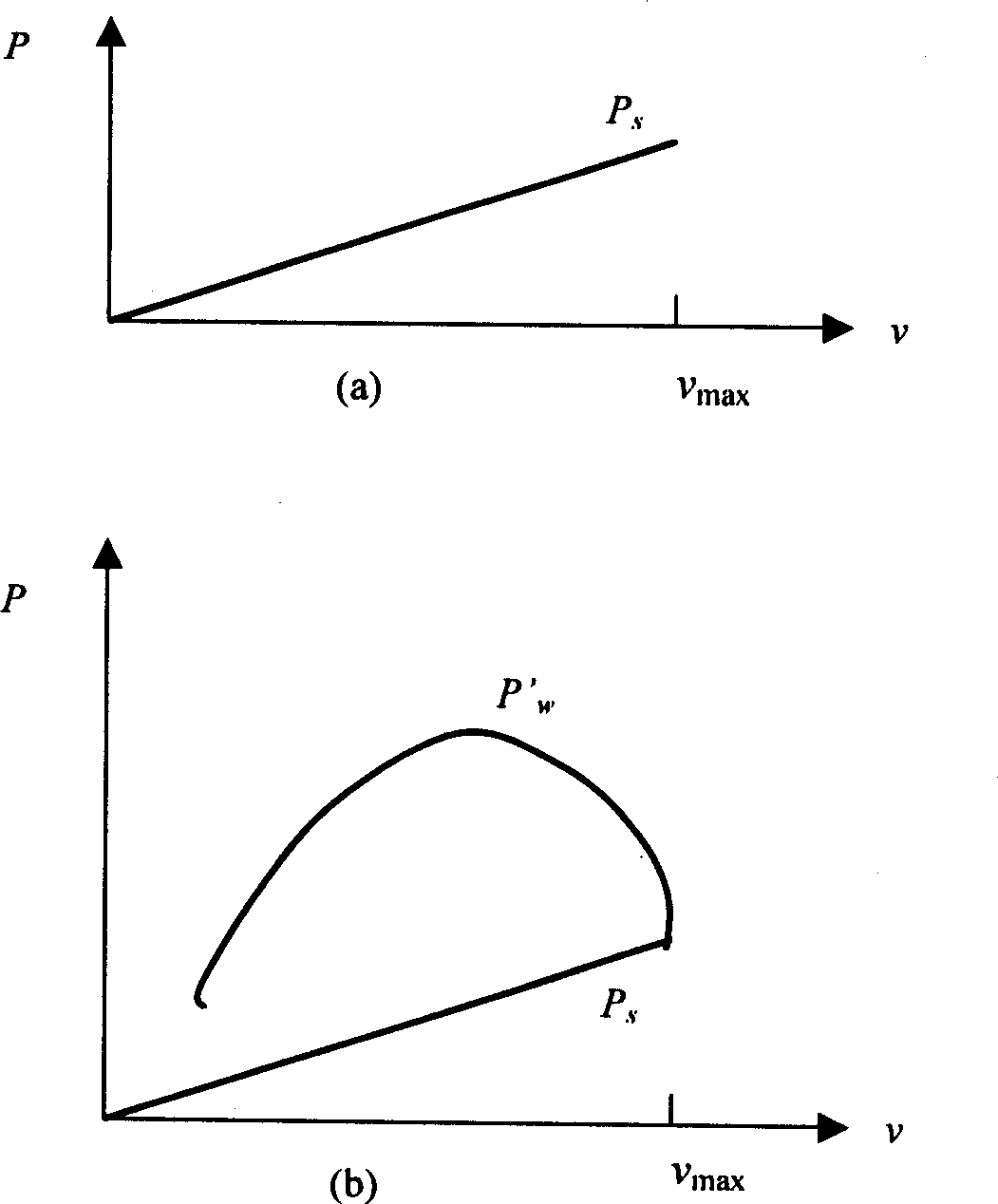

Automobile hub power characteristic rapid measuring method

InactiveCN1488925AStable jobEliminate overheatingMeasurement of vehicle's tractive/propulsive powerPower absorptionDiesel fuel

The present invention relates to a method for quickly testing car wheel edge powder characteristics. It is characterized by that according to a certain testing process it can use chassis dynamometer machine to test the power characteristics of car wheel edge. Under the condition of that the drum speed of the chassis dynamometer machine is changed with car wheel, but is not stable, i.e. when the drum implements variable motion in a certain rotational speed, the absorption power value of the chassis dynamometer machine can be measured, and an inaccurate wheel edge power value under said speed can be obtained, then the inaccurate wheel edge power value can be corrected so as to obtain the accurate wheel edge power value.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

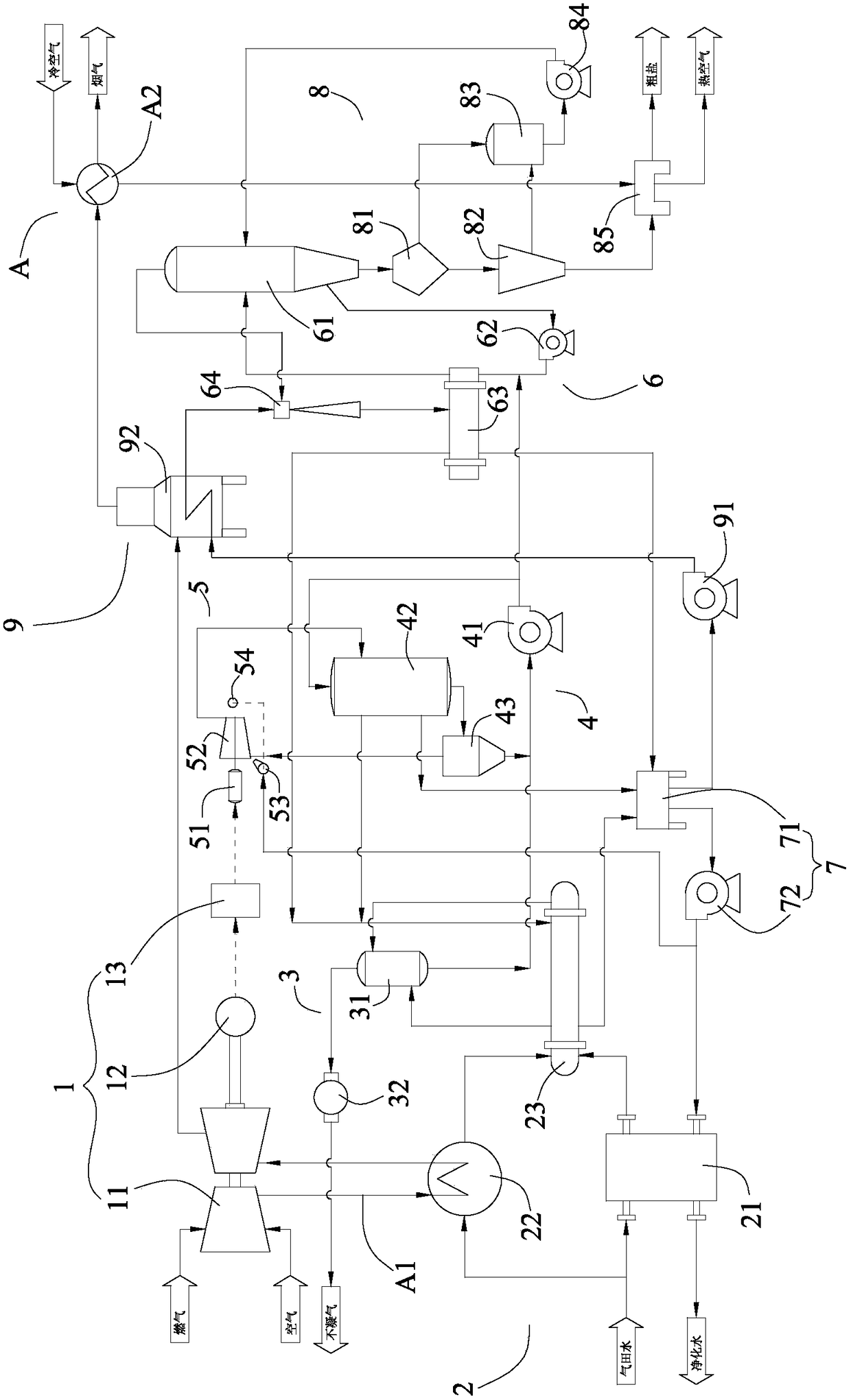

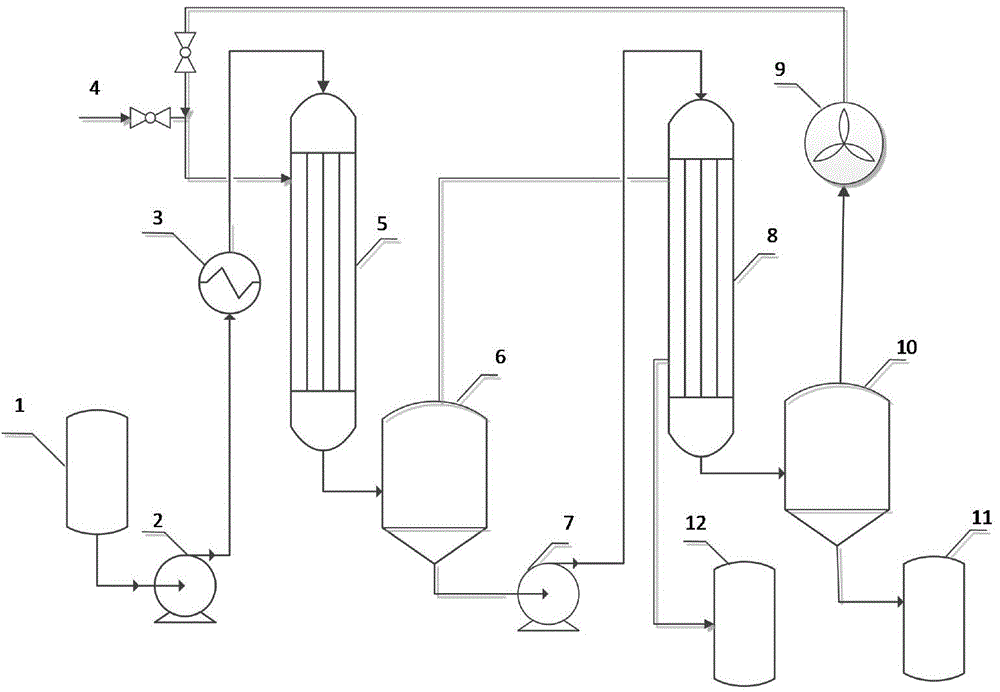

High salt gas field water evaporation crystallization treatment device

InactiveCN108217795AFree from consumptionEliminate overheatingWaste water treatment from quariesEnergy inputVapor–liquid separatorEnvironmental engineering

The invention provides a high salt gas field water evaporation crystallization treatment device which comprises a power system, a preheating system, a degassing system, an evaporation condensation system, a vapor compression system, an evaporation crystallization system, a condensate recycling system, a crystallization and salt making system, a vapor generation system and a waste heat recovery system; the power system comprises a gas engine, a power generator and a power supply and distribution mechanism; the preheating system comprises a first preheater, a second preheater and a third preheater; the degassing system comprises a degassing tank and a vacuum pump; the evaporation condensation system comprises a concentrated liquid circulation pump, a falling film evaporator and a gas-liquidseparator; the vapor compression system comprises a motor, a compressor and a sprinkler; the evaporation crystallization system comprises a crystallizer, a halide solution circulation pump, a forced circulation evaporator and a vapor ejector; the condensate recycling system comprises a purification water tank and a purification water pump; the crystallization and salt making system comprises a thickener, a centrifuge, a mother liquor tank, a mother liquor pump and a drying bed; and the vapor generation system comprises a water feeding pump and a waste heat boiler.

Owner:中石化石油工程技术服务有限公司 +1

Double-effect Roots-type MVR (Mechanical Vapor Recompression) falling film evaporation system

InactiveCN104162283AEliminate overheatingConserve waterMultiple-effect evaporationWater vaporLower grade

The invention relates to a double-effect Roots-type MVR (Mechanical Vapor Recompression) falling film evaporation system. The double-effect Roots-type MVR falling film evaporation system comprises double-effect falling film evaporators and a water vapor recompression system, wherein the double-effect falling film evaporators comprise a primary-effect evaporator and a secondary-effect evaporator which respectively comprises a heating chamber and a separation chamber; the water vapor recompression system is mainly formed by a Roots-type MVR compressor; a vapor outlet of a separation chamber of the secondary-effect evaporator is connected with a vapor inlet of the water vapor compressor, and a vapor outlet of the water vapor compressor is connected with a vapor inlet of the primary-effect evaporator. According to the double-effect Roots-type MVR falling film evaporation system, by recycling low-grade waste heat of the primary-effect evaporator and the secondary-effect evaporator and reutilizing all latent heat of secondary vapor generated in a solution evaporation process, primary energy is saved, the energy consumption in a solution evaporation process is greatly reduced, and the environmental pollution is reduced. The double-effect Roots-type MVR falling film evaporation system is simple in structure, small in occupied space and high in automation degree, only requires a small amount of vapor when being started, does not require live vapor after being started, is particularly suitable for heat-sensitive materials, has a wide application range and can be used on occasions of evaporation concentration, evaporation crystallization and low-temperature evaporation.

Owner:天津市红特顺科技有限公司

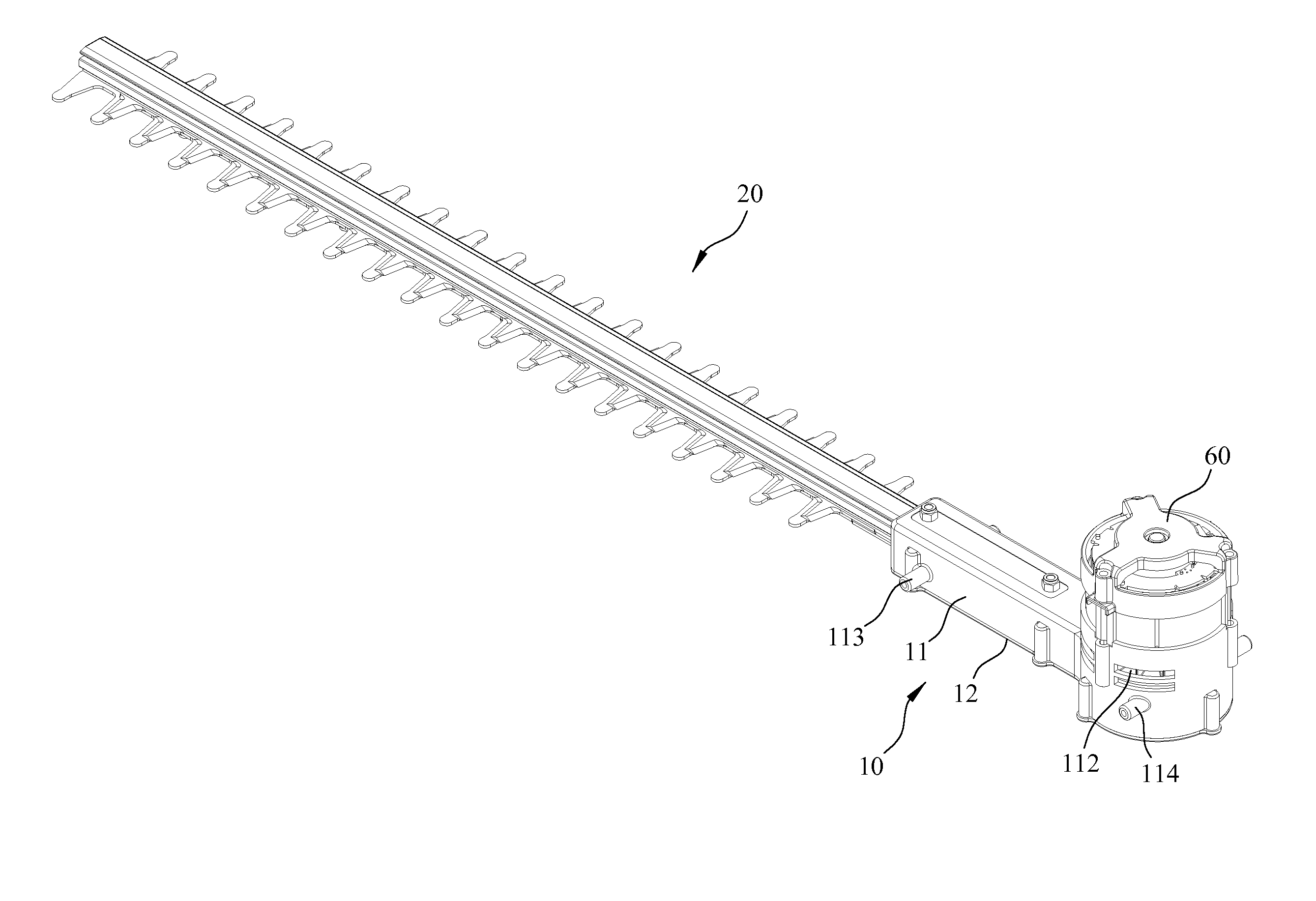

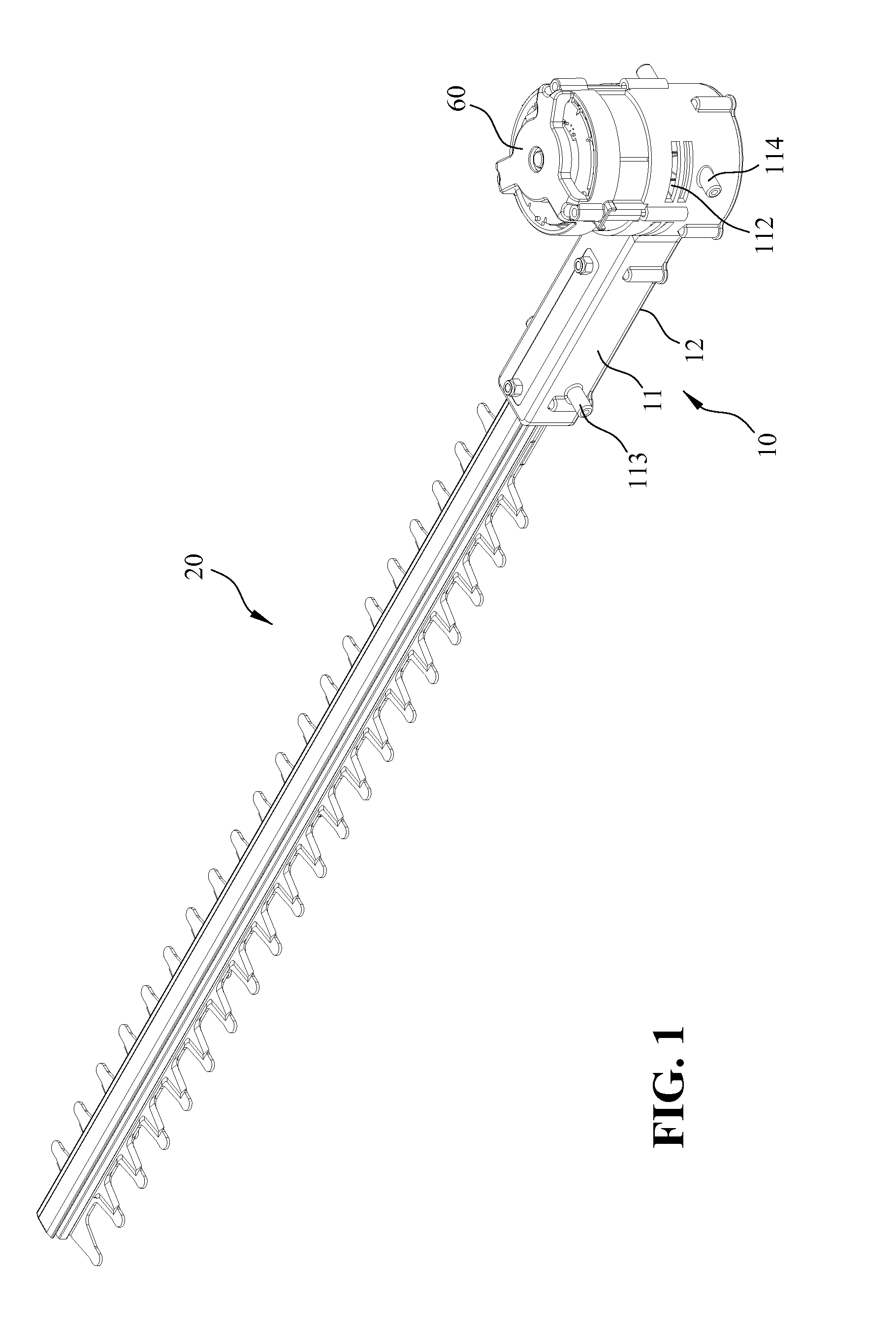

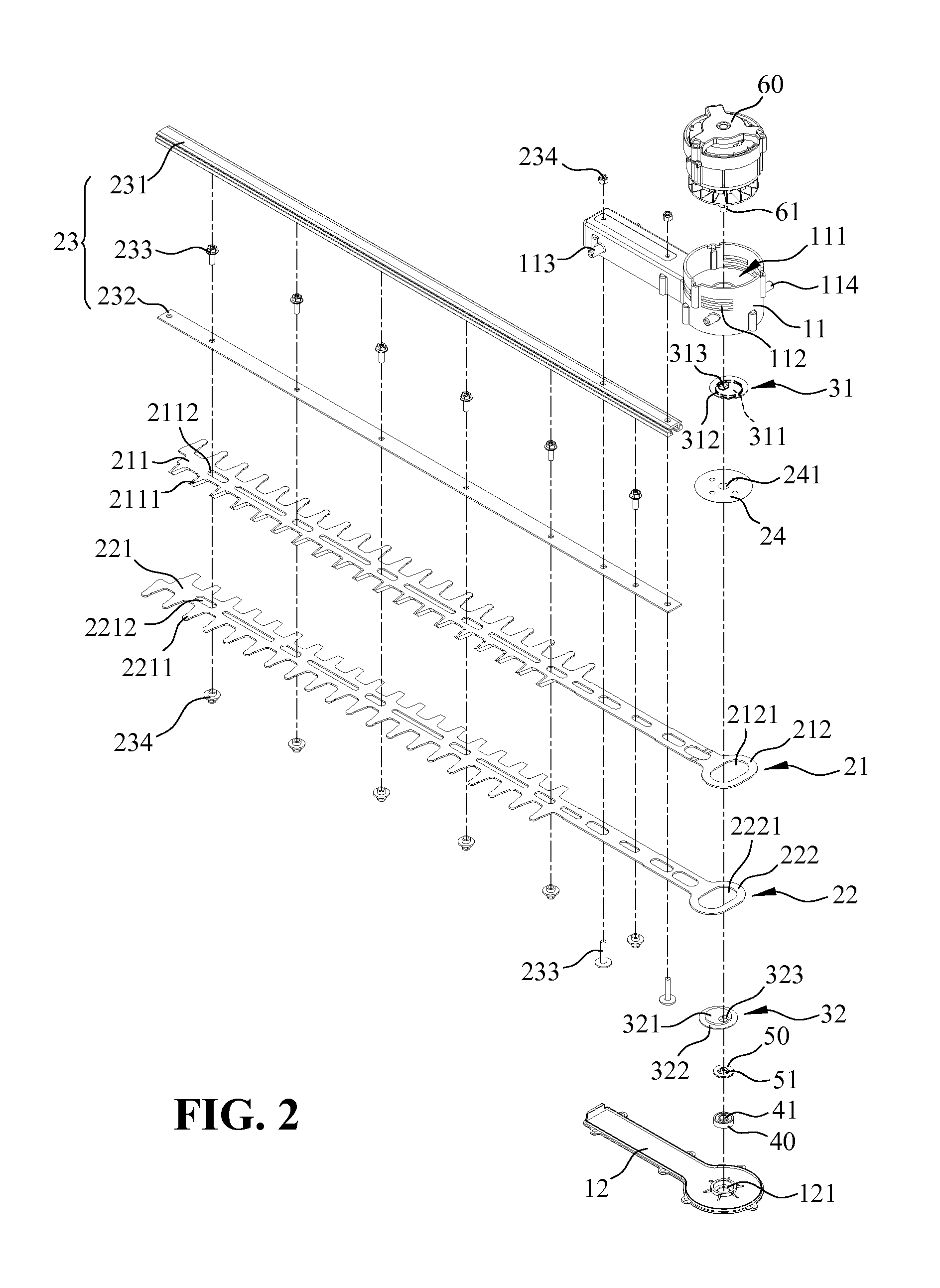

Hedge trimmer

InactiveUS20160330914A1Reduce expensesReduce noiseCuttersCutting implementsBrushless motorsEngineering

A hedge trimmer includes elongated upper and lower blades overlapping relative to each other, each of the blades including a trimming portion having an outer periphery formed with a plurality of trimming edges and a mounting portion formed with a guiding hole; upper and lower eccentric wheels that extend into the guiding holes of the blades and that is formed with an eccentric hole respectively; and a brushless motor including an output shaft extending into and operably coupled with the eccentric holes in the eccentric wheels such that activation of the motor results in rotation of the eccentric wheels within the guiding holes in the blades, thereby driving the blades reciprocally relative to each other along their longitudinal direction.

Owner:JENN FENG NEW ENERY CO LTD

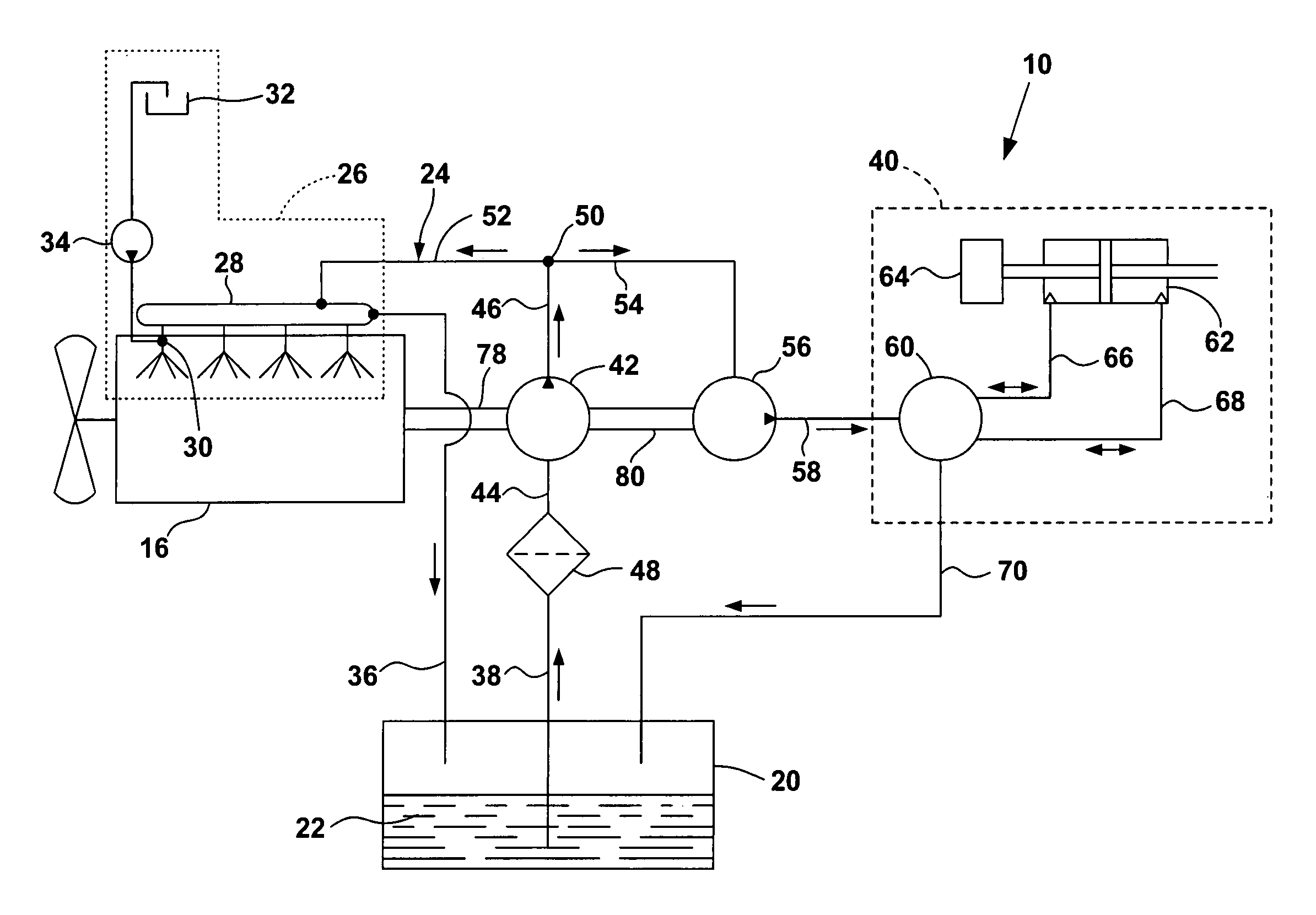

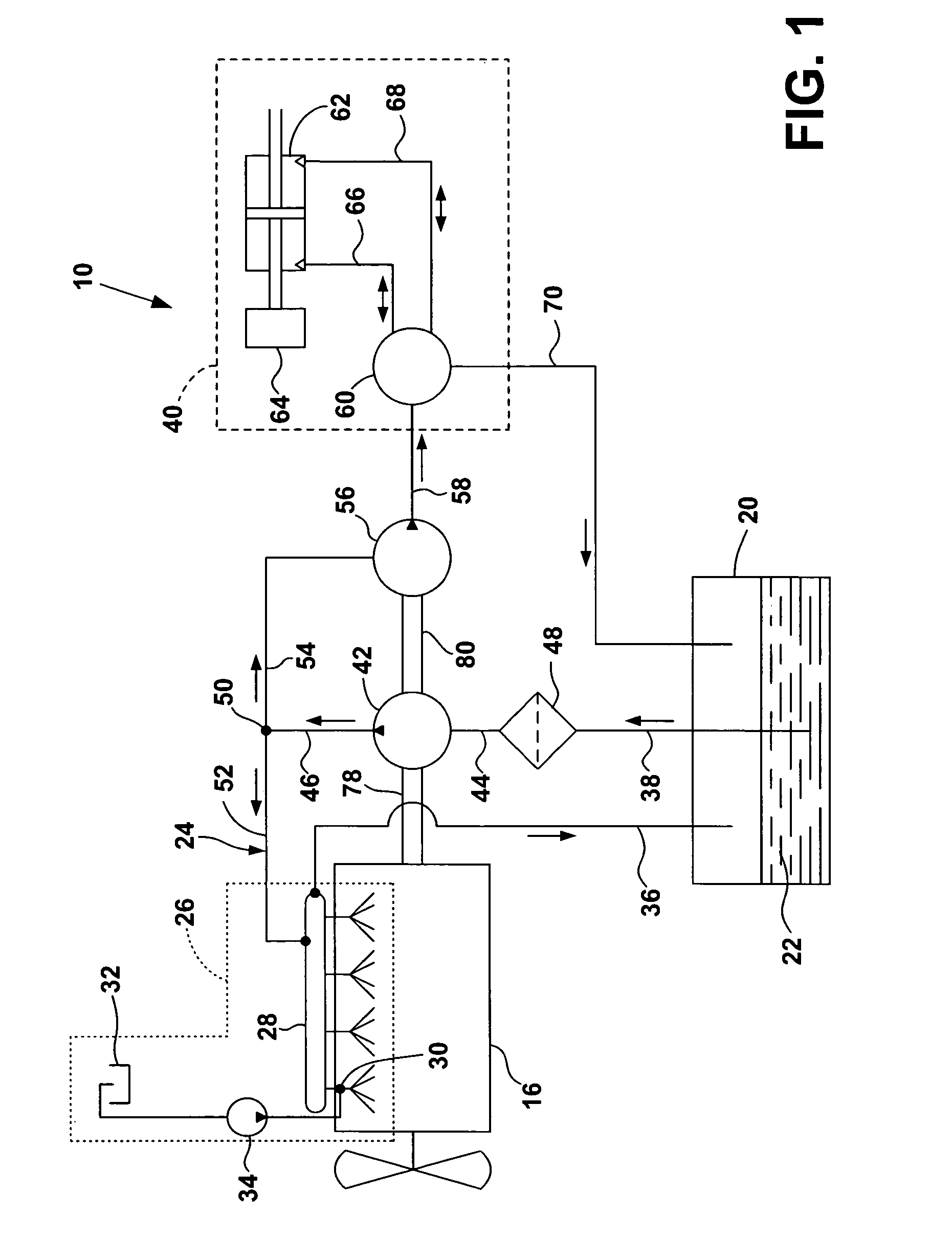

Hydraulic power steering system utilizing fuel as a working fluid

InactiveUS6929087B1Improve cooling effectEliminate overheatingGearingMachines/enginesWorking fluidFuel tank

A hydraulic power steering system for a diesel-fueled truck utilizes vehicle fuel as a working fluid. The steering system includes a power steering gear connected to the steerable wheels of the truck. A first pump flows fuel from the truck's fuel tank to both the steering gear and to the engine. A second pump increases the pressure of the fluid to the steering gear to provide power assist. The flow to the steering gear returns to the fuel tank for recirculation.

Owner:R H SHEPPARD

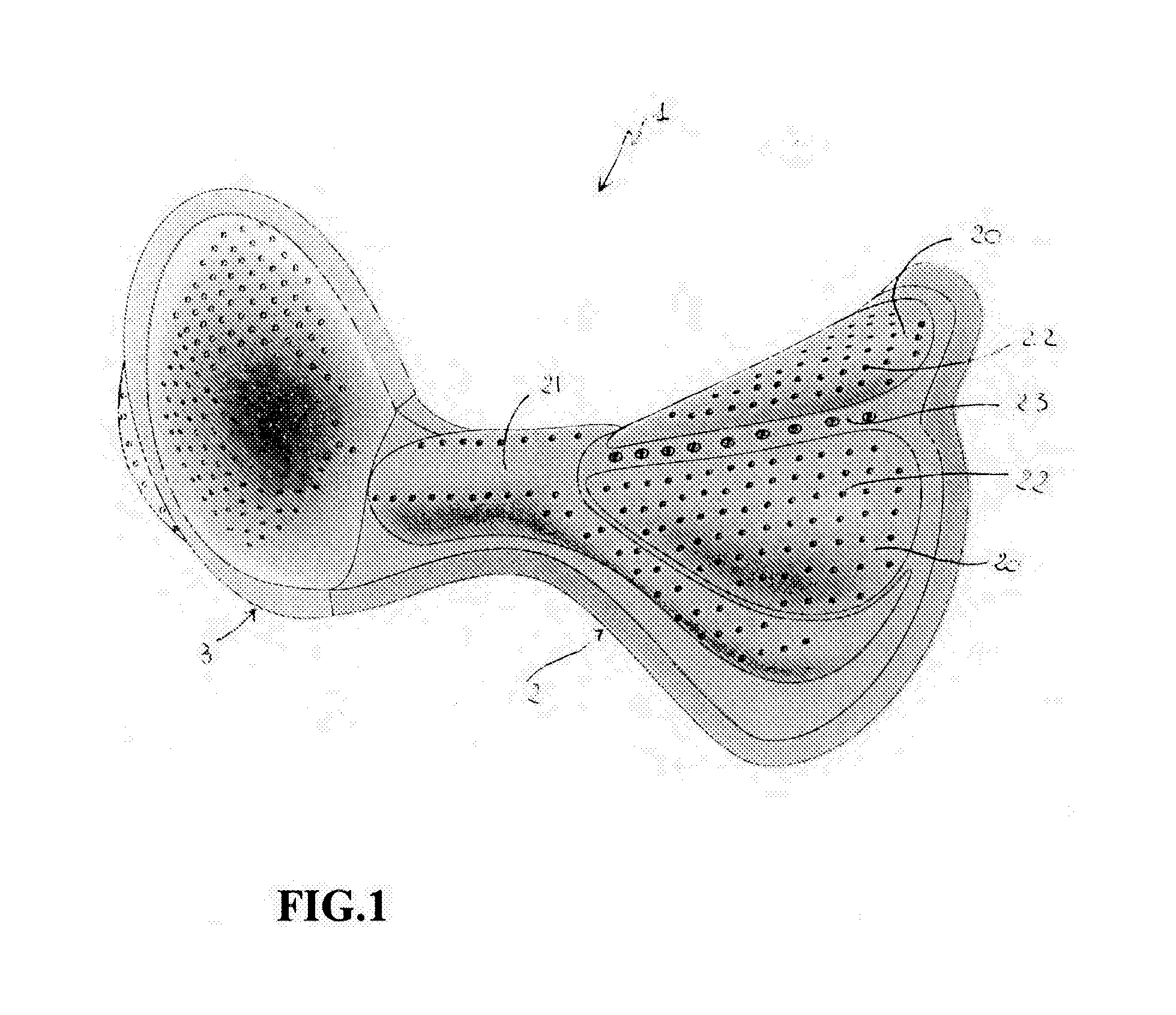

Crotch liner for cycling tights and shorts

InactiveUS20160219950A1Improve protectionOptimized areaTrousersProtective garmentButtocksAdhesive glue

The present invention relates to a crotch liner for cycling tights and shorts of the type comprising a first portion (2) designed to protect the cyclist's perineal and ischial area and a second portion (3), positioned in front of the first portion, which is designed to protect the user's genital area, wherein the said first portion (2) is, in turn, subdivided into a plurality of sectors which comprise a pair of first pads (20), positioned at the point of contact between the buttocks and the saddle, and a second pad (21) with a Y-shaped configuration, which is positioned at the point of contact between the rear portion of the scrotum and the saddle and forks out around the external lateral ends of each of the first pads (20). Furthermore, the said second portion (3), positioned in front of the first portion and designed to protect the cyclist's genital area, is a concave supporter wherein the particular concave shape thereof allows the genitals to assume a slightly raised position, cupped within the said seat and detached from the thighs and the saddle. The first and the second portions are covered with a lower layer and an upper layer of foam, which is, in turn, covered with fabric and all the components are joined together and assembled by heat-moulding by means of the interposition of a glue.

Owner:NICOLINI SILVANA

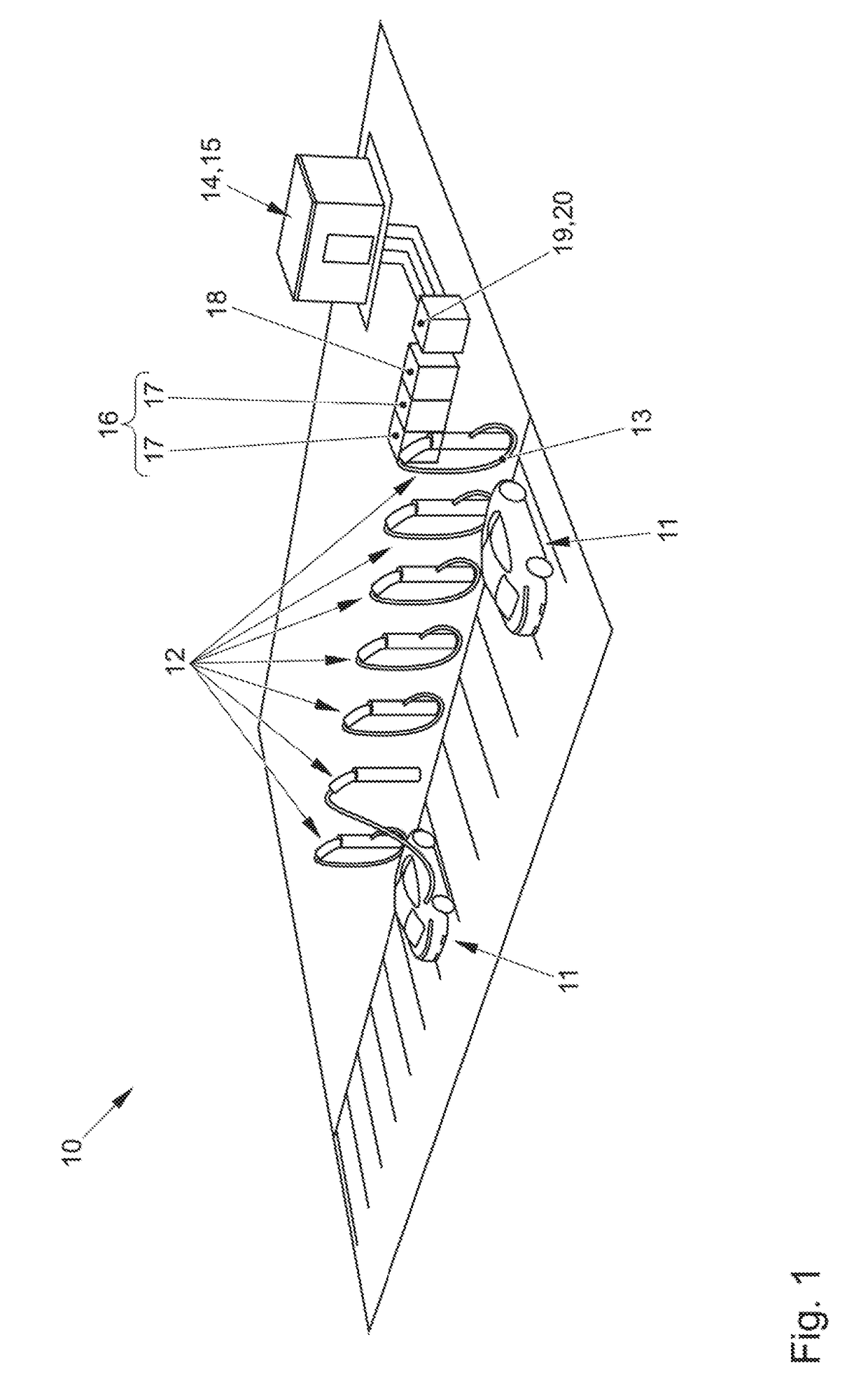

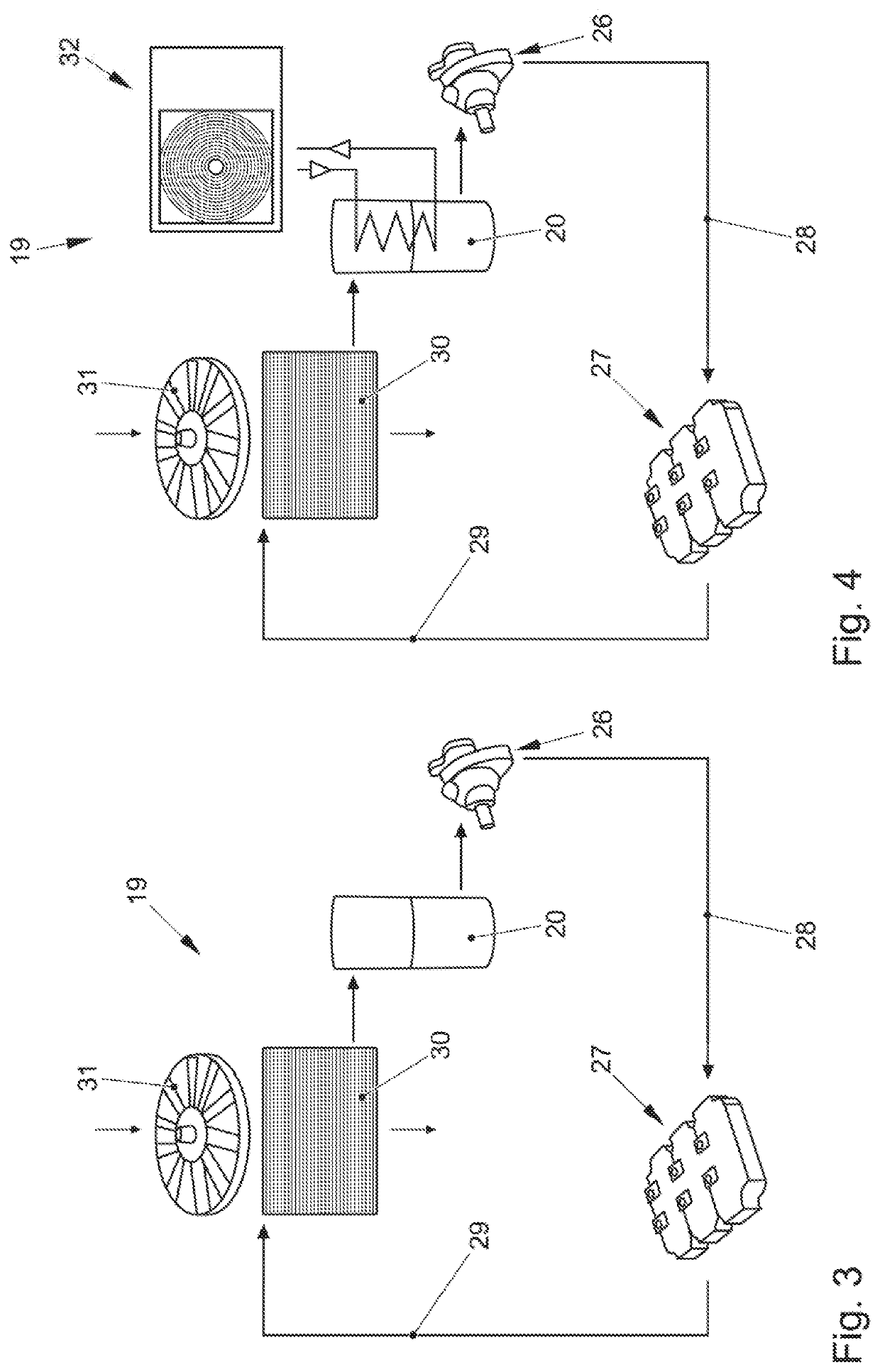

Charging system for electric vehicles

ActiveUS20180370374A1Increase the speed of chargingEfficiently dissipatedBatteries circuit arrangementsCharging stationsElectrical batteryElectric cables

Charging system for electric vehicles, having: a charging station to which a traction battery of an electric vehicle can be coupled via a charging cable; power electronics, the charging station being able to be connected, with the interposition of the power electronics, to an electrical current and voltage supply network which provides a defined electrical network power; an electrical storage device which is connected between the electrical current and voltage supply network and the charging station such that said storage device is charged on the basis of the electrical network power and is discharged on the basis of a charging speed of the charging station; a re-cooling apparatus, the charging station, the power electronics and the electrical storage device connected to the re-cooling apparatus which provides a defined as thermal re-cooling power; a thermal storage device connected to the re-cooling apparatus, to the charging station, to the power electronics and to the electrical storage device such that said storage device or a cooling medium of said storage device is heated on the basis of the power loss of the power electronics, charging station and electrical storage device and can be cooled on the basis of the thermal re-cooling power of the re-cooling apparatus.

Owner:DR ING H C F PORSCHE AG

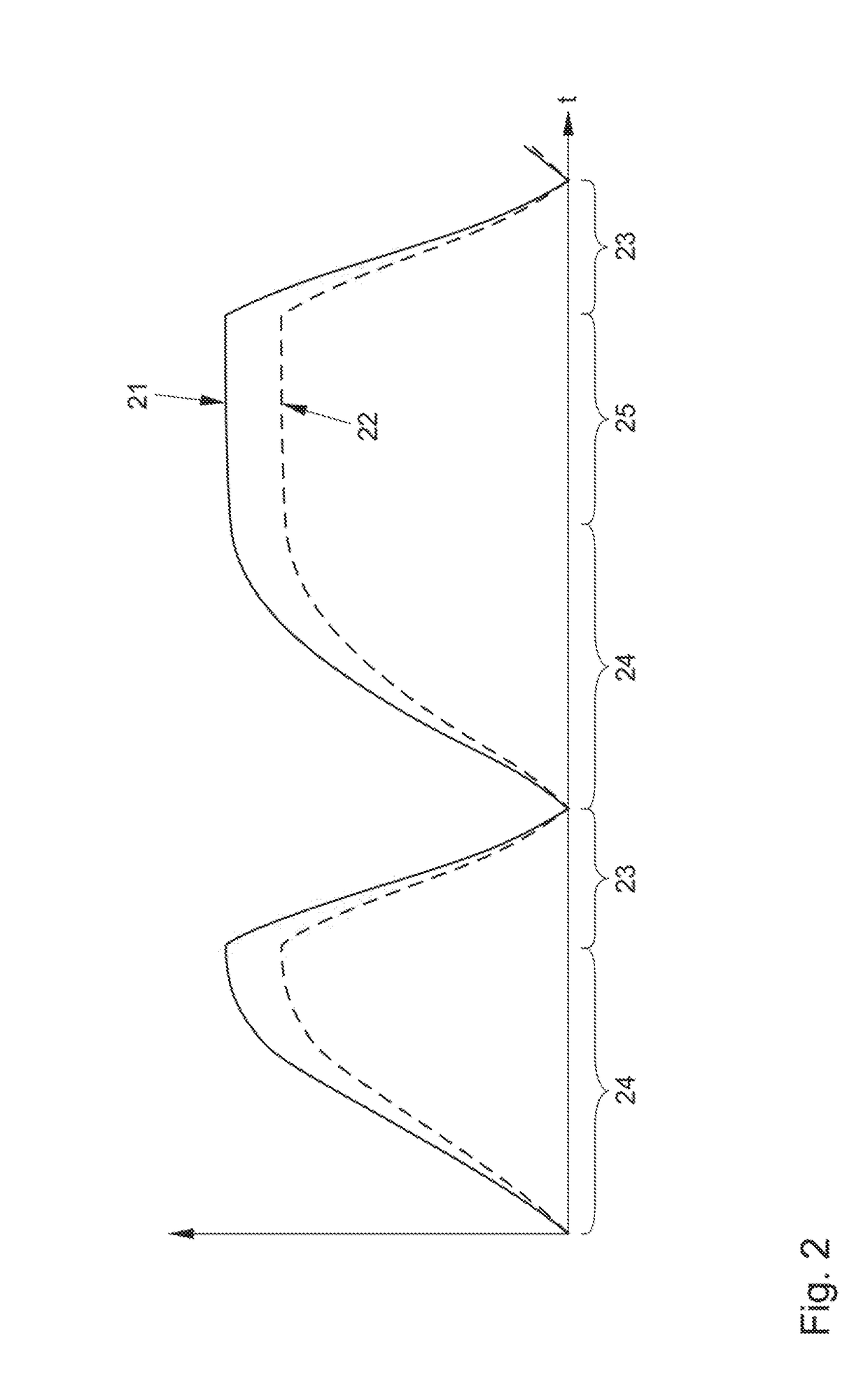

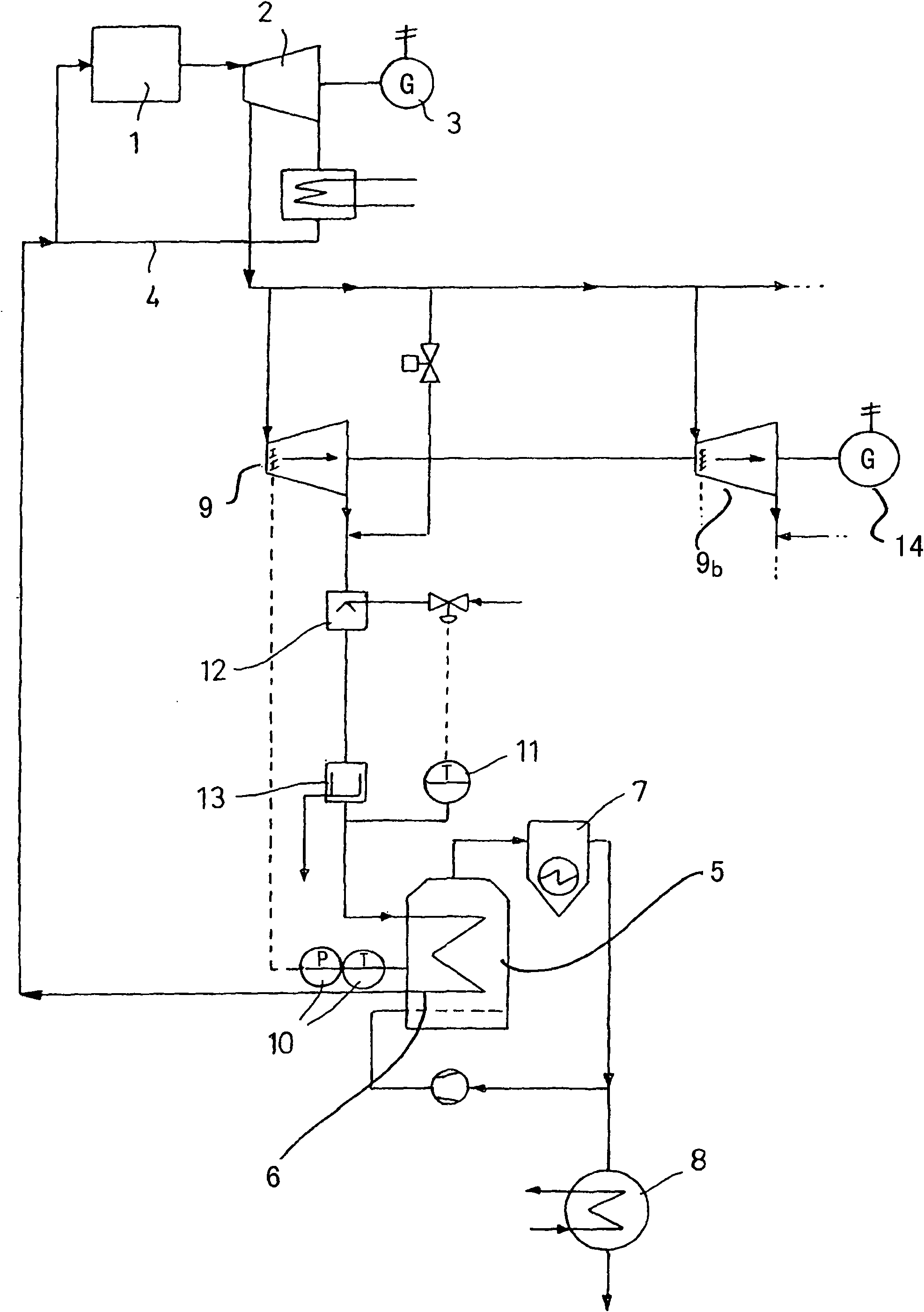

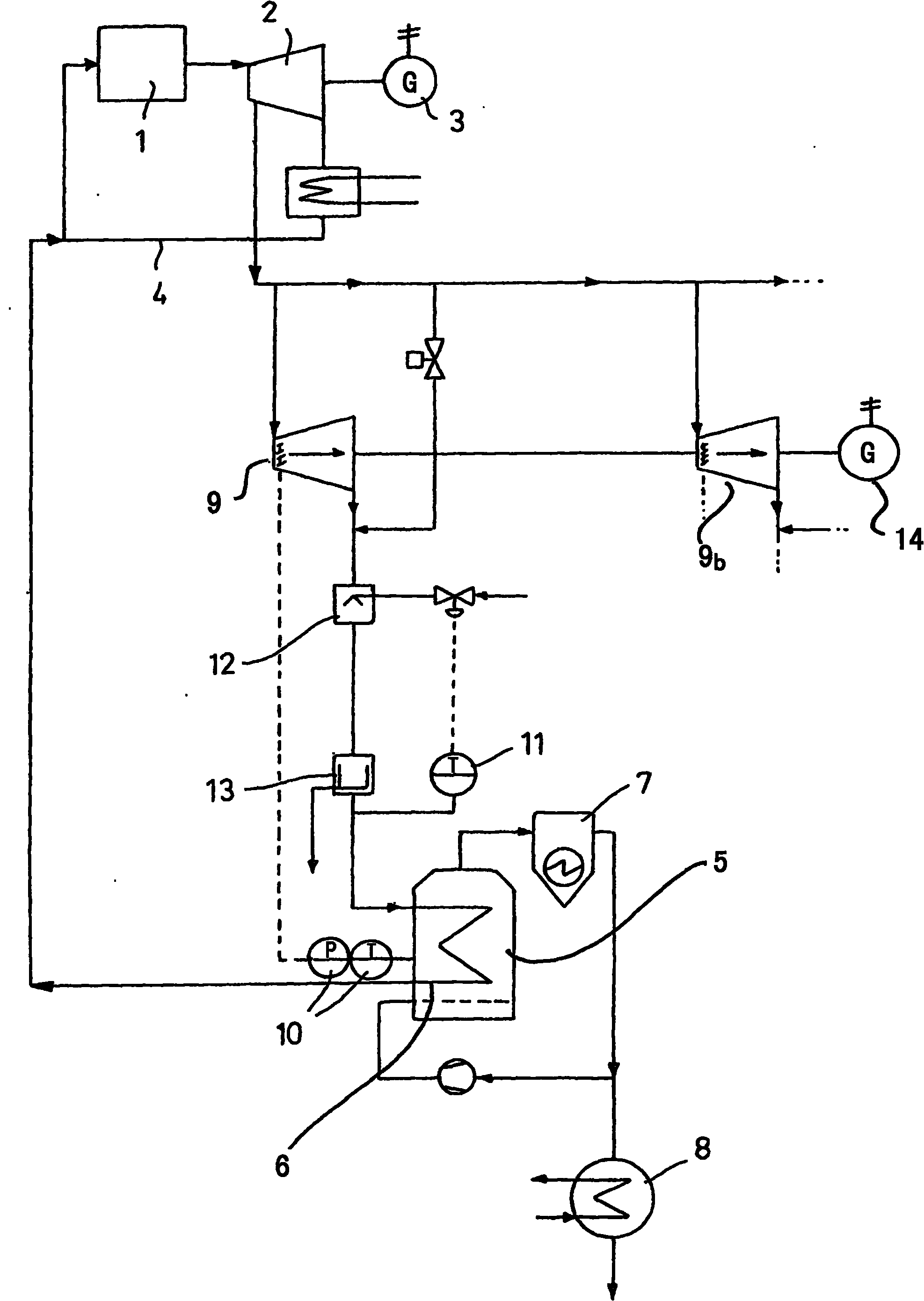

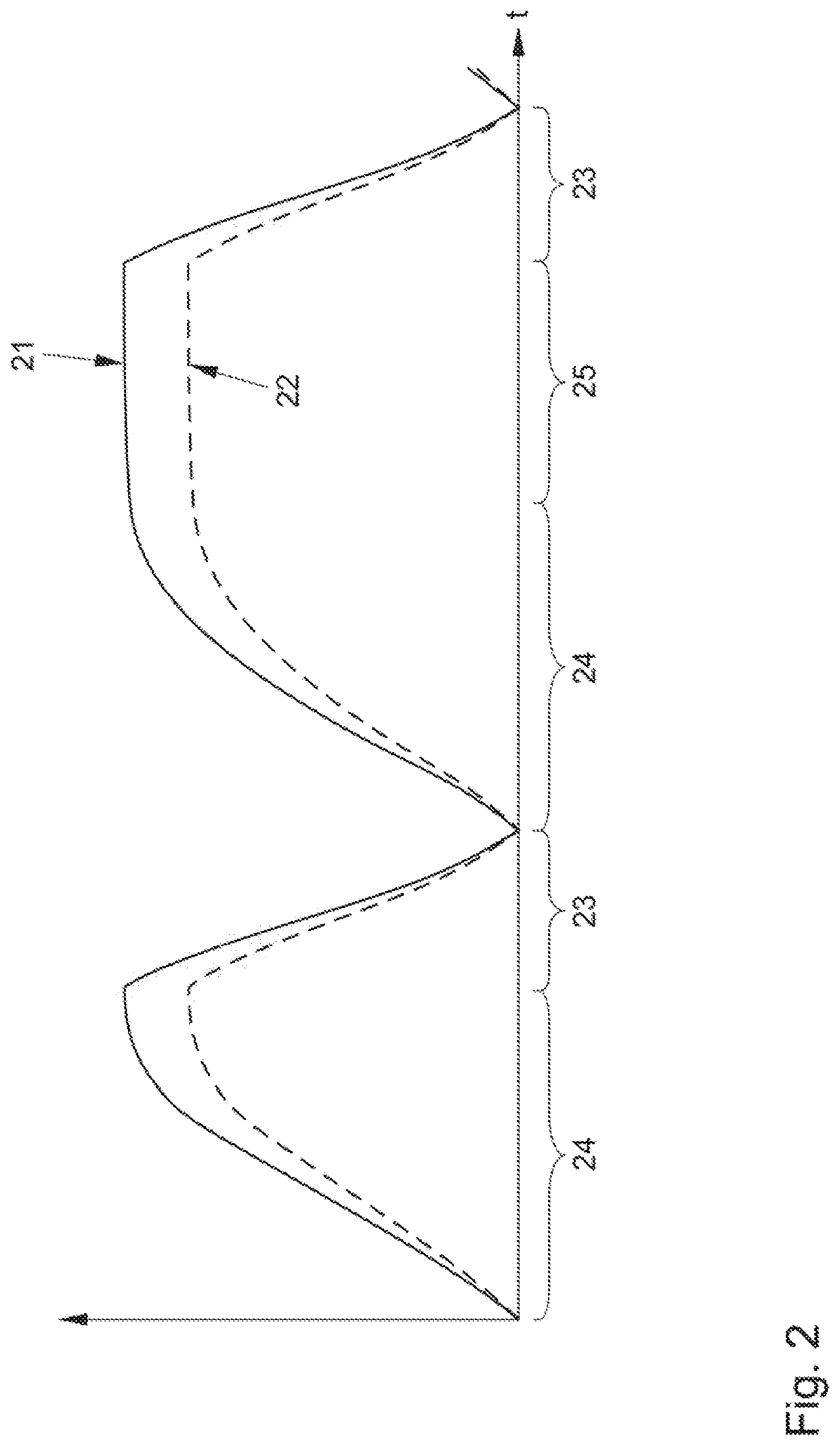

Method for operating a steam turbine power plant and also device for generating steam

InactiveCN101821483AEliminate overheatingFavorable power generationSuperheating controlDrying solid materials with heatSteam pressurePower station

Disclosed is a method for operating a steam turbine power plant, encompassing at least one steam generator (1) that is heated using a solid granular combustible, e.g. lignite. In said method, the combustible is first indirectly dried in a fluidized bed drier (5) that is heated at least in part by steam from the water-steam circuit of the steam generator (1). Said method is characterized in that the temperature in the drier (5) is regulated in two stages in accordance with the humidity of the combustible; first, the temperature of the fluidized bed drier (5) is regulated using the pressure of the heating steam, downstream of which the superheating temperature of the heating steam is regulated in accordance with the steam pressure.

Owner:RWE POWER AKTIENGESELSCHAFT

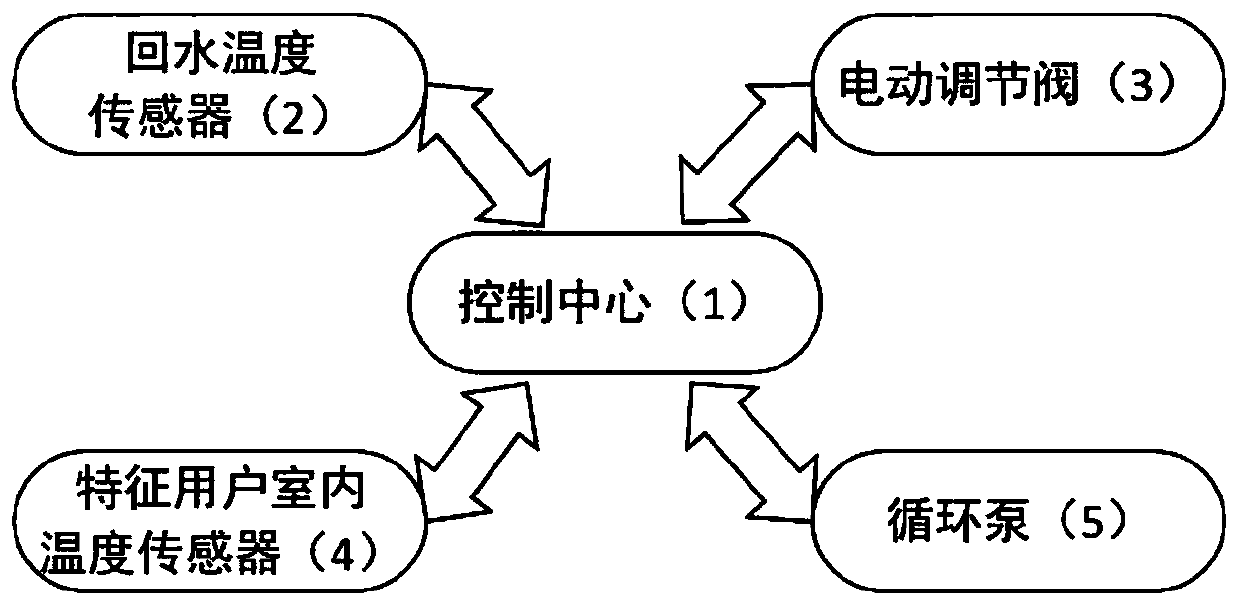

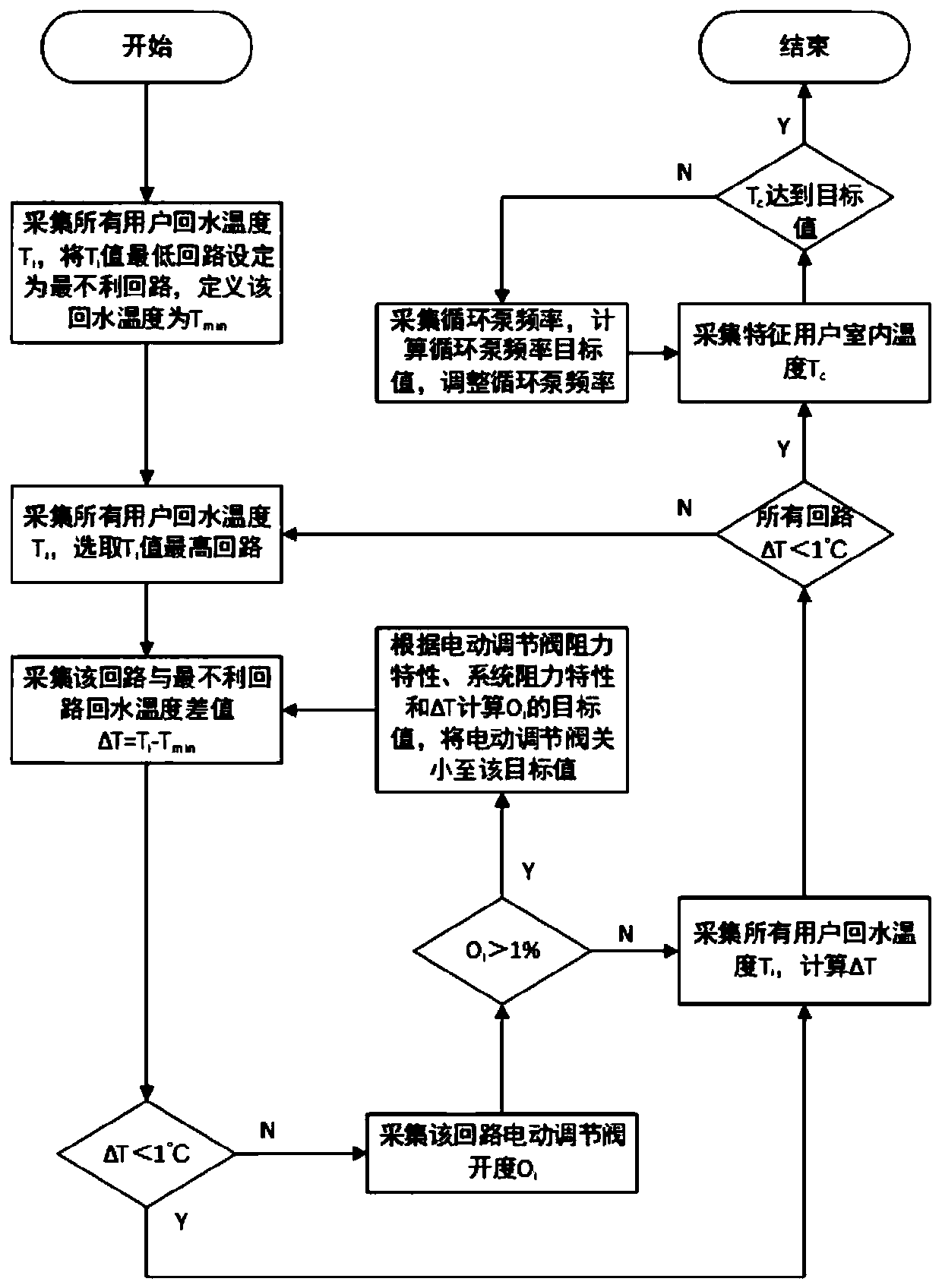

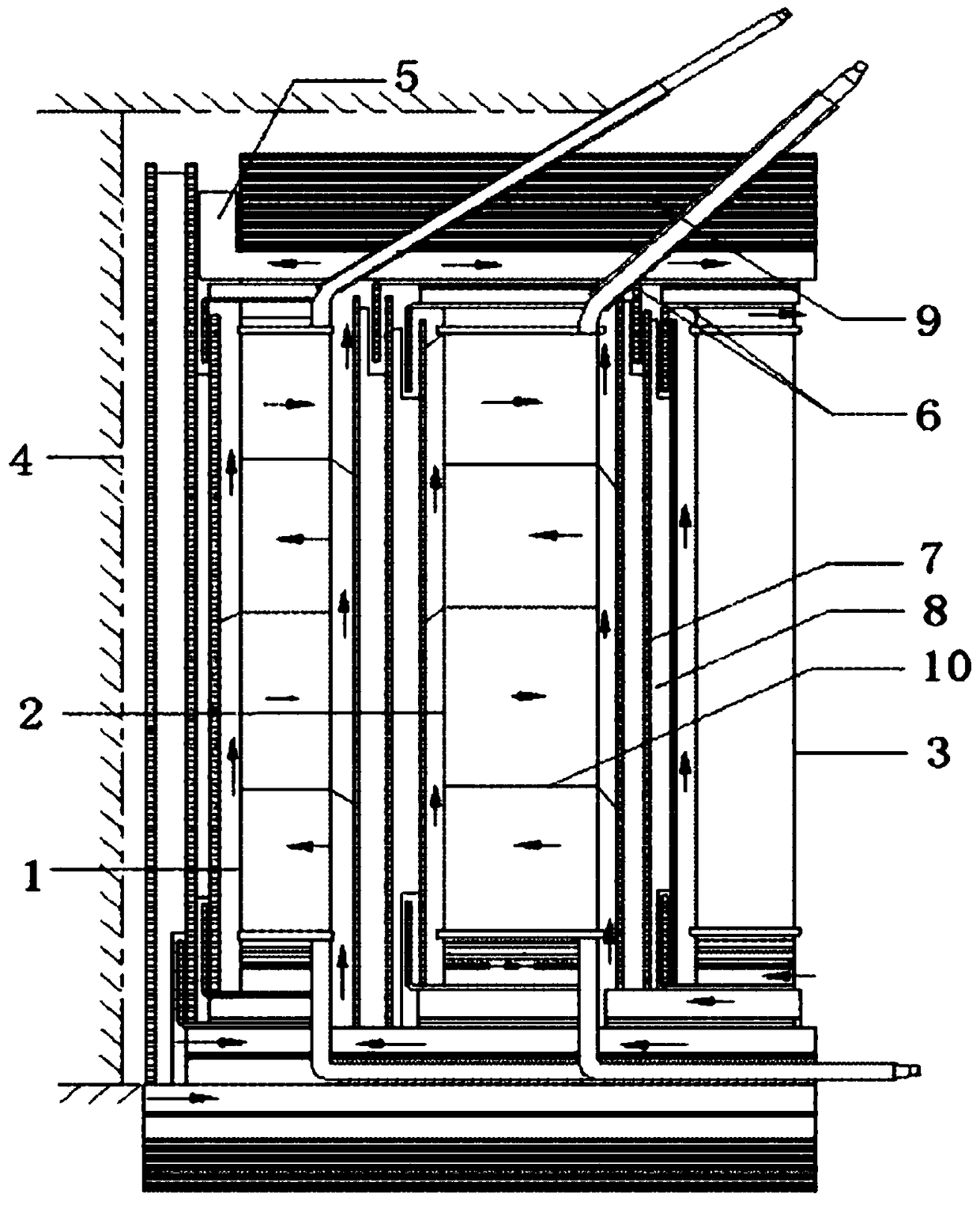

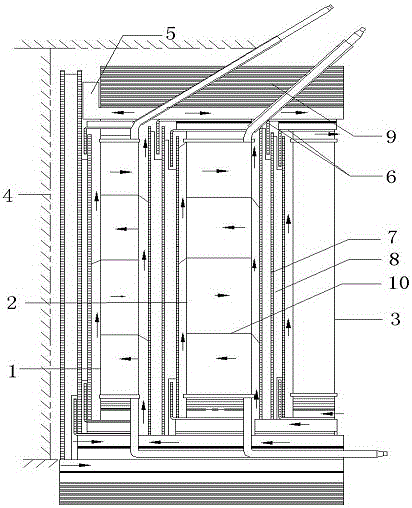

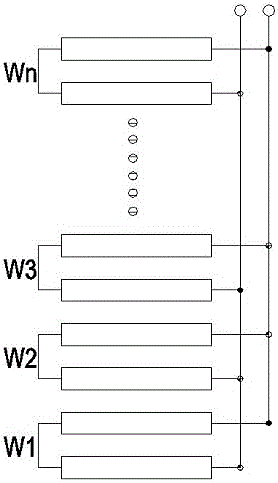

Hydraulic balance adjusting system of branch shaped heat supplying pipe network and control monitoring method

PendingCN109915878AImproved indoor temperature uniformityReduce the problem of substandard heatingLighting and heating apparatusSpace heating and ventilation detailsTraffic capacityElectricity

The invention discloses a hydraulic balance adjusting system and method of a branch shaped heat supplying pipe network. The system comprises a control center, a returned water temperature sensor, an electric adjusting valve, a characteristic user indoor temperature sensor and a circulating pump. According to the system, the returned water temperature sensor is used for transmitting the returned water temperature of a user to the control center, so that a heat supplying company can quickly directly master the returned water temperature of the users in the whole network; and meanwhile, the returned water temperature is monitored in real time, thus the user losing water can be determined within the first time, and the economic loss caused by water losing can be avoided; the heat supplying pipe network is subjected to hydraulic balance adjusting, so that the indoor temperature uniformity of the users in the whole network can be greatly improved; the problem that the heating of some user does not meet the standard due to maladjusted hydraulic balance is reduced; the ideal running mode of 'high temperature difference and small flow rate' is achieved, namely, the circulating flow rate isdecreased, the supplied water temperature is increased, the electricity of a heat exchange station is saved, and meanwhile, the overheat of the front end is avoided, and the heat consumption of the heat exchange station is saved.

Owner:GUOHUI ENVIRONMENTAL PROTECTION NEW ENERGY

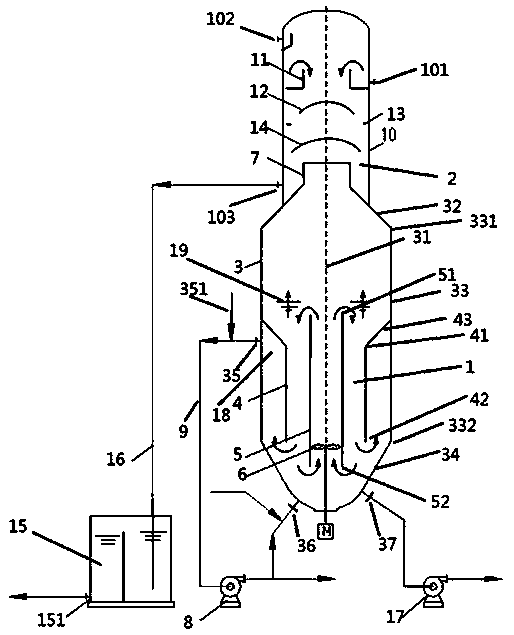

Vertical vacuum crystallization device

PendingCN108714311AAccelerate evaporationEliminate overheatingSolution crystallizationCrystallization by component evaporationCirculator pumpEngineering

The invention provides a vertical vacuum crystallization device. The vertical vacuum crystallization device comprises a crystallization part and a condensing part, wherein the crystallization part islocated below the condensing part and comprises a crystallization section cylinder, an outer flow guiding cylinder, a central flow guiding cylinder, a bottom stirrer, a secondary stream rising cylinder, a circulating cylinder, an inner circulating channel and an outer circulating channel; and the condensing part comprises a condensing section cylinder as well as an overflow weir, a first water baffling cap, a liquid baffling ring and a second water baffling cap which are sequentially arranged in the condensing section cylinder from top to bottom. The vertical vacuum crystallization device hasthe advantages that a heat exchanger does not need to be replaced, and the problems that the inner surface is seriously scaled, and the scale is difficult to clean are prevented; an vacuum processingpressure is similar to a solution steam partial pressure, and the operation is relatively stable; the crystallization part and the condensing part form equipment, so that a secondary steam flow path is shortened, and the leakage of leaking points caused due to the connection of pipelines is eliminated; by utilizing the inner circulating channel, the high-saturability region in the crystallizationpart is eliminated, and the saturability at each site is relatively uniform and low; and by utilizing the outer circulating channel, the excess crystallization is eliminated; and meanwhile, products with relatively narrow particle size distribution can be elutriated.

Owner:JIANGSU XINHONGDA GROUP

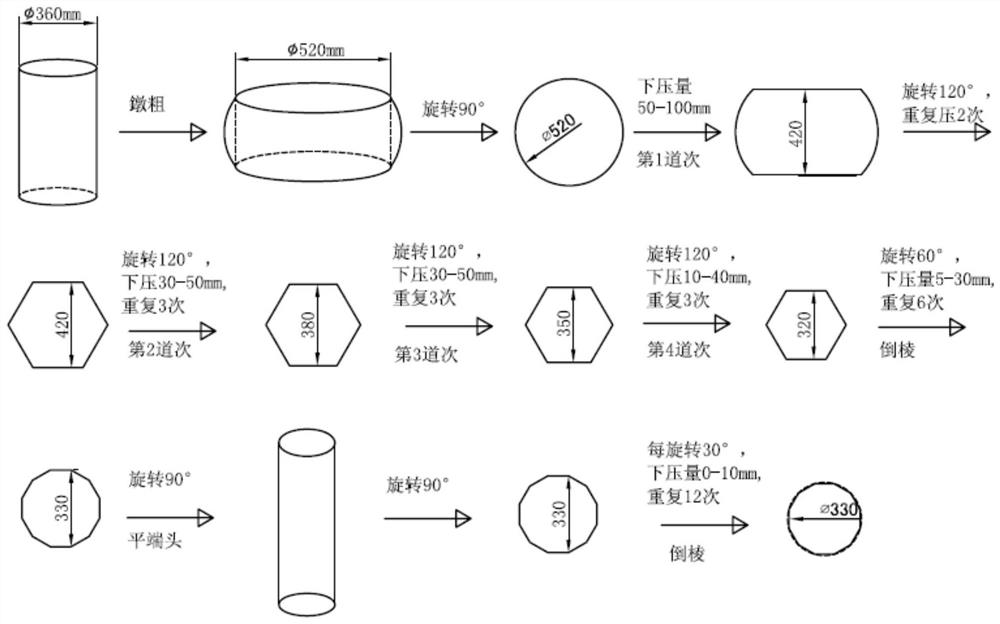

Upsetting-drawing deformation method for TB6 titanium alloy large-specification bar

ActiveCN112275828AUniform deformationEliminates deformation dead zones and core overheatingMetal-working apparatusRound barMetallurgy

The invention discloses an upsetting-drawing deformation method for a TB6 titanium alloy large-specification bar. The upsetting-drawing deformation method comprises the steps that the TB6 titanium alloy bar is heated for preset time at the temperature of 10-40 DEG C below a beta phase transformation point; upsetting of the bar is carried out; multi-pass drawing-out is conducted in a hexagonal drawing-out forging manner; and chamfering, flattening and rounding are carried out. According to the method, the multi-pass hexagonal drawing-out manner is adopted, the deformation amount and the deformation pass are controlled, deformation of all parts of the TB6 titanium alloy large-specification bar can be uniform, deformation dead zones and core overheating are eliminated, and meanwhile the deformation process from a round bar to a hexagon and then to a round bar is achieved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

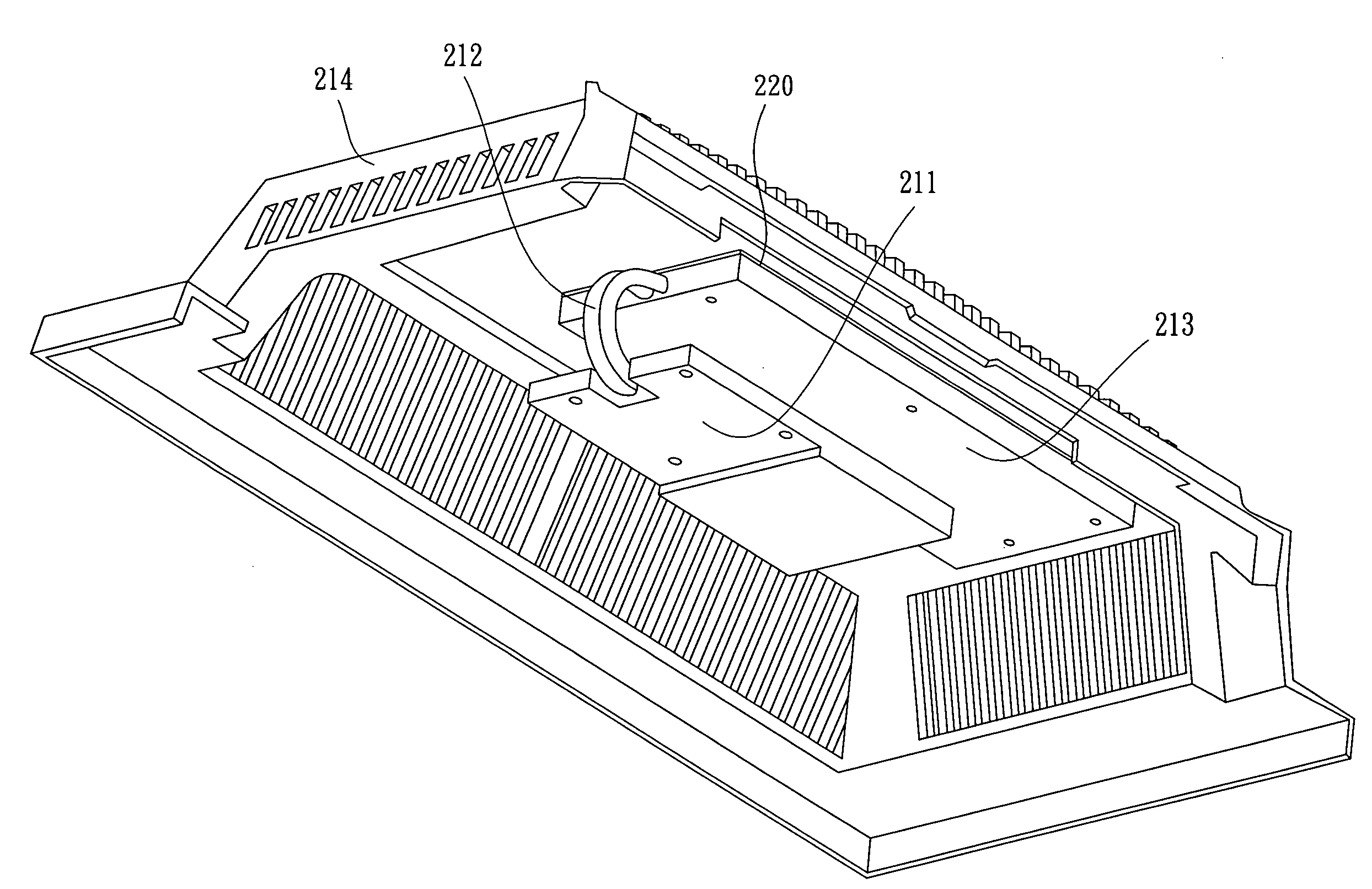

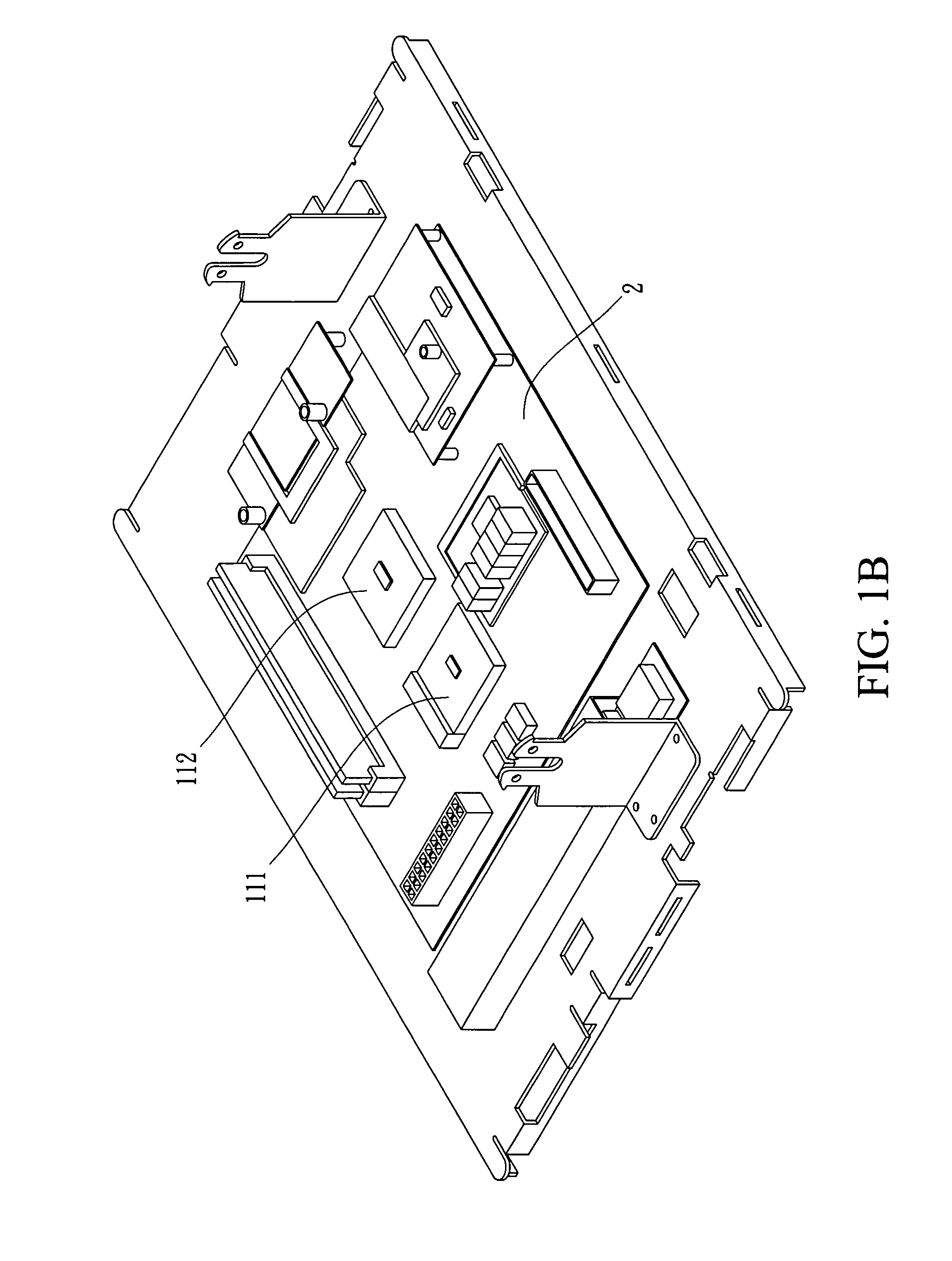

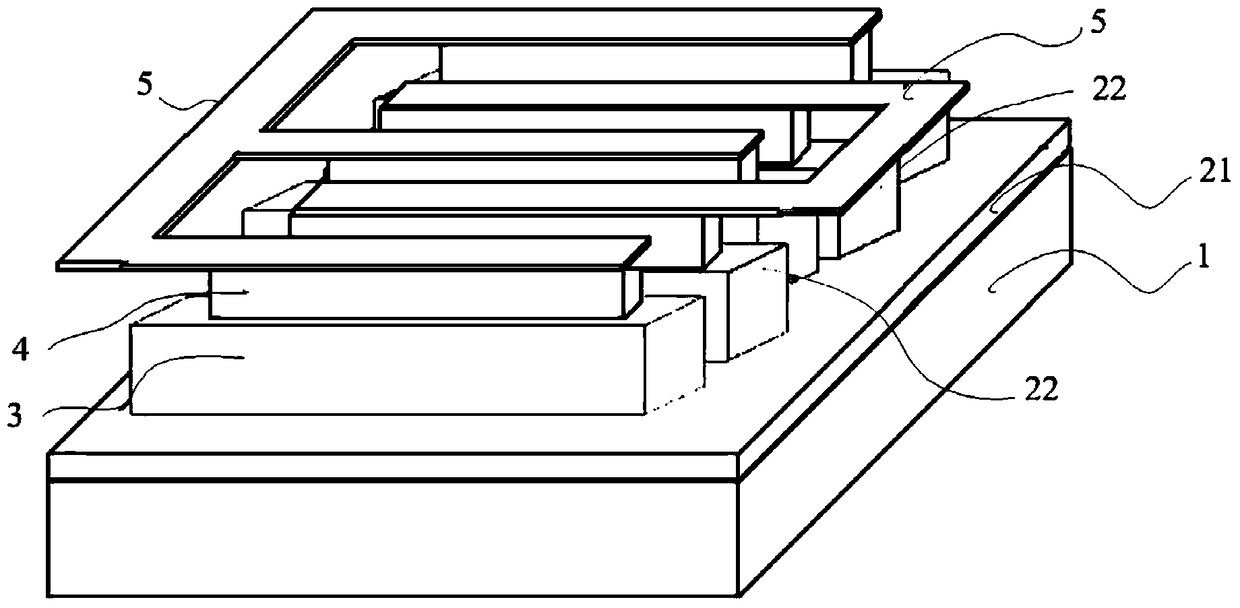

Cooling Module

InactiveUS20090151908A1Even heat dissipationFast absorptionDigital data processing detailsIndirect heat exchangersEngineering

A cooling module for using in a metal housing of a calculation processing apparatus is disclosed. The cooling module is adapted to cool at least one heat source inside the metal housing. The cooling module comprises a first heat conduction plate, a second heat conduction plate and a heat conduction device, wherein the first heat conduction plate covers the heat source, the second heat conduction plate connects to the metal housing, and the heat conduction device is adapted to connect the first heat conduction plate with the second heat conduction plate. After the heat generated by the heat source is absorbed by the first heat conduction plate, the heat is transmitted to the second heat conduction plate through the heat conduction device, and will be dissipated uniformly throughout the metal housing.

Owner:PARTNER TECH

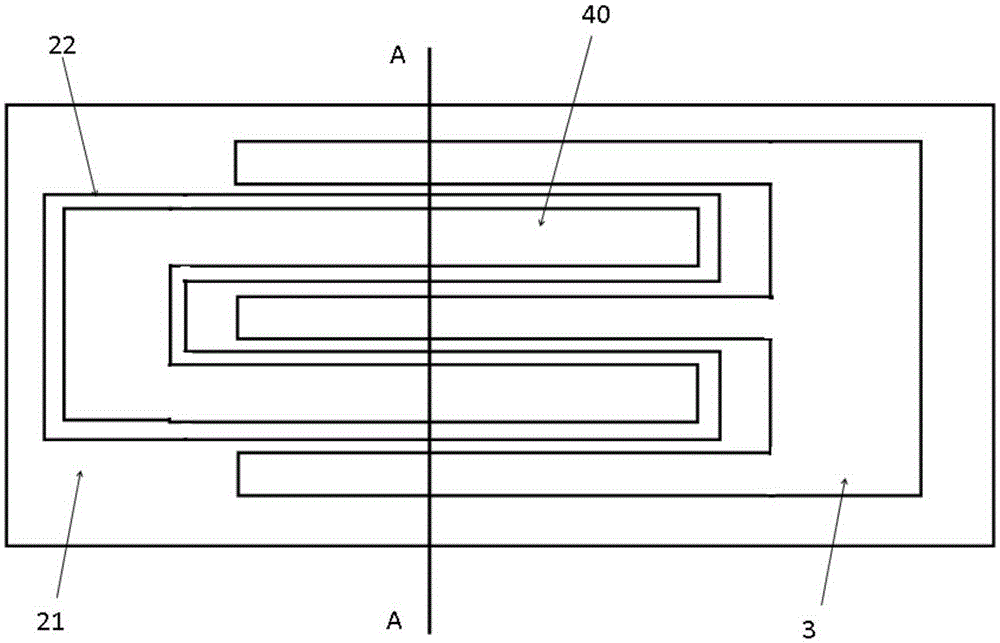

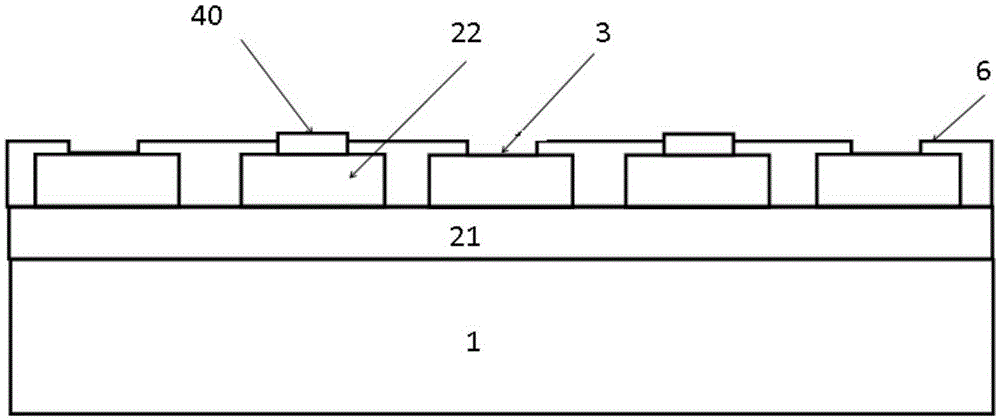

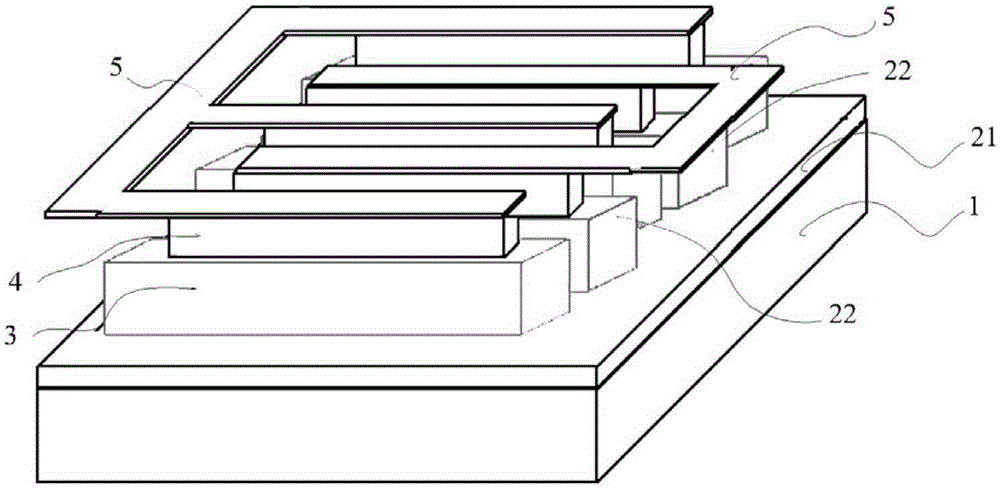

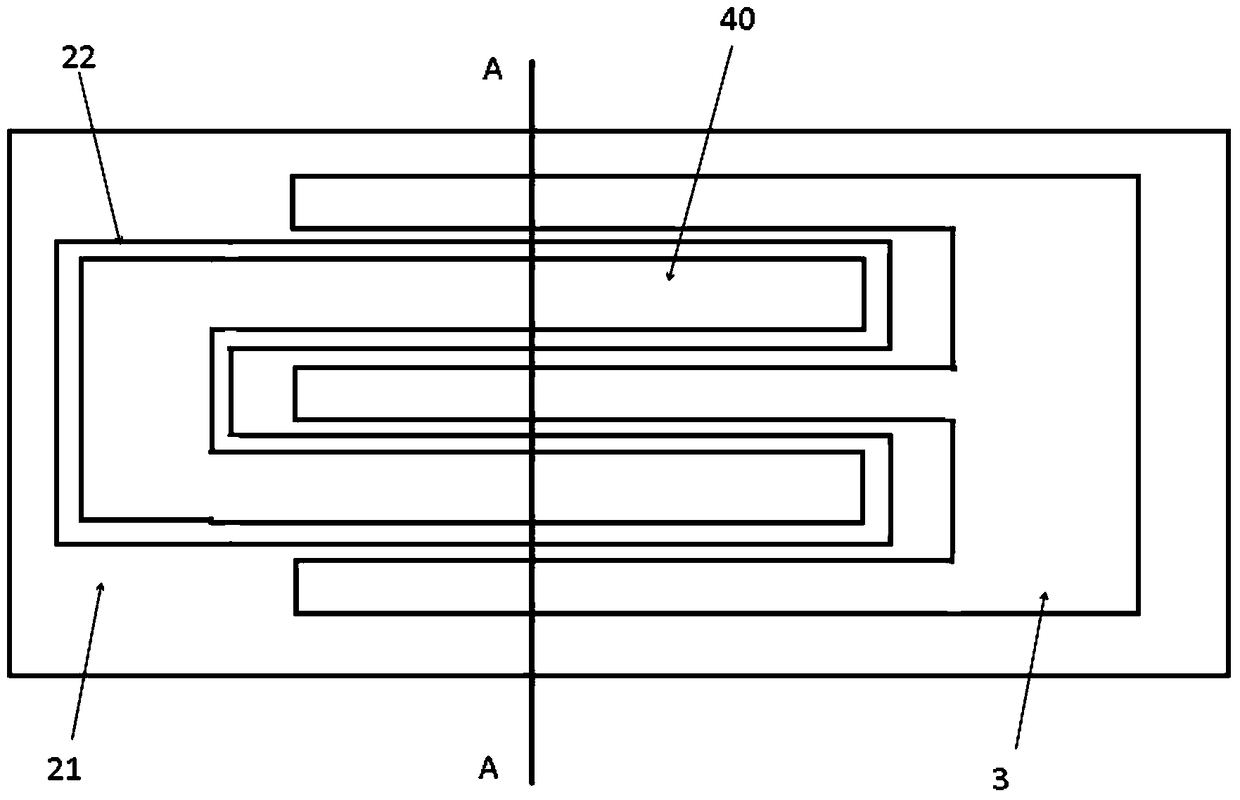

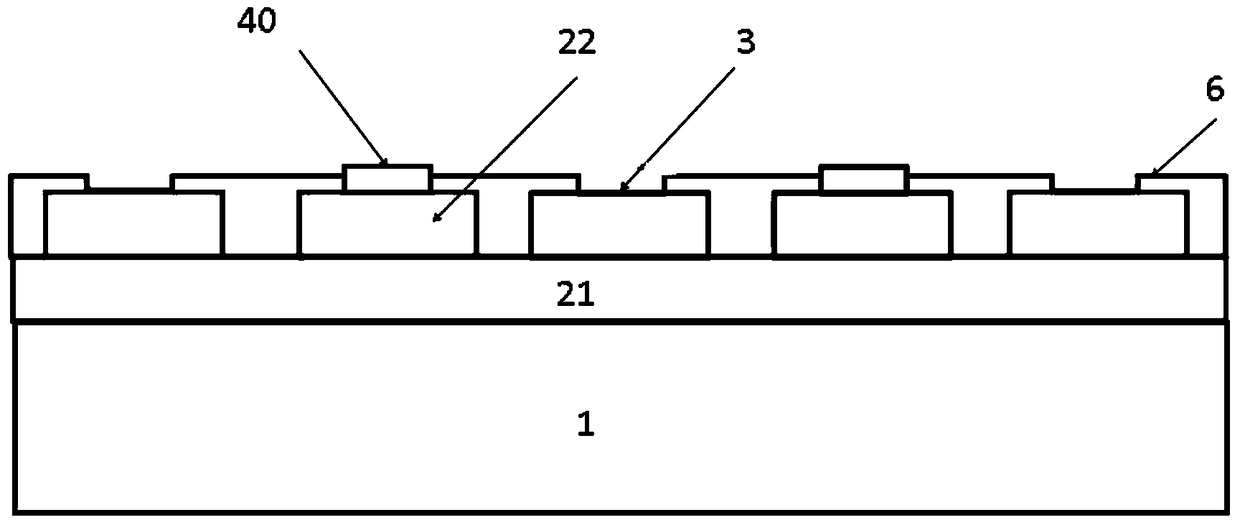

GaN power device and manufacture method thereof

ActiveCN105355665AReduce the occupied areaEliminate overheatingSemiconductor/solid-state device manufacturingDiodeCurrent distributionGallium nitride

The present invention provides a GaN power device and a manufacture method thereof. The GaN power device comprises a substrate, an epitaxial layer formed on the upper surface of the substrate, first metal layers which are radially arranged with intervals, and second metal layers which comprise multiple groups of connection parts and two groups of electrode parts for externally connecting wiring electrodes, wherein multiple groups of convex outward extension steps are etched and formed at the upper part of the epitaxial layer, the first metal layers and the outward extension steps are arranged in a staggered way, the multiple groups of connection parts are formed at the upper surfaces of each group of the outward extension steps and each group of the first metal layers, one group of the electrode parts is communicated with the connection part on each group of the outward extension steps, and the other group of the electrode parts is communicated with the connection part of each group of the first metal layers. According to the GaN power device, the device occupation area in the same power is reduced, under the driving of high current, the current distribution is uniform, and the device overheating caused by the current congestion of a local area is eliminated.

Owner:JIANGSU CORENERGY SEMICON CO LTD

Charging system for electric vehicles

ActiveUS10688873B2Increase the speed of chargingEfficiently dissipatedBatteries circuit arrangementsCharging stationsElectrical batteryElectric network

Charging system for electric vehicles, having: a charging station to which a traction battery of an electric vehicle can be coupled via a charging cable; power electronics, the charging station being able to be connected, with the interposition of the power electronics, to an electrical current and voltage supply network which provides a defined electrical network power; an electrical storage device which is connected between the electrical current and voltage supply network and the charging station such that said storage device is charged on the basis of the electrical network power and is discharged on the basis of a charging speed of the charging station; a re-cooling apparatus, the charging station, the power electronics and the electrical storage device connected to the re-cooling apparatus which provides a defined as thermal re-cooling power; a thermal storage device connected to the re-cooling apparatus, to the charging station, to the power electronics and to the electrical storage device such that said storage device or a cooling medium of said storage device is heated on the basis of the power loss of the power electronics, charging station and electrical storage device and can be cooled on the basis of the thermal re-cooling power of the re-cooling apparatus.

Owner:DR ING H C F PORSCHE AG

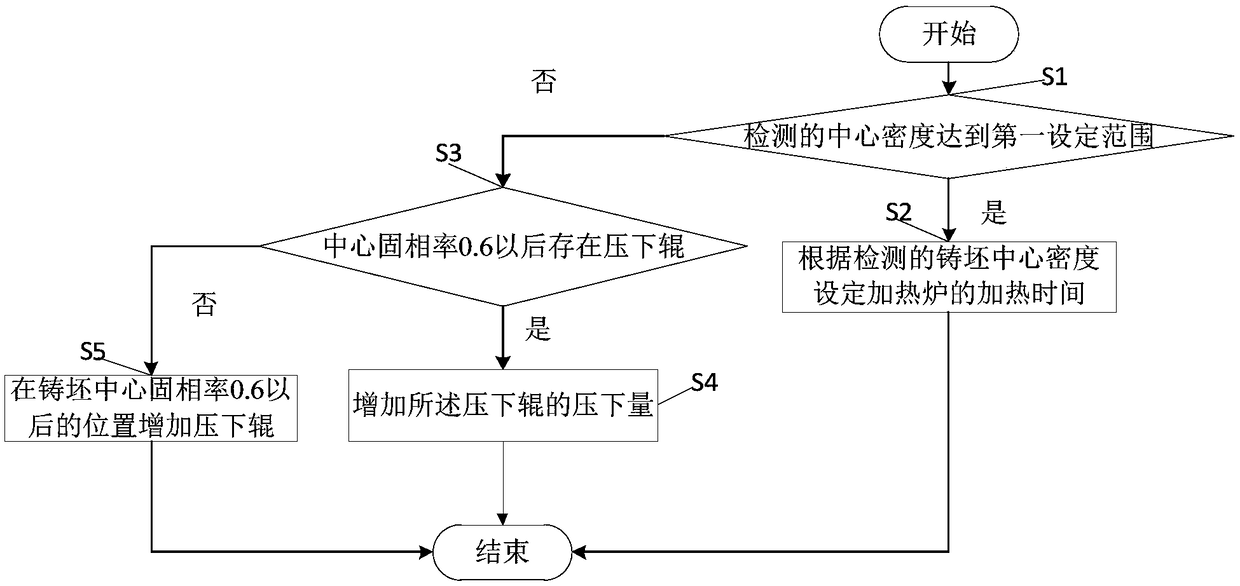

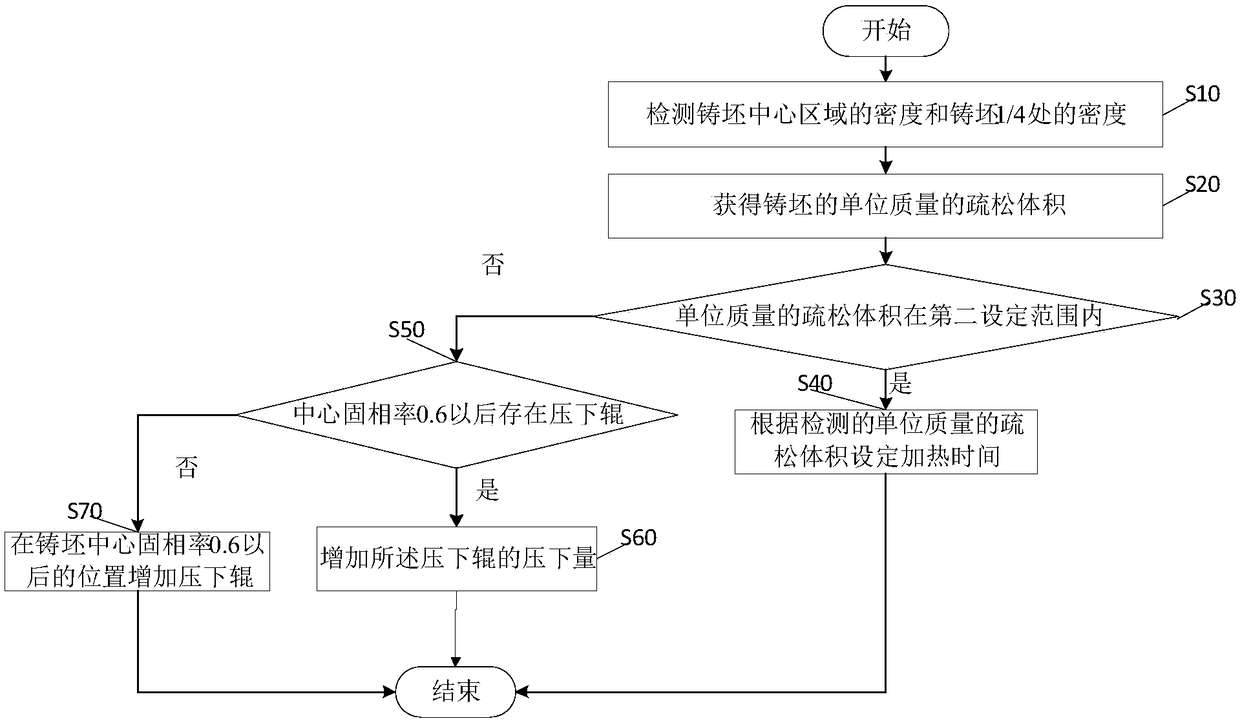

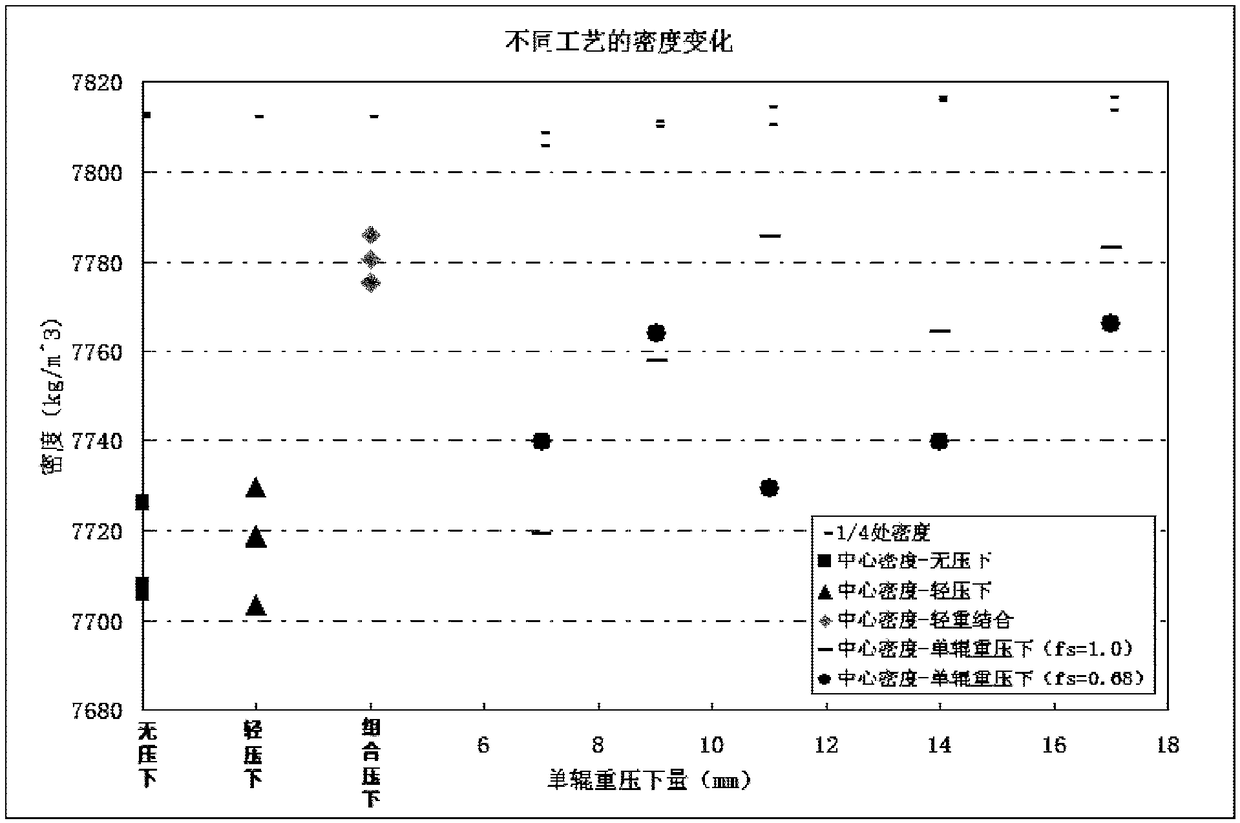

A method for controlling network carbon and banded structures

ActiveCN108823385AShorten heating timeReduce overheatingFurnace typesHeat treatment furnacesHeating timeSolid fraction

A method for controlling network carbon and banded structures is disclosed. The method includes detecting whether the density of the center zone of a casting billet reaches a first set range or not, with the first set range being determined according to steel variety and casting billet uniformity; if the density reaches the first set range, putting the casting billet into a heating furnace, heating the casting billet, and setting heating time of the heating furnace according to the detected density of the center zone of the casting billet; if the density does not reach the first set range, determining whether a reduction roller exists in a position behind a position where the center solid fraction of the casting billet is 0.6; if the reduction roller exists, increasing the reduction of thereduction roller; and if no reduction roller exists, additionally arranging a reduction roller in a position behind a position where the center solid fraction of the casting billet is 0.6. The methodensures structure uniformity of a final material, ensures product performance, and can significantly reduce the production cost of current processes.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

Gallium nitride power device and manufacturing method thereof

ActiveCN105355665BReduce the occupied areaEliminate overheatingSemiconductor/solid-state device manufacturingDiodeCurrent distributionGallium nitride

The present invention provides a GaN power device and a manufacture method thereof. The GaN power device comprises a substrate, an epitaxial layer formed on the upper surface of the substrate, first metal layers which are radially arranged with intervals, and second metal layers which comprise multiple groups of connection parts and two groups of electrode parts for externally connecting wiring electrodes, wherein multiple groups of convex outward extension steps are etched and formed at the upper part of the epitaxial layer, the first metal layers and the outward extension steps are arranged in a staggered way, the multiple groups of connection parts are formed at the upper surfaces of each group of the outward extension steps and each group of the first metal layers, one group of the electrode parts is communicated with the connection part on each group of the outward extension steps, and the other group of the electrode parts is communicated with the connection part of each group of the first metal layers. According to the GaN power device, the device occupation area in the same power is reduced, under the driving of high current, the current distribution is uniform, and the device overheating caused by the current congestion of a local area is eliminated.

Owner:JIANGSU CORENERGY SEMICON CO LTD

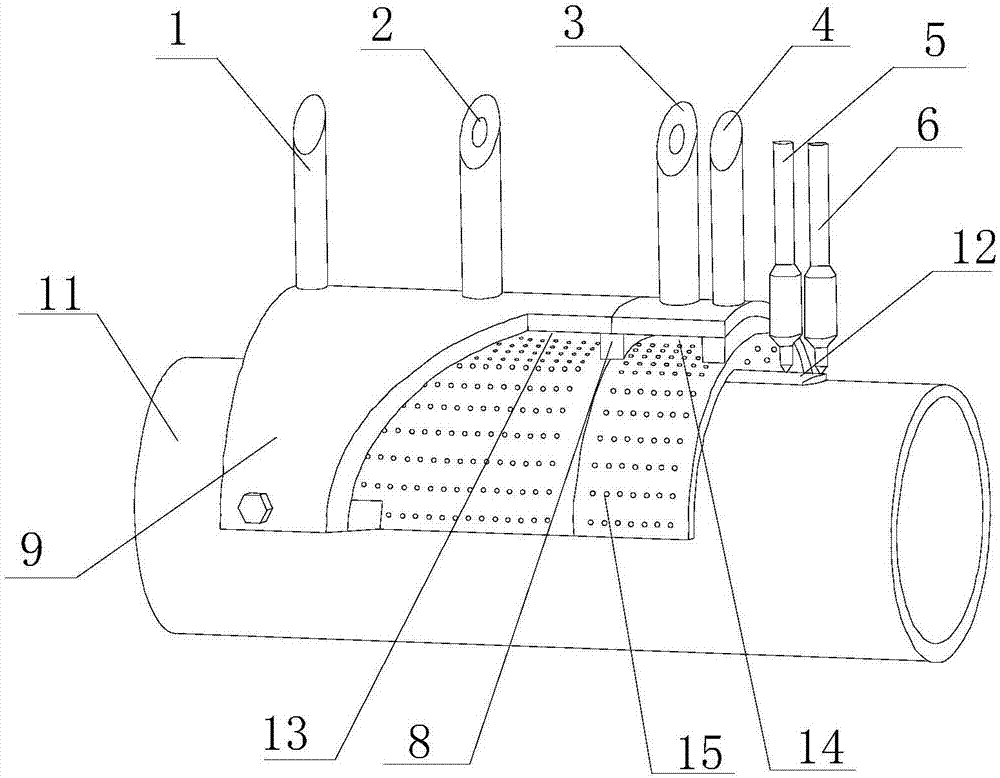

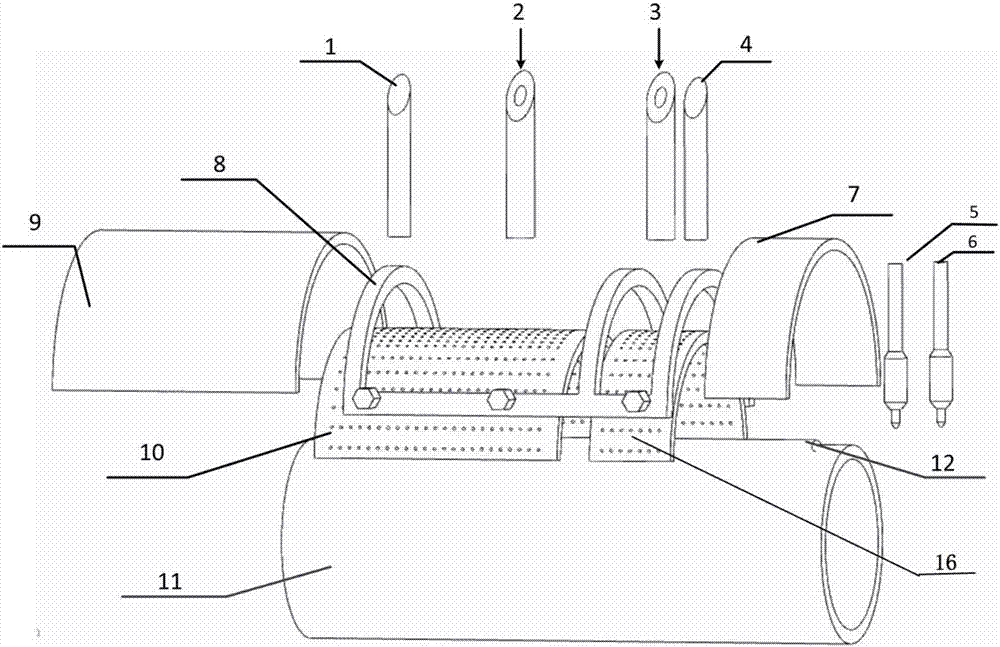

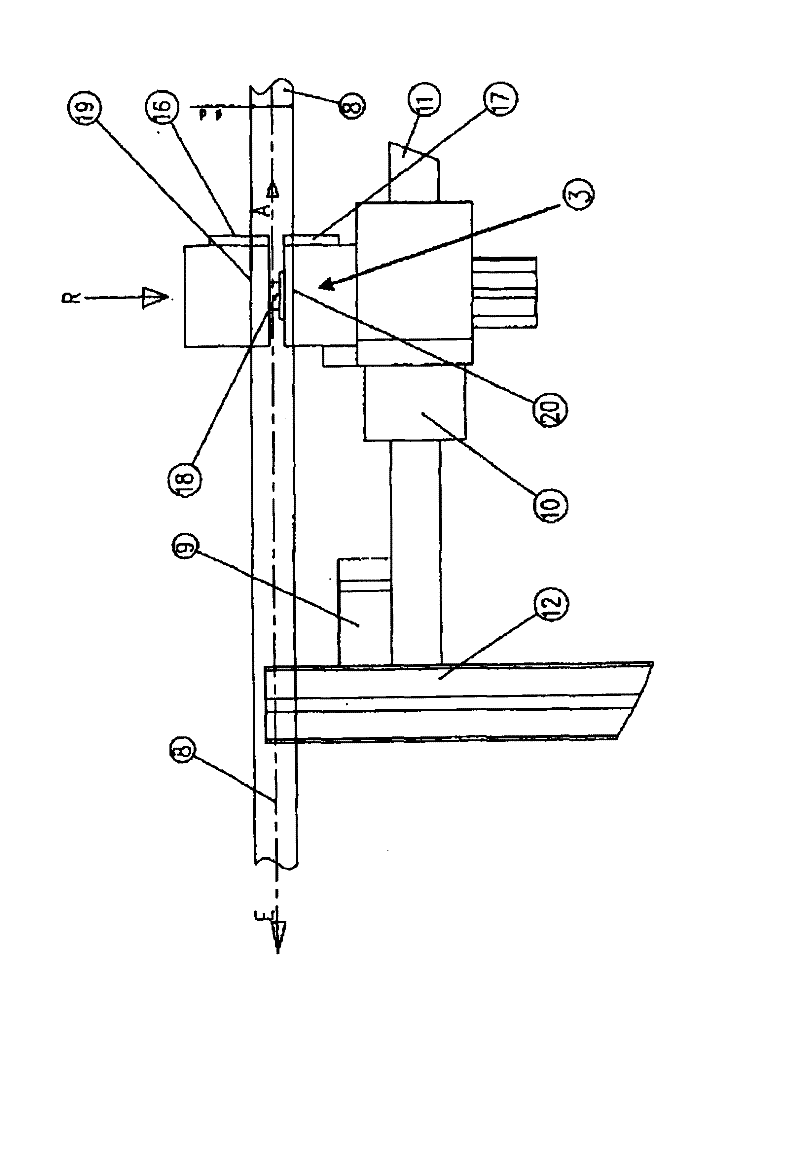

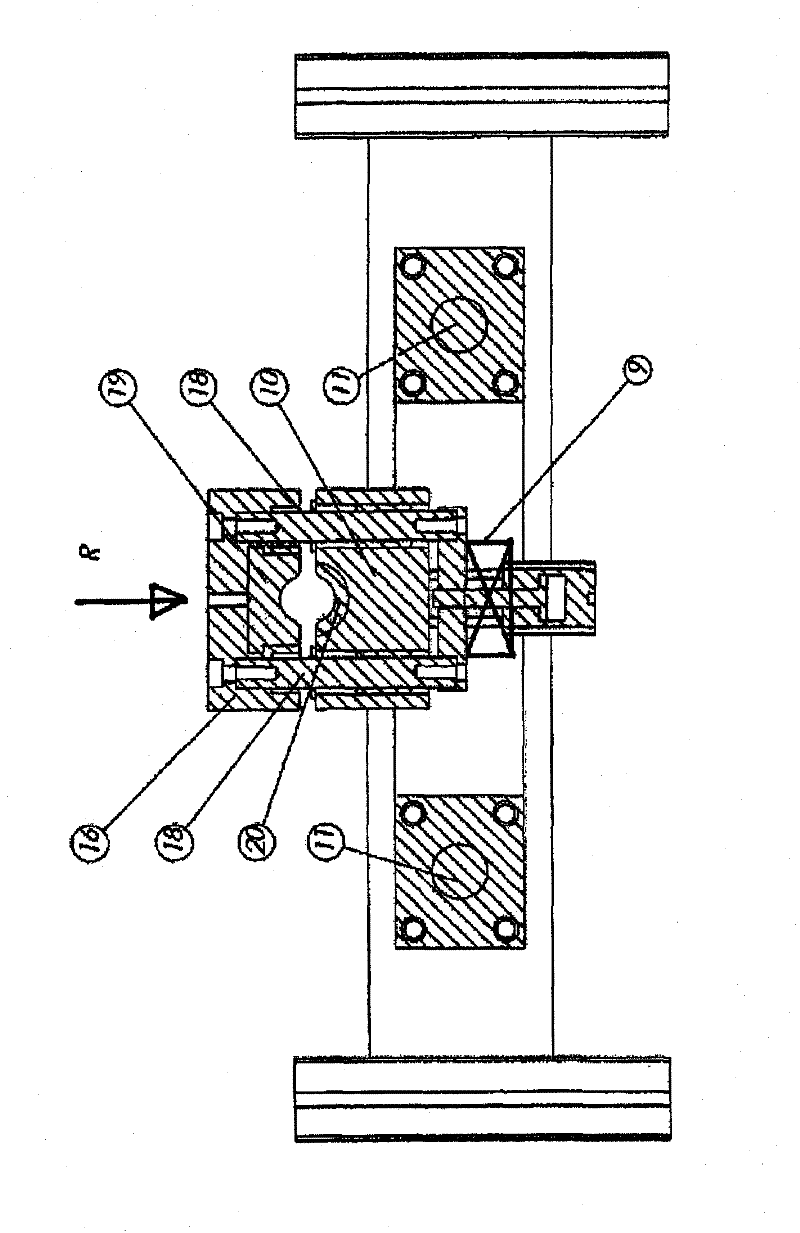

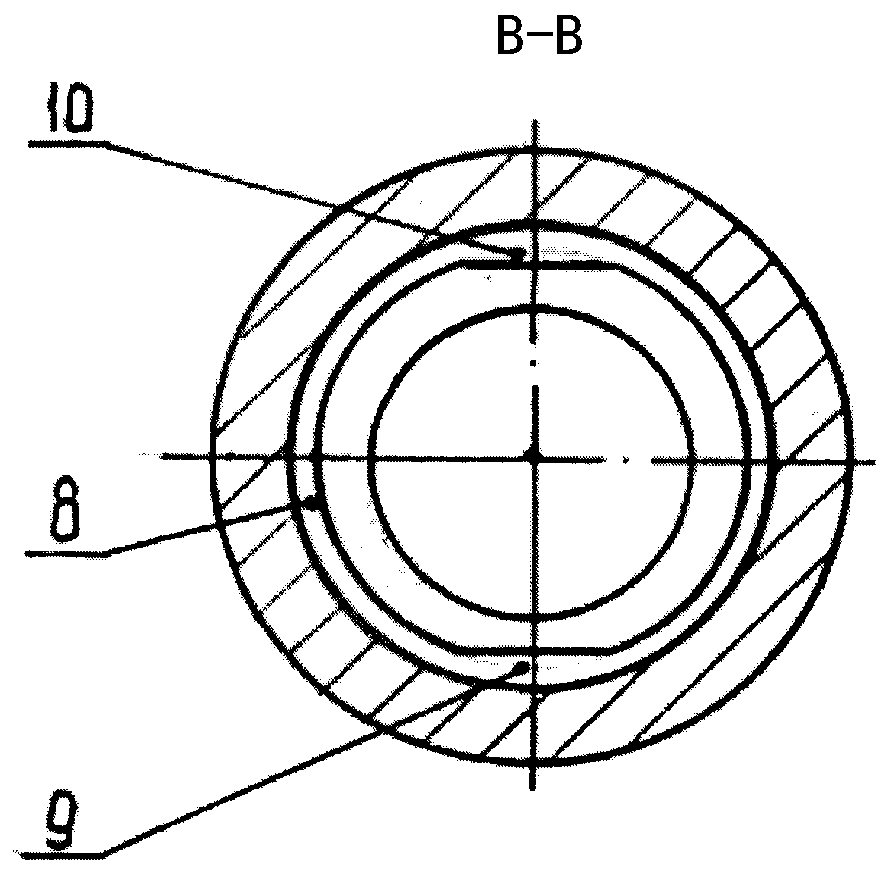

Device and process for removing local overheating effect in pipeline welding process

InactiveCN106975823AProtected weldEliminate overheatingWelding coupling meansWelding protection meansWater storagePipe

The invention discloses a device and process for removing the local overheating effect in the pipeline welding process. According to the device and process, the phenomenon of local overheating of a weld can be removed effectively. According to the technical scheme, the device comprises a mechanical skeleton, a cooling sleeve I, a cooling sleeve II, a cooling sleeve III, a cooling sleeve IV, a suspension rod I, a suspension rod II, a water injecting pipe and an argon injecting pipe; the inner sides of the cooling sleeve III and the cooling sleeve IV make contact with a welding pipeline; the mechanism skeleton is arranged on the outer sides of the cooling sleeve III and the cooling sleeve IV; the cooling sleeve I and the cooling sleeve II are arranged on the outer side of the mechanism skeleton; a cavity formed between the mechanism skeleton and the cooling sleeve III is a water storage cavity; a cavity formed among the cooling sleeve II, the mechanism skeleton and the cooling sleeve IV is an argon cavity; the suspension rod I and the water injecting pipe are arranged on the outer side of the cooling sleeve I; and the suspension II and the argon injecting pipe are arranged on the outer side of the cooling sleeve II.

Owner:山东朝日不锈钢有限公司

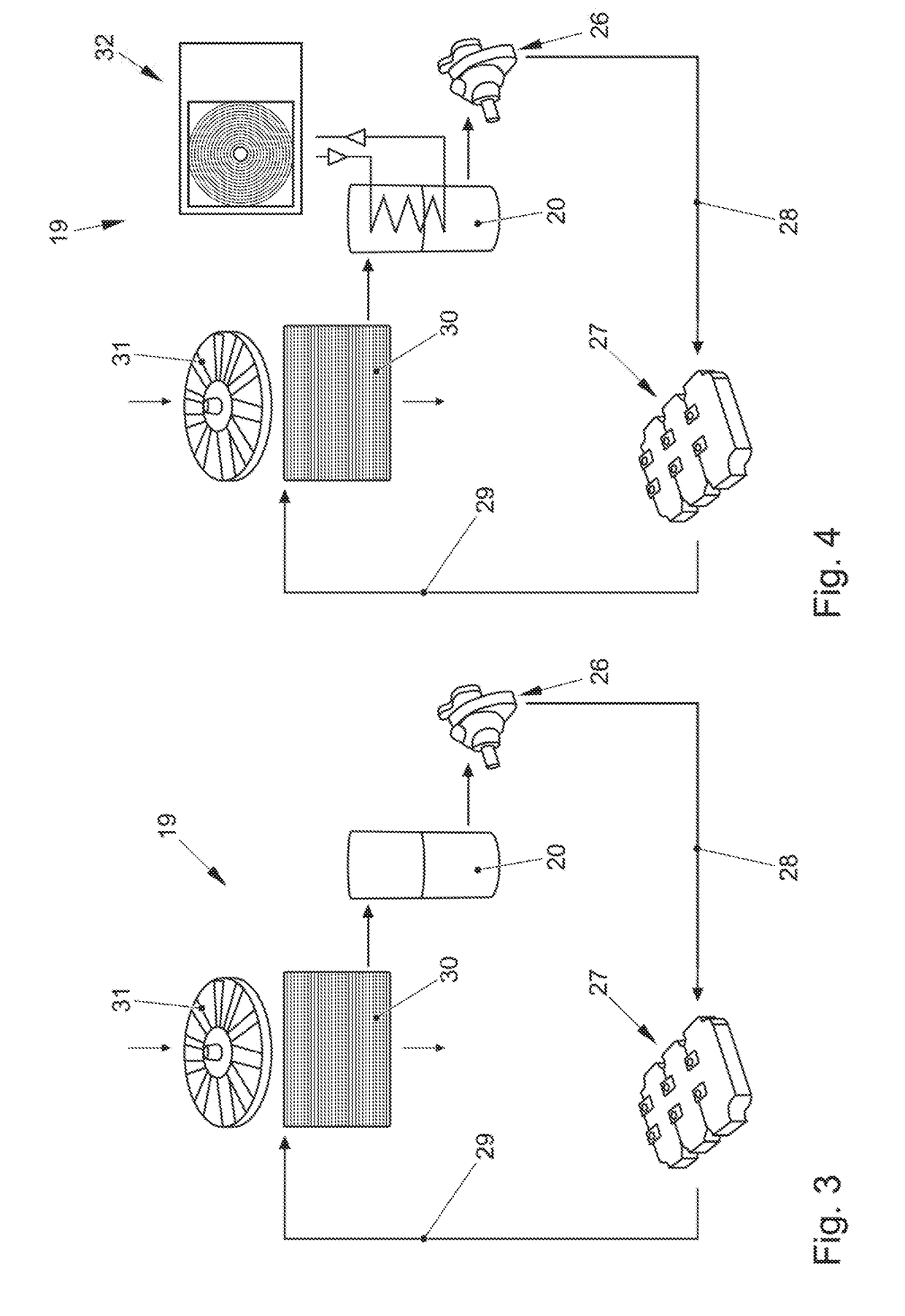

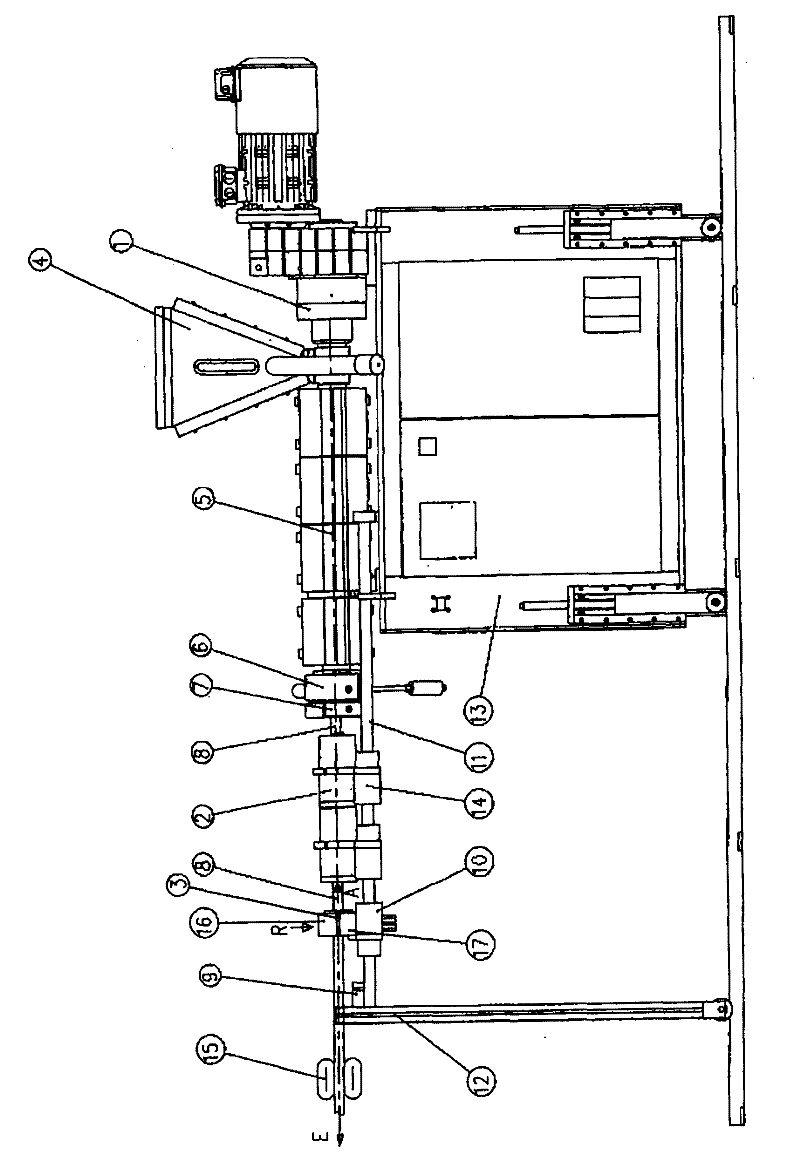

Extrusion machines with brakes for regulating back pressure

InactiveCN102292205AEliminate overheatingRelieve pressureThin material handlingTubular articlesWork in processAxial force

The invention relates to an extrusion plant for producing cylindrical semi-finished products made of plastic, comprising: an extruder (1) for supplying a pressurized plastic melt; at least one Extrusion die (7) at the press (1) through which the melt exits the extruder (1) as a substantially cylindrical plastic billet (8); placed in the extrusion die ( 7) the subsequent correcting part (2) passed through by the plastic blank (8) that has just been extruded, the correcting part (2) cools the plastic blank (8) and defines the outer diameter (d) of the plastic blank (8); A braking device (3) placed behind the correction element (2), by means of the braking device (3) an axial force (A) directed opposite to the feed of the plastic blank (8) is variably introduced into the plastic blank (8); and a force receiver (9), which measures the axial force (A) introduced into the plastic blank (8) by the braking device (3). The object of the present invention is to improve an extrusion system of this type in such a way that it achieves a better adjustment quality and is suitable for processing highly heat-resistant plastics. This object is achieved in that the brake device (3) comprises at least one brake shoe (16) provided with a friction surface (19) which is guided in a radially movable manner relative to the plastic blank (8), In this case, the radially movably guided brake shoe (16) can be acted upon with a radial force (R) when the friction surface (19) is in contact with the periphery of the plastic blank (8) Axial forces (A) are introduced into the plastic blank ( 8 ), and the friction surface ( 19 ) has the shape of a groove-shaped section of a cylindrical peripheral surface.

Owner:EVONIK DEGUSSA GMBH

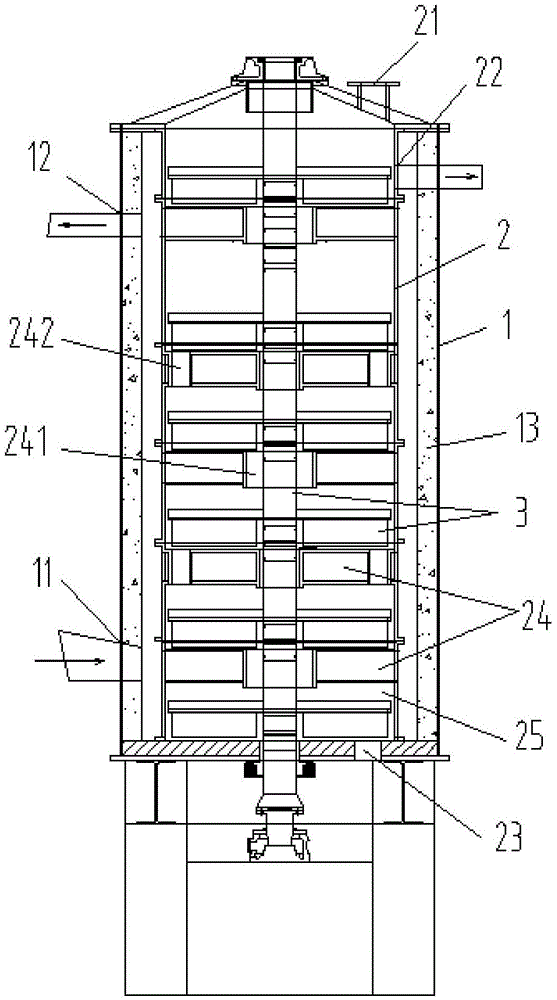

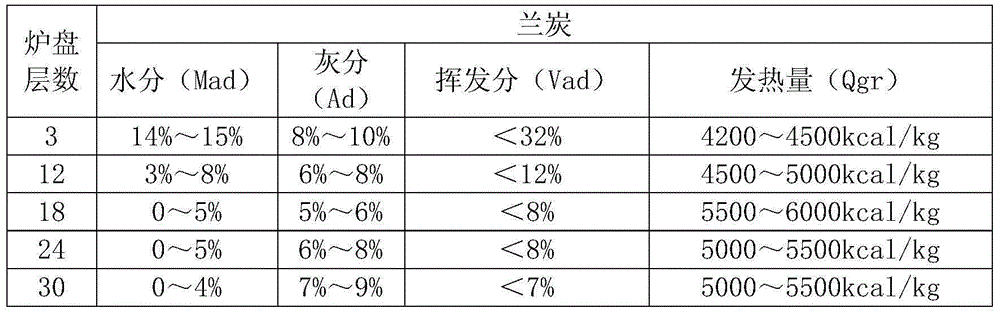

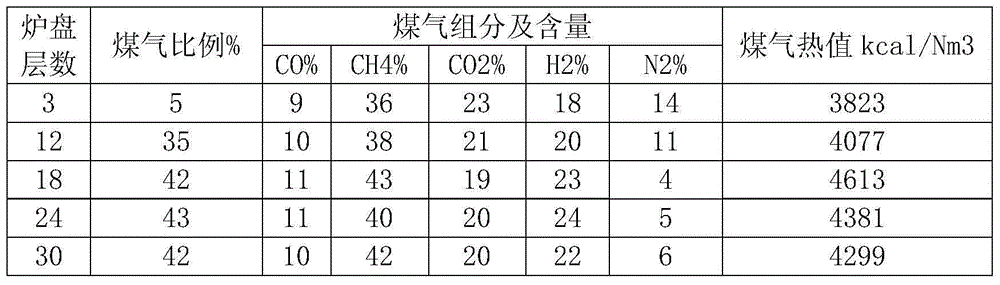

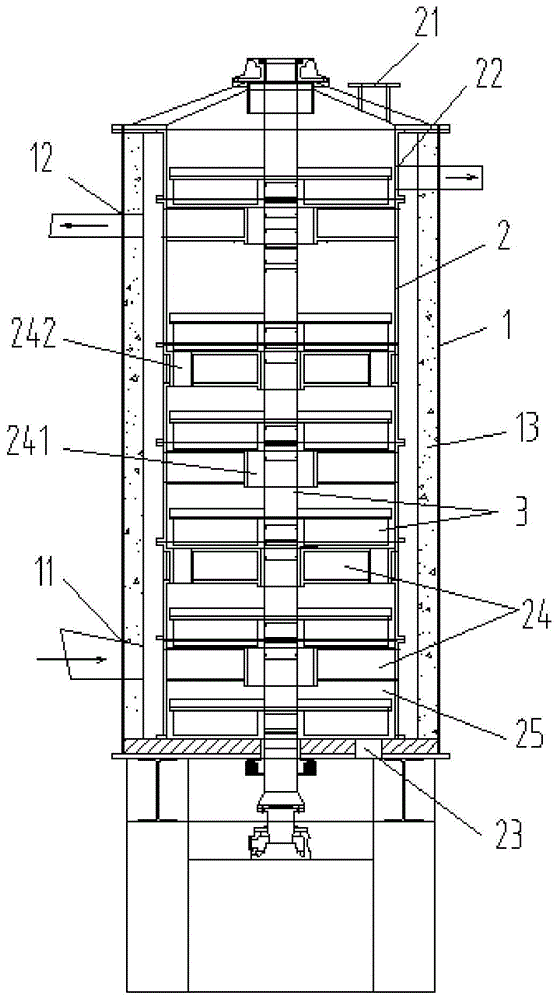

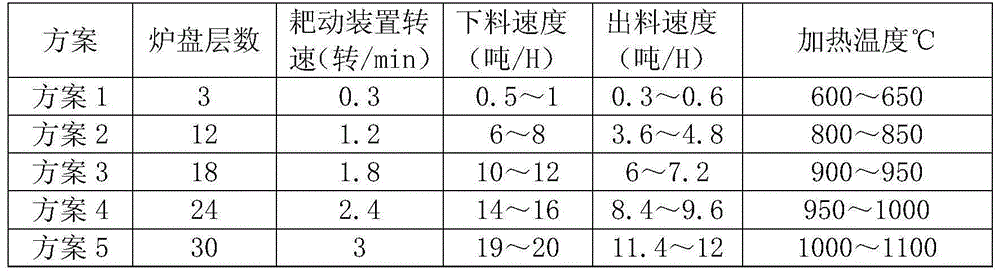

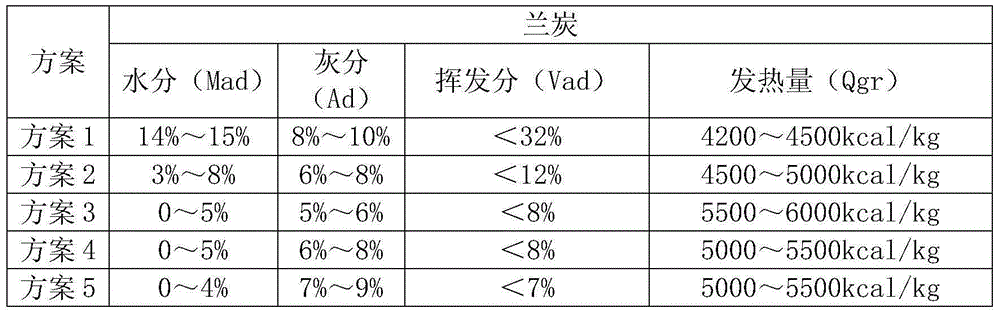

External heat type multilayer baking furnace for coal upgrading

InactiveCN105131983AAchieve purification effectAchieve separationSpecial form destructive distillationHeating furnaceCoal

The present invention relates to an external heat type multilayer baking furnace for coal upgrading, and belongs to the technical field of coal coking equipment. The external heat type multilayer baking furnace comprises an outer furnace having a heating device, wherein a heating furnace is arranged inside the outer furnace, the top portion of the heating furnace is provided with a material inlet and a coal gas collection port, the bottom portion of the heating furnace is provided with a material outlet, at least three layers of furnace trays are arranged inside the heating furnace along the height direction at intervals, the N-layer furnace tray is provided with a middle portion material discharge hole, and the N+1-layer furnace tray is provided with an end portion material discharge hole so as to form a S-shaped material discharge channel. According to the present invention, the external heat type heating pyrolysis way and the turning-back type S-shaped material discharge are performed on the coal, such that the produced coal gas is pure and has the high heat value, the semi-coke quality is good, and the production efficiency is high.

Owner:刘东远

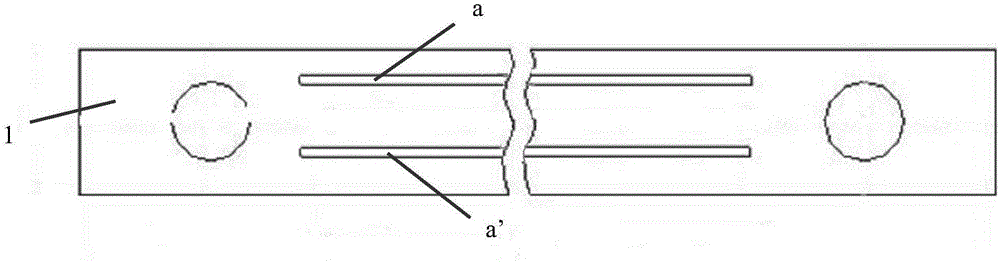

Pulling plate structure for electric transformer core

InactiveCN105070483AReduce lossEliminate overheatingTransformers/inductances magnetic coresTransformerEddy current

The invention provides a pulling plate structure for an electric transformer core. A pulling plate is a rectangular steel plate, at least two long-bar-shaped notches are formed in the center of the pulling plate in the vertical length direction of the pulling plate, the sizes of the notches are equal, and the notches are symmetrically distributed in the vertical length direction of the pulling plate. Due to the design of the notches of the pulling plate of the core, the eddy-current loss can be obviously reduced, and local overheat can be eliminated.

Owner:BAODING TIANWEI GRP JIANGSU WUZHOU TRANSFORMER

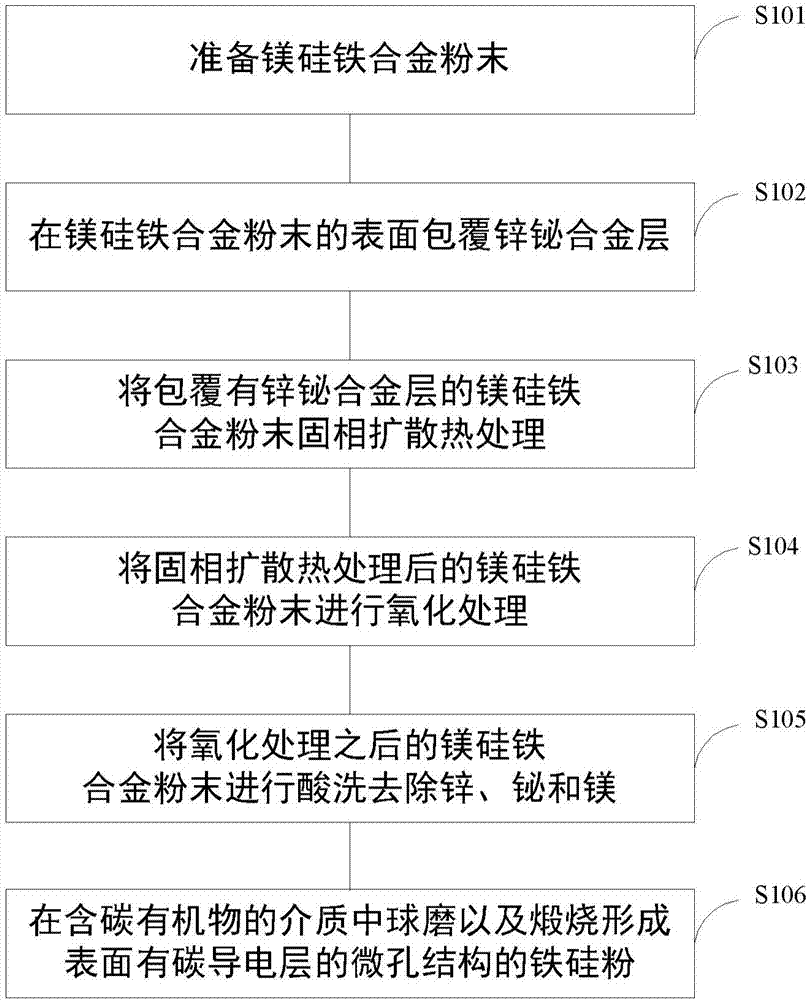

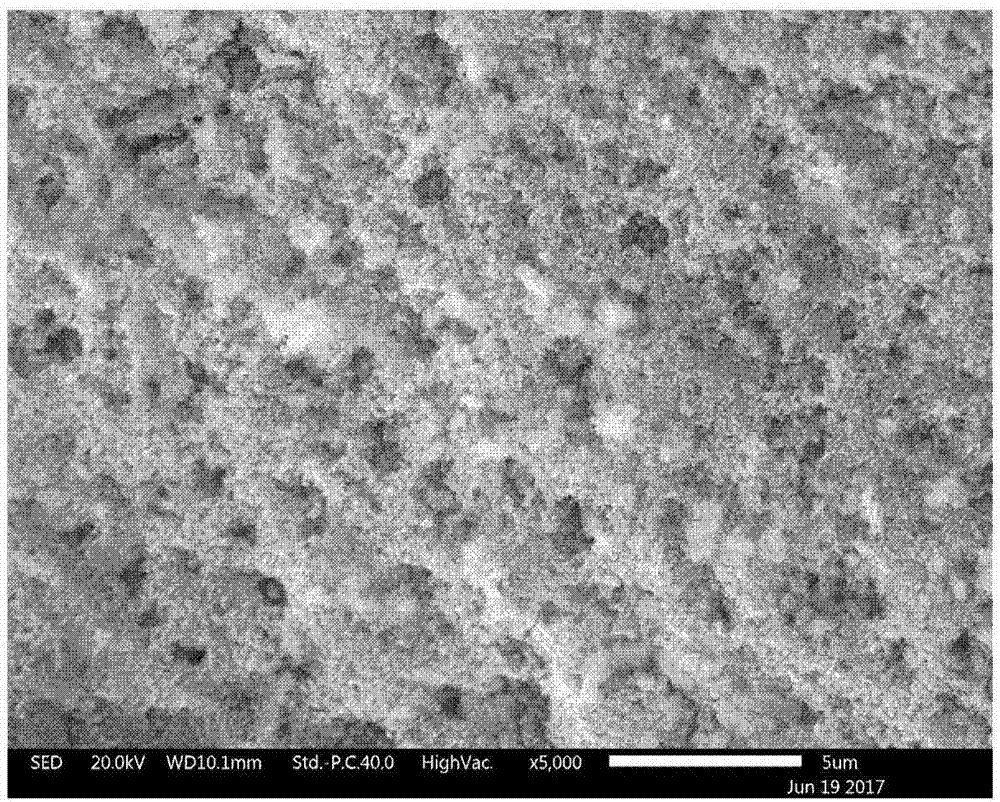

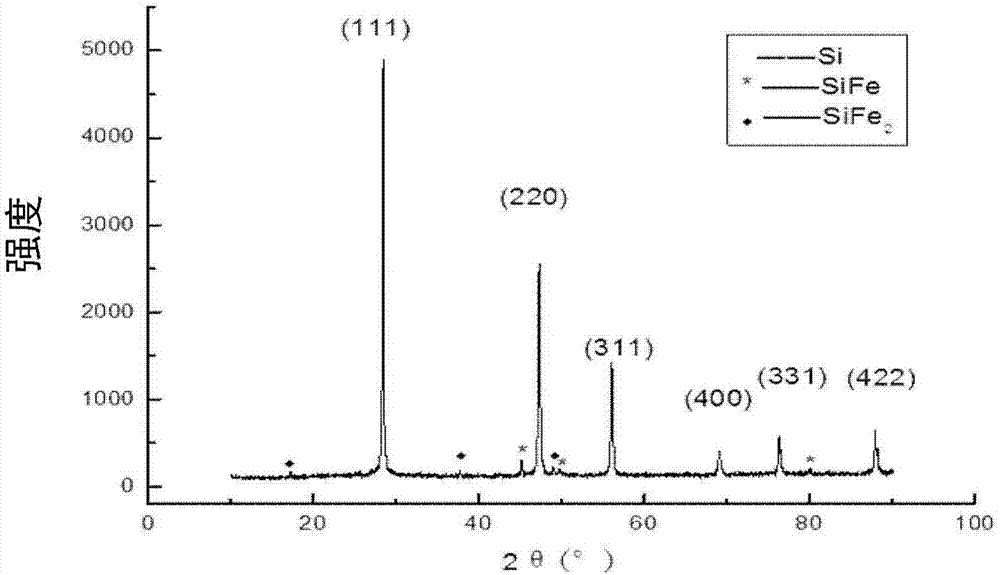

Method for preparing silicon-iron powder through zinc-bismuth alloy coated magnesium-silicon-iron particles and silicon-iron composite powder

ActiveCN107999781AReduce the risk of surface oxidation and fireFacilitated Diffusion ReactionTransportation and packagingMetal-working apparatusAlloyLow oxygen

The invention discloses a method for preparing foam-shaped silicon powder through zinc-bismuth alloy coated magnesium-silicon-iron particles. The method comprises the steps that magnesium-silicon-ironcomposite powder is prepared; the surface of the magnesium-silicon-iron composite powder is coated with a zinc-bismuth alloy layer; the magnesium-silicon-iron composite powder coated with the zinc-bismuth alloy layer is subjected to solid-phase diffusion heat treatment to promote zinc and bismuth metal in the coating layer to conduct reaction combination with magnesium and silicon; the magnesium-silicon-iron composite powder subjected to solid-phase diffusion heat treatment is subjected to oxidation treatment; and the magnesium-silicon-iron composite powder subjected to oxidation treatment issubjected to acid pickling to remove zinc, bismuth and magnesium. By adopting the zinc-bismuth alloy coated magnesium-silicon-iron composite particles not likely to be oxidized and with the melting point being lower than the ignition point of magnesium and by combining with the solid-phase diffusion treatment and low-oxygen oxidation treatment processes under a certain temperature, the foam silicon powder with a micropore structure is obtained, the preparation efficiency is improved, and the primary particle size of the foam silicon powder is small.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

Regeneration method of molecular sieve catalyst

ActiveCN102836743BEfficient regenerationNo overheatingMolecular sieve catalystsMolecular sieveOxygen

The invention provides a regeneration method of a molecular sieve catalyst, comprising the following steps: roasting a molecular sieve catalyst to be regenerated at 300-750 DEG C to decomposing the carbon deposit in the molecular sieve catalyst to be regenerated into CO2, wherein the roasting step is characterized in that: in the presence of oxygen-containing gas, the molecular sieve catalyst to be regenerated is subject to roasting of multiple stages at a constant temperature, the roasting of multiple stages comprises a first roasting stage and roasting stages after the first roasting stage, the roasting temperature of any one roasting stage after the first roasting stage is 5-70 DEG C higher than that of the adjacent former roasting stage, and the roasting time of each roasting stage is long enough to generate no CO2 when roasting is conducted under the roasting condition of the roasting stage. According to the invention, the performance of the regenerated molecular sieve catalyst is recovered and even better than the performance of a fresh catalyst, thus good regeneration effect can be achieved by using the method disclosed herein.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving coal quality through multi-layer roaster

InactiveCN105087024AAchieve purification effectAchieve separationDirect heating destructive distillationSpecial form destructive distillationTarProcess engineering

The invention relates to a method for improving coal quality through a multi-layer roaster, and belongs to the technical field of coal coking. The multi-layer roaster is adopted and comprises an outer roaster body provided with a heating device. A heating furnace is disposed in the outer roaster body. A feed inlet and a gas collecting port are formed in the top of the heating furnace. A discharge opening is formed in the bottom of the heating furnace. At least three layers of roaster plates are arranged in the heating furnace in the height direction at intervals. The Nth layer of roaster plate is provided with a middle discharge hole, and the N+1th layer of roaster plate is provided with an end discharge hole, so that an S-shaped discharge channel is formed. When coal quality is improved, the heating furnace is preheated through the heating device, then a coal raw material is added from the feed inlet in the top of the heating furnace, the coal raw material gradually falls through the S-shaped discharge channel, the coal raw material makes contact with the heated roaster plates in the discharge process so as to be heated, and accordingly the coal quality is improved. Finally, raw gas and tar are obtained from the gas collecting port in the top of the heating furnace, and semi coke is obtained from the discharge opening in the bottom of the heating furnace.

Owner:刘东远

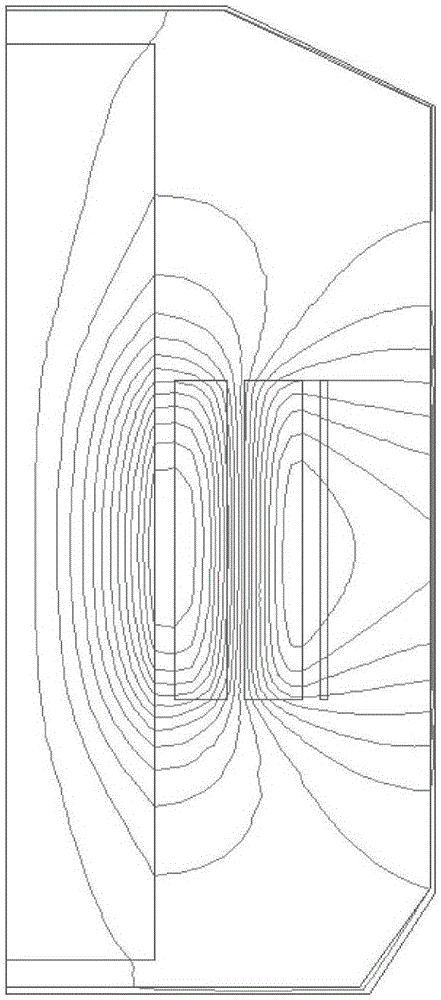

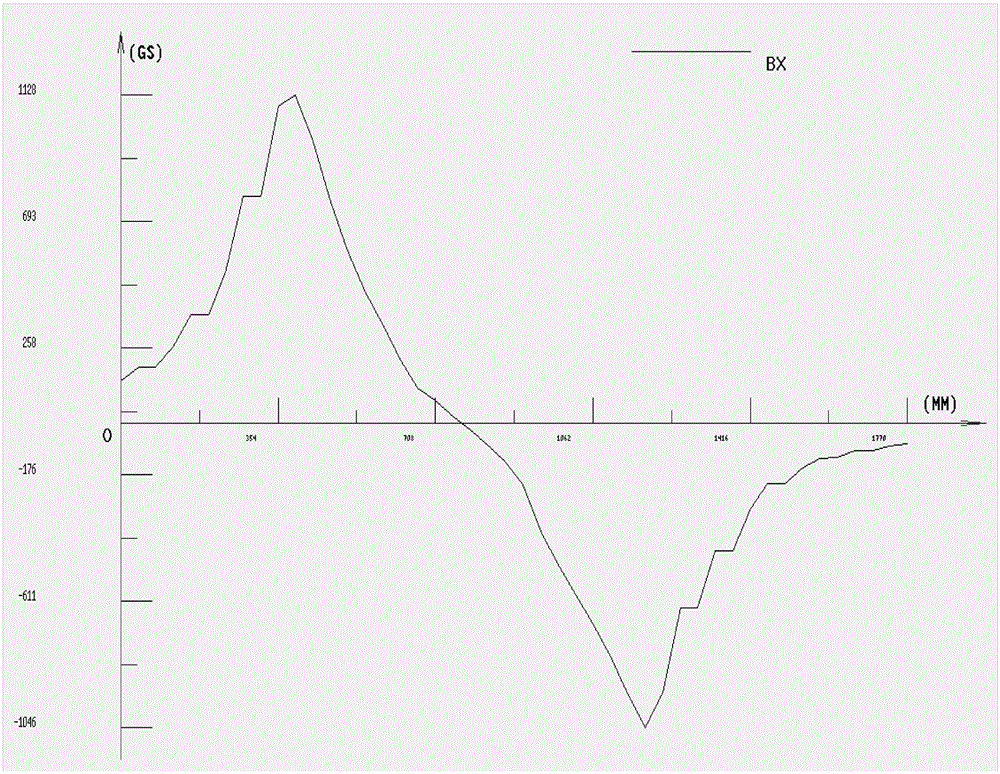

Electric furnace transformer body structure for preventing transformer windings from being overheated locally

InactiveCN108831696APrevent overheatingEliminate overheatingTransformers/inductances coolingTransformers/inductances coils/windings/connectionsElectric arc furnaceLow voltage

The invention discloses an electric furnace transformer body structure for preventing transformer windings from being overheated locally, and relates to the technical field of structural design of transformer structures. The electric furnace transformer body structure comprises the high-voltage phase-shifting windings, the high-voltage basic windings, the low-voltage windings, an iron core and insulated heat dissipating systems; the high-voltage phase-shifting windings, the high-voltage basic windings and the low-voltage windings are sequentially installed from the iron core to the outside; the insulated heat dissipating systems are distributed at the peripheries of the high-voltage phase-shifting windings, the high-voltage basic windings and the low-voltage windings; the low-voltage windings are located at the outermost side of a transformer body, and the low-voltage windings are in contact with insulated oil close to the outer side of the transformer body. Since the temperature of the insulated oil at the outer side of the transformer body is low, heat exchange and dissipation are better facilitated, heat generated by the low-voltage windings is timely dissipated, and the phenomenon that the low-voltage windings are overheated is avoided; a multipath parallel dual-cake-type structure is adopted for the low-voltage windings, the density of current generated by the low-voltagewindings is uniform, and the phenomenon that the low-voltage windings are locally overheated when the current is not uniformly distributed is avoided.

Owner:江苏鑫航电力设备工程有限公司

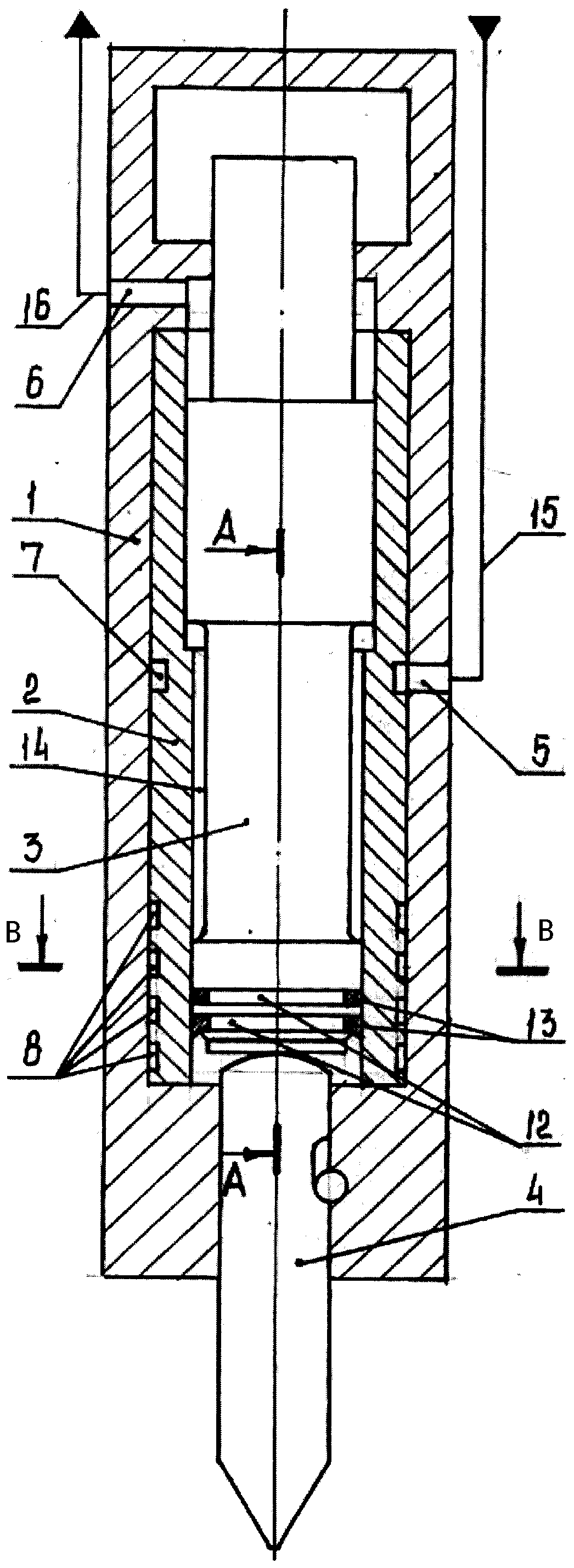

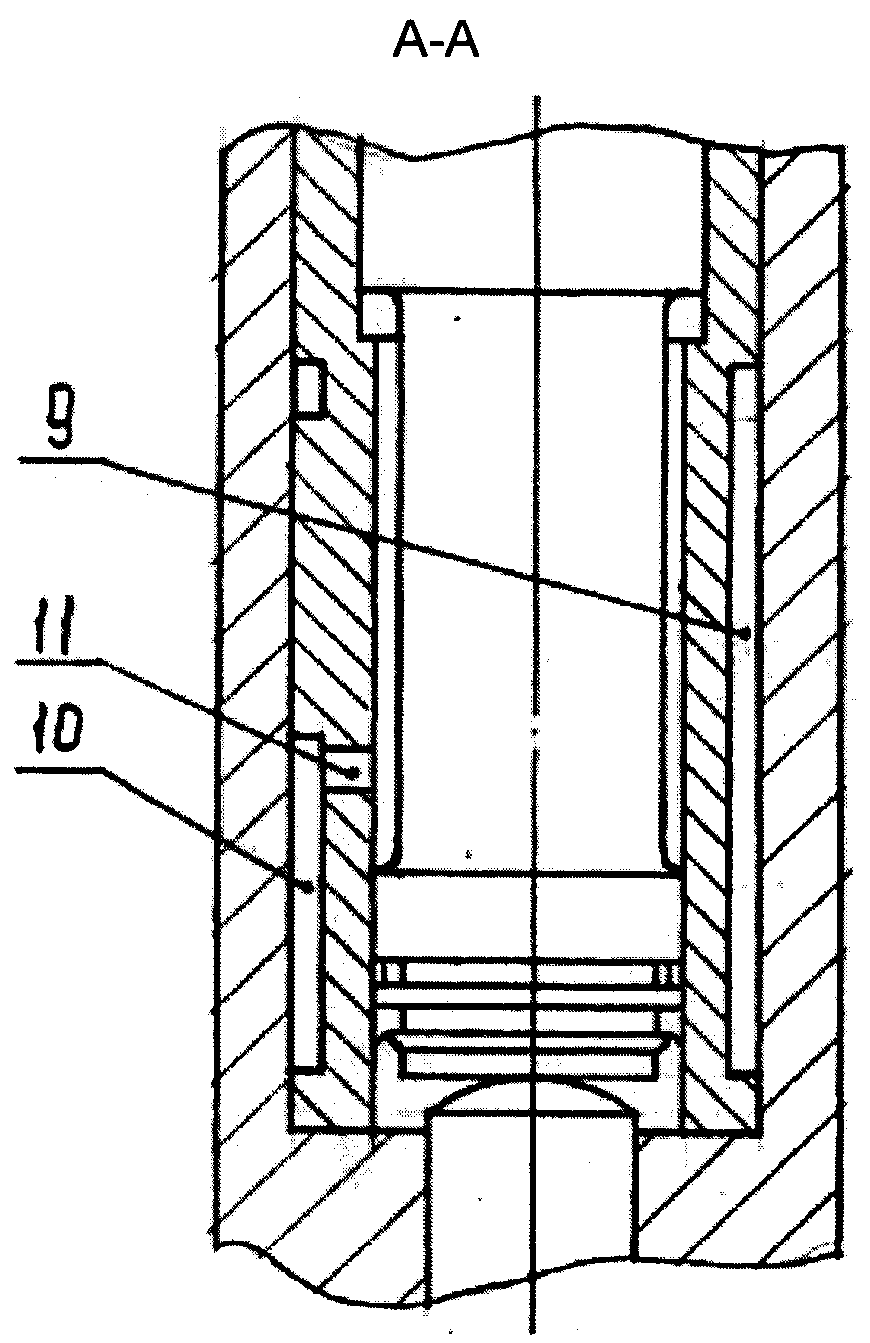

Hydraulic hammer

PendingCN111163904AReduce the temperatureImprove operational efficiencySoil-shifting machines/dredgersPortable percussive toolsConstruction industryEngineering

The invention relates to the mining and construction industry and is directed toward increasing the operating efficiency and reliability of a hydraulic hammer by increasing heat transfer (cooling) andlowering the temperature both of the hydraulic hammer as a whole and of a liner thereof without complicating the structure of the hydraulic hammer. This technical result is achieved in a hydraulic hammer consisting of a housing having a pressure port and a drain port and having a liner disposed in said housing that has a pressure groove and a pressure port, a head that is disposed inside of the liner such that it can move reciprocally and that interacts with a working instrument, and a pressure line and a drain line, moreover, on the outer surface of the liner, there are annular grooves and two longitudinal canals, said canals being diametrically opposite one another.

Owner:塔迪缇斯亚有限责任公司

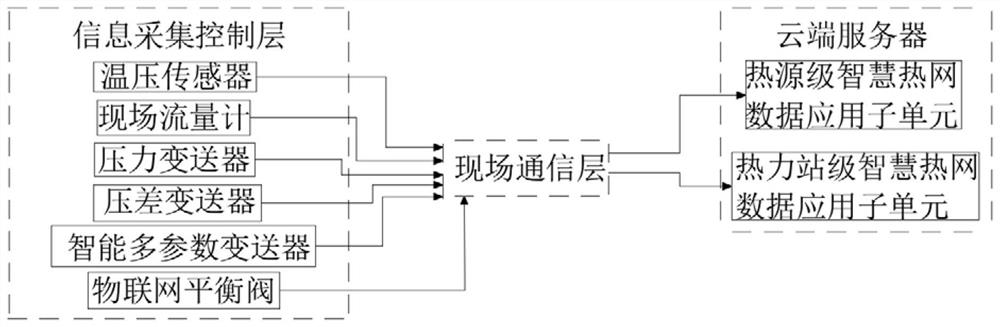

Two-network balance detection system based on sensor fusion

PendingCN114877405ASave electricityPrecise regulation of heating temperatureLighting and heating apparatusSpace heating and ventilation detailsCloud processingIp address

The invention discloses a two-network balance detection system based on sensor fusion, and the system comprises an information collection control layer which is directly in remote communication with an intelligent gateway through MODBUS communication, and obtains flow, pressure and temperature parameters. Various operation states, operation parameters and standby battery electric quantity information are transmitted to a server with a specified IP address through an Internet of Things access technology, and the server deploys a cloud processing system in a unified manner and is used for receiving data and safely processing information. The water return temperature of a user is uploaded to a control center through an internet-of-things hydraulic balance valve, and the heat supply temperature among all systems, all units and all loops is accurately adjusted; the method has an automatic adjusting function, and by taking the calculated current theoretical balance temperature value as the target temperature, the whole network can quickly reach the target value, the network adjusting speed is higher, the balance of the secondary network can be accurately controlled, the power consumption of the heat exchange station is saved, and the phenomena that the front end is overheated and the tail end is not hot are eliminated.

Owner:北京北燃环能科技发展有限公司 +1

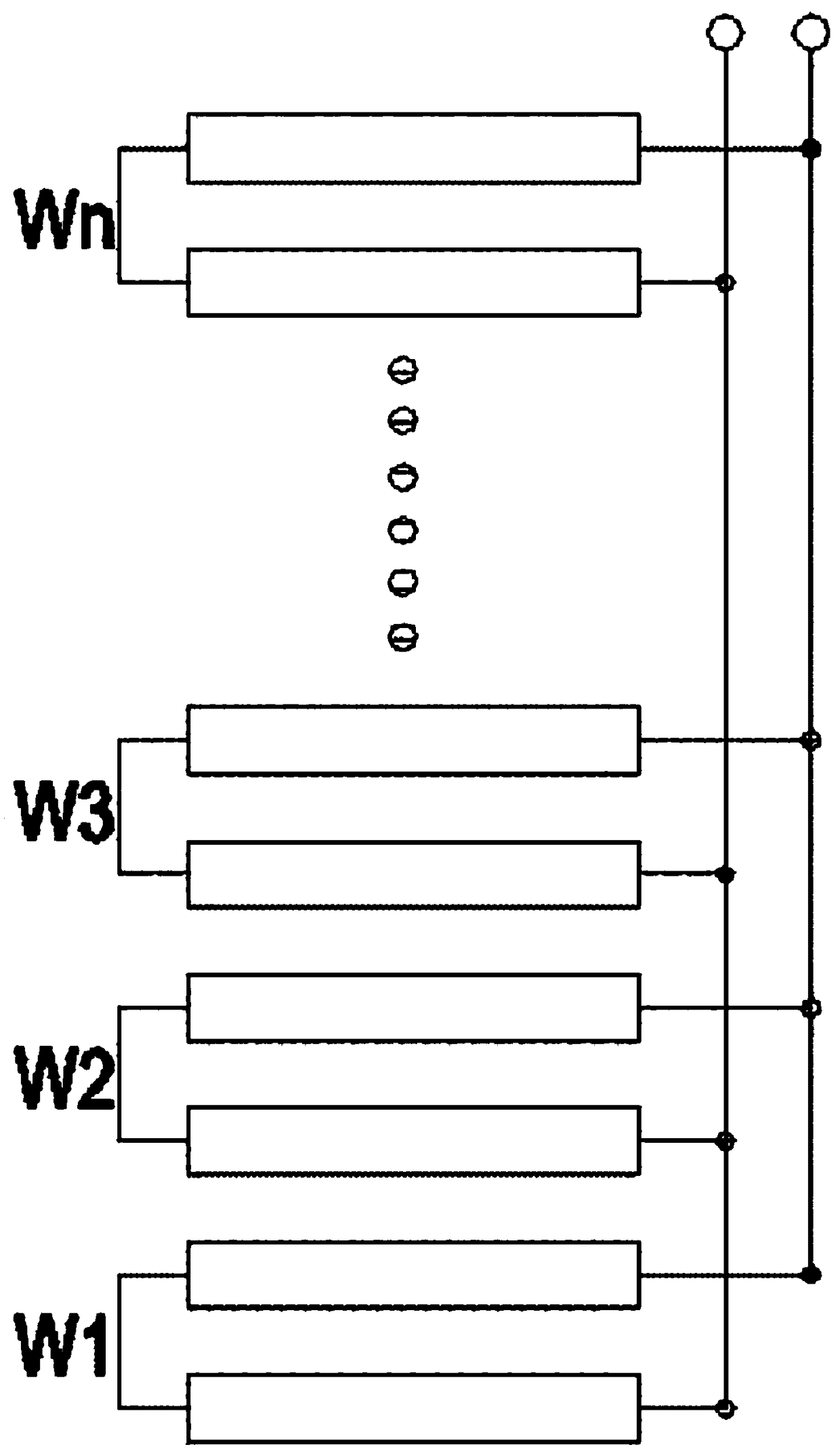

Electric furnace transformer body structure for preventing local overheating of transformer winding

ActiveCN106504872APrevent overheatingEliminate overheatingTransformers/inductances coolingTransformers/inductances coils/windings/connectionsPhase shiftedCurrent distribution

The invention discloses an electric furnace transformer body structure for preventing local overheating of a transformer winding and relates to the technical field of transformer structure design. The electric furnace transformer body structure comprises a high-voltage phase shift winding, a high-voltage basic winding, a low-voltage winding, an iron core and an insulated cooling system, wherein the high-voltage phase shift winding, the high-voltage basic winding and the low-voltage winding are sequentially arranged from inside of the iron core to outside; the insulated cooling system is distributed and arranged around the high-voltage phase shift winding, the high-voltage basic winding and the low-voltage winding; the low-voltage winding is located at the outmost layer of a transformer body; and the low-voltage winding is in contact with insulating oil close to the outer side of the transformer body. Since the insulating oil at the outer side of the transformer body is relatively low in temperature, heat exchange and emission are facilitated, the heat generated by the low-voltage winding is timely emitted, the overheating phenomenon of the low-voltage winding is prevented, a multichannel parallel double-cake structure is adopted by the low-voltage winding, current generated by the low-voltage winding is uniform in density, and the local overheating phenomenon of the low-voltage winding generated by non-uniform current distribution is prevented.

Owner:BAODING TIANWEI GROUP TEBIAN ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com