Cooling Module

a technology of cooling module and cooling fan, which is applied in the field of cooling module, can solve the problems of insufficient space for a large cooling fan, unsuitable for electronic products with power or noise limitations, and generation of undesired nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

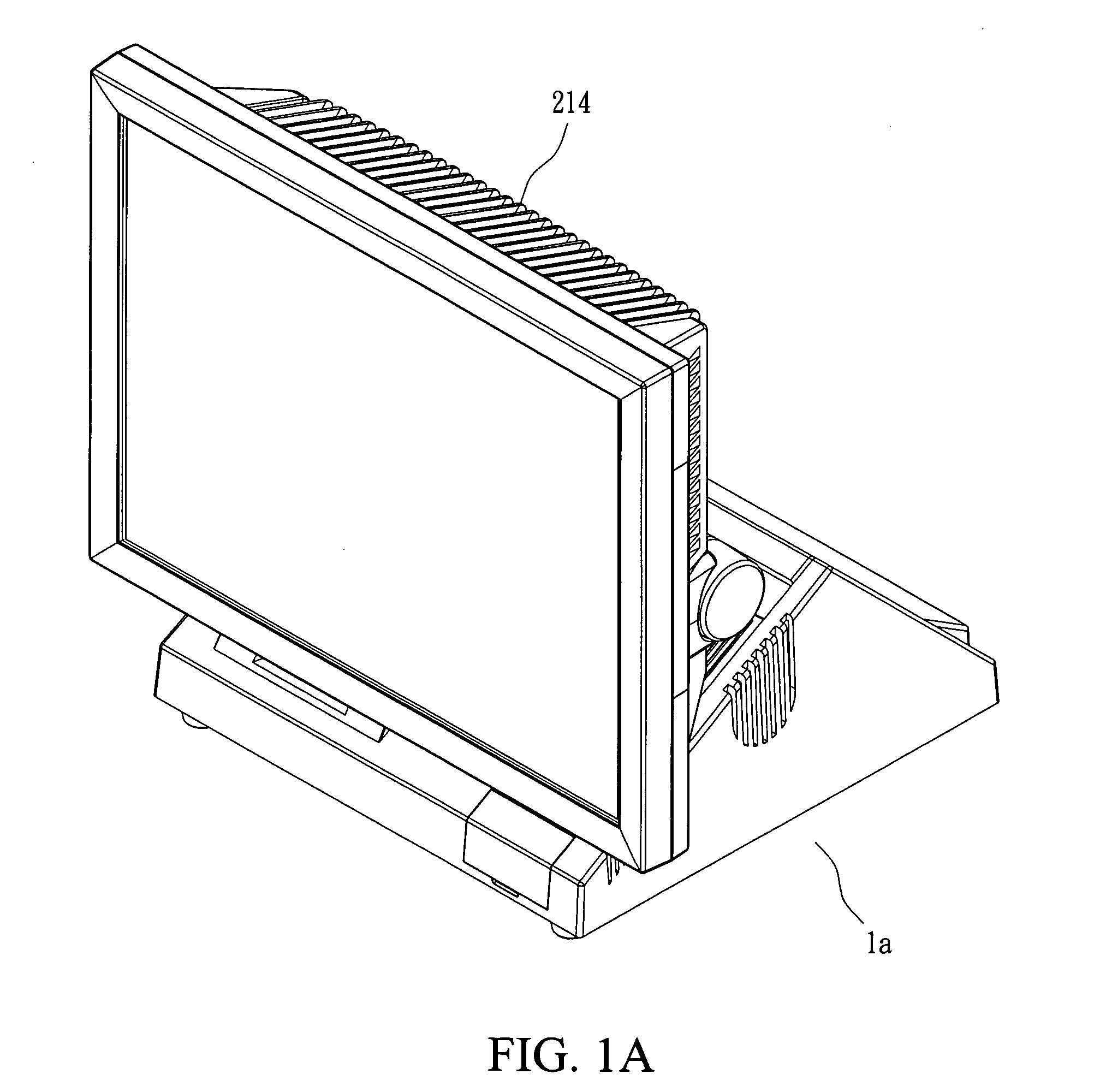

[0022]FIG. 1A illustrates an electronic apparatus, for example, a calculation processing apparatus. More particularly, the calculation processing apparatus is a point of sale (POS) apparatus 1a. One of the features of the POS apparatus 1a is that no cooling fan is used therein so that the noise caused by the fan can be effectively decreased and the maintenance is easy. The following description provides several embodiments of a cooling module of this invention when being used to provide effective heat dissipation in the POS apparatus 1a. However, as may be appreciated by those skilled in the art, the cooling module disclosed in this invention may also be applied to other different electronic apparatuses.

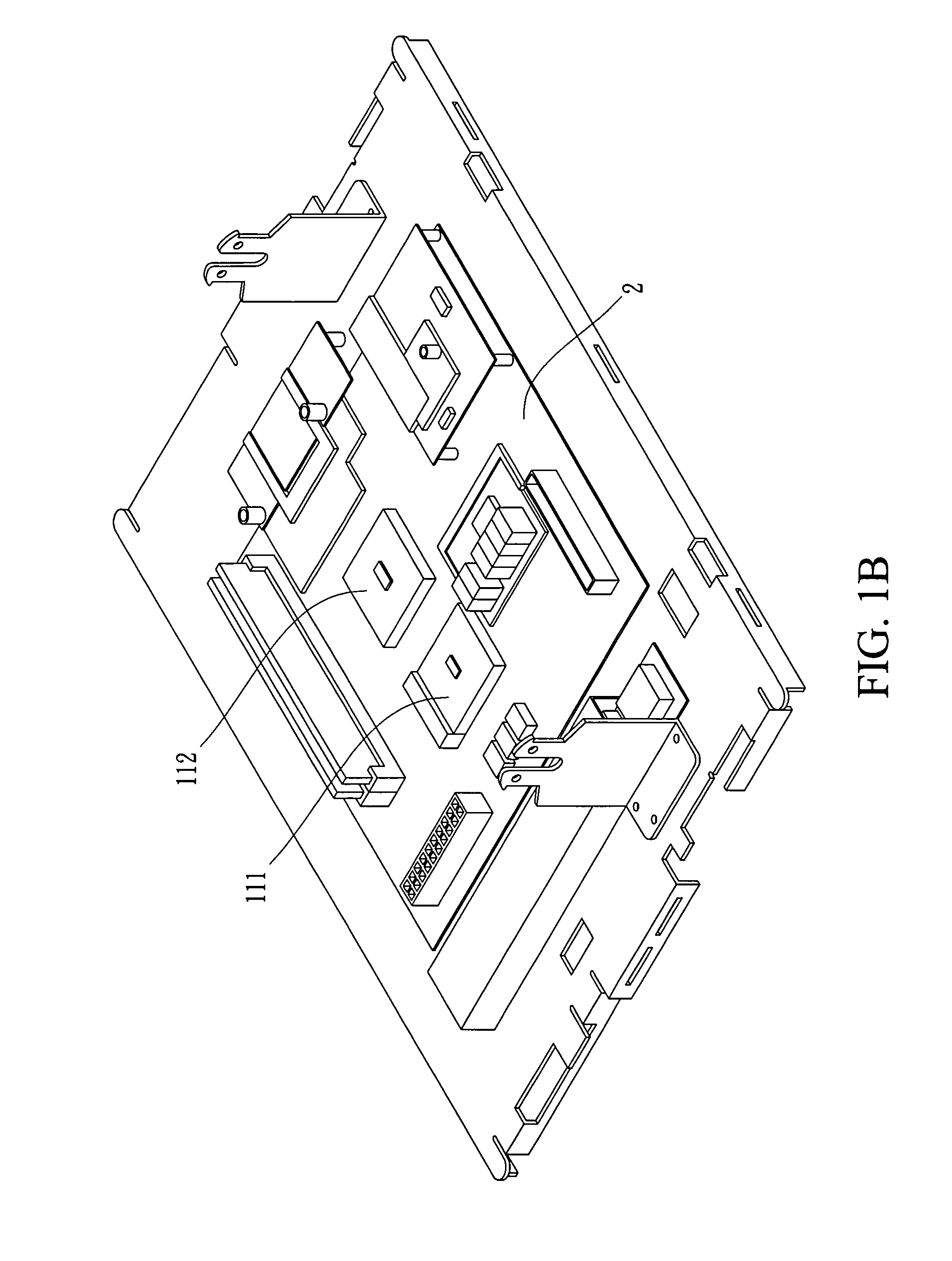

[0023]FIG. 1B depicts a heat-generating block of a circuit board 2 disposed inside the POS apparatus 1a. The block includes at least one electronic component. For instance, there are two electronic components 111, 112, which may be South Bridges, North Bridges, CPUs, memories or the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com