Method for reducing hexavalent selenium into tetravalent selenium

A hexavalent, selenium solution technology, applied in chemical instruments and methods, selenium/tellurium compounds, selenium/tellurium oxysalts, etc., can solve the problems of long process, unsuitable for large-scale industrial application, etc. Simple restoration method and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

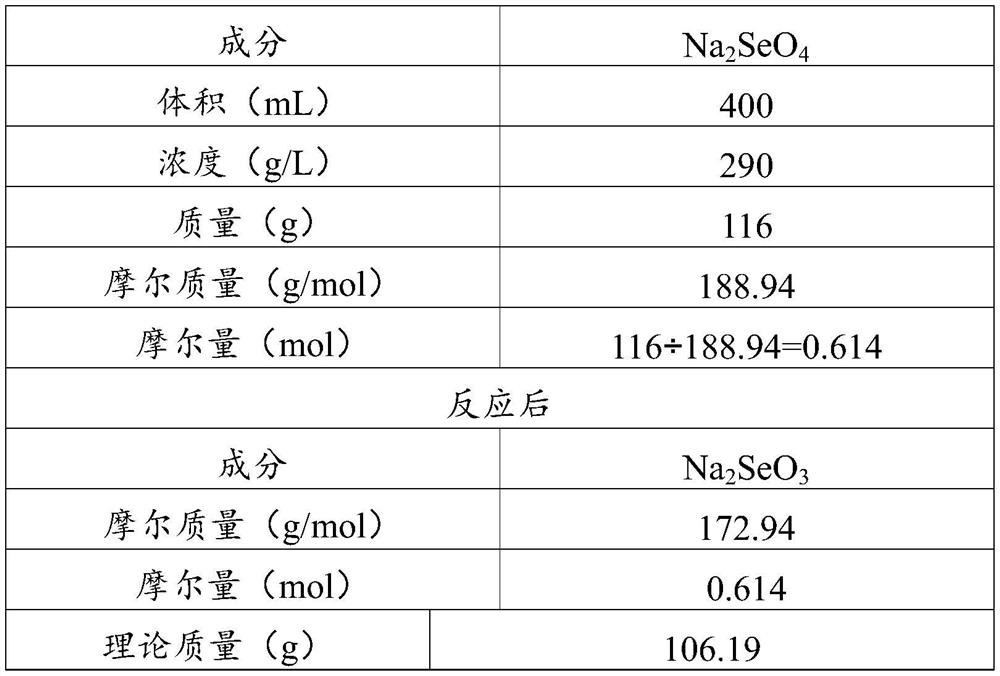

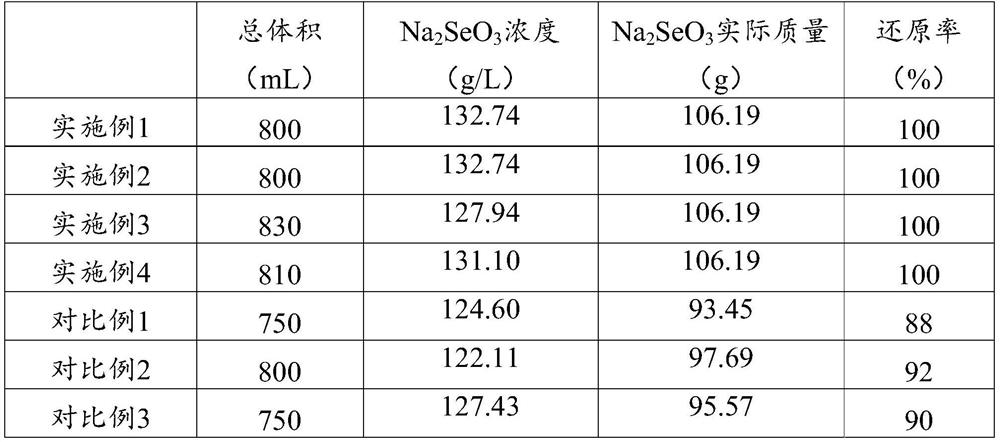

[0023] In this embodiment, the method for reducing hexavalent selenium to tetravalent selenium comprises the following steps:

[0024] (1) 400mL of sodium selenate solution with a concentration of 290g / L was added to the reactor, and the temperature was raised to 70-90°C;

[0025] (2) Slowly add 400mL of hydrochloric acid until the potential of the solution system is 1100mv, stop adding hydrochloric acid, continue to stir the reaction until the potential is 960mv, stop the reaction, and detect the content of tetravalent selenium.

Embodiment 2

[0027] In this embodiment, the method for reducing hexavalent selenium to tetravalent selenium comprises the following steps:

[0028] (1) 400mL of sodium selenate solution with a concentration of 290g / L was added to the reactor, and the temperature was raised to 70-90°C;

[0029] (2) Slowly add 400mL of hydrochloric acid, stir continuously during the addition process, until the reaction reaches a potential of 960mv, stop the reaction, and detect the content of tetravalent selenium.

Embodiment 3

[0031] In this embodiment, the method for reducing hexavalent selenium to tetravalent selenium comprises the following steps:

[0032] (1) 400mL of sodium selenate solution with a concentration of 290g / L was added to the reactor, and the temperature was raised to 70-90°C;

[0033] (2) Slowly add 430mL of hydrochloric acid until the potential of the solution system is 970mv, stop adding hydrochloric acid, continue to stir the reaction until the potential is 900mv, stop the reaction, and detect the content of tetravalent selenium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com