Compound technology for removing As, Sb, Bi by utilizing copper electrolyte

A composite process and copper electrolyte technology, applied in the field of metallurgy, can solve problems such as high cost and inability to solve the problem of As open circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

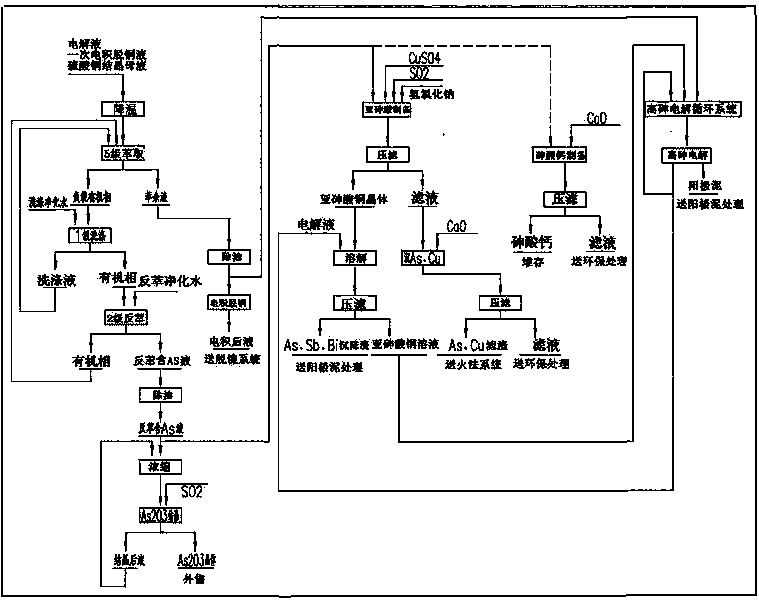

Image

Examples

Embodiment 1

[0028] An expanded test was carried out on the transformation of the copper electrolyte cleaning process in a factory. The process of removing As, Sb and Bi in the cleaning process before the transformation was one-time electrowinning copper removal + electrowinning induced copper removal and arsenic removal. It is now transformed into solvent extraction to remove As + prepare copper arsenite + high arsenic electrolysis to remove Sb and Bi.

[0029] Preparation of High Arsenic Electrolyte

[0030] Primary electrowinning copper removal solution (see Table 1 for composition, t~60°C, Q=24m 3 / d) Return all to electrolysis. When the concentration of As in the electrolyte rises to 9 g / L, the plate heat exchanger is used to cool the electrowinning copper removal solution to room temperature, and then send it to extract As.

[0031] Extraction of As

[0032] Using TBP as the extraction agent, the organic phase composition is (50%-60%) TBP+(40%-50%) 260# solvent oil (v / v), the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com