A wastewater treatment device coupled with electro-Fenton and electrocatalytic oxidation without solid waste generation

A technology for electrocatalytic oxidation and wastewater treatment, which is used in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of improving the effective utilization of energy, improving the depth of degradation, and improving the treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

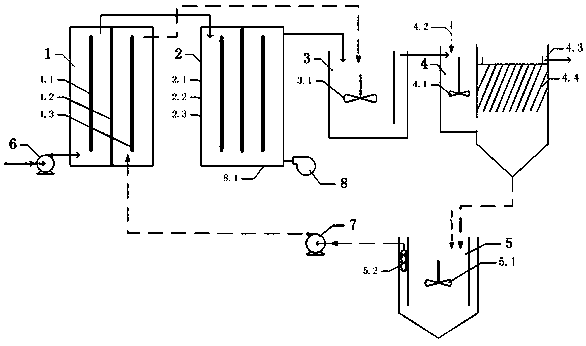

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0033] Such as figure 1 As shown, a wastewater treatment device coupled with electro-Fenton and electrocatalytic oxidation without solid waste, including sequentially connected raw water pump 6, first diaphragm electrolyzer 1, second diaphragm electrolyzer 2, and Fenton reaction Tank 3, coagulation sedimentation tank 4 and iron slime dissolving tank 5,

[0034]The first diaphragm electrolytic cell 1 includes a first anode 1.1, a first diaphragm 1.2 and a first cathode 1.3, the first diaphragm 1.2 is located in the middle of the first electrolytic cell 1, and the first anode 1.1 and the first cathode 1.3 are respectively located in the first diaphragm The two sides of 1.2 form an anode chamber and a cathode chamber, and the upper and lower ends of the anode chamber and the cathode chamber are not connected; in the first diaphragm electrolytic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com