Method for operating a steam turbine power plant and also device for generating steam

A technology for steam turbines and power plants, which is used in the field of operating steam turbine power plants and devices for generating steam. It can solve the problems of energy optimization and reduce mechanical losses and investment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

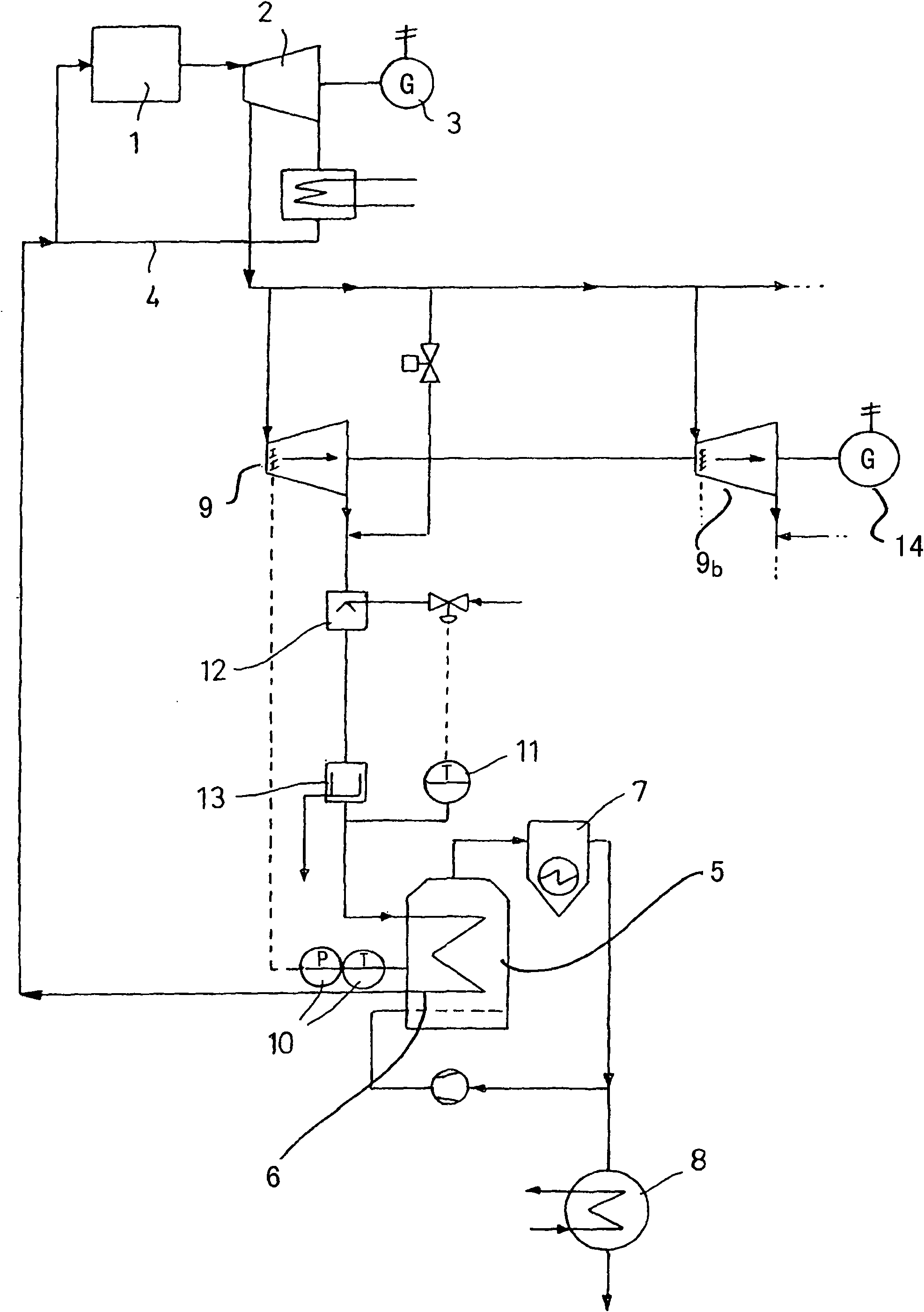

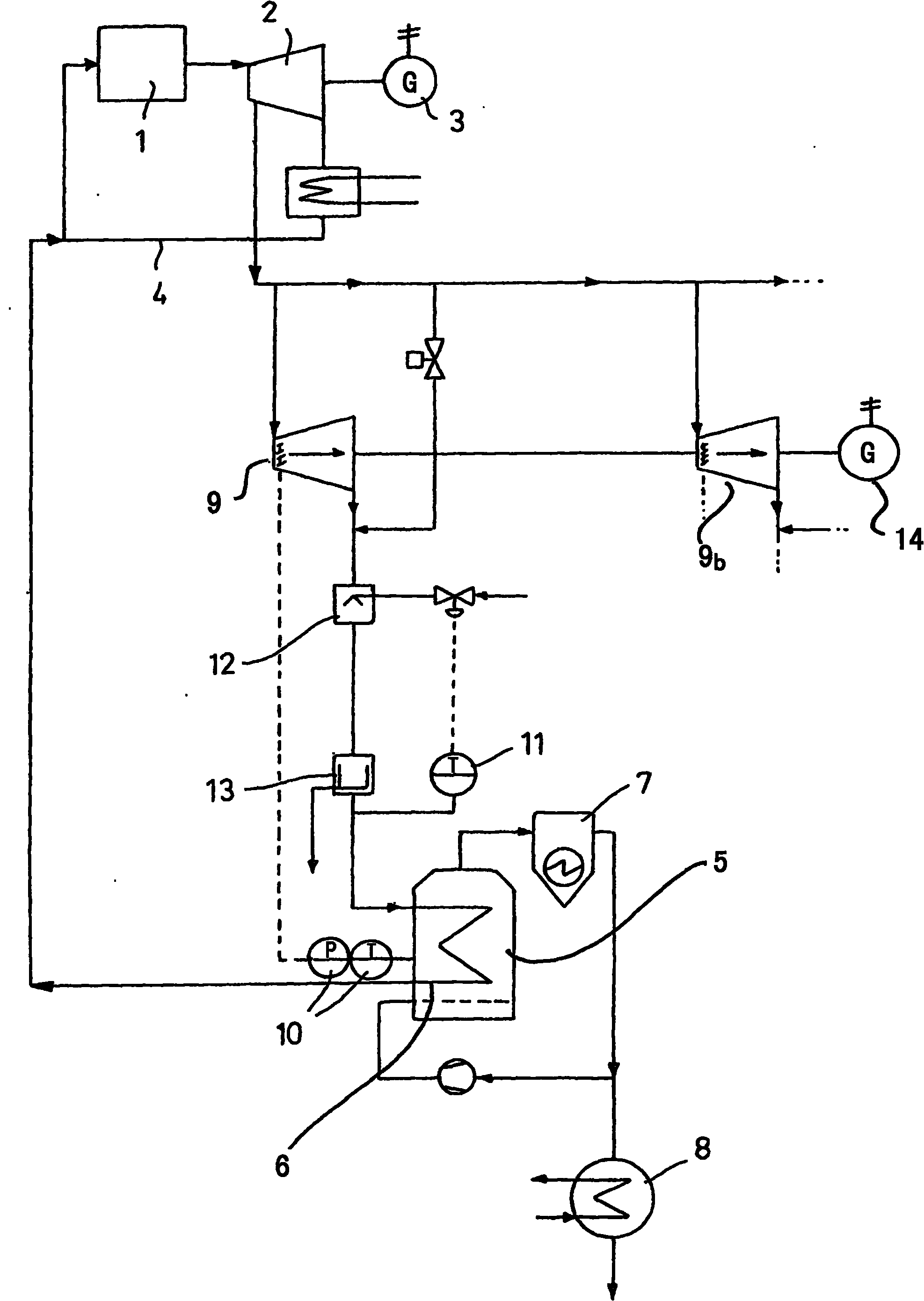

[0024] The power plant process depicted in the figures comprises a steam generator 1 , a first steam turbine 2 and a first generator 3 , which are the main components in a water-steam circuit 4 .

[0025] The steam generator 1 is designed, for example, as a powder-fired boiler in which lignite is burned as fuel. The lignite is pre-dried in a drier denoted 5. The dryer 5 is designed in a known manner as a fluidized bed dryer, in which the fluidized coal is heated directly via the heat exchanger 6 . For example lignite with a moisture content or water content of 60% by weight is dried in a dryer to a residual humidity of 12% by weight at a temperature of about 110° C. before being fed to the steam generator 1 for combustion. The energy required for this is mainly in the form of extracted steam from the first steam turbine 2 of the power plant into the dryer 5 . Hot steam at 6 bar flows from the low-pressure part of the first steam turbine 2 through the heat exchanger 6 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com