Method for preparing Ni52Mn24Ga24 alloy film through laser pulse sputtering deposition

A ni52mn24ga24, sputtering deposition technology, applied in the field of metal alloys, can solve the problems of low strength, high brittleness of Ni-Mn-Ga, etc., and achieve the effect of high strength, strong anisotropy and low roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

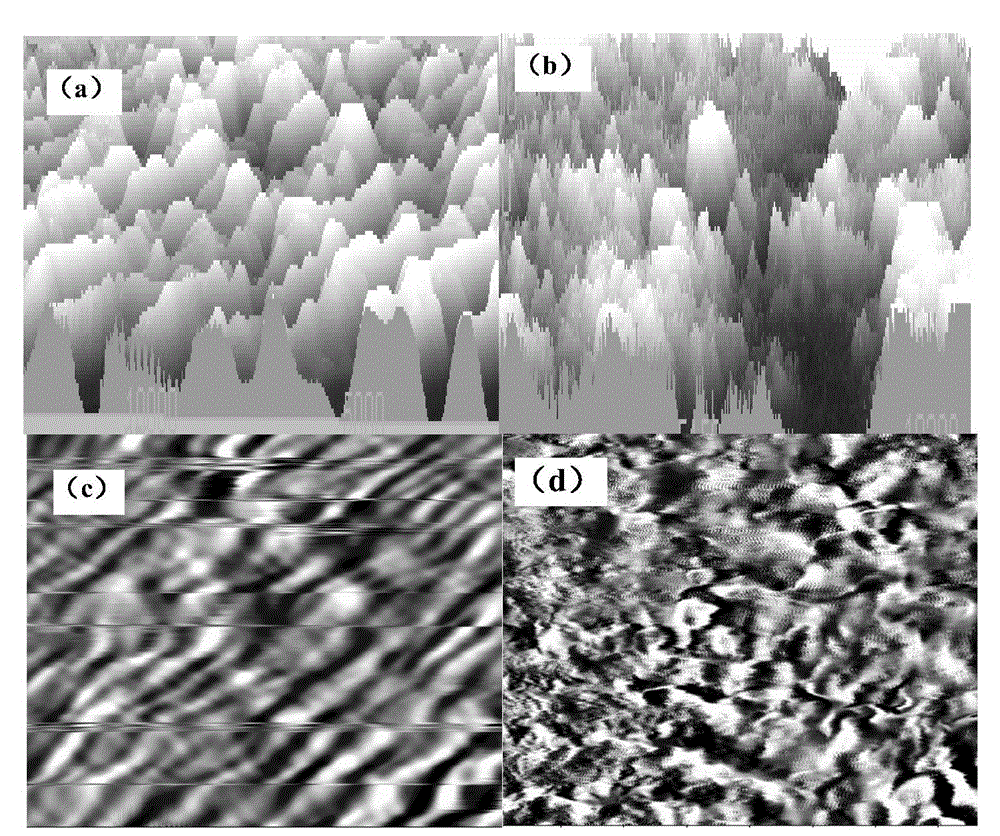

Embodiment 1

[0023] The test alloy target is selected from three metal elements with a purity of 99.99at.%-Ni, 99.95at.%-Mn, and 99.99at.%-Ga. According to the molar ratio, 52 parts of Ni, 24 parts of Mn, 24 parts Ga is placed in a vacuum non-consumable electrode electric arc furnace, and the furnace chamber is evacuated before melting, and the vacuum degree reaches 5×10 -3 Pa, filled with Ar protective gas. In order to make the composition of the material uniform, the material is turned over by a manipulator before each smelting, and the smelting is turned over at least 4 times, and magnetic stirring is added during the smelting process. After smelting, an ingot with a diameter of about 50 mm is obtained. After being ground on the grinding wheel, the ingot was placed on a wire electric discharge machine and cut into a circular target with a diameter of 3mm×2mm. Quartz glass with a specification of 30mm×30mm×3mm is selected as the substrate of the thin film. Pretreatment of the quartz g...

Embodiment 2

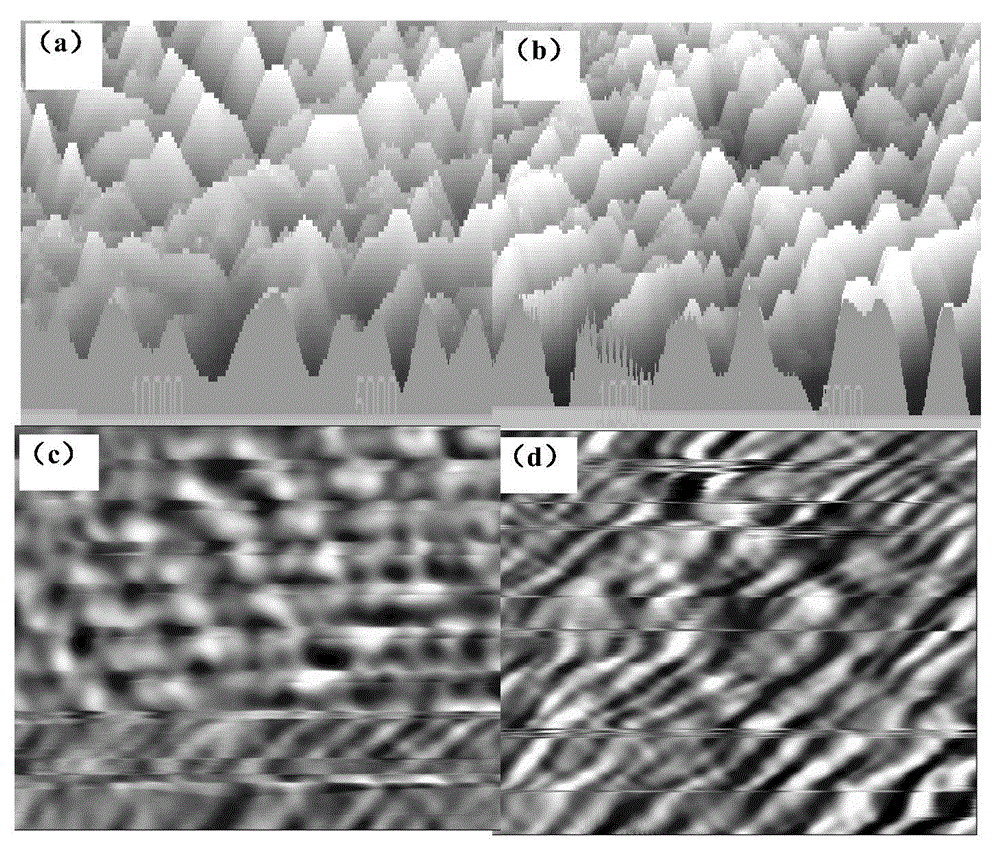

[0025] The test alloy target is selected from three metal elements with a purity of 99.99at.%-Ni, 99.95at.%-Mn, and 99.99at.%-Ga. According to the molar ratio, 52 parts of Ni, 24 parts of Mn, 24 parts Ga is placed in a vacuum non-consumable electrode electric arc furnace, and the furnace chamber is evacuated before melting, and the vacuum degree reaches 5×10 -3 Pa, filled with Ar protective gas. In order to make the composition of the material uniform, the material is turned over by a manipulator before each smelting, and the smelting is turned over at least 4 times, and magnetic stirring is added during the smelting process. After smelting, an ingot with a diameter of about 50 mm is obtained. After being ground on the grinding wheel, the ingot was placed on a wire electric discharge machine and cut into a circular target with a diameter of 3mm×2mm. Quartz glass with a specification of 30mm×30mm×3mm is selected as the substrate of the thin film. Pretreatment of the quartz g...

Embodiment 3

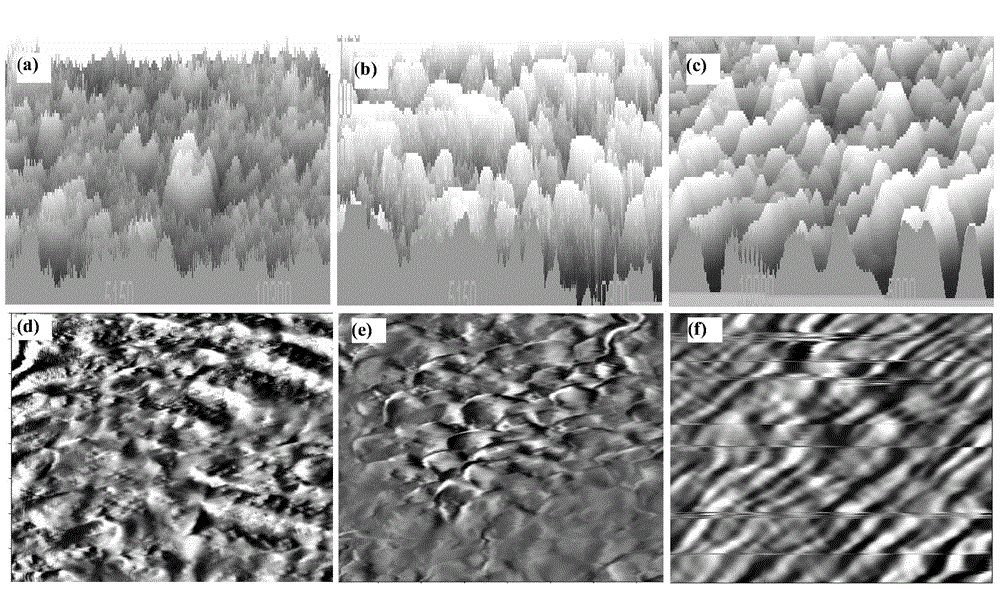

[0027]The test alloy target is selected from three metal elements with a purity of 99.99at.%-Ni, 99.95at.%-Mn, and 99.99at.%-Ga. According to the molar ratio, 52 parts of Ni, 24 parts of Mn, 24 parts Ga is placed in a vacuum non-consumable electrode electric arc furnace, and the furnace chamber is evacuated before melting, and the vacuum degree reaches 5×10 -3 Pa, filled with Ar protective gas. In order to make the composition of the material uniform, the material is turned over by a manipulator before each smelting, and the smelting is turned over at least 4 times, and magnetic stirring is added during the smelting process. After smelting, an ingot with a diameter of about 50 mm is obtained. After being ground on the grinding wheel, the ingot was placed on a wire electric discharge machine and cut into a circular target with a diameter of 3mm×2mm. Quartz glass with a specification of 30mm×30mm×3mm is selected as the substrate of the thin film. Pretreatment of the quartz gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com