Graphene-titanium black composite conductive agent and preparation method thereof

A technology of composite conductive agent and titanium oxide, applied in oxide conductors, carbon-silicon compound conductors, cable/conductor manufacturing and other directions, can solve problems such as unfavorable production and application, many preparation process steps, easy powder agglomeration, etc. Improve dispersion effect and utilization, simple process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

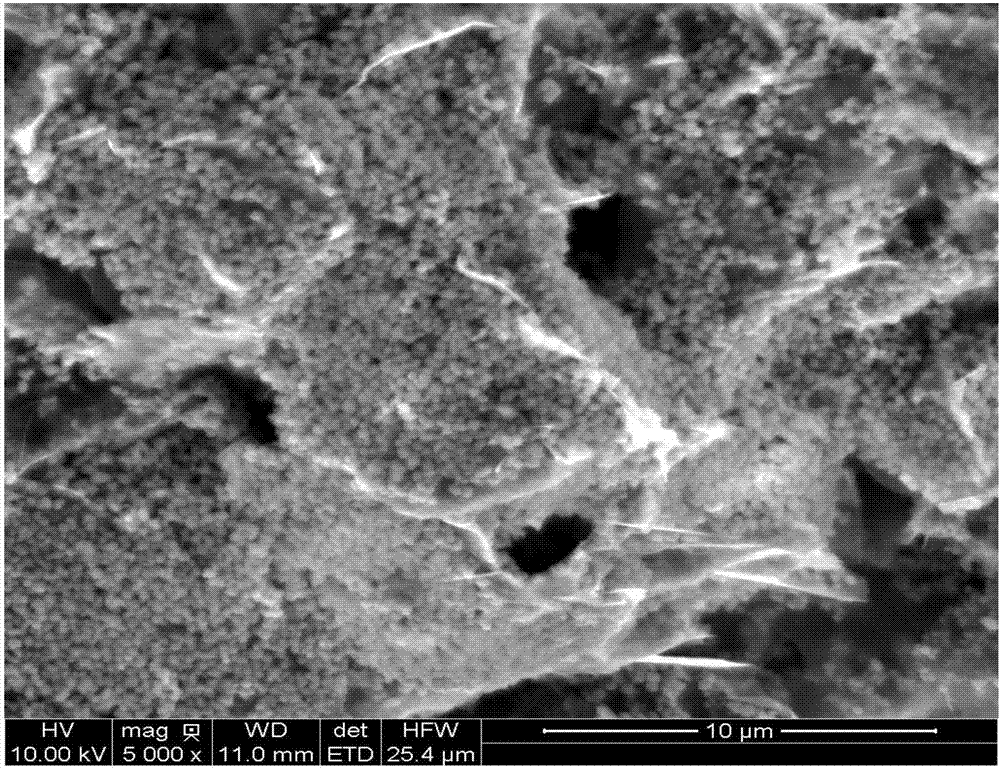

Image

Examples

preparation example Construction

[0023] The invention provides a kind of preparation method of graphene-titanium oxide composite conductive agent, it comprises the following steps:

[0024] S1, mixing the titanium dioxide material, a modifier and water to prepare a modified titanium dioxide slurry, wherein the modifier is a polymer alcohol or a polyol;

[0025] S2, dispersing the graphene material in water to obtain a graphene slurry, then mixing the graphene slurry with the modified titanium dioxide slurry, and obtaining a composite slurry through self-assembly; and

[0026] S3, drying the composite slurry to obtain a graphene-titanium oxide composite conductive agent.

[0027] In step S1, the titanium oxide material is Ti 4 o 7 、Ti 3 o 5 、Ti 5 o 9 One of. The microscopic shape of the titanium oxide material is not limited, and it can be at least one of powder, rod, porcelain flake, and porous. The polyhydric alcohol is at least one of pentaerythritol, ethylene glycol, propylene glycol, butanediol, h...

Embodiment 1

[0041] The graphene water-based slurry with a mass concentration of 2% and the Ti with a mass concentration of 4% were prepared respectively. 4 o 7 Modified water-based slurry:

[0042] a) preparation of graphene material water-based slurry with a mass concentration of 2%: take 40Kg of a graphene water-based slurry with a mass concentration of 5%, dilute with water until the graphene content is 2%, and stir evenly;

[0043] b) Ti with a mass concentration of 4% 4 o 7 Preparation of modified water-based slurry: weigh 2kg Ti 4 o 7 Material, according to Ti 4 o 7 The mass ratio of material to polyethylene glycol is 1:0.05. Weigh polyethylene glycol and add a certain amount of water to dilute to Ti 4 o 7 The mass concentration of the material is 4%, stirring and dispersing evenly;

[0044] The above prepared graphene material aqueous slurry and Ti 4 o 7 The aqueous slurry is mixed evenly to obtain graphene / Ti 4 o 7 Composite slurry, the intermediate slurry is spray-dr...

Embodiment 2

[0047] The aqueous slurry of graphene material with a mass concentration of 0.1% and the Ti with a mass concentration of 5% were prepared respectively. 4 o 7 Material modified water-based slurry:

[0048] a) preparation of graphene material water-based slurry with a mass concentration of 0.1%: take 40Kg of a graphene water-based slurry with a mass concentration of 5%, and dilute with water until the graphene content is 0.1%;

[0049] b) Ti with a mass concentration of 5% 4 o 7 Preparation of material modified water-based slurry: weigh 0.2kg Ti 4 o 7 , according to Ti 4 o 7 The mass ratio to ethylene glycol is 1:1, weigh 0.2kg of ethylene glycol, add a certain amount of water to dilute to Ti 4 o 7 The mass concentration is 5%, stirring and dispersing evenly;

[0050] The above prepared graphene material aqueous slurry and Ti 4 o 7 The aqueous slurry is mixed evenly to obtain graphene / Ti 4 o 7 Composite slurry, the intermediate slurry is spray-dried to obtain graphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com