Preparation method of micro-nano suspension beam arm-structured elastic contactor

An elastic contact and cantilever arm technology, applied in the field of micro-electromechanical, can solve the problems of large surface roughness of the hemispherical boss, unfavorable demoulding, difficult process control, etc., to overcome low processing efficiency, high processing efficiency, and improve processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a micro-nano cantilever arm structure elastic contactor, the specific steps are as follows:

[0037] (1) Photolithography: transfer the pattern of the mask to the Si substrate by photolithography;

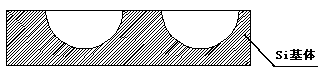

[0038] (2) Etching: using an etching machine to etch a hemispherical silicon groove on the Si substrate;

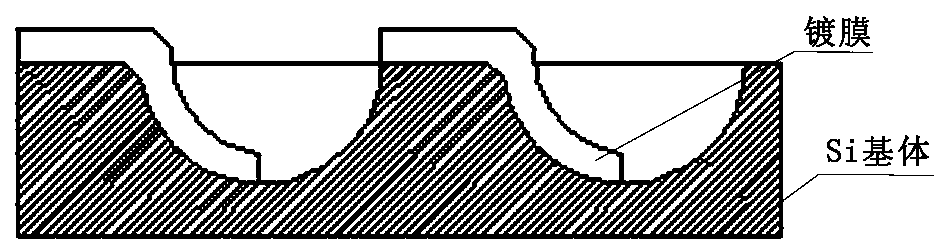

[0039] (3) Coating: Hollow coating in a semicircular silicon tank, the coating material is copper alloy;

[0040] (4) Brazing: Braze the hollow coating on another material substrate; the material substrate can be a PCB circuit board, or a high-insulation quartz SiO 2 chip;

[0041] (5) Removing the Si matrix: the Si matrix is removed by physical or chemical methods to obtain the elastic contactor.

[0042] In step (1), use a chemical film layer photoresist mask, adopt a thick glue process, coat a 7-10 μm thick photoresist on the upper surface of the Si substrate, and then prepare a mask by irradiating strong light on the photoresist. film gr...

Embodiment 2

[0060] A method for preparing a micro-nano cantilever arm structure elastic contactor, the specific steps are as follows:

[0061] (1) Photolithography: Use photolithography to transfer the pattern of the mask to the Si substrate; specifically: a. Coating: first coat the photoresist on the Si substrate, and then use the photoresist to smear the photoresist Uniform; set the initial speed of the homogenizer to 400r / min, time 6s; normal speed 1000r / min, time 10s, photoresist thickness is 7μm; b. Film hardening treatment, set the temperature at 100°C, and the time is 200s; c. Exposure: Expose with a photolithography machine, and the exposure illumination is 10W / cm 2 , the exposure time is 20s; d. Development: develop with 1:6 (original developer: water), and the development time is 60s.

[0062] (2) Etching: use an etching machine to etch a hemispherical silicon groove on the Si substrate; specifically: use SF 6 The etching gas is used to etch the Si substrate in an ICP high-den...

Embodiment 3

[0068] A method for preparing a micro-nano cantilever arm structure elastic contactor, the specific steps are as follows:

[0069] (1) Photolithography: Use photolithography to transfer the pattern of the mask to the Si substrate; specifically: a. Coating: first coat the photoresist on the Si substrate, and then use the photoresist to smear the photoresist Uniform; set the initial speed of the homogenizer to 500r / min, time 7s; normal speed 1500r / min, time 12s, photoresist thickness is 8μm; b. Film hardening treatment, set the temperature at 110°C, and the time is 250s; c. Exposure: Expose with a photolithography machine, and the exposure illumination is 12W / cm 2 , the exposure time is 25s; d. Development: develop with 1:6 (original developer: water), and the development time is 60s.

[0070] (2) Etching: use an etching machine to etch a hemispherical silicon groove on the Si substrate; specifically: use SF 6 The etching gas is used to etch the Si substrate in the ICP high-de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com