Novel shaving board and production technology thereof

A production process and particle board technology, applied in the direction of manufacturing tools, ceramic forming machines, pressing rollers, etc., can solve the problems of long production cycle, low strength and high energy consumption, and achieve the effect of long production cycle, low strength and high energy consumption

Inactive Publication Date: 2015-03-25

NINGBO TIANJIN NEW MATERIAL

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a high-strength, formaldehyde-free and flame-retardant inorganic gelling agent particle board and a simple and operational production process, which solves the problem of long production cycle, high energy consumption and high energy consumption of the existing ordinary particle board containing formaldehyde and cement particle board. Disadvantages of lower strength

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0018] Select 10 parts of 5-mesh wood particles, add 1 part of surfactant to modify, add 2 parts of magnesium oxychloride cement and stir until uniform, and roll the mixture into a roller press with a pressure of 0.5 MPa. The product is sent to a curing room with a temperature of 40 ℃ and a humidity of 60% for 3 days to obtain the product, and the product density is 0.6 g / cm 3 , the flexural strength reaches 6 MPa.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

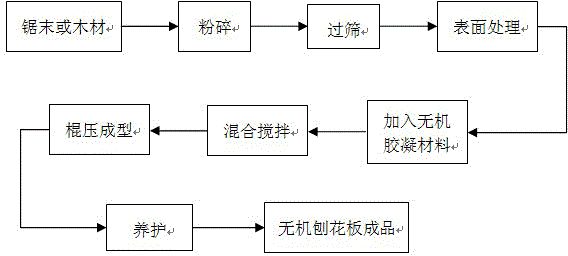

The invention discloses a novel shaving board and a production technology of the novel shaving board. The novel shaving board is composed of saw powder or poor wood such as remaining edges, skin and ends formed by wood machining and inorganic bond materials,. The density of a product is controllable within the range of 0.6g / cm<3> to 1.2g / cm<3>. The production technology comprises the steps that the saw powder or the wood materials are smashed, and then are sieved, so that wooden particles with a certain mesh number can be selected; the sieved-out particles are conveyed to surface modification equipment, and therefore surface modification treatment can be carried out on the particles, and then the particles are manufactured into hydrophobic particles, and the inorganic bond materials and water are added into the hydrophobic particles to be mixed and stirred; stirred mixing materials are conveyed to a rolling machine to be rolled and formed; and finally the formed shaving board is conveyed to a curing chamber to be cured for a certain time, and a finished product is obtained. The shaving board has the advantages of being simple in production technology, rich in raw material source, low in production cost, high in product strength, free of formaldehyde, and resistant to flame; the utilization rate of the wood is greatly improved; and obvious social benefits and economic benefits are achieved.

Description

technical field [0001] The invention relates to a new type of decorative building material and its production process, in particular to a high-strength, zero-formaldehyde flame-retardant novel inorganic adhesive particle board and its production process. Background technique [0002] As an economical, environmentally friendly, and comfortable decorative material, particleboard is widely used in home decoration. However, most organic materials such as urea-formaldehyde resin and phenolic resin are used as binders, which contain harmful formaldehyde and poor frost resistance. Its use is limited. Cement particleboard overcomes this shortcoming as an inorganic cementitious particleboard, but it is made of ordinary Portland cement, which has a long production cycle, relatively low strength, requires autoclaving and high energy consumption. Contents of the invention [0003] The purpose of the present invention is to provide a high-strength, formaldehyde-free and flame-retardan...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B28B1/52B28B3/00

CPCB28B1/52B28B3/12

Inventor 李天君郭武明

Owner NINGBO TIANJIN NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com