Stabilized treatment method for realgar tailing residues

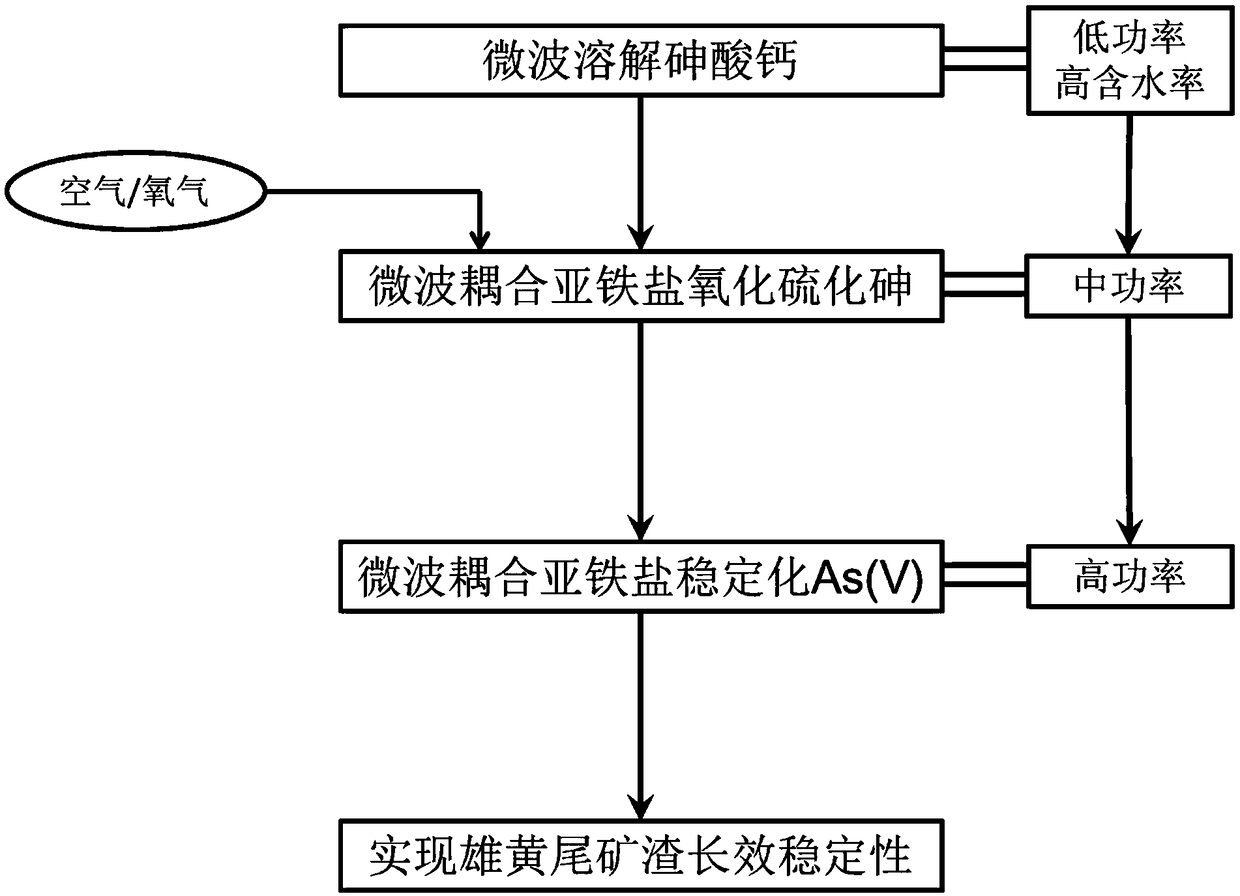

A tailings slag and stabilization technology, which is applied in the field of realgar tailings slag stabilization and disposal, can solve the problems of reducing volume increase ratio, insufficient long-term stability of products, slow oxidation rate of arsenic sulfide, etc., and achieves the effect of accelerating dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Crushing the realgar tailing slag to a particle size ≤ 5mm.

[0058] (2) Take 30 g of the crushed realgar tailing slag, add 12 mL of water (that is, the mass ratio of water to realgar tailing slag is 5:10), and stir evenly.

[0059] (3) Put the mixture obtained in step (2) into a quartz container for microwave treatment for 10 minutes, the microwave power is set to 250W, and the microwave frequency is 2455MHz.

[0060] (4) Add 10 mL of water to the mixture after microwave dissolution treatment (i.e. the mass ratio of water to realgar tail slag is 3.3:10), and then add 7.5 g of ferrous sulfate heptahydrate (i.e. ferrous sulfate heptahydrate and realgar The mass ratio of tailings slag is 2.5:10), and stir evenly.

[0061] (5) Continuously feed air into the mixture obtained in step (4), and carry out microwave treatment for 10 minutes at the same time, the microwave power is set to 450W, and the microwave frequency is 2455MHz.

[0062] (6) Stop feeding air, and carry...

Embodiment 2

[0068] (1) Crushing the realgar tailing slag to a particle size ≤ 5mm.

[0069] (2) Take 30 g of the crushed realgar tail slag, add 20 mL of water (that is, the mass ratio of water to realgar tail slag is 6.7:10), and stir evenly.

[0070] (3) Put the mixture obtained in the step (2) into a quartz container for microwave treatment for 15 minutes, the microwave power is set to 150W, and the microwave frequency is 2455MHz.

[0071](4) Add 15mL of water to the mixture after microwave dissolution treatment (i.e. the mass ratio of water to realgar tail slag is 5:10), and then add 9g of ferrous sulfate heptahydrate (i.e. ferrous sulfate heptahydrate and realgar tail The mass ratio of slag is 3:10), and stir evenly.

[0072] (5) Pass air into the mixture obtained in step (4), and carry out microwave treatment for 5 minutes at the same time, the microwave power is set to 350W, and the microwave frequency is 2455MHz.

[0073] (6) The mixture obtained in step (5) was subjected to micr...

Embodiment 3

[0079] (1) Crushing the realgar tailing slag to a particle size of ≤2mm.

[0080] (2) Take 30 g of crushed realgar tailing slag, add 9 mL of water (that is, the mass ratio of water to realgar tailing slag is 3:10), and stir evenly.

[0081] (3) Put the mixture obtained in the step (2) into a quartz container for microwave treatment for 20 min, the microwave power is set to 100 W, and the microwave frequency is 2455 MHz.

[0082] (4) Add 7 mL of water to the mixture after microwave dissolution treatment (i.e. the mass ratio of water to realgar tail slag is 2.3:10), and then add 4.5 g of ferrous sulfate heptahydrate (i.e. ferrous sulfate heptahydrate and realgar The mass ratio of tailings slag is 1.5:10), and stir evenly.

[0083] (5) Pass air into the mixture obtained in step (4), and carry out microwave treatment for 20 min at the same time, the microwave power is set to 300W, and the microwave frequency is 2455MHz.

[0084] (6) The mixture obtained in step (5) was subjected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com