Upsetting-drawing deformation method for TB6 titanium alloy large-specification bar

A titanium alloy, large-scale technology, applied in the field of upsetting and drawing deformation of TB6 titanium alloy large-scale bars, can solve the problems of insufficient fragmentation of the original structure, large and uneven deformation, and achieve the elimination of deformation dead The effect of overheating and uniform deformation of the zone and core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to understand the purpose, technical solutions and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

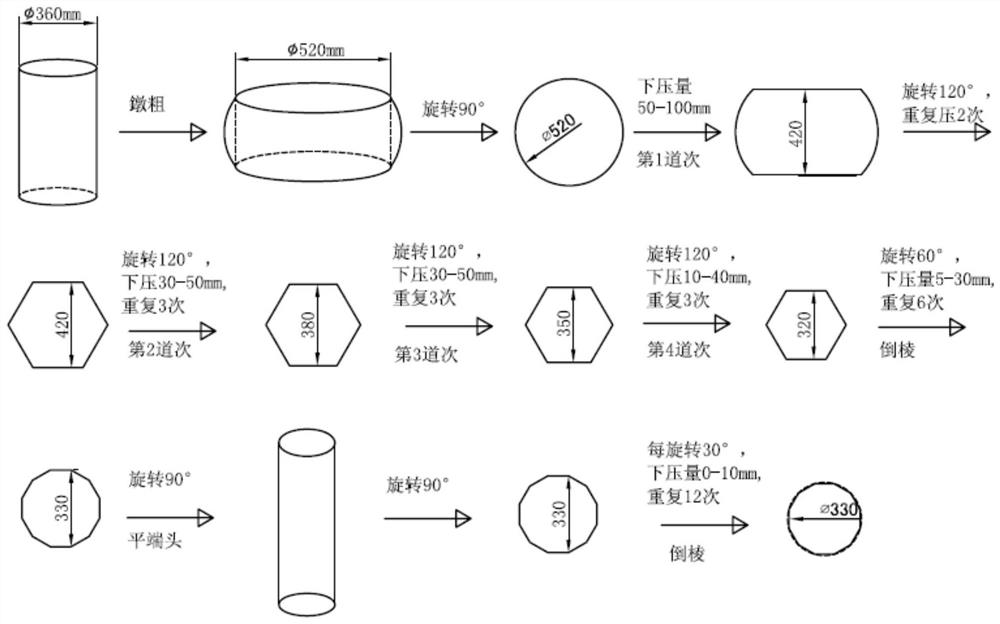

[0024] figure 1 The flow chart of the upsetting and drawing deformation method of TB6 titanium alloy large-scale bar of the present invention is illustrated. The diameter of the TB6 titanium alloy large-size bar is ≥300mm, generally 300-400mm. In this embodiment, the forging equipment is a 2000T fast forging machine, the width of the upper hammer head and the lower flat anvil is 450mm, and the fillet radius of the flat anvil is 30mm , the length is 1200mm. The bar is a round billet with a diameter D equal to 360 mm. As shown in the figure, the method of the present invention comprises the following steps:

[0025] Step 1: Heat the Ф360mm×570mm bar in an electric heating furnace at a heating temperature of 780°C, and the heating time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com