A kind of welding equipment for producing electric ignition head bracket

An electric ignition head and welding equipment technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of restricting the development of electric ignition products, low production efficiency, unstable welding quality, etc. The effect of adjustable control, high welding yield and fast welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

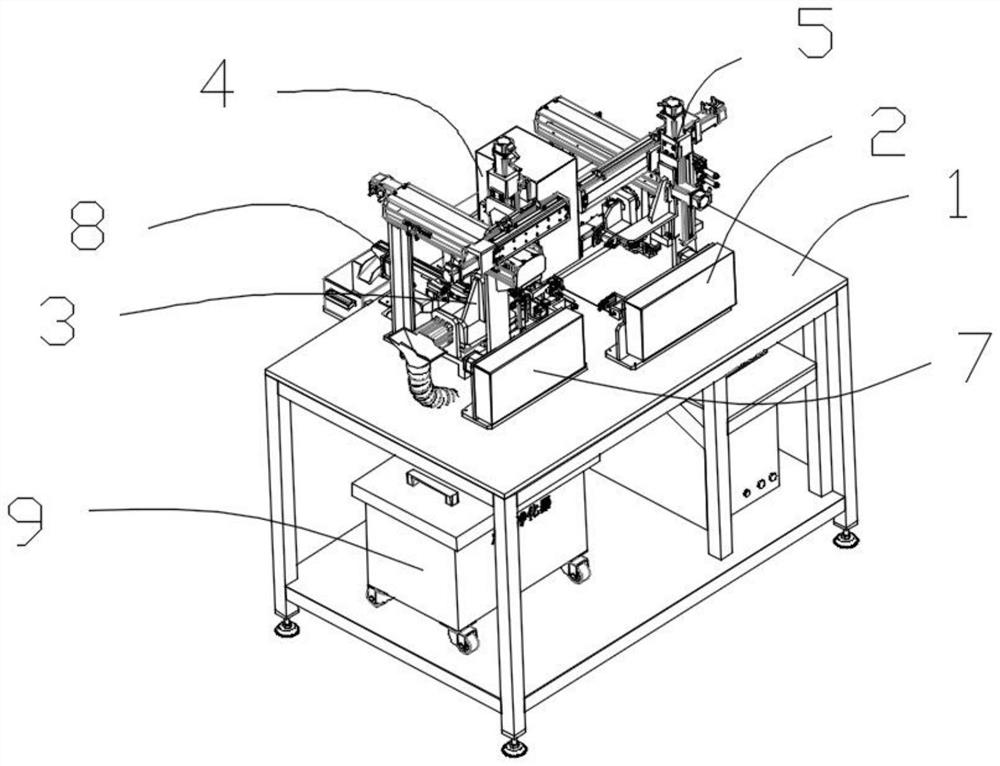

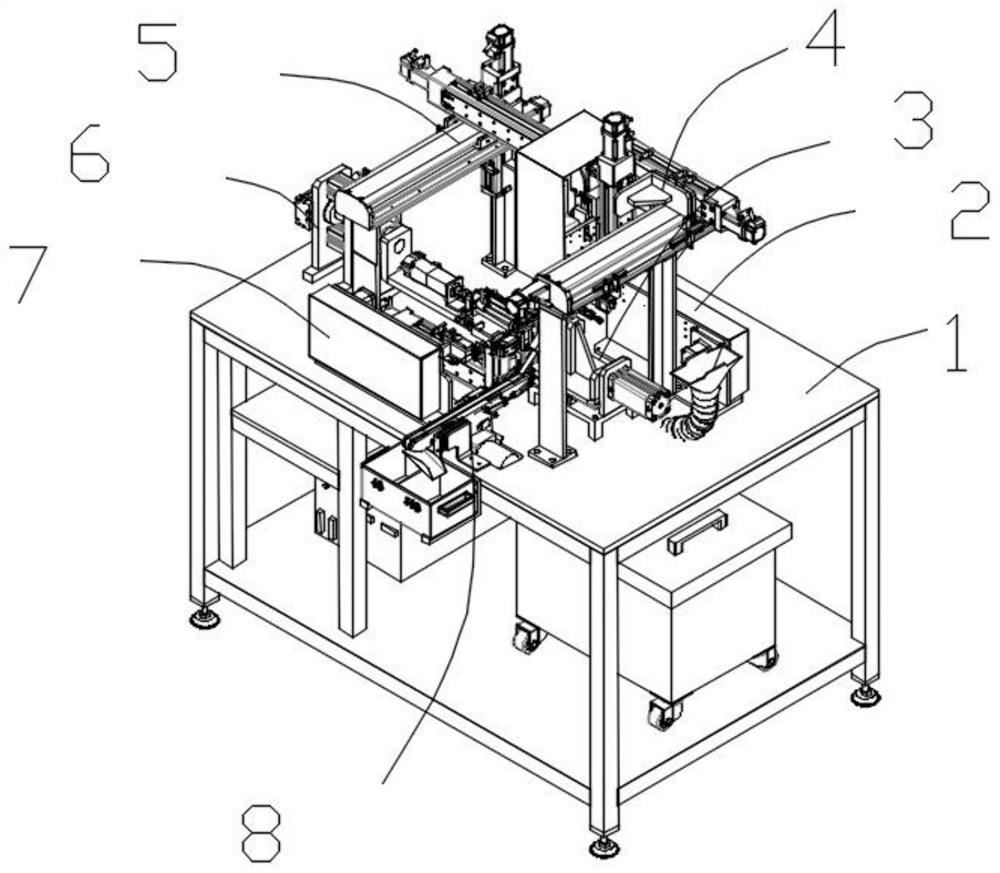

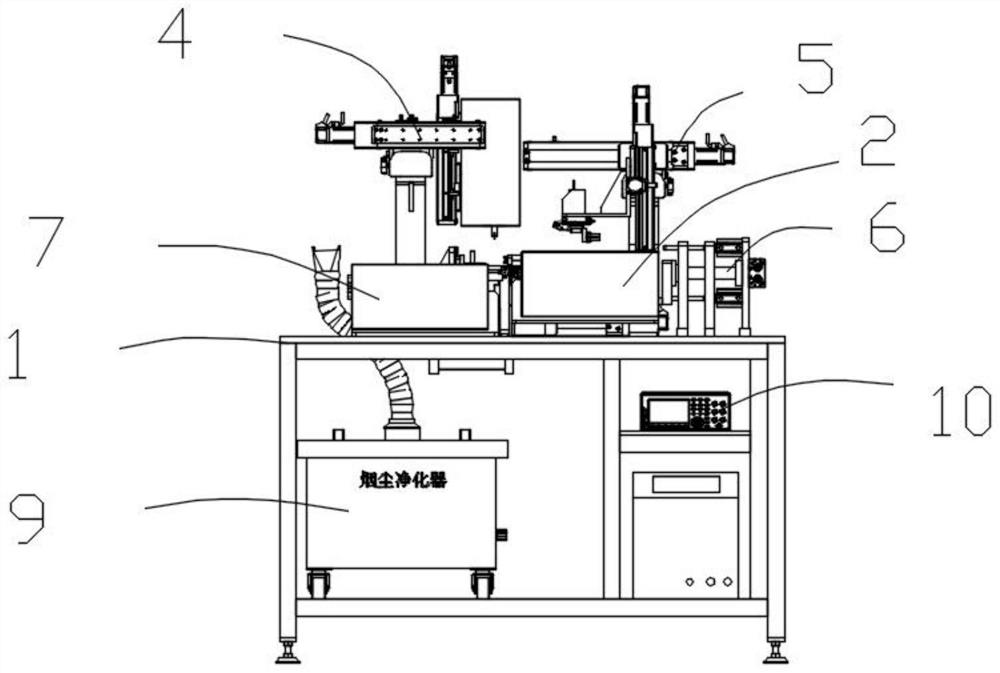

[0034] Such as Figure 1 to 11 As shown, the present embodiment provides a welding apparatus for producing electric pit head stents, including the welding frame 1 and a sheet-to-open mechanism 6 for pushing and fliping the tooth sheets mounted on the welding frame 1 for The foot line of the active output footer is used for actively outputting the bridge of the bridge. The wireless tension feeder 2 for traction and shear and the bridge are drawn mechanism 5, and the foot line The laser welding system 4 is welded to the toothed sheet for the bridge, for cutting the toothed sheet shearing machine 3, which forms the electric point head, and the electric nitad head cooperate with the toothed sheet shearing machine 3 Line mechanism 8, a resistance detection system 10 for detecting a toothed sheet resistance for processing a soot processing apparatus 9 of the smoke.

[0035] The upper flip mechanism 6 includes a sheet 6.3 for loading a tooth sheet for mounting a bin 6.3 and can launch a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com