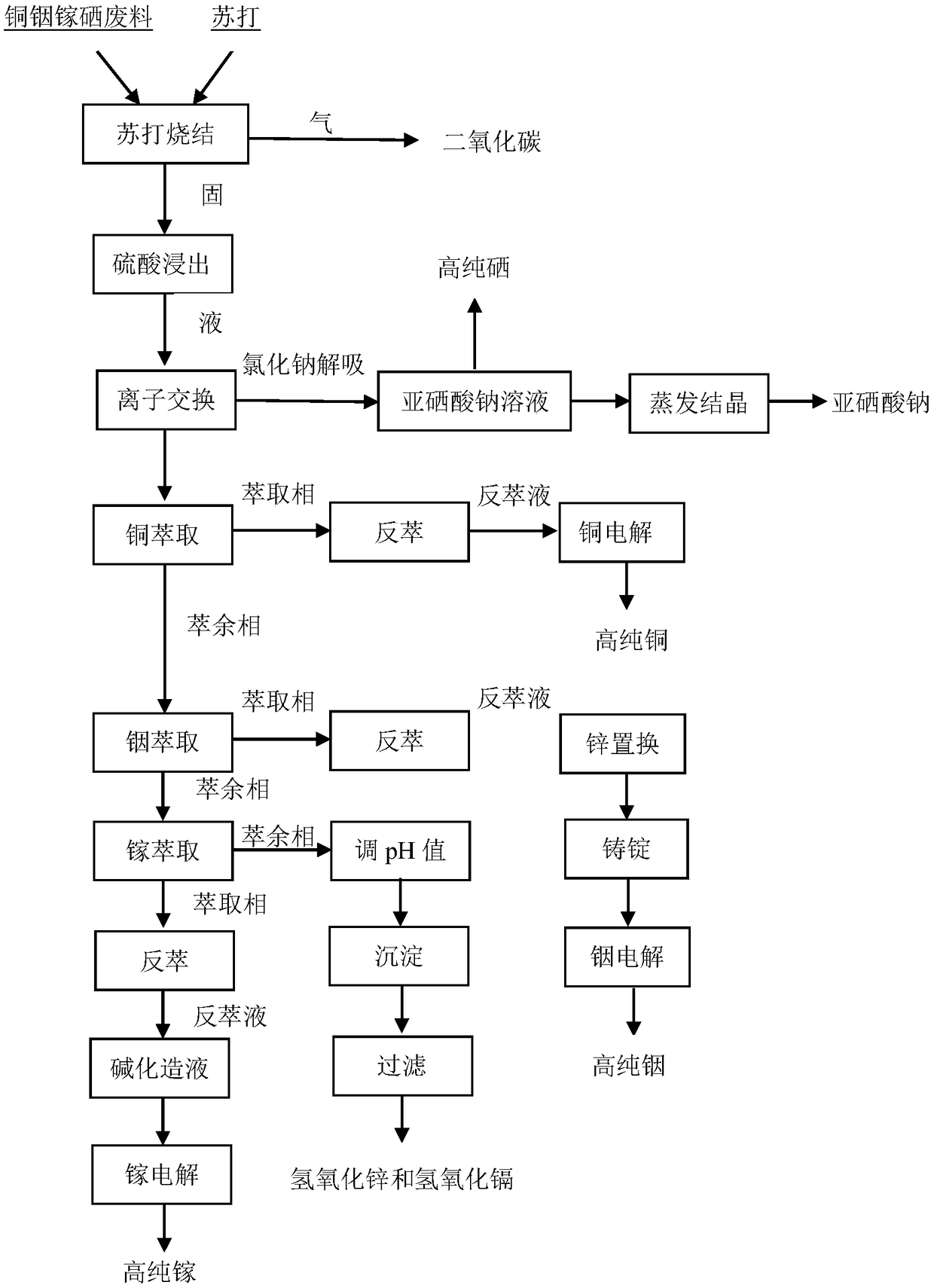

Copper indium gallium diselenide treatment method

A technology of copper indium gallium selenide and a processing method, which is applied in chemical instruments and methods, selenium/tellurium compounds, selenium/tellurium oxysalts, etc., can solve the problems of low valuation coefficient, low added value, single product, etc. Efficiency of process simplicity, reduction and oxidation reduction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

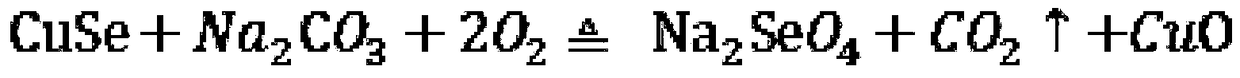

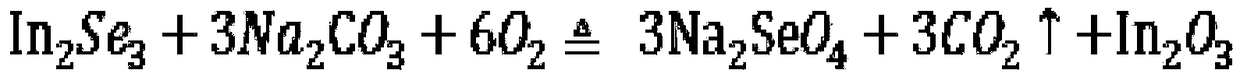

[0099] A. Sintering: Mix 3kg of copper indium gallium selenide with 25% sodium carbonate, add water to make a thick slurry, extrude and granulate, dry at 90°C for 2 hours, put it into an electric furnace, and control it at 550°C to feed air Carry out sodium carbonate sintering, sintering for 1 hour and 30 minutes, selenium is converted into sodium selenite, copper indium gallium is converted into the corresponding oxide, and carbon dioxide and sintering material are obtained;

[0100] B. Dissolving: Transfer the sintered material into a 30L leaching tank, leaching with dilute sulfuric acid, the mass fraction of dilute sulfuric acid is 1-5%, and filter to obtain the filtrate and a small amount of insoluble matter. The filtrate contains copper sulfate, gallium sulfate, A mixed solution of indium sulfate and sodium selenite;

[0101] C. Ion exchange method for selenium extraction: the filtrate is passed into the exchange column that the cathode is equipped with 717 strong basic a...

Embodiment 2

[0107]A. Sintering: Mix 1 kg of copper indium gallium selenide with 20% sodium carbonate, add water to make a thick slurry, extrude and granulate, dry at 100°C for 1 hour, put it into an electric furnace, and control it at 450°C to feed air Carry out sodium carbonate sintering, sintering for 1 hour, selenium is converted into sodium selenite, copper indium gallium is converted into corresponding oxides, and a sintered material is obtained;

[0108] B. Dissolving: Transfer the sintered material to a 10L leaching tank, leaching with dilute sulfuric acid with a mass fraction of 1-5%, and filtering to obtain a filtrate and a small amount of insoluble matter. The filtrate contains copper sulfate, gallium sulfate, indium sulfate and A mixed solution of sodium selenate;

[0109] C. Ion exchange method for selenium extraction: the filtrate is passed into the exchange column that the cathode is equipped with D201 strong basic anion exchange resin, and the sodium selenite in the filtrat...

Embodiment 3

[0115] A. Sintering: Mix 5kg of copper indium gallium selenide with 30% sodium carbonate, add water to make a thick slurry, extrude and granulate, dry at 80°C for 2 hours, put it into an electric furnace, and control it at 650°C to feed air Carry out sodium carbonate sintering, sintering for 2 hours, selenium is converted into sodium selenite, copper indium gallium is converted into corresponding oxides, and a sintered material is obtained;

[0116] B. Dissolution: Transfer the sintered material to a 50L leaching tank, leaching with dilute sulfuric acid with a mass fraction of 1-5%, and filtering to obtain a filtrate and a small amount of insoluble matter. The filtrate contains copper sulfate, gallium sulfate, indium sulfate and A mixed solution of sodium selenate;

[0117] C. Ion exchange method for selenium extraction: the filtrate is passed into the exchange column that the cathode is equipped with D301 strong basic anion exchange resin, and the sodium selenite in the filtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com