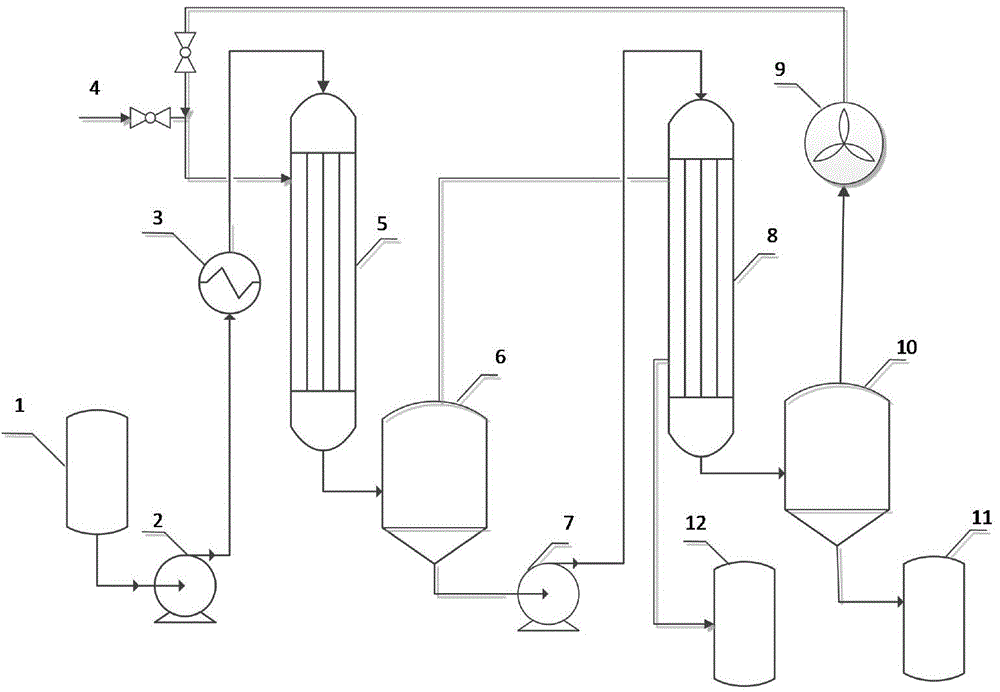

Double-effect Roots-type MVR (Mechanical Vapor Recompression) falling film evaporation system

A technology of falling film evaporation and falling film evaporator, which is applied in the field of double-effect Roots type MVR falling film evaporation system, to achieve the effects of saving investment cost, high efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings. as attached figure 1 As shown, when working, the raw material tank 1 is first filled with raw materials, then the feed pump 2 is turned on, the preheater 3 is turned on to preheat, and after the preheater is preheated by raw steam, it enters the heating chamber 5, 8 and separates Chambers 6 and 10, turn on the circulation pump 7, and turn on the raw steam 4 at the same time, heat the raw material to the boiling temperature, turn on the Roots-type MVR compressor 9, the vacuum degree in the evaporation chamber can be changed by the suction of the Roots compressor Large, until the material liquid boils and evaporates.

[0024] When the outlet temperature and pressure of the compressor exceed the theoretical value, open the water injection valve and adjust the water injection volume so that the temperature and pressure at the outlet correspond to the theoretical value, so a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com