Patents

Literature

114 results about "Thick photoresist" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

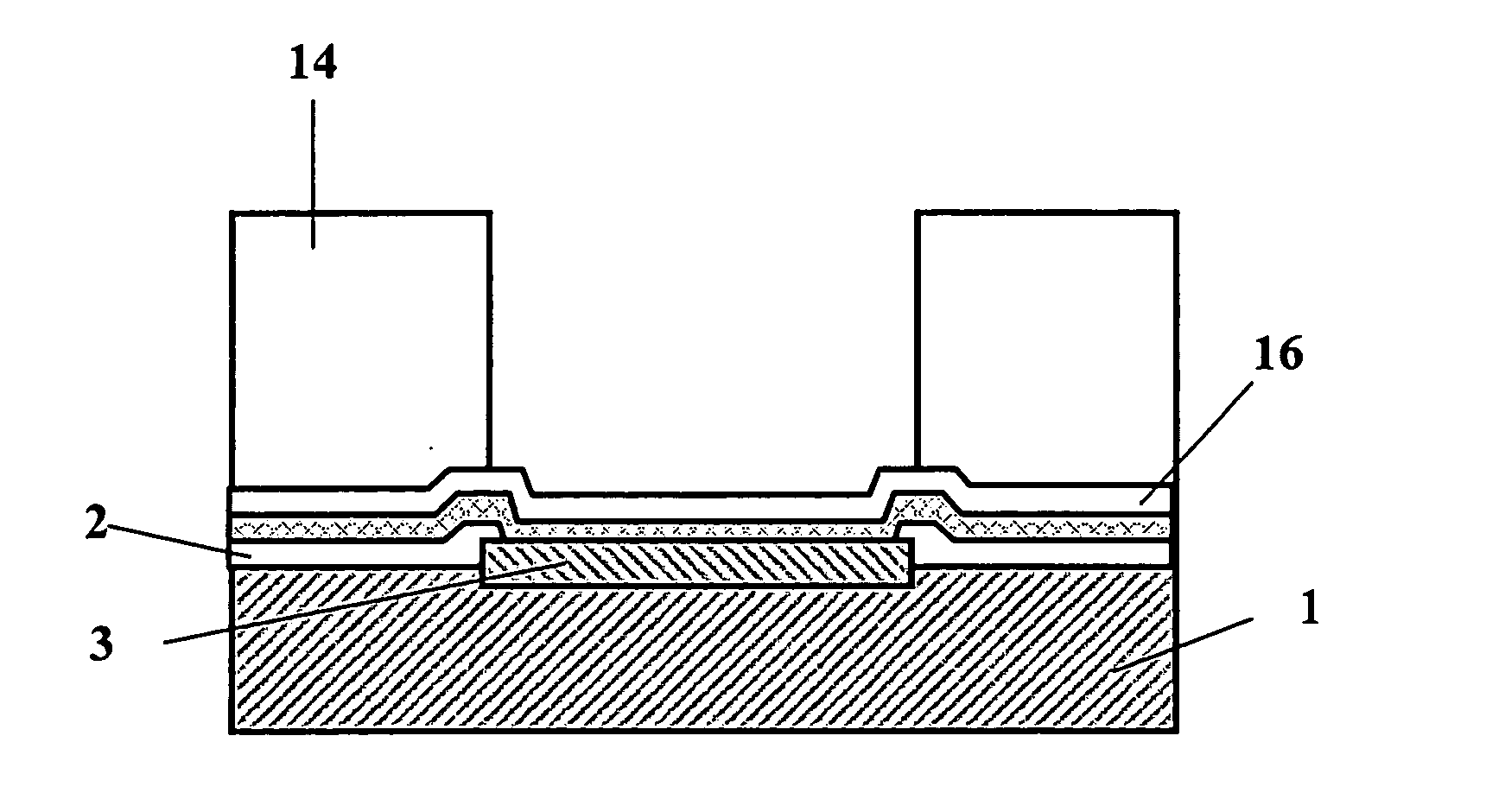

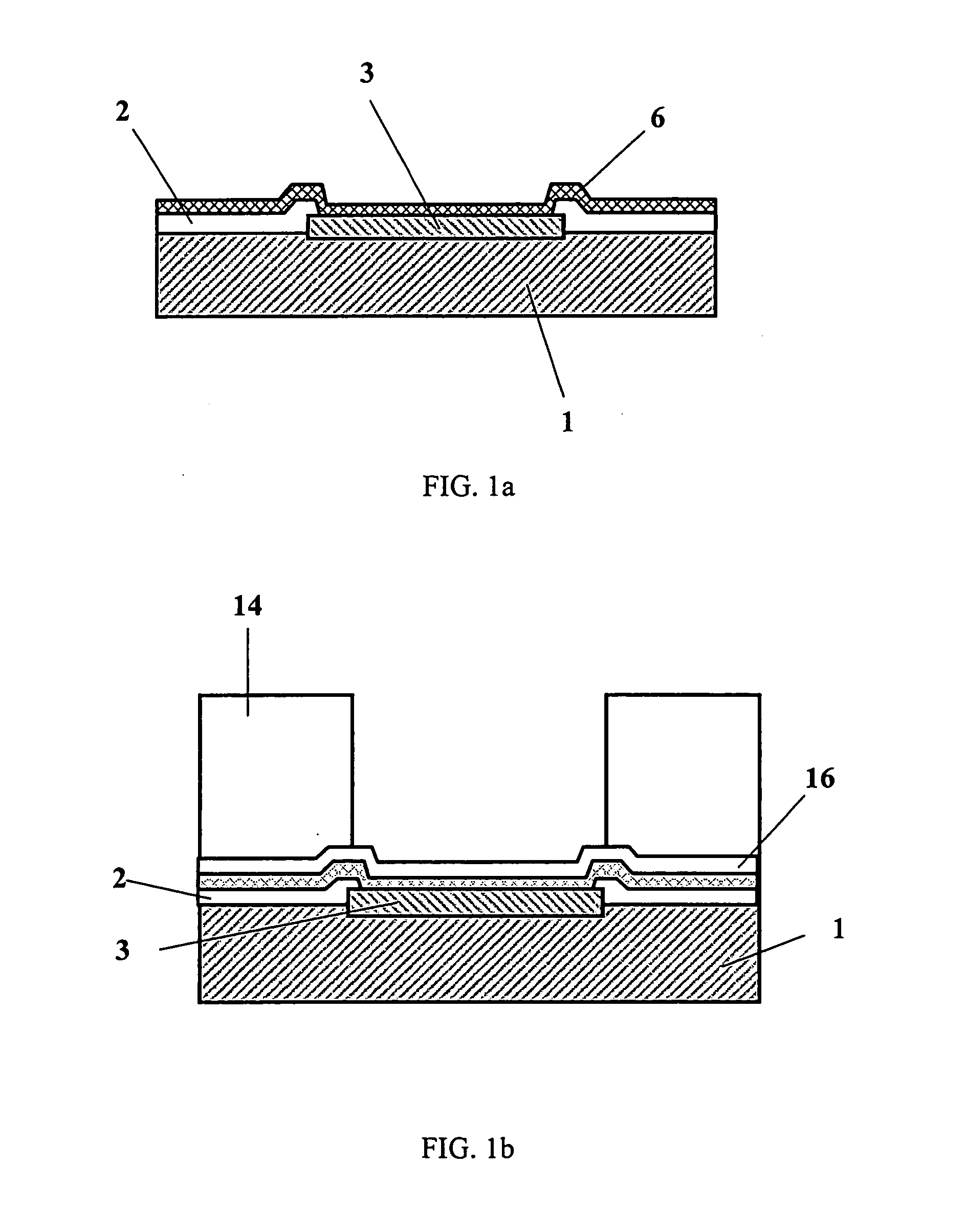

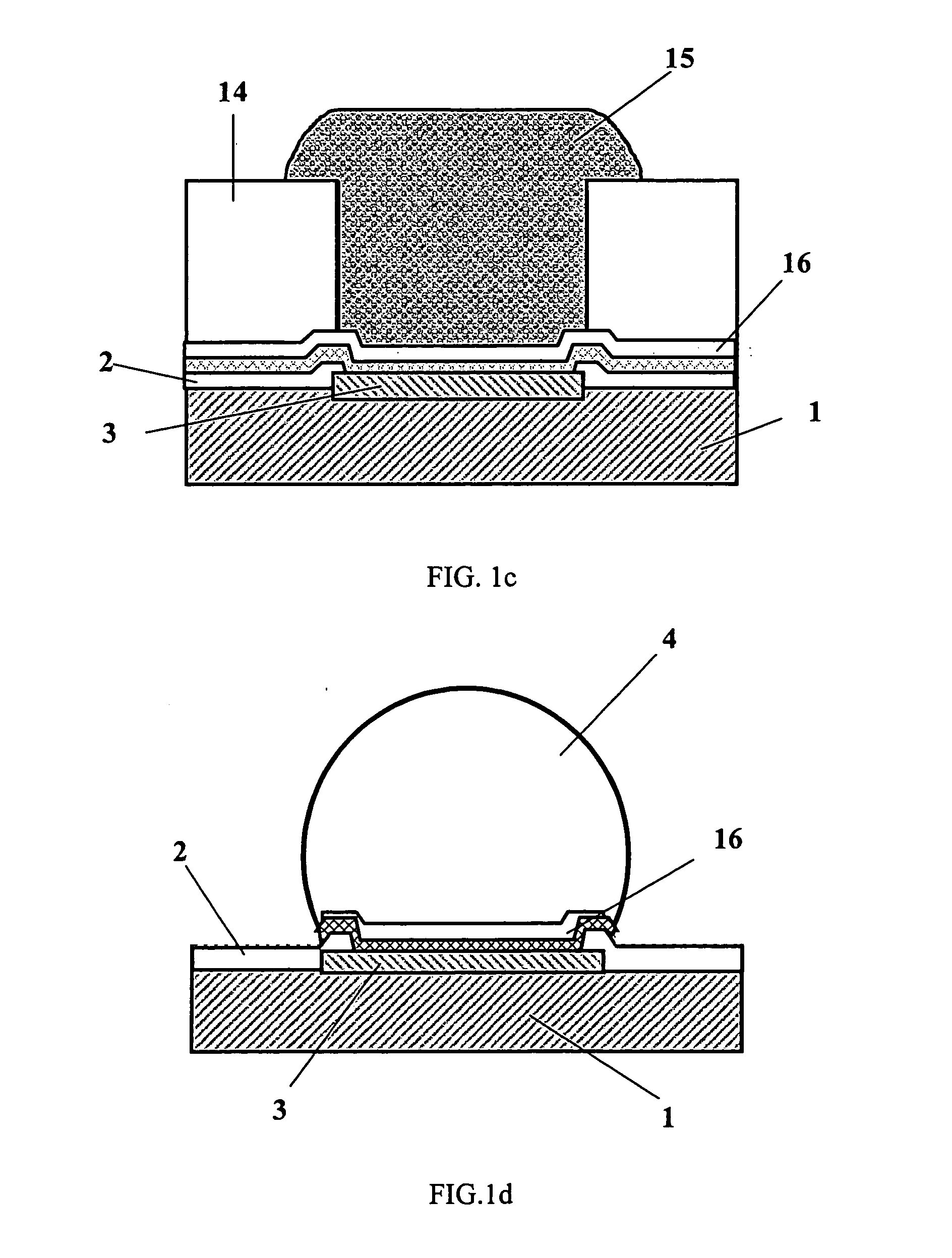

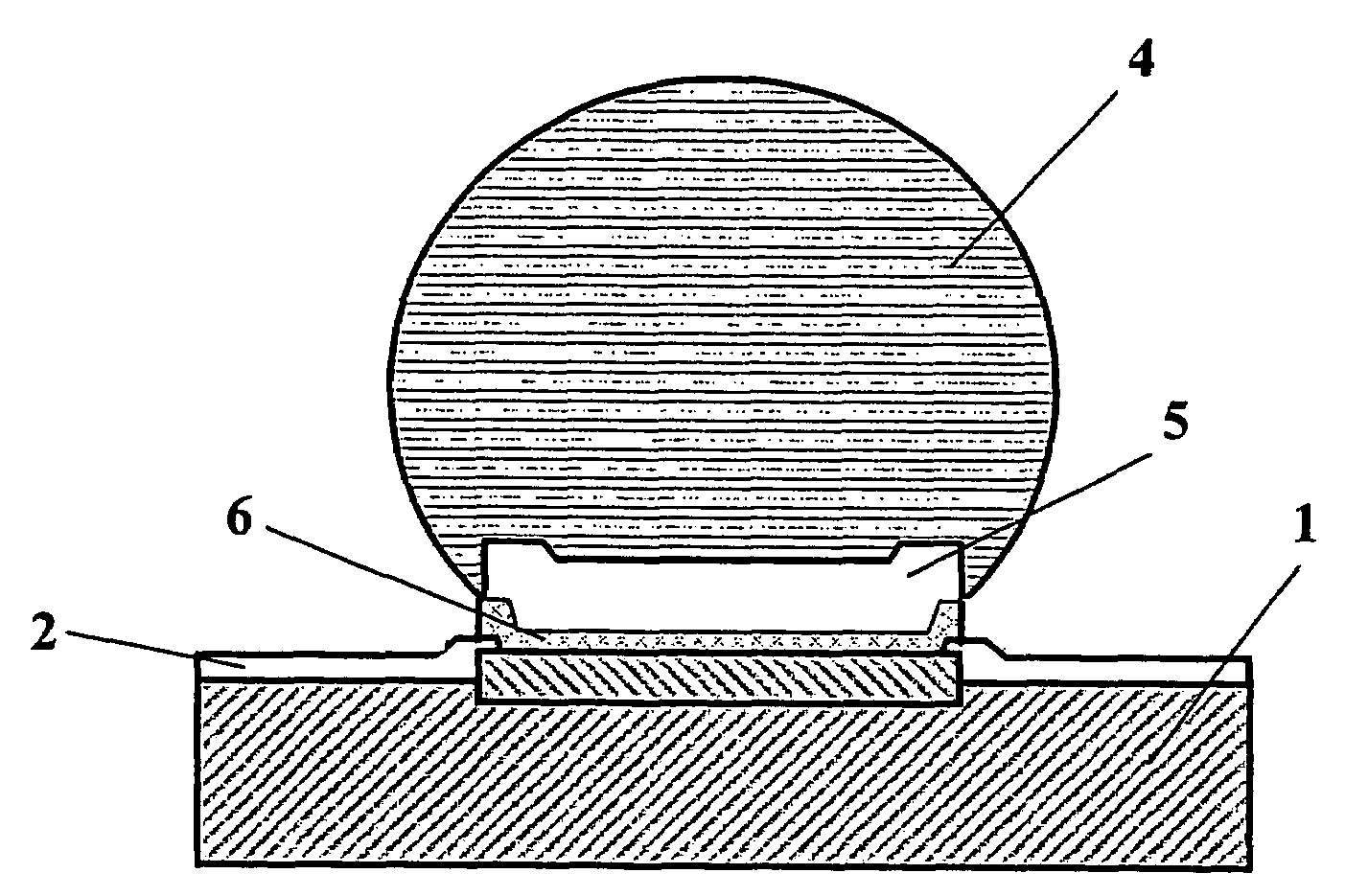

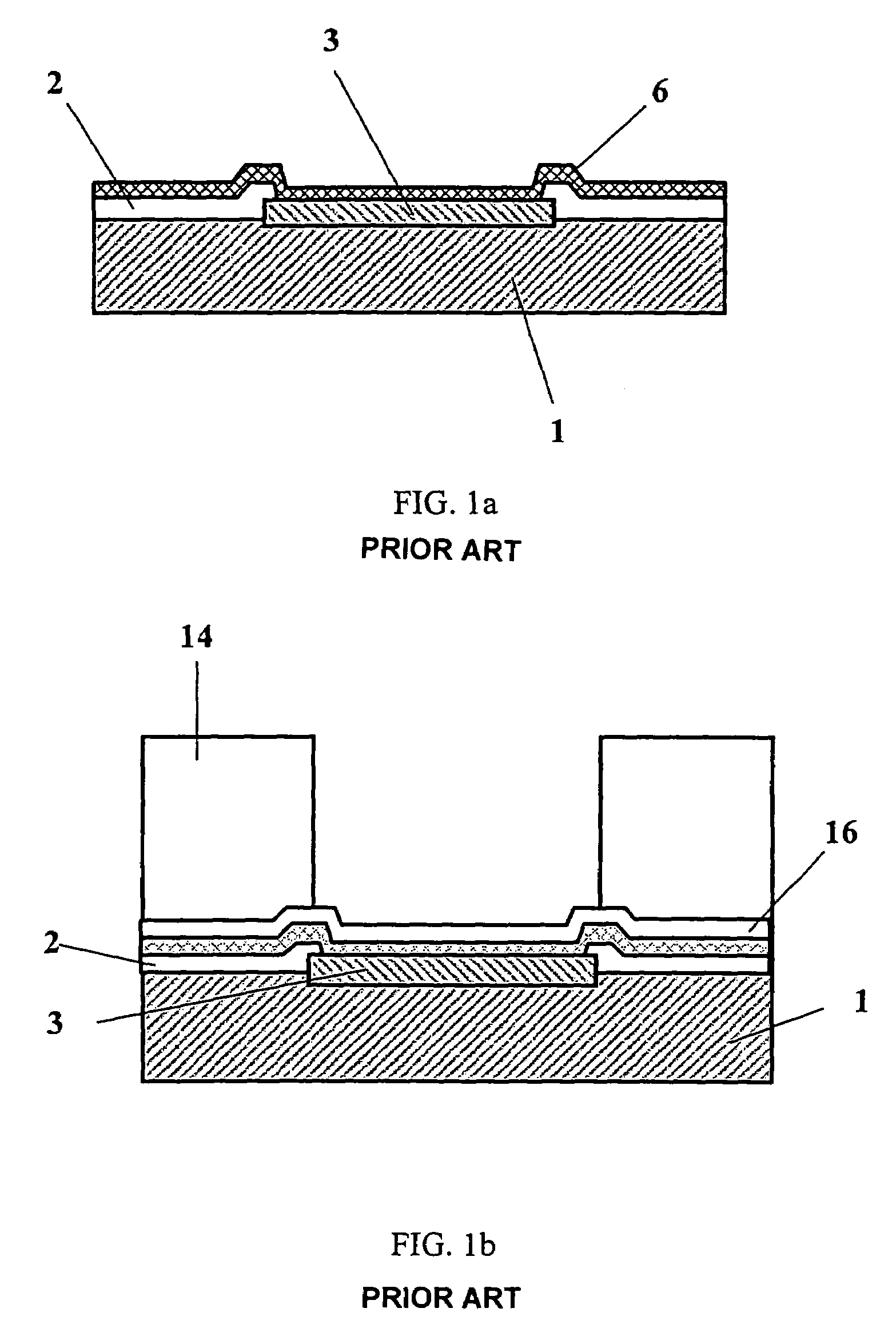

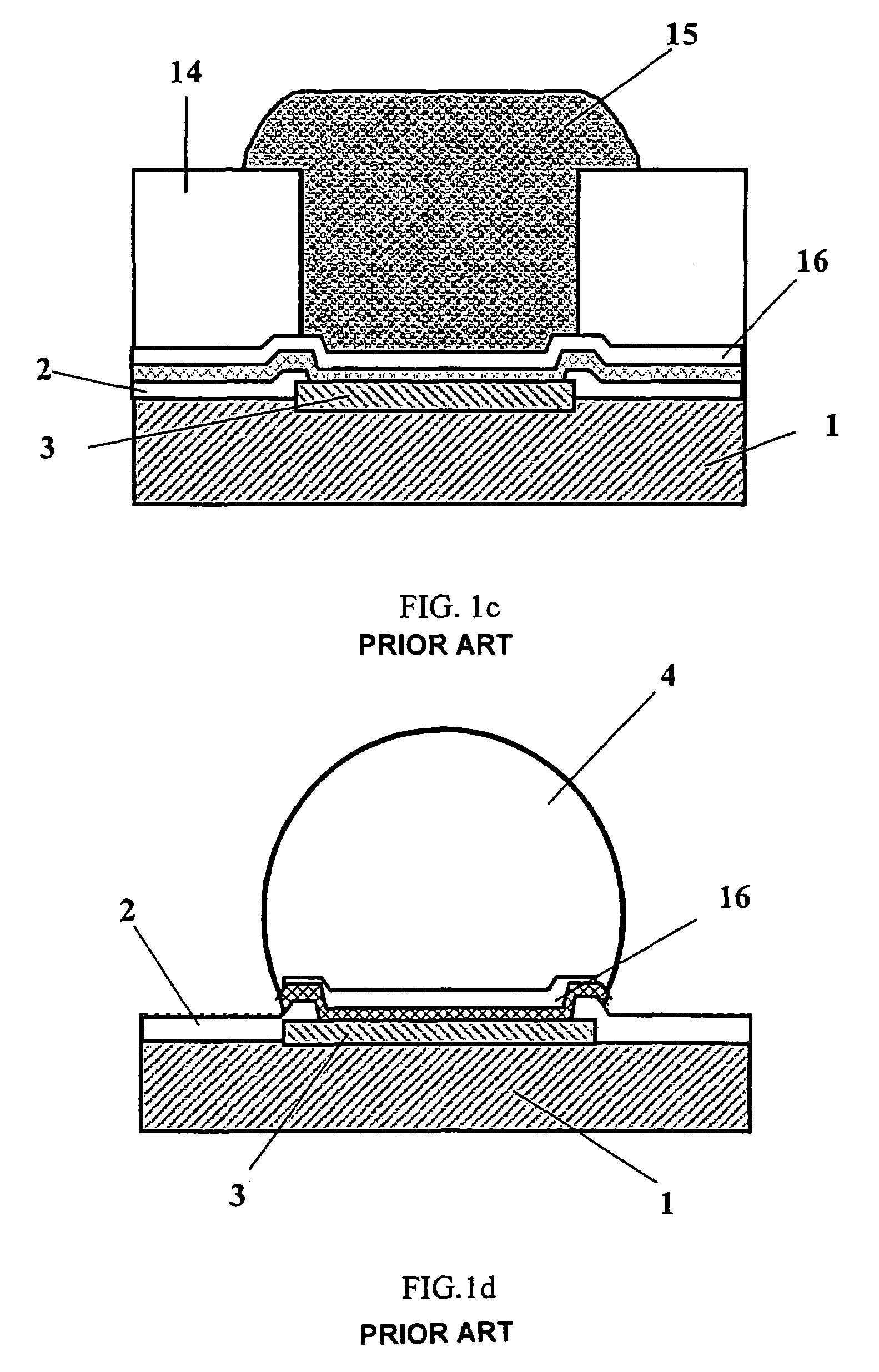

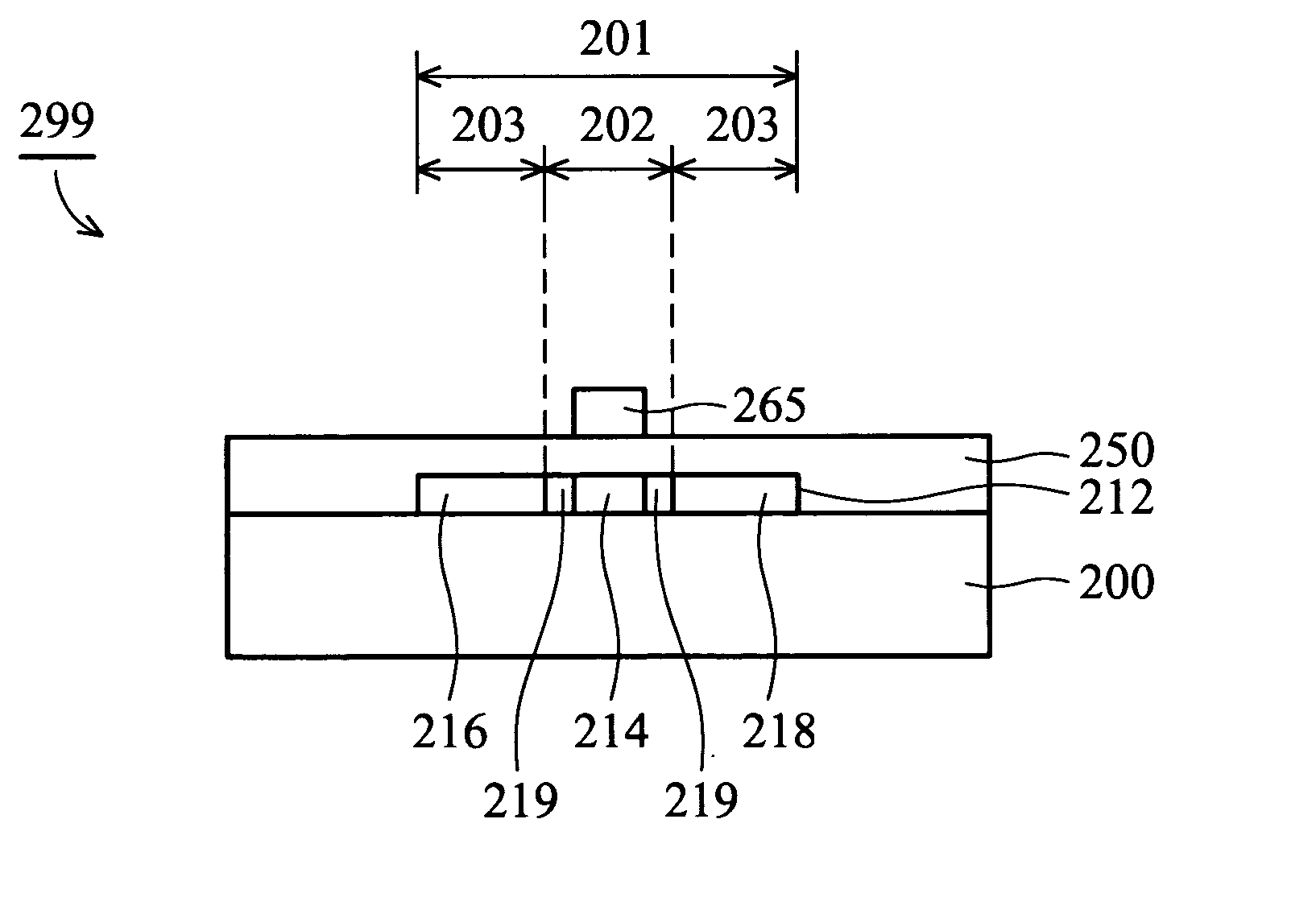

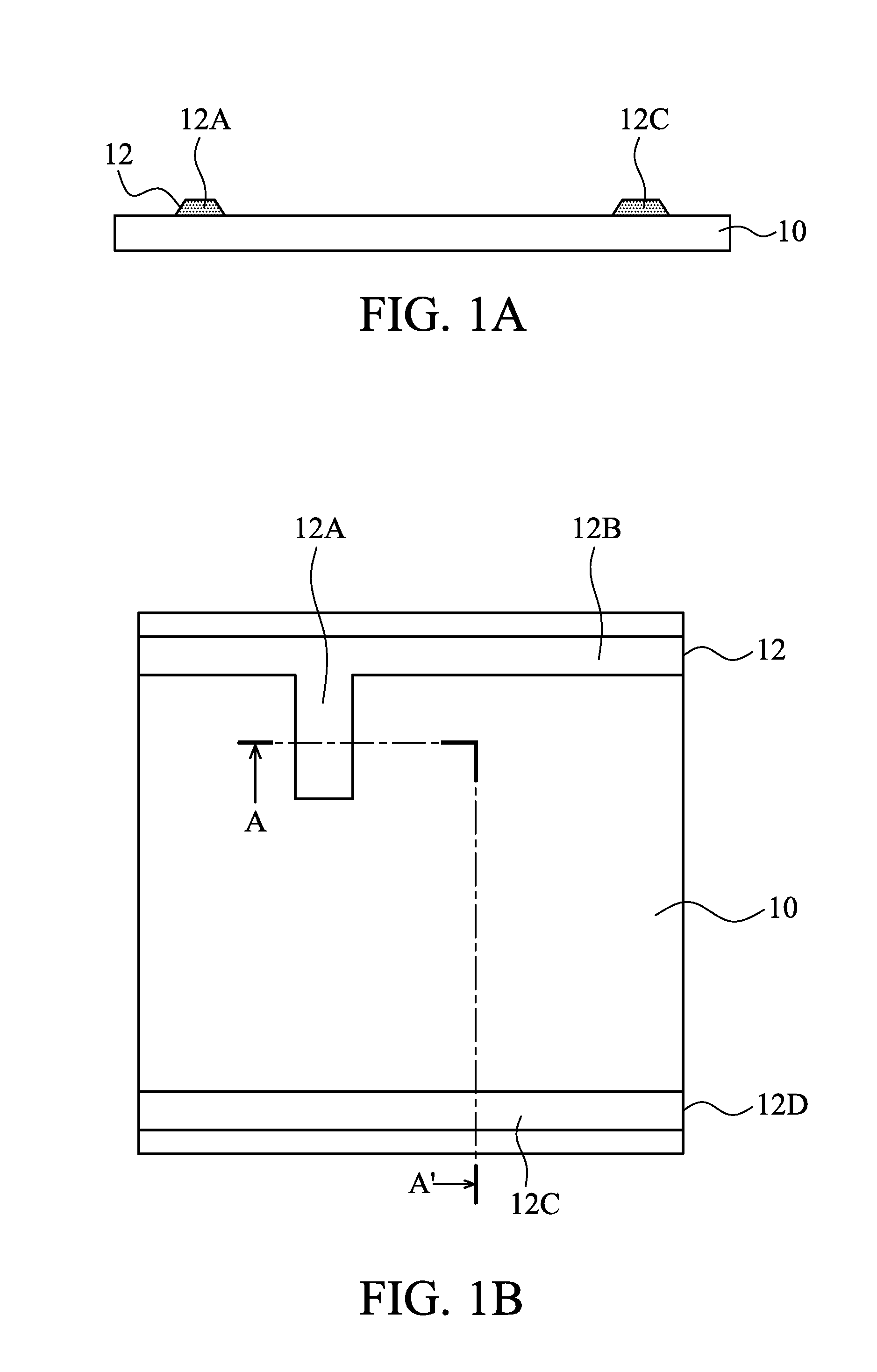

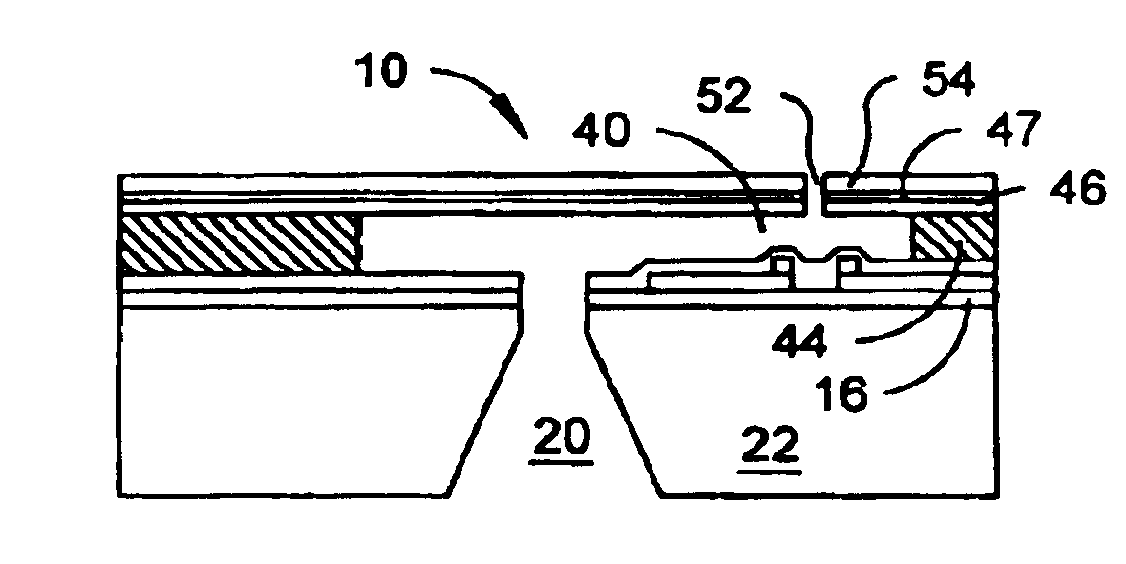

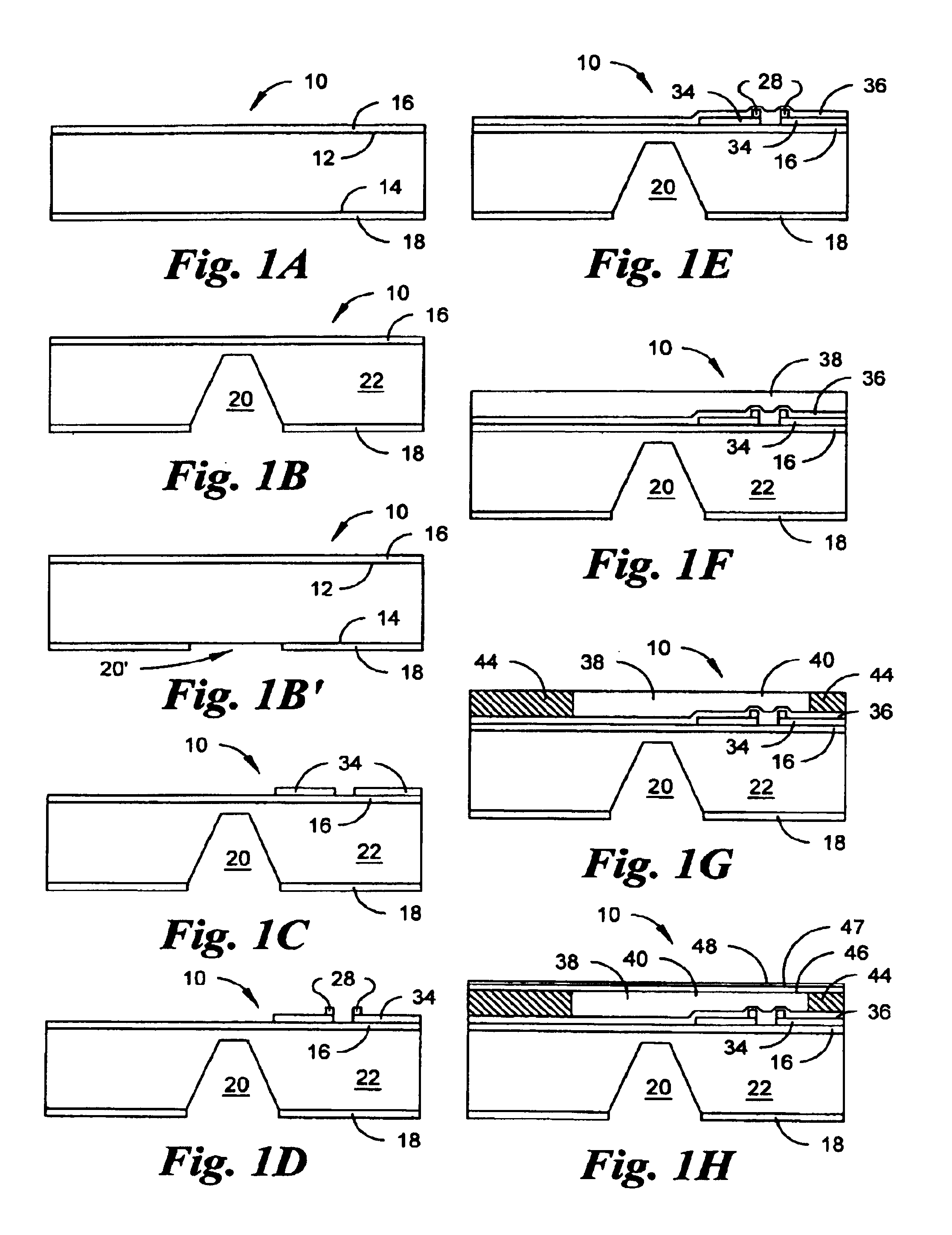

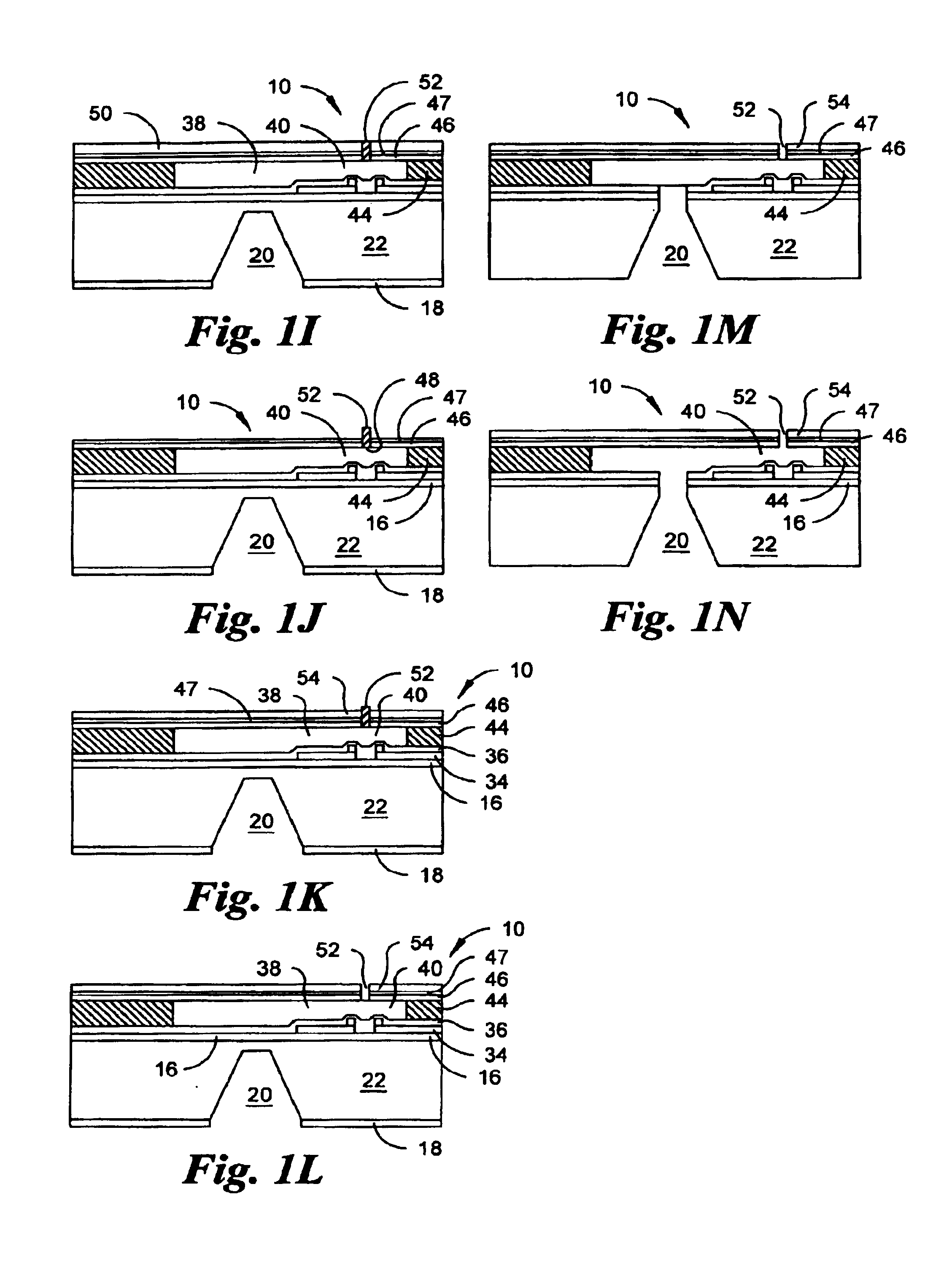

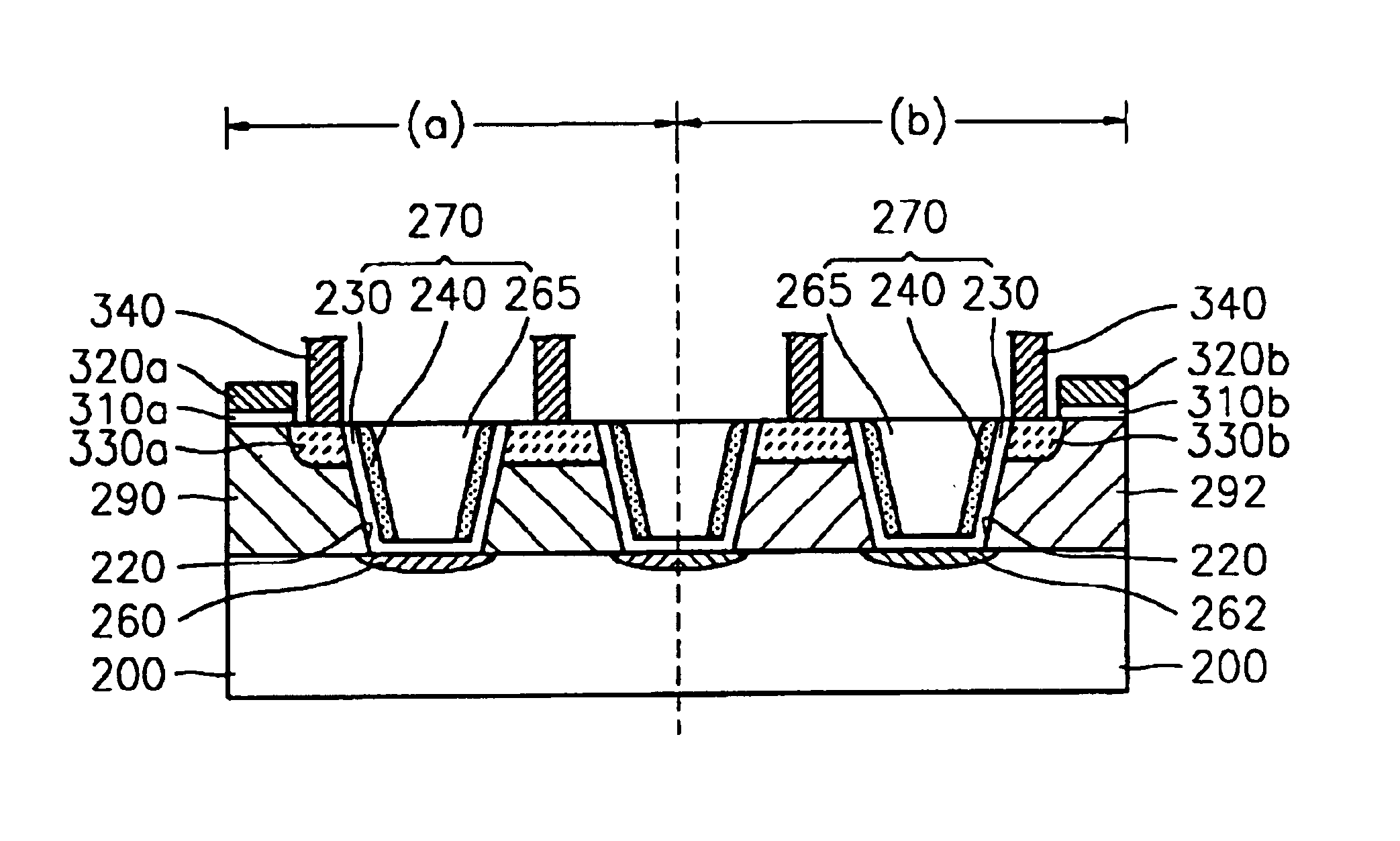

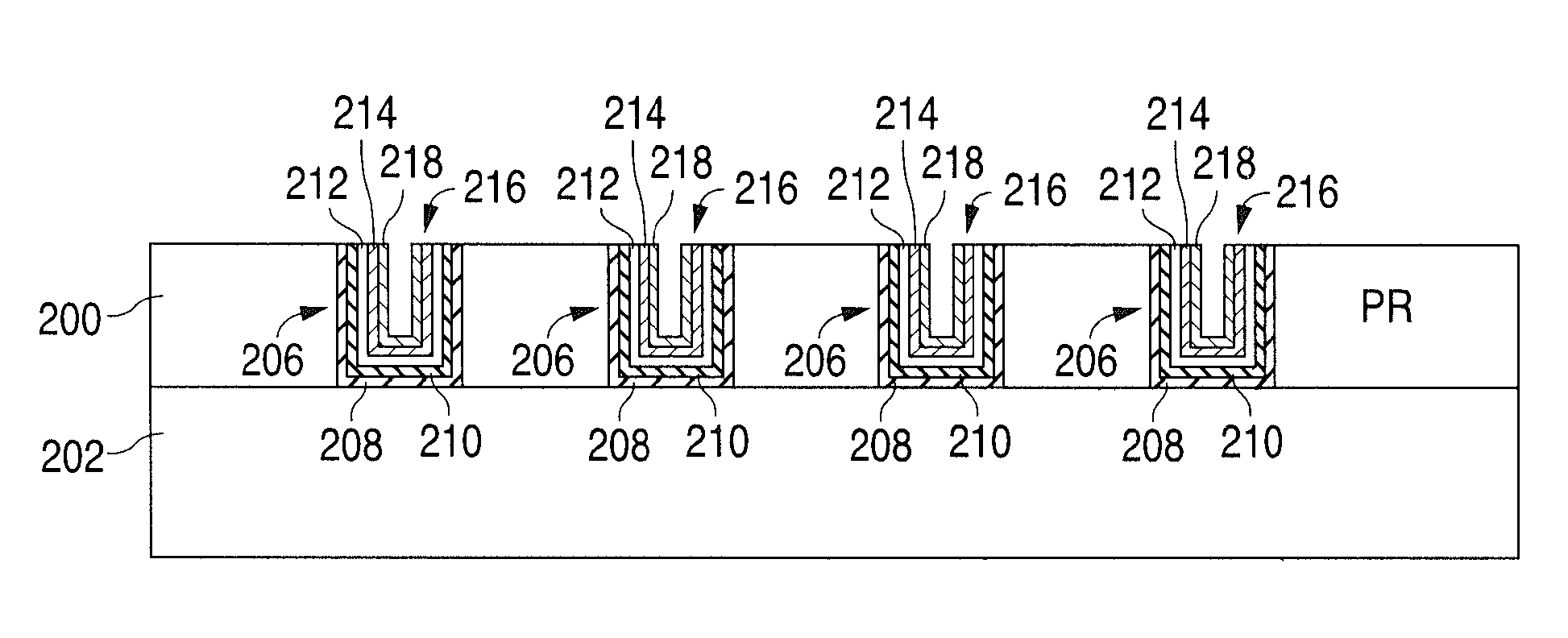

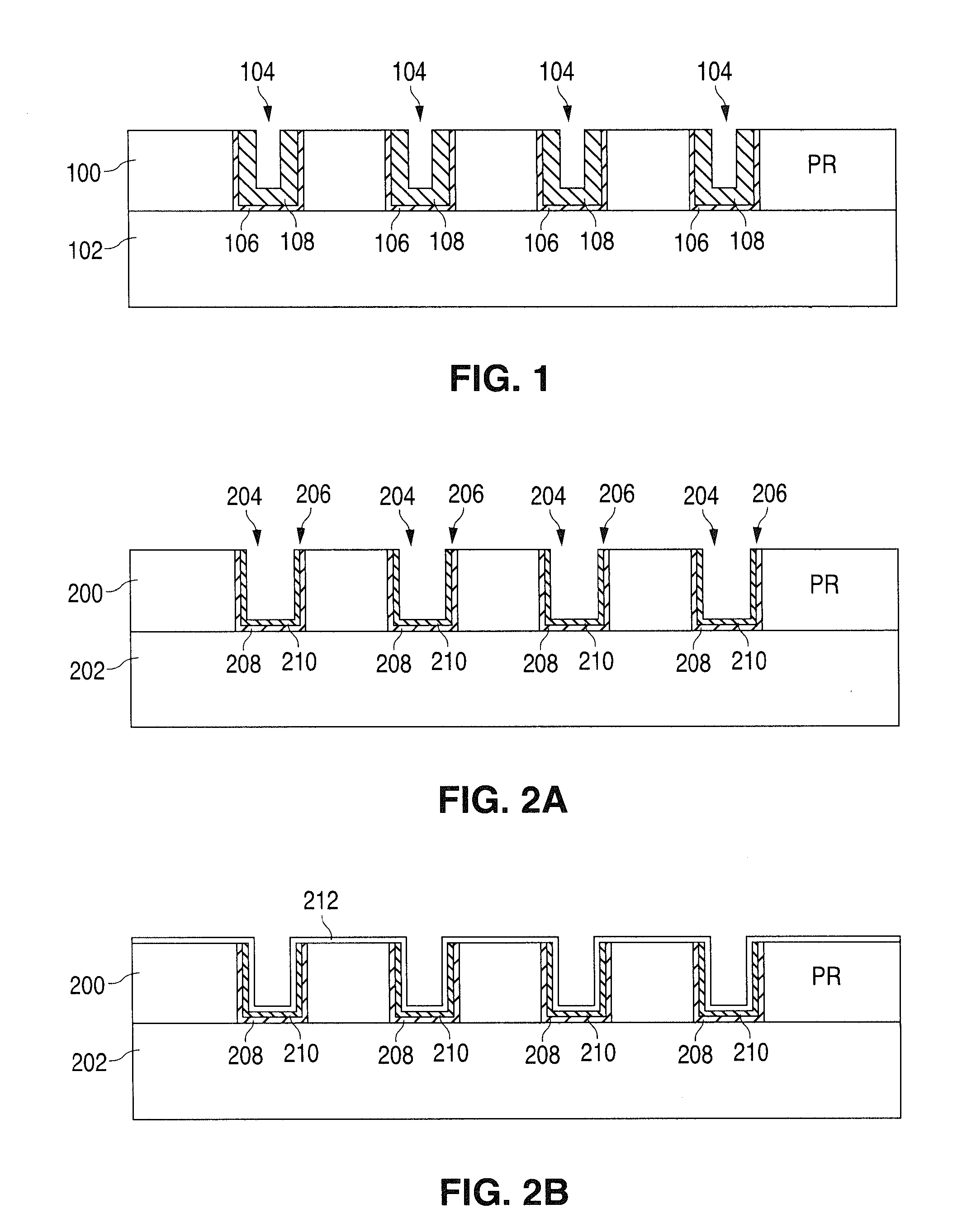

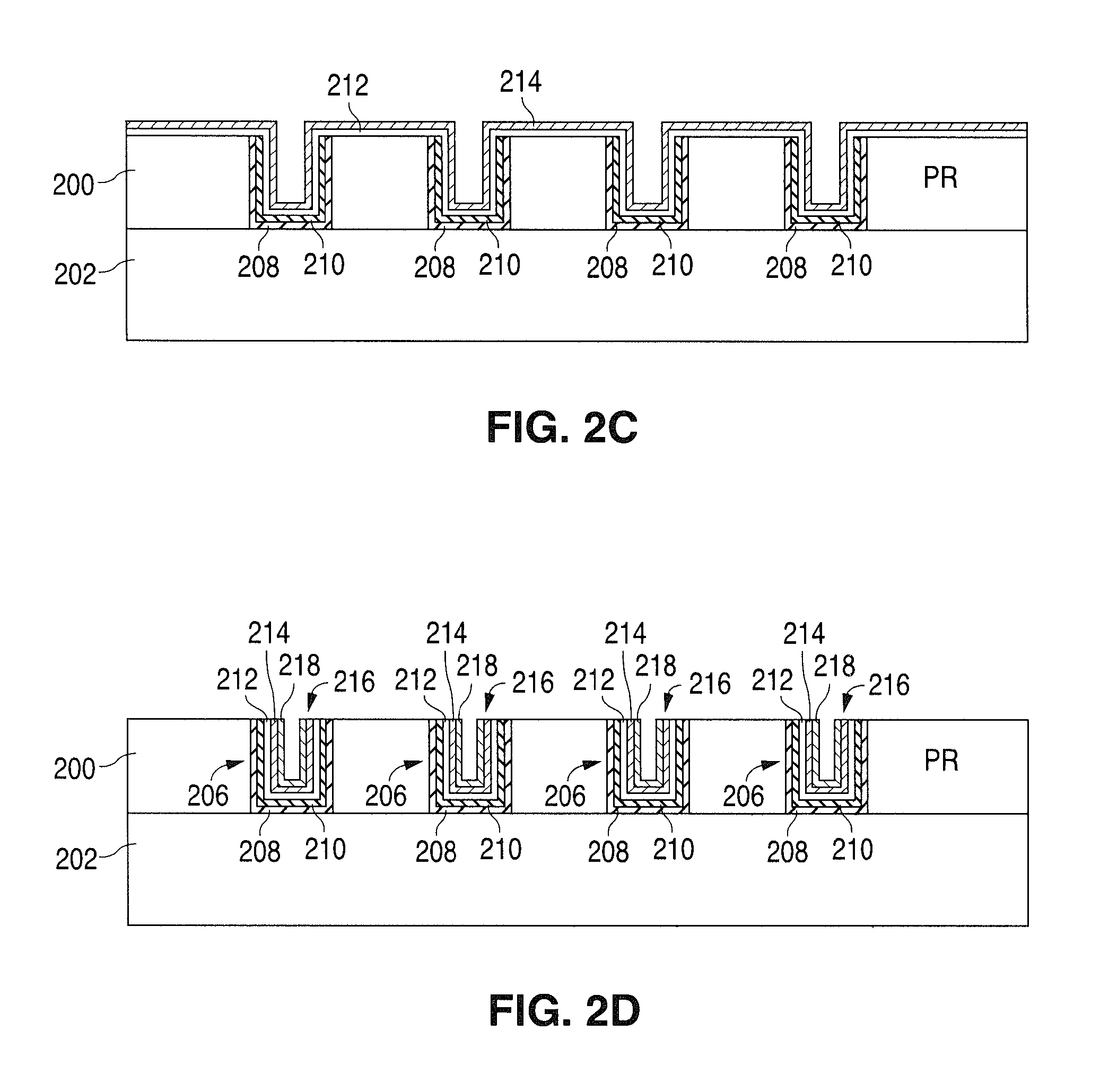

Under-bump metallization layers and electroplated solder bumping technology for flip-chip

ActiveUS20050014355A1Increase solder formationWell formedSemiconductor/solid-state device detailsSolid-state devicesControl layerManufacturing technology

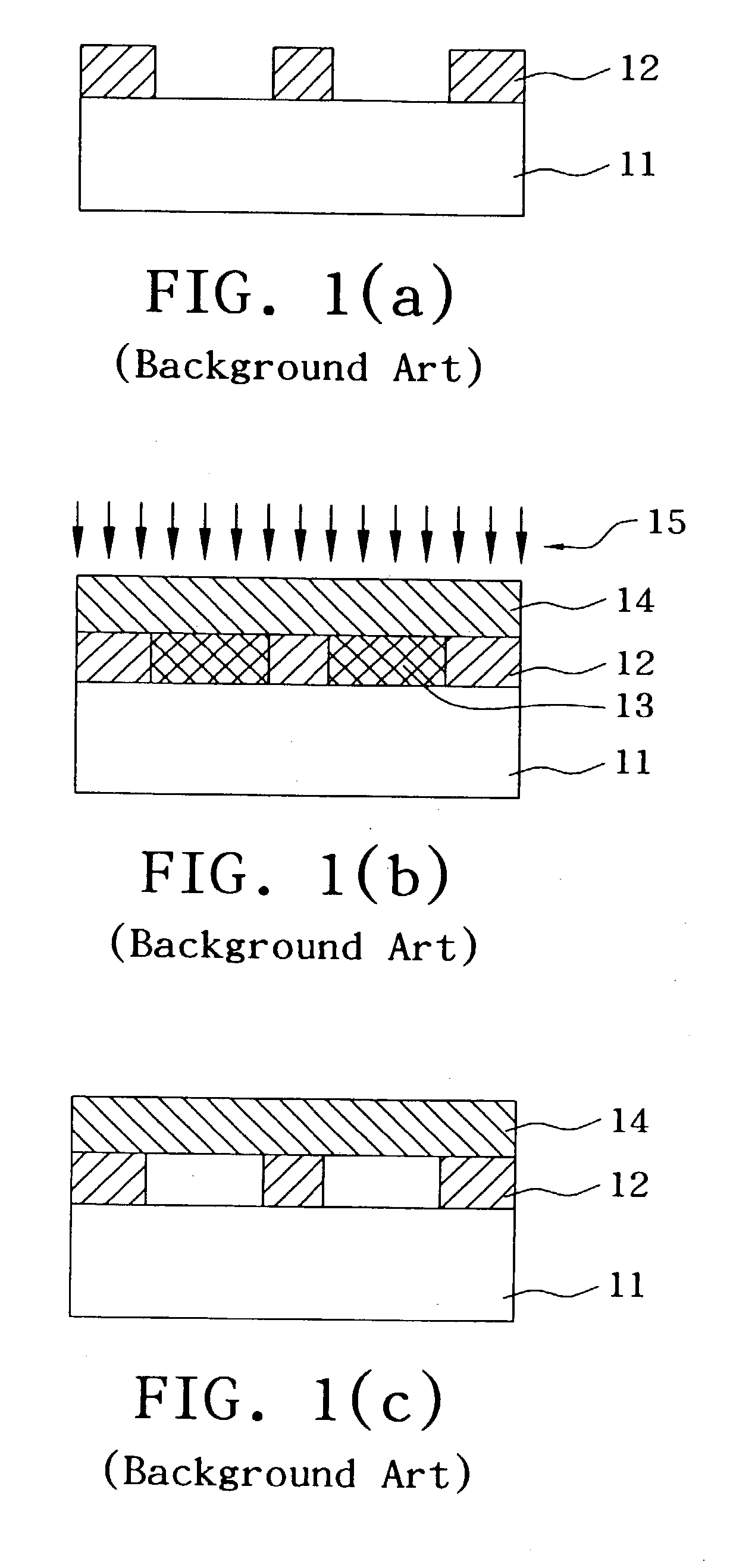

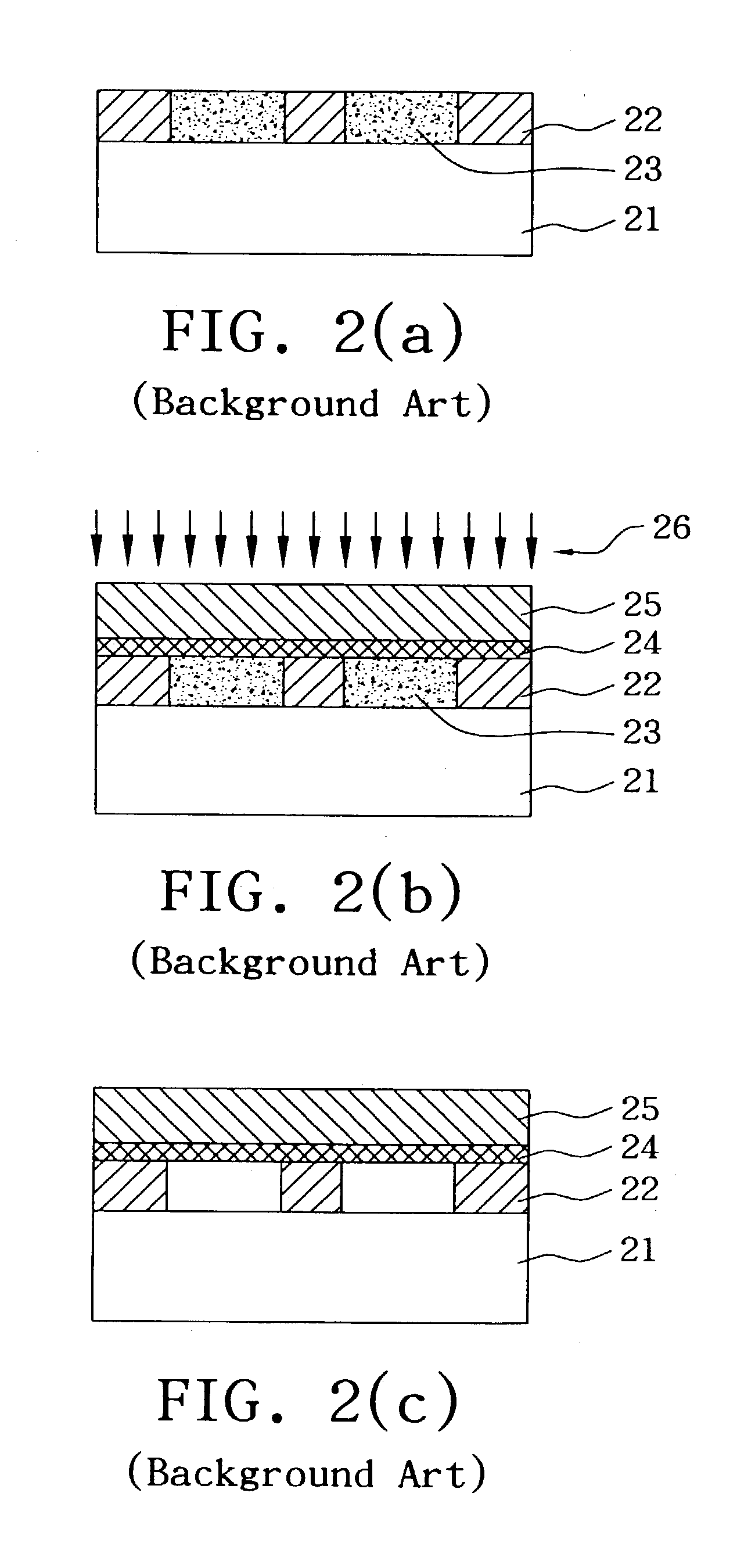

A series of improved processes and methods to manufacture solder bumps on the wafer which shrink the space among solder bumps and reduce the cost of manufacturing. A design method and a relevant manufacturing process are introduced to form an organic material or metal material layer, which is called a Bump-Reflow-Control Layer. The pad patterns can be defined by this method. A mechanical part is designed with a hermetic cover to improve the photoresist process. The series of photolithography process including the designing method of related photolithography mask is introduced to achieve the high quality and thick photoresist.

Owner:THE HONG KONG UNIV OF SCI & TECH

Plating method

ActiveUS7344970B2Improve thickness uniformitySolid-state devicesSemiconductor/solid-state device manufacturingThick photoresistChemistry

Photoresist compositions and methods suitable for depositing a very thick photoresist layer in a single coating process are provided. Such photoresist layers are particularly suitable for use in chip scale packaging.

Owner:SHIPLEY CO LLC

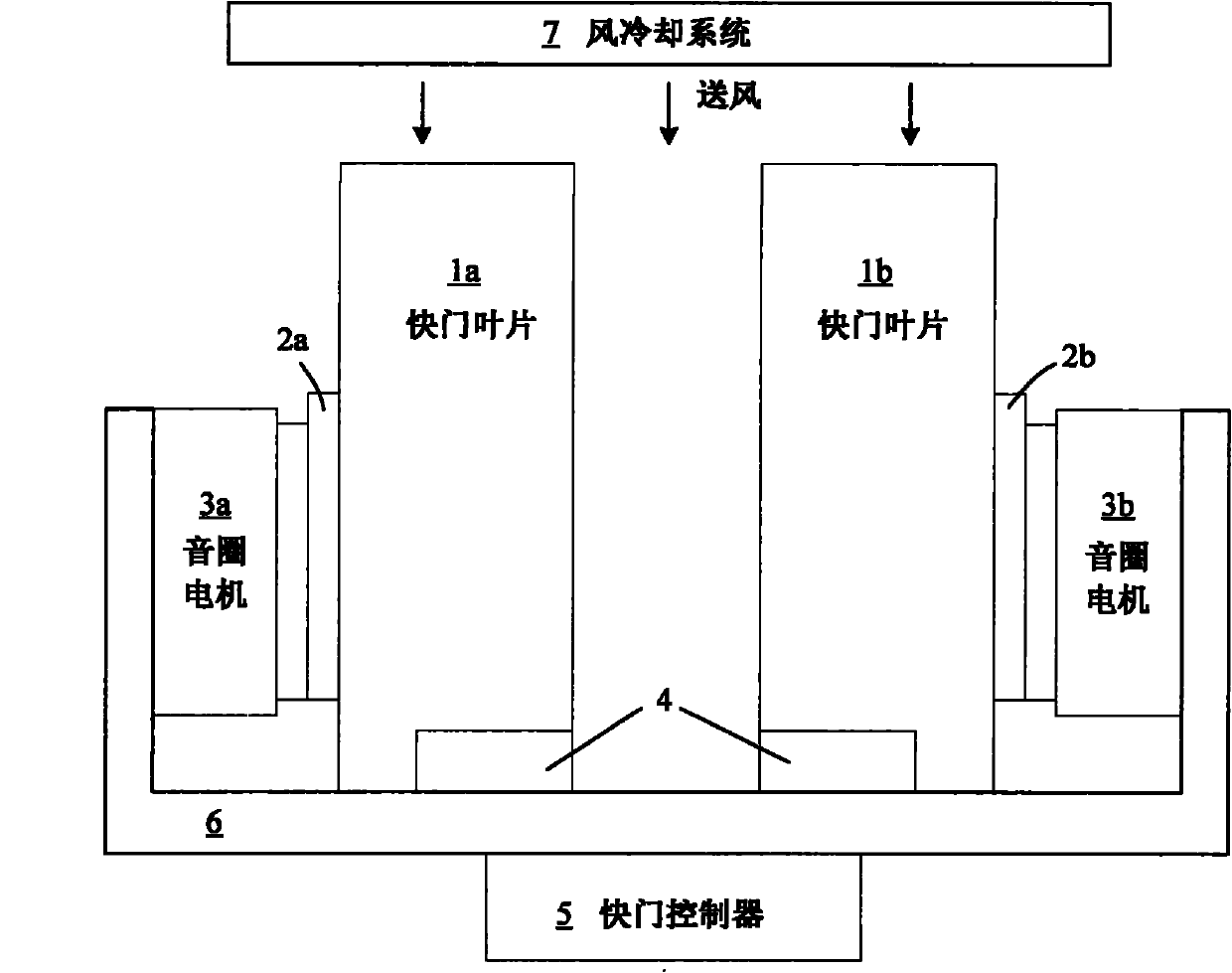

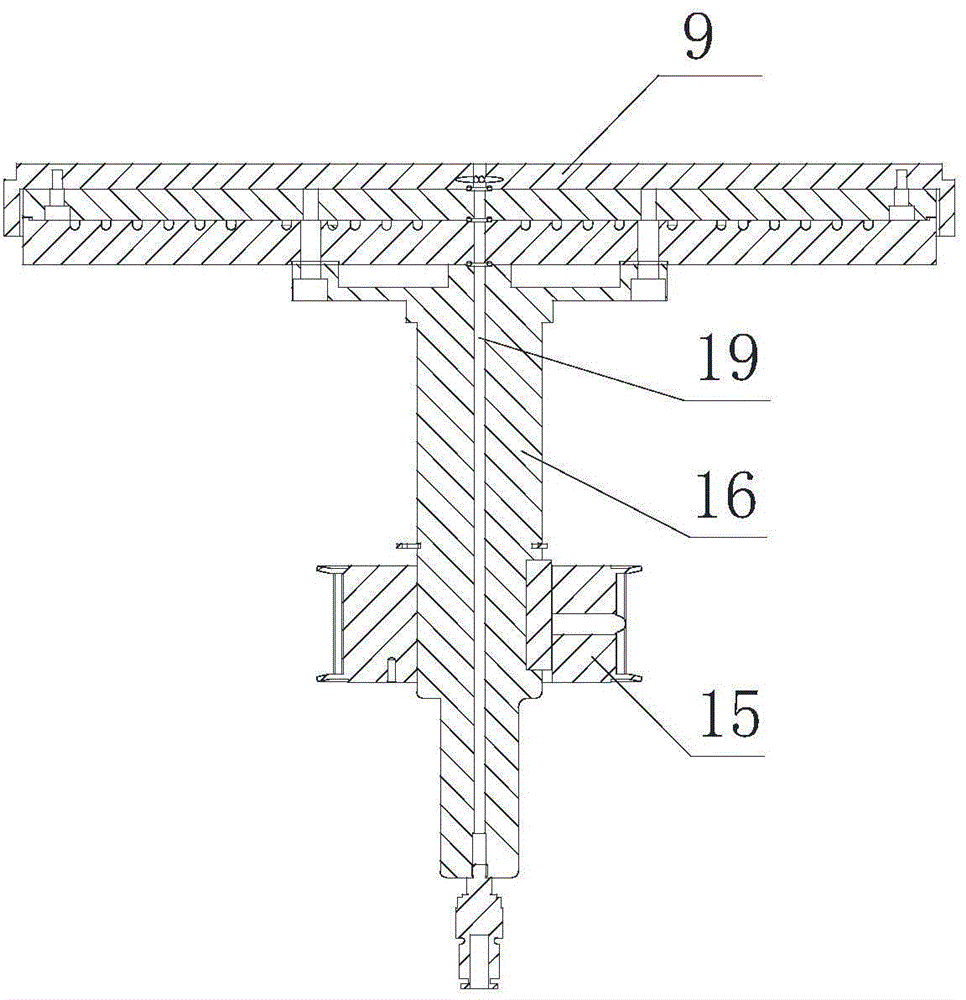

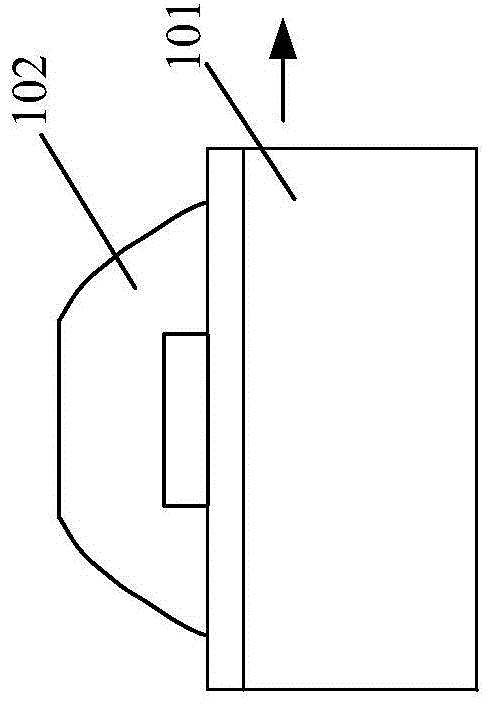

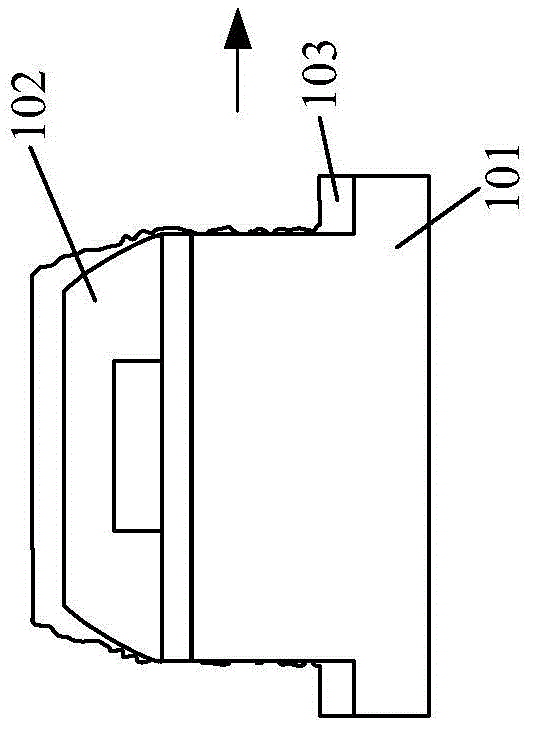

Shutter device for exposure subsystem of photoetching machine

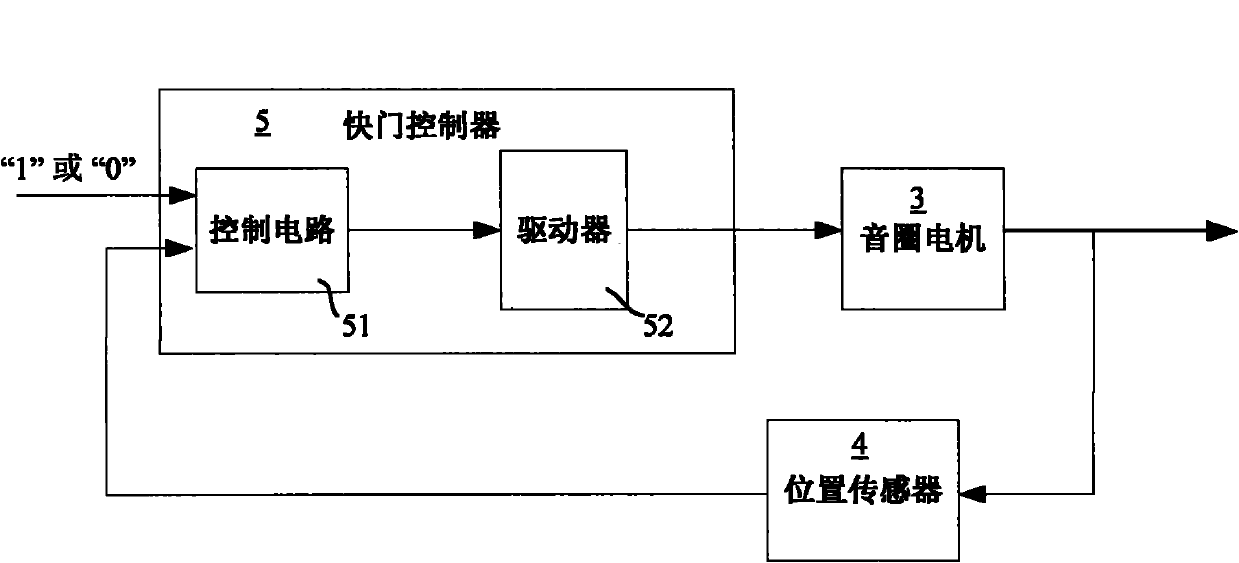

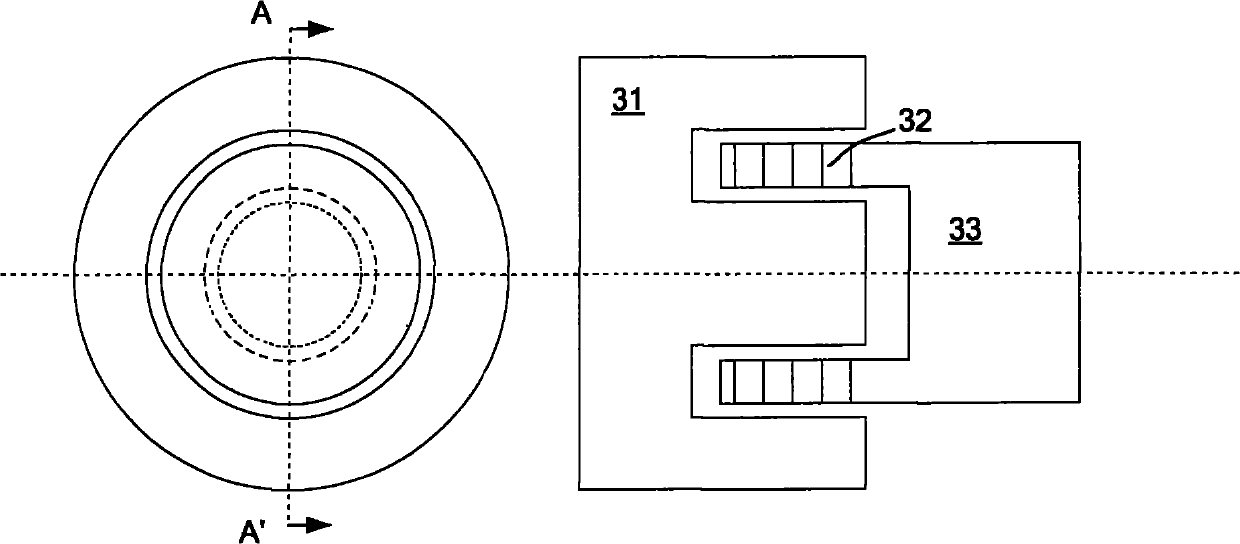

InactiveCN102087476ARealize the photolithography processFast shutter speedPhotomechanical exposure apparatusMicrolithography exposure apparatusMotor driveControl theory

The technical problem to be solved by the invention is to provide a shutter device for an exposure subsystem of a photoetching machine. The shutter device comprises at least one shutter blade, a shutter controller, a position sensor, a bracket and a voice coil motor, wherein the shutter controller is used for controlling opening and closing of the shutter blade; the positioning sensor is coupled with the shutter controller and the shutter blade and provides movement position information of the shutter blade for the shutter controller; the bracket is positioned below the shutter controller and the position sensor and is used for supporting the voice coil motor and the position sensor; the voice coil motor is controlled by the shutter controller to move; the voice coil motor is positioned on the bracket, is coupled with the shutter controller and is controlled by the shutter controller to move; the voice coil motor drives the shutter blade to move so as to form the operation of opening and closing the shutter blade; and the thickness of the shutter blade is 0.5 to 2mm. The shutter device is suitable for a large-dose exposure device. Due to the adoption of the shutter device, a thin photoresist process and a thick photoresist process can be realized simultaneously and on the premise of guaranteeing the speed of a shutter, the service life of the shutter in the high temperature environment is prolonged.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

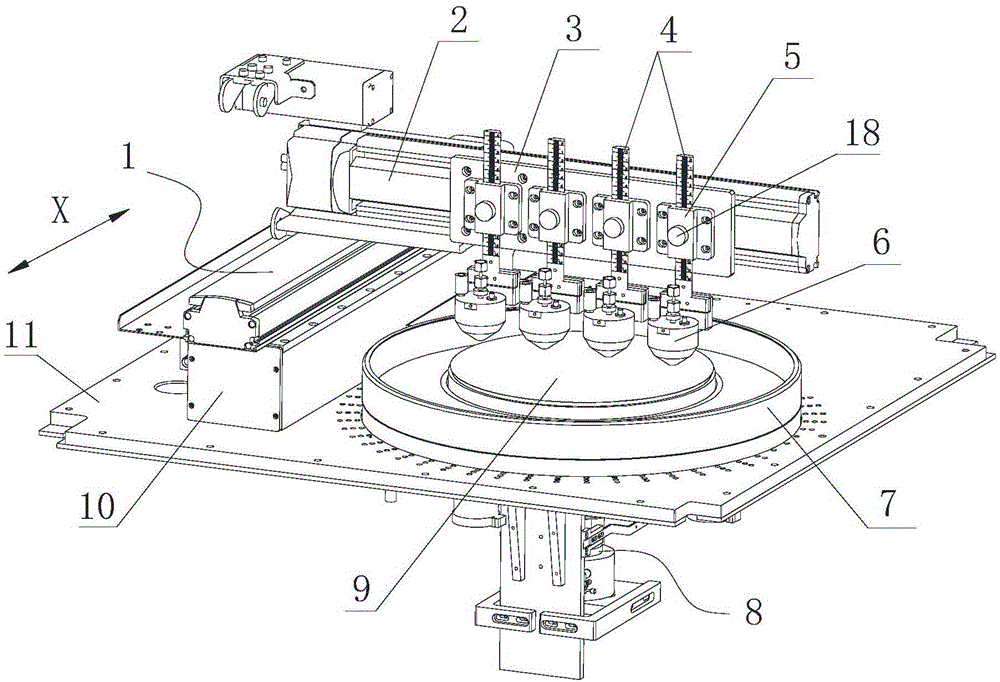

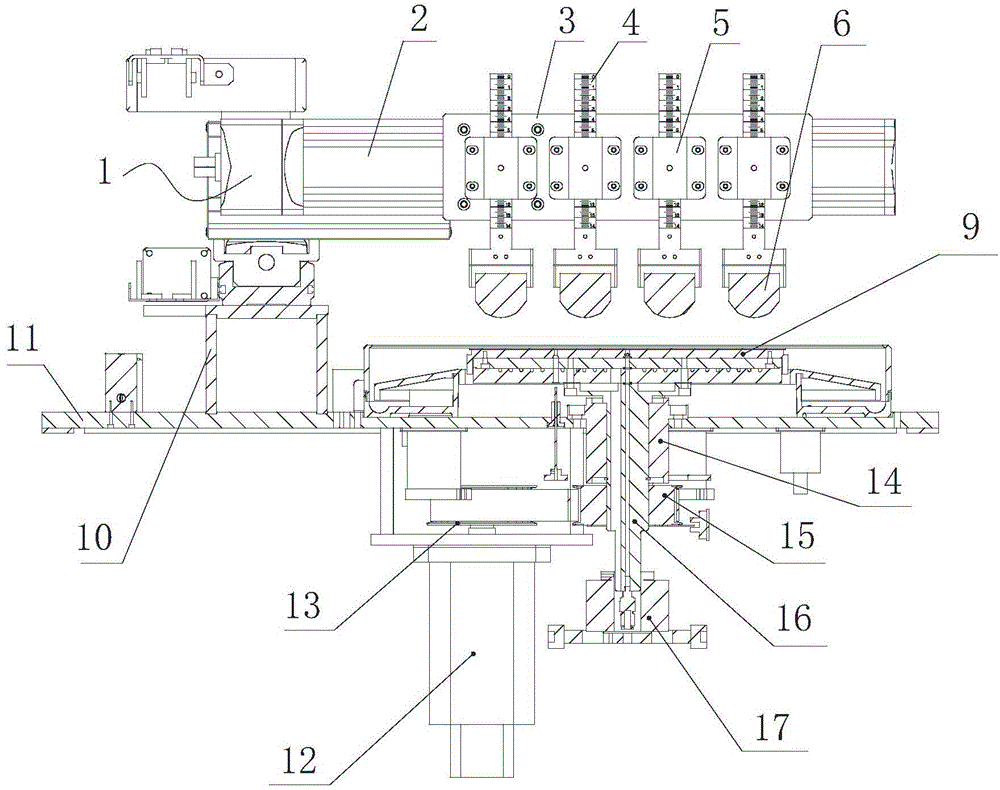

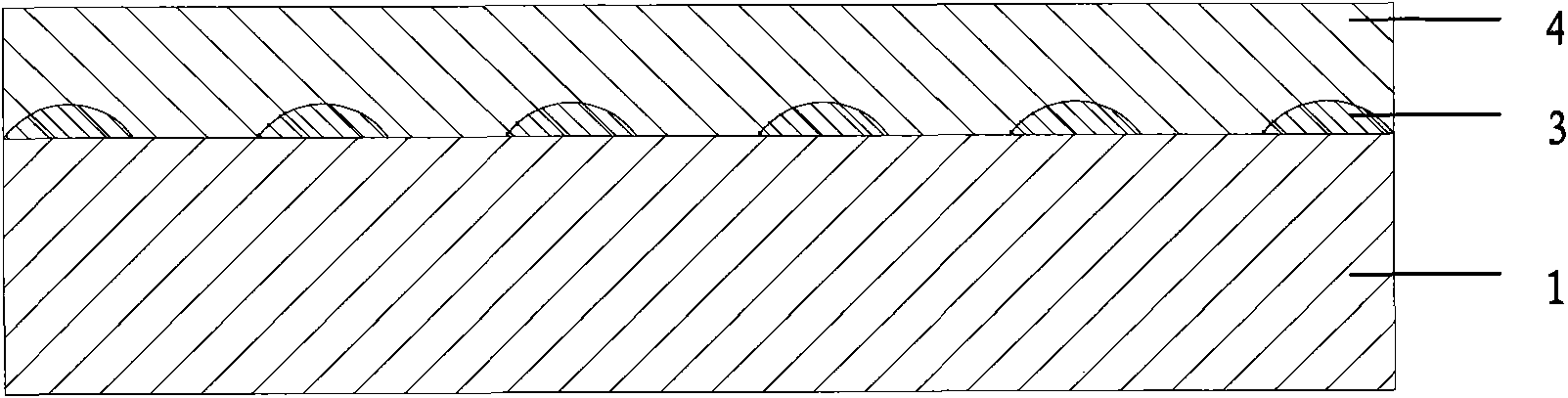

Semiconductor made thick photoresist film coating device and application method thereof

ActiveCN105772323AUniform film thicknessAvoid bumpingLiquid surface applicatorsSpraying apparatusEngineeringFilm-coated tablet

The invention relates to the field of semiconductor processing, in particular to a semiconductor made thick photoresist film coating device and an application method thereof. The semiconductor made thick photoresist film coating device comprises an electric cylinder, spraying heads, a photoresist cup assembly, a rotary adsorption mechanism and a base plate. The electric cylinder and the photoresist cup assembly are both arranged on the base plate. A movable beam is arranged on the electric cylinder. The spraying heads spraying heads of which the intervals and the height can be all adjusted are arranged on the movable beam. The rotary adsorption mechanism is provided with a rotary adsorption disk used for adsorbing a wafer. The adsorption disk is arranged in the middle of the photoresist cup assembly. During photoresist film coating, the spraying heads are driven by the movable beam of the electric cylinder to move horizontally above the adsorption disk. The to-be-processed wafer is put on the adsorption disk. The multiple spraying heads are driven by the electric cylinder to move synchronously and horizontally and spraying photoresist, and then the wafer is fixedly adsorbed by the adsorption disk. The multiple spraying heads are driven by the electric cylinder to move synchronously and horizontally and spray the atomized photoresist. According to the semiconductor made thick photoresist film coating device and the application method thereof, even spraying is ensured, the film thickness of the whole wafer is made to be uniform, and edge protrusions of the wafer is avoided completely.

Owner:SHENYANG KINGSEMI CO LTD

Under-bump metallization layers and electroplated solder bumping technology for flip-chip

ActiveUS7199036B2Increase solder formationWell formedSemiconductor/solid-state device detailsSolid-state devicesControl layerManufacturing technology

A series of improved processes and methods to manufacture solder bumps on the wafer which shrink the space among solder bumps and reduce the cost of manufacturing. A design method and a relevant manufacturing process are introduced to form an organic material or metal material layer, which is called a Bump-Reflow-Control Layer. The pad patterns can be defined by this method. A mechanical part is designed with a hermetic cover to improve the photoresist process. The series of photolithography process including the designing method of related photolithography mask is introduced to achieve the high quality and thick photoresist.

Owner:THE HONG KONG UNIV OF SCI & TECH

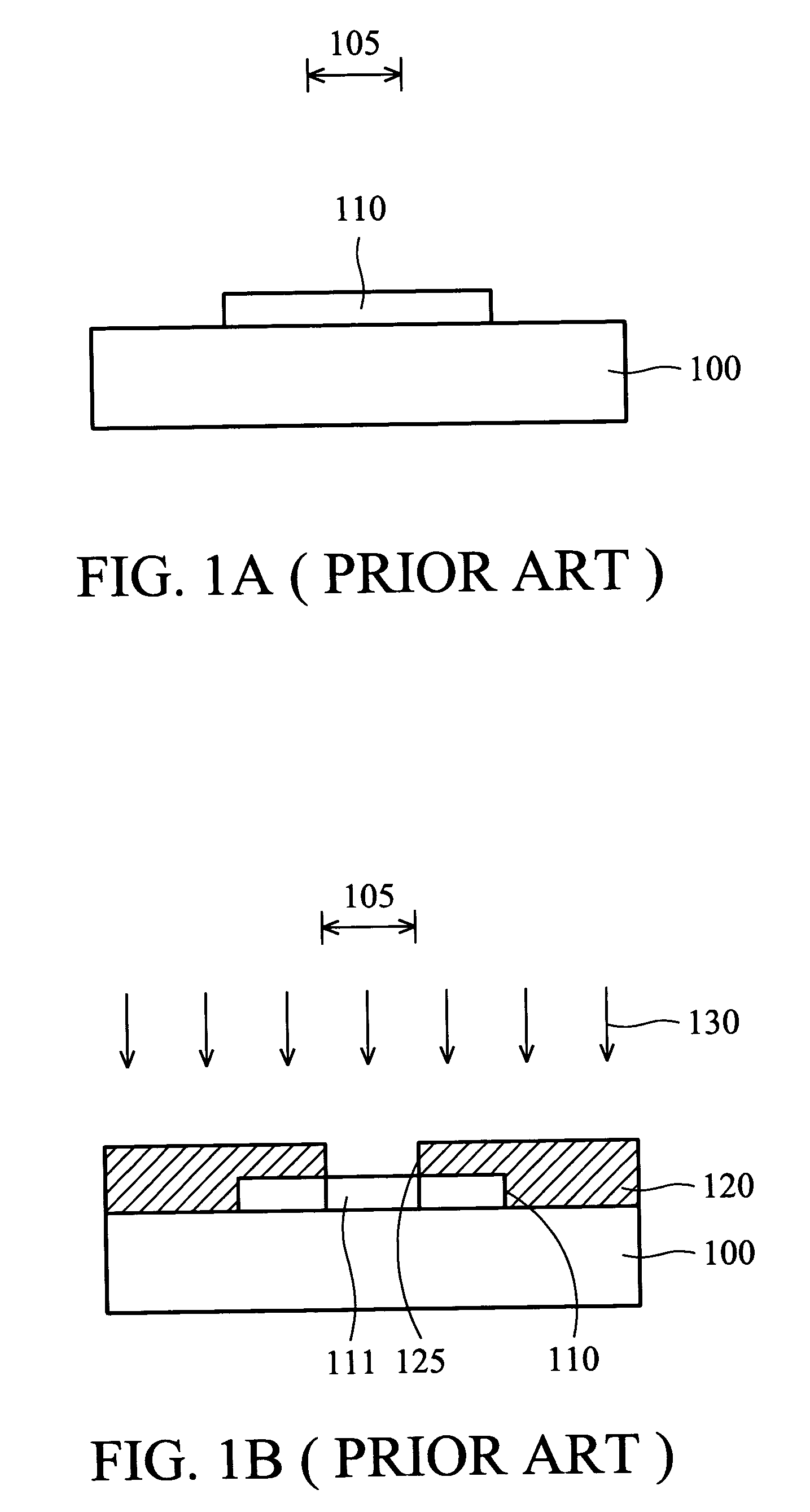

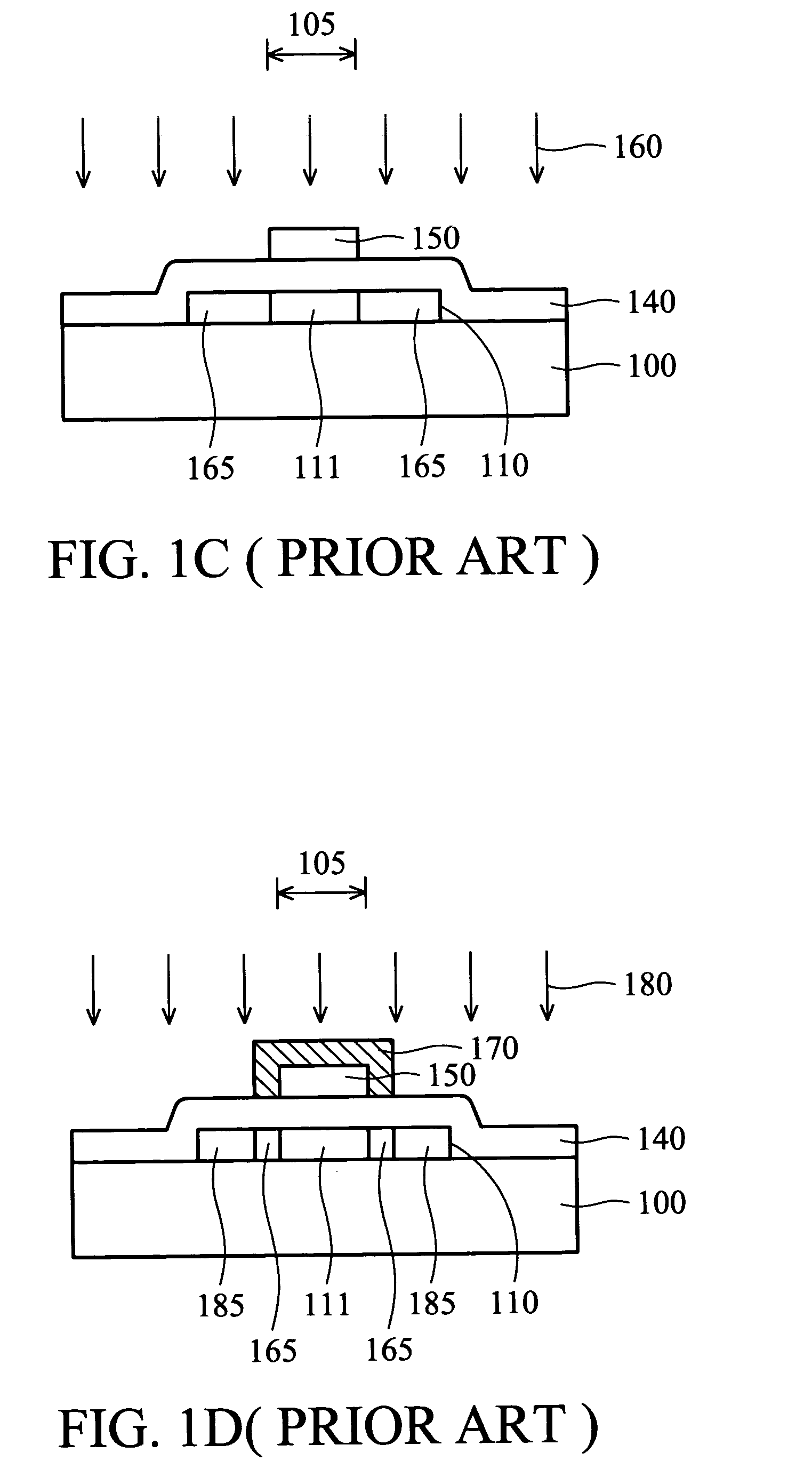

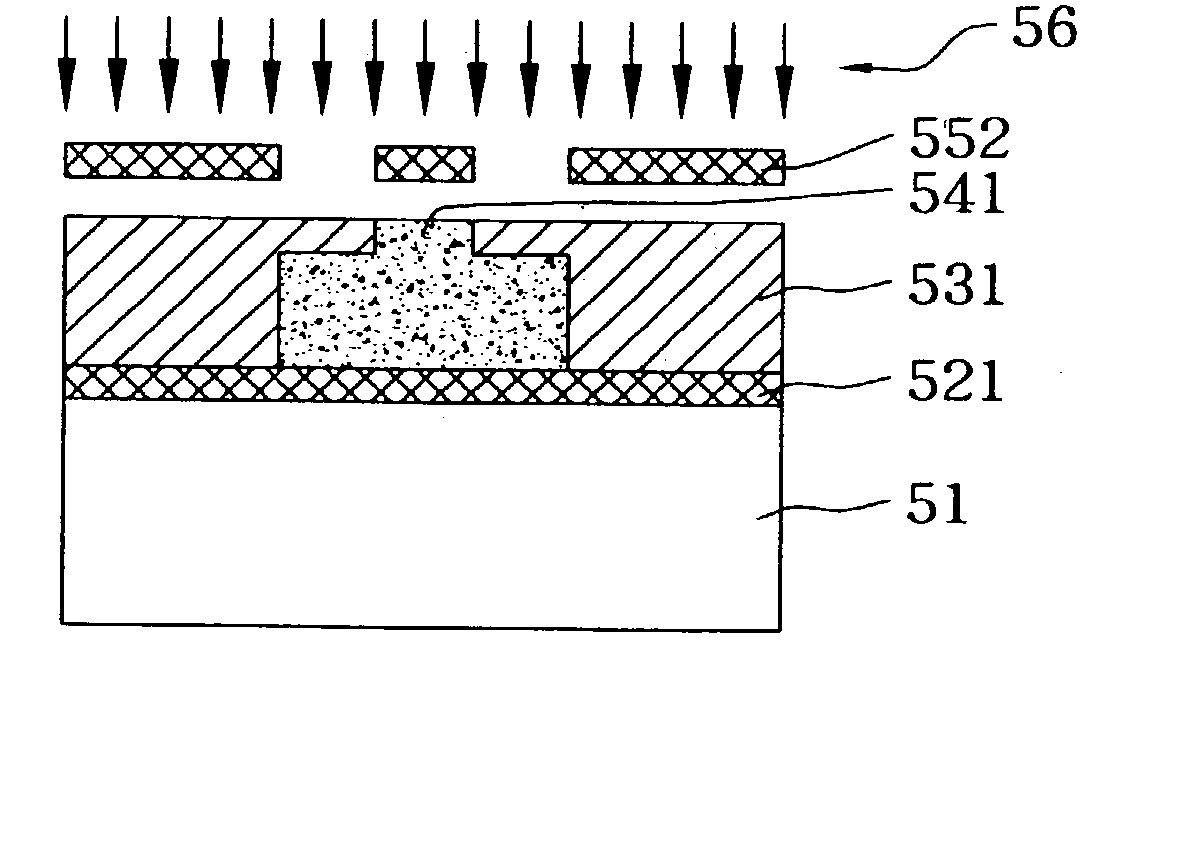

Method of forming a top gate thin film transistor

InactiveUS20050250050A1Decrease reticle consumptionLow costTransistorPhotomechanical apparatusResistThick photoresist

A method of forming a top gate thin film transistor (TFT). By performing photolithography using a first reticle, a photoresist layer having a thick photoresist layer portion and a thin photoresist layer portion is formed on a silicon layer in an active area. Thus, a channel layer and source / drain regions in a silicon island are defined by the same patterning process. In addition, a gate and an LDD region in the silicon island are defined by photolithography using a second reticle and a backside exposure process. Accordingly, the top gate TFT fabrication process of the present invention requires only two reticles, and thereby reduces costs.

Owner:IND TECH RES INST

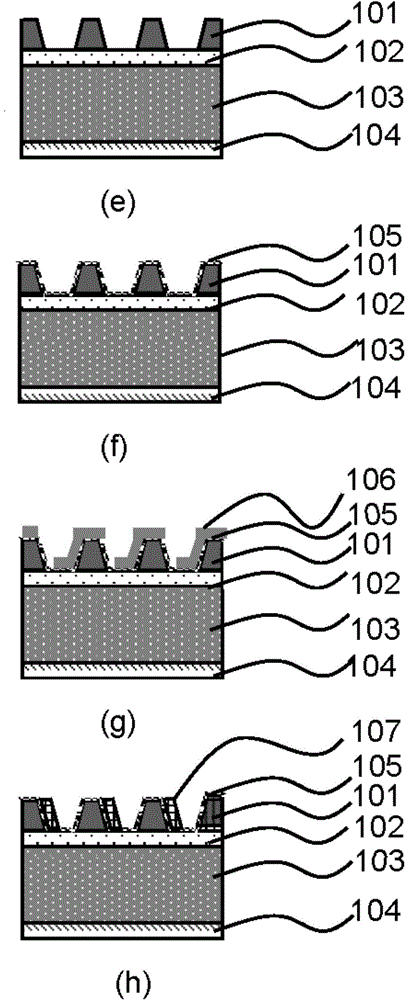

Method for manufacturing gecko-foot-seta-inspired biomimetic array

ActiveCN105460885AThe preparation process is stableImprove yieldDecorative surface effectsChemical vapor deposition coatingBiomimeticsThick photoresist

The invention discloses a method for manufacturing a gecko-foot-seta-inspired biomimetic array. The method can comprise the following steps: selecting a material of which an upper layer is (100) type silicon and a lower layer is provided with a self-etching stopping layer to serve as a substrate; depositing an etching resistant layer on the surface of the upper silicon layer and patterning the etching resistant layer to form an etching resistant mask; corroding an exposed silicon structure through a silicon anisotropic etching method to form a strip with a trapezoidal cross section; removing the remaining etching resistant mask to expose the silicon structure; coating the silicon structure with a photoresist through a photoresist spraying process or a thick photoresist spin-coating method, and performing photoetching; depositing a seta structure with metal or other materials, and peeling the residual photoresist; and lastly, releasing sacrificial layer silicon through silicon isotropic etching to form the gecko-foot-seta-inspired biomimetic structural array. The method is simple in process, high in yield and suitable for large-scale manufacturing. The manufactured gecko-foot-seta-inspired biomimetic array has the advantages of long service life, high structural strength and the like, and has a wide application prospect in the fields of gecko foot form bionics, and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Manufacturing method of nanoscale super resolution optical focusing device

InactiveCN103076646ASolve the defects of low transmission efficiency and weak focal spot intensityImprove resolutionNanotechnologyDiffraction gratingsLength waveNanoscopic scale

The invention relates to a manufacturing method of a nanoscale super resolution optical focusing device, which comprises the following steps that S1 an operating wavelength of incident light is selected, a euphotic substrate is selected, a metal film is evaporated and coated on a surface, and the incident light is perpendicular to the upper surface of the metal film; S2 materials of the metal film and a dielectric film are selected in accordance with the operating wavelength, and fresnel wavezone radii at all levels are designed; S3 the position of a groove band, i.e. the radius of an inner ring, is selected; S4 the width and the depth of the groove band are modulated in accordance with the requirement of the intensity of focal spots; S5 the orientation of the groove band is selected in accordance with a polarization state of the incident light; S6 a processing technique is utilized to obtain metal masks of fresnel wavezone annular gaps and grooves; S7 nanometer-thick metal and dielectric multilayer film structures are alternately evaporated and coated on back surfaces of the metal masks, and the total thickness of a multilayer film is deposited as a focal length of a lens; and S8 a layer of nanometer-thick photoresist and a layer of reflecting metal layer are evaporated and coated on the multilayer film structures, and then the nanoscale super resolution optical focusing device is obtained.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

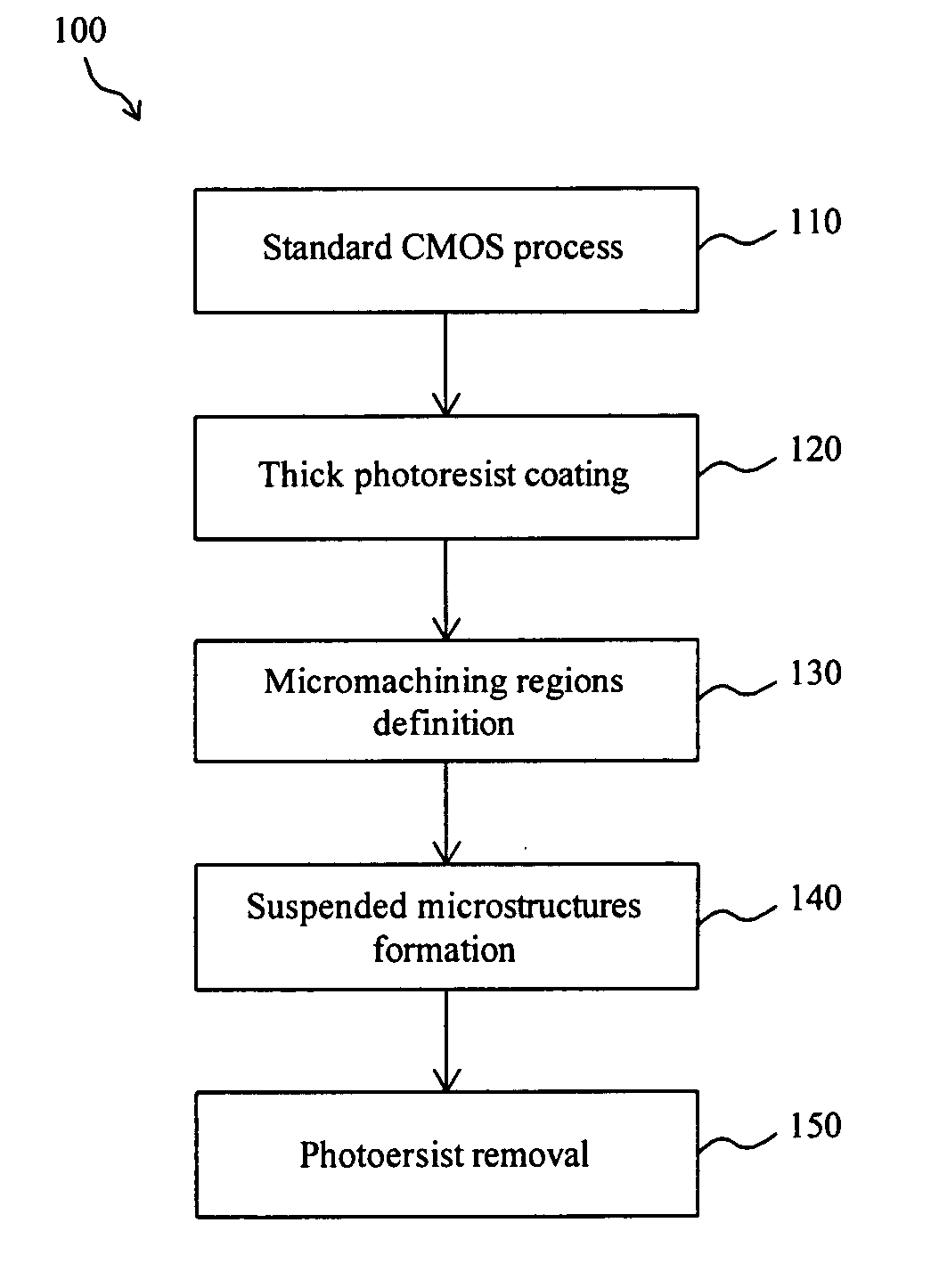

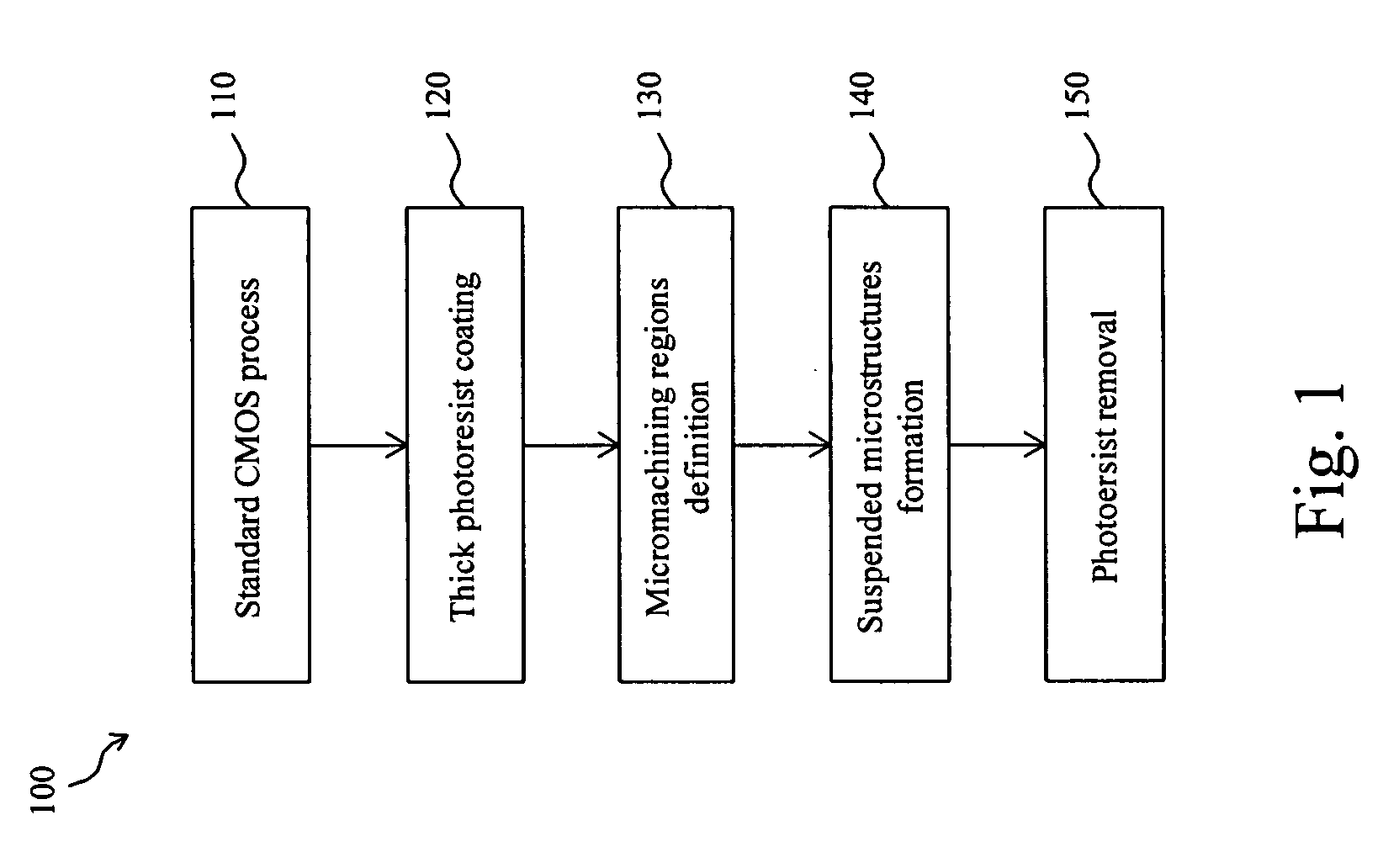

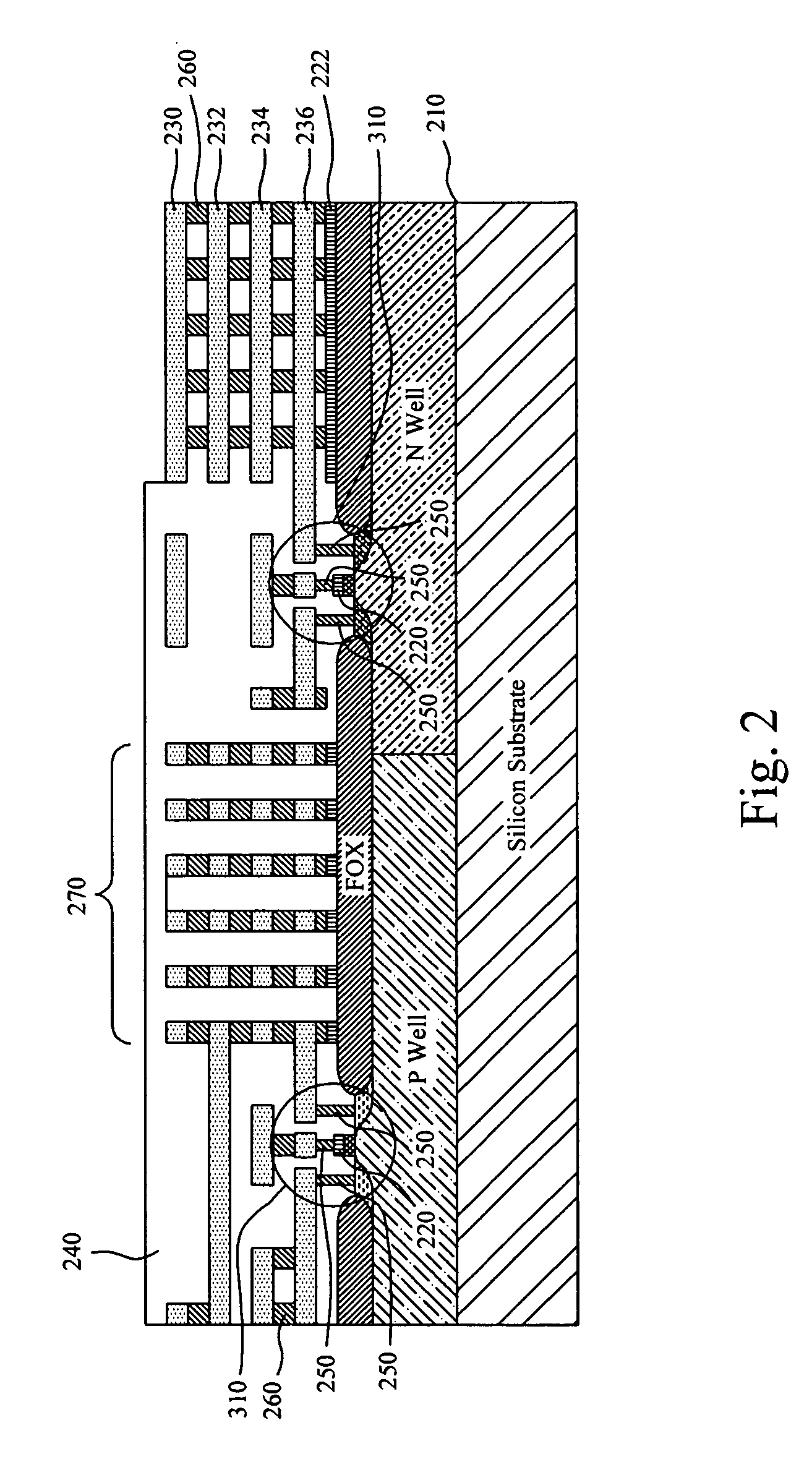

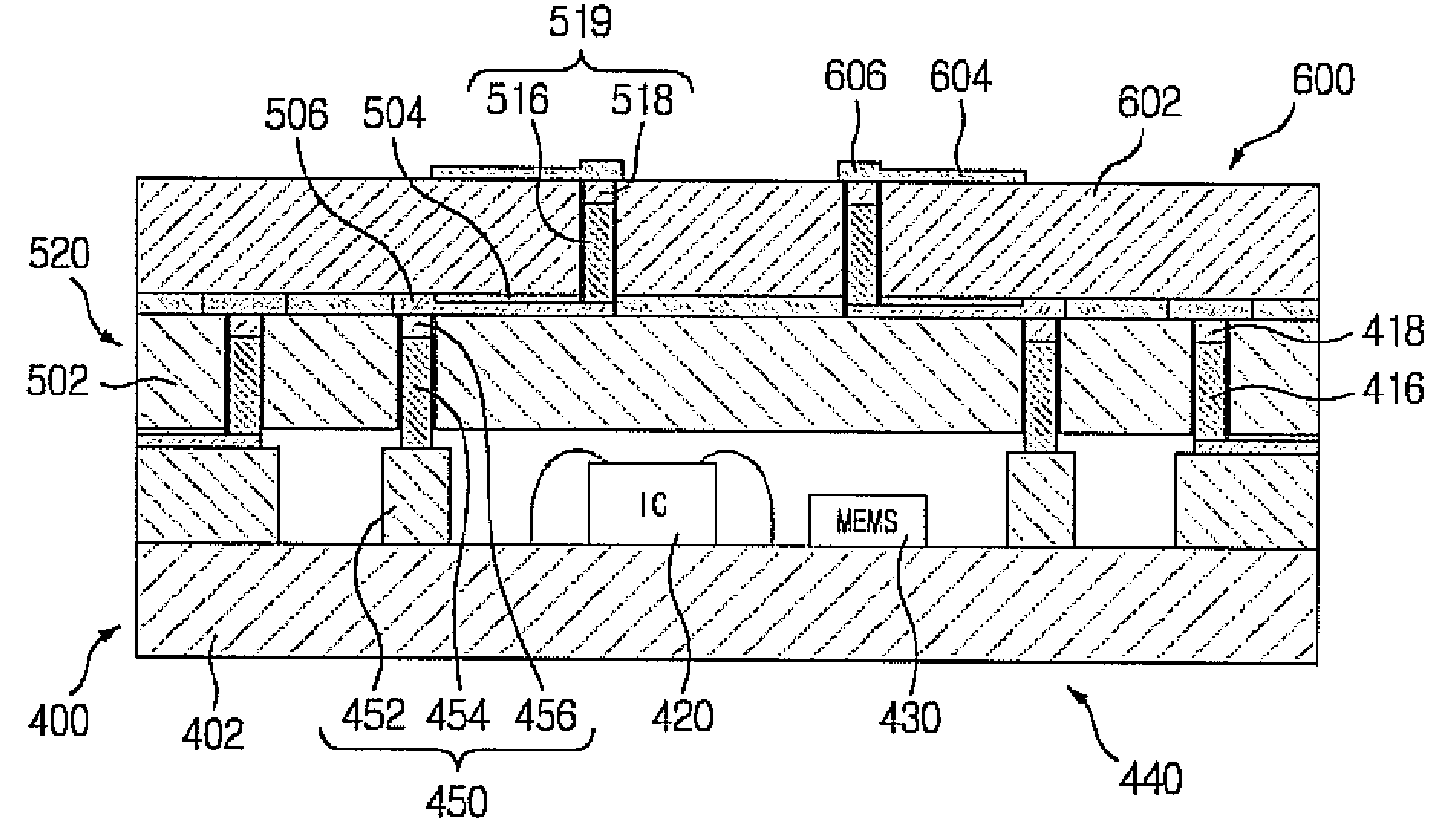

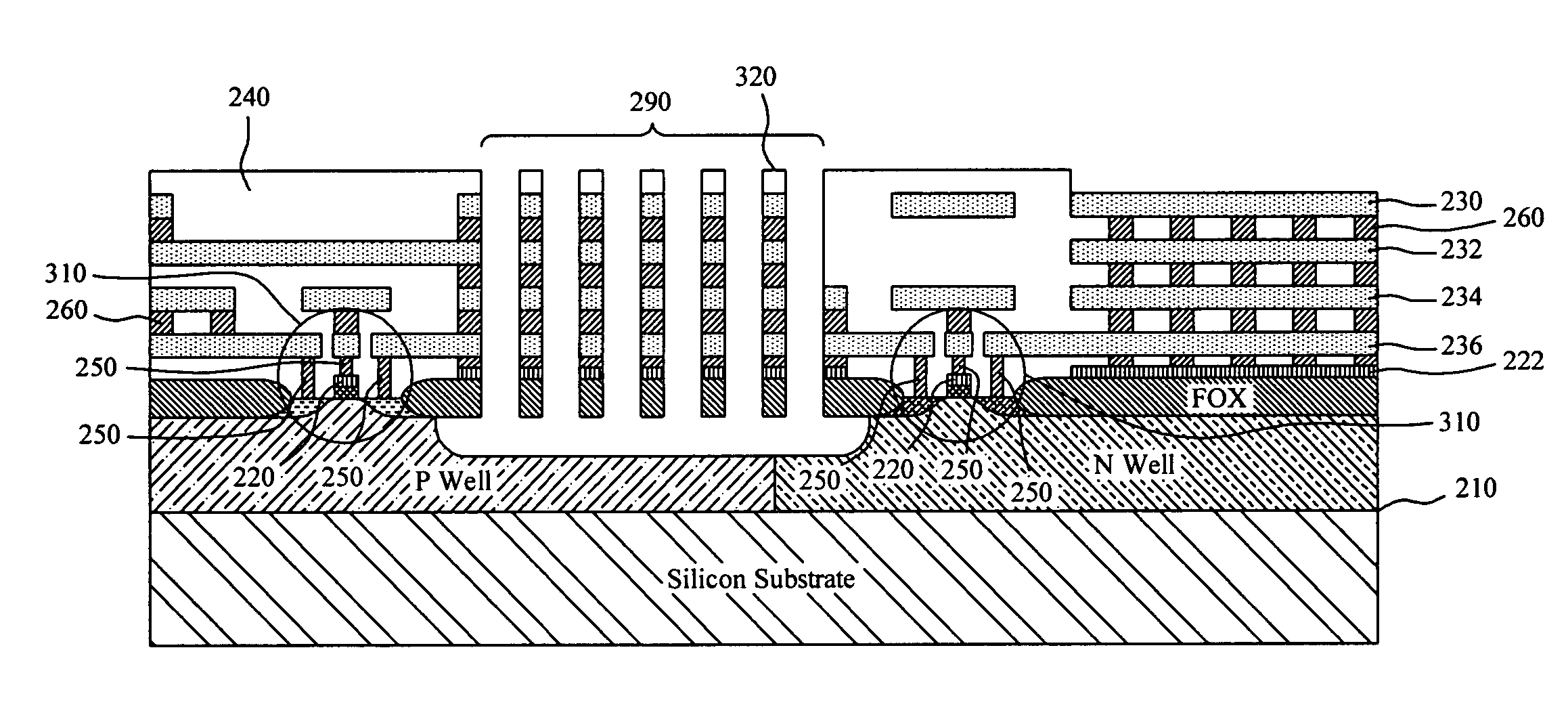

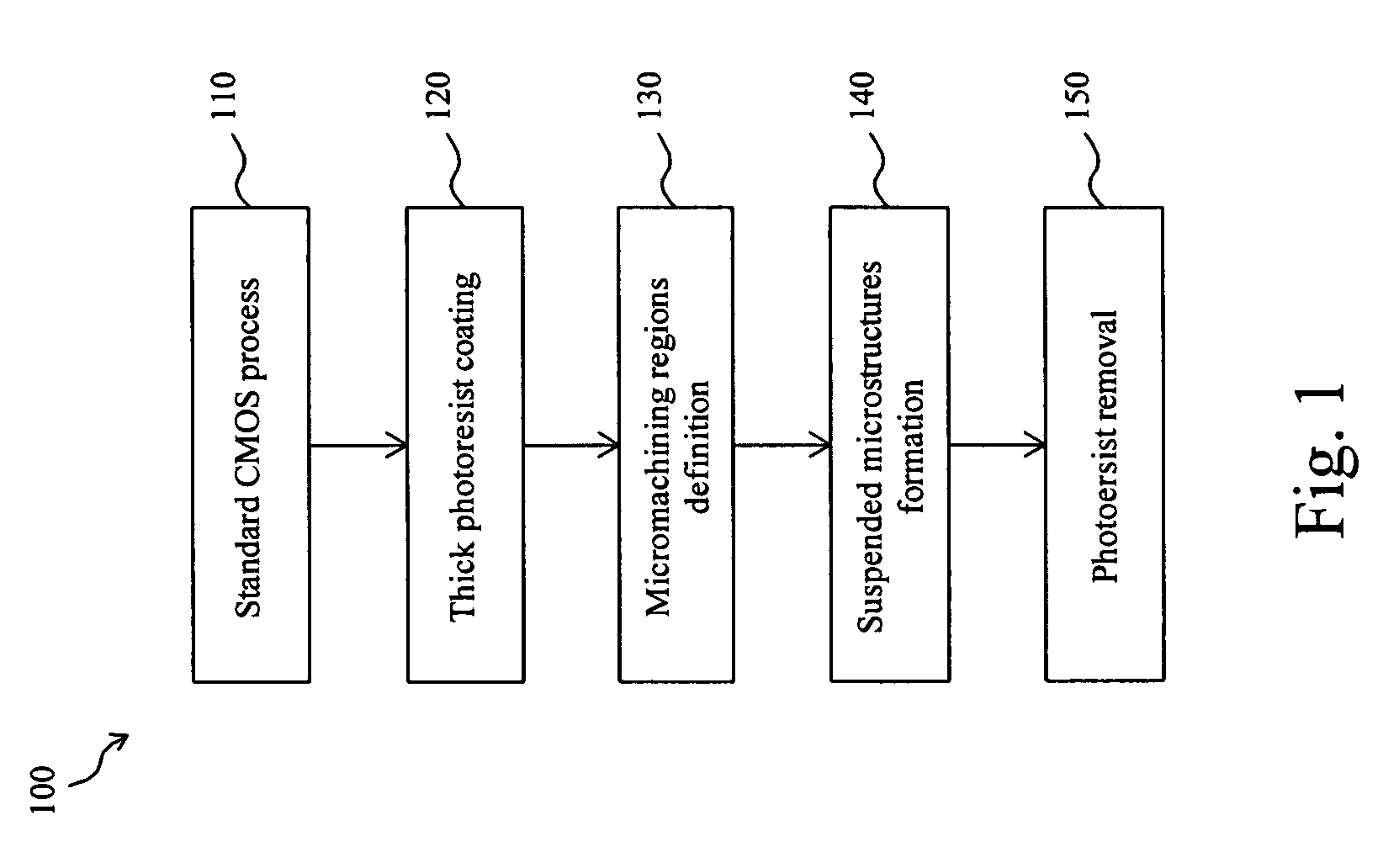

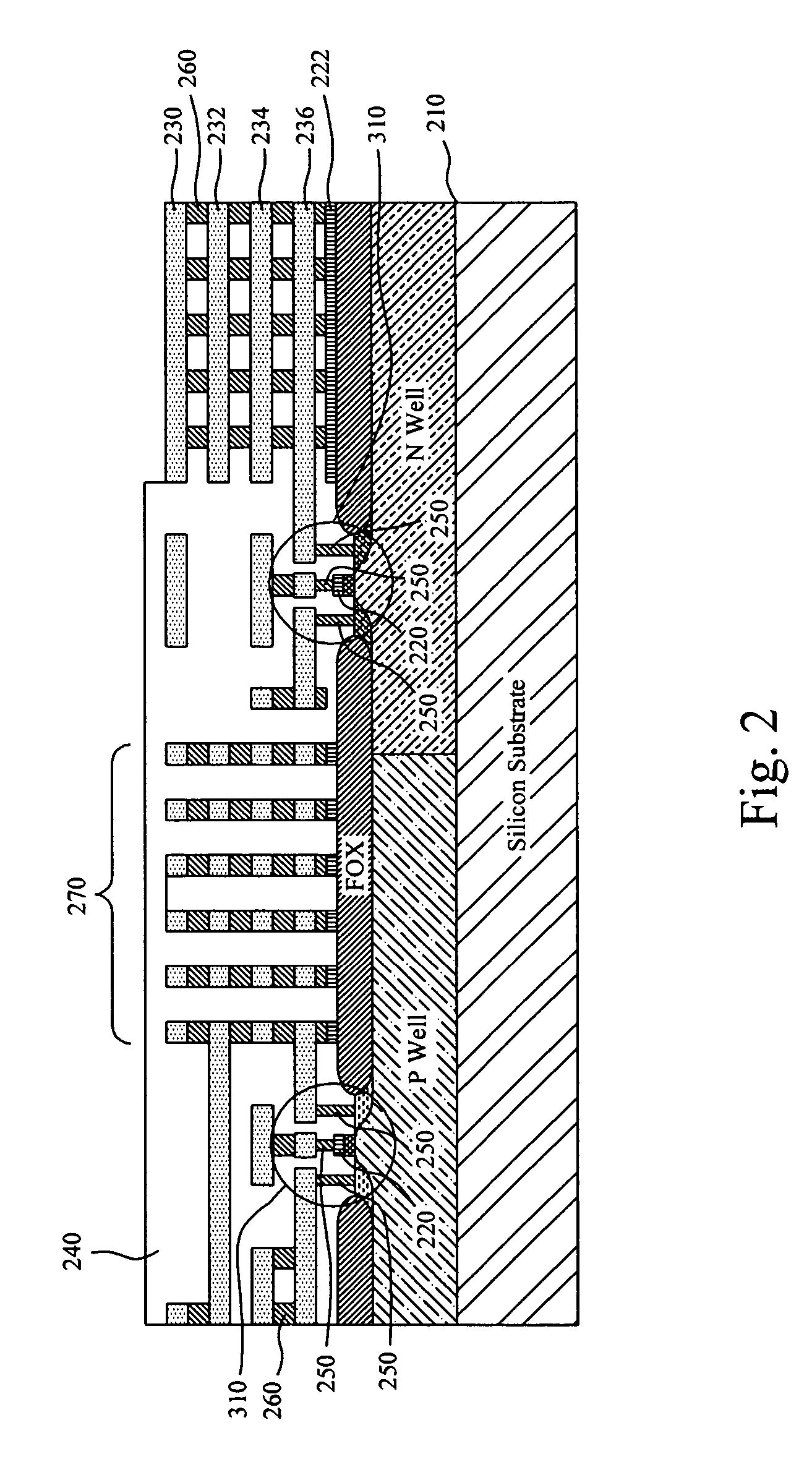

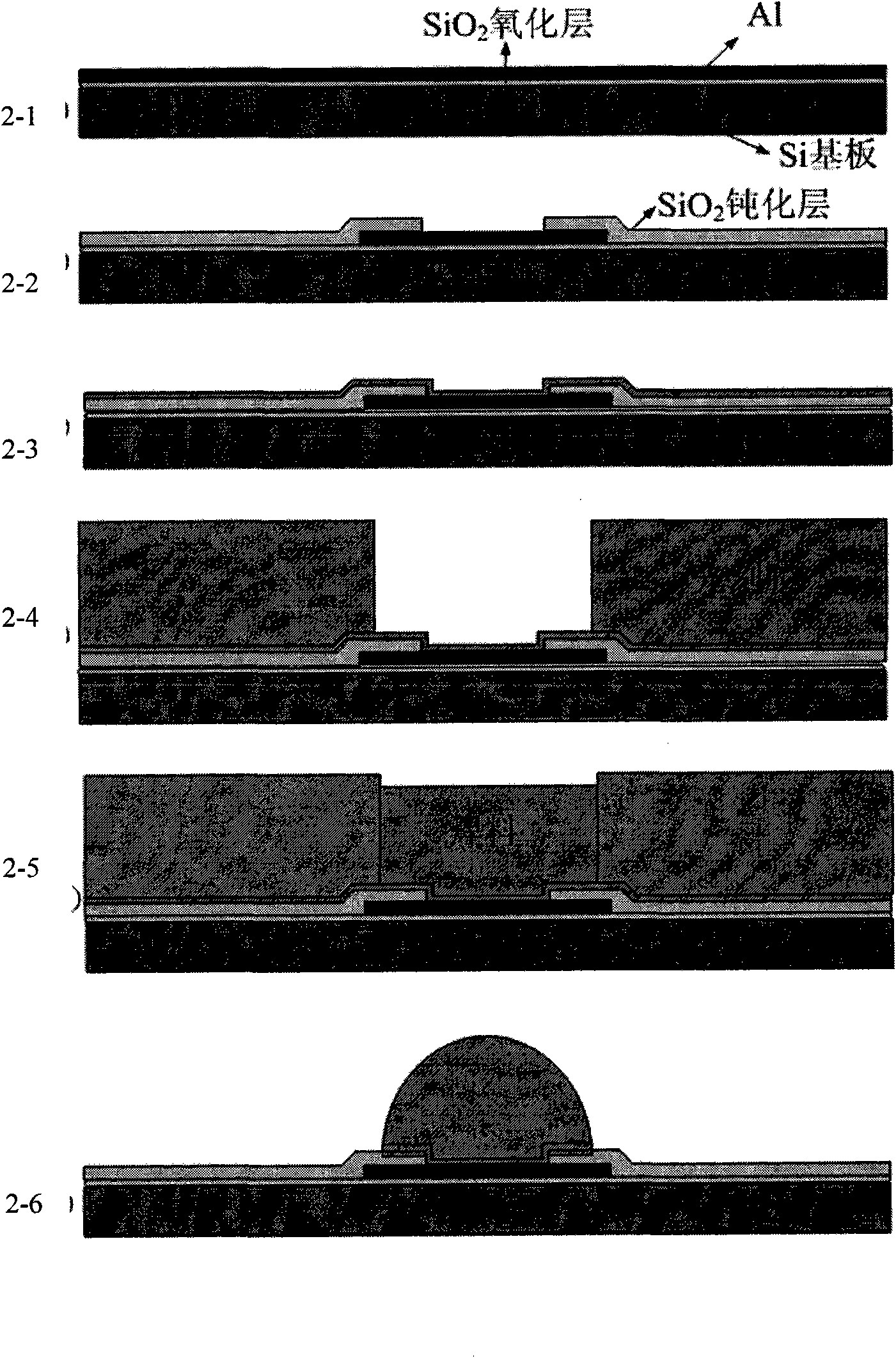

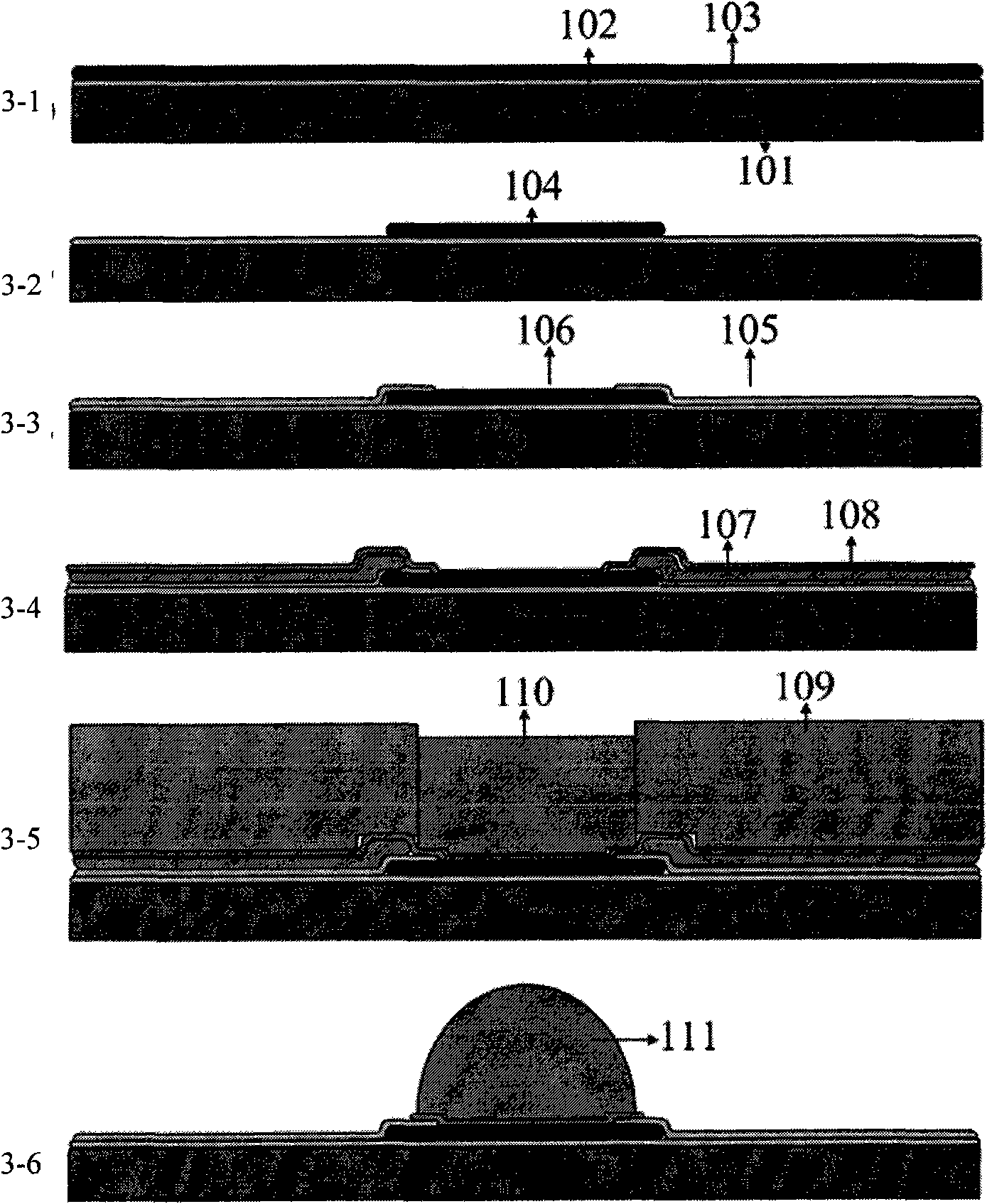

CMOS-MEMS process

ActiveUS20060105543A1Avoid disadvantagesIncreased processing flexibilitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringCmos mems

A fully CMOS compatible MEMS multi-project wafer process comprises coating a layer of thick photoresist on a wafer surface, patterning the photoresist to define a micromachining region, and performing a micromachining in the micromachining region to form suspended microstructures.

Owner:NAT APPLIED RES LAB

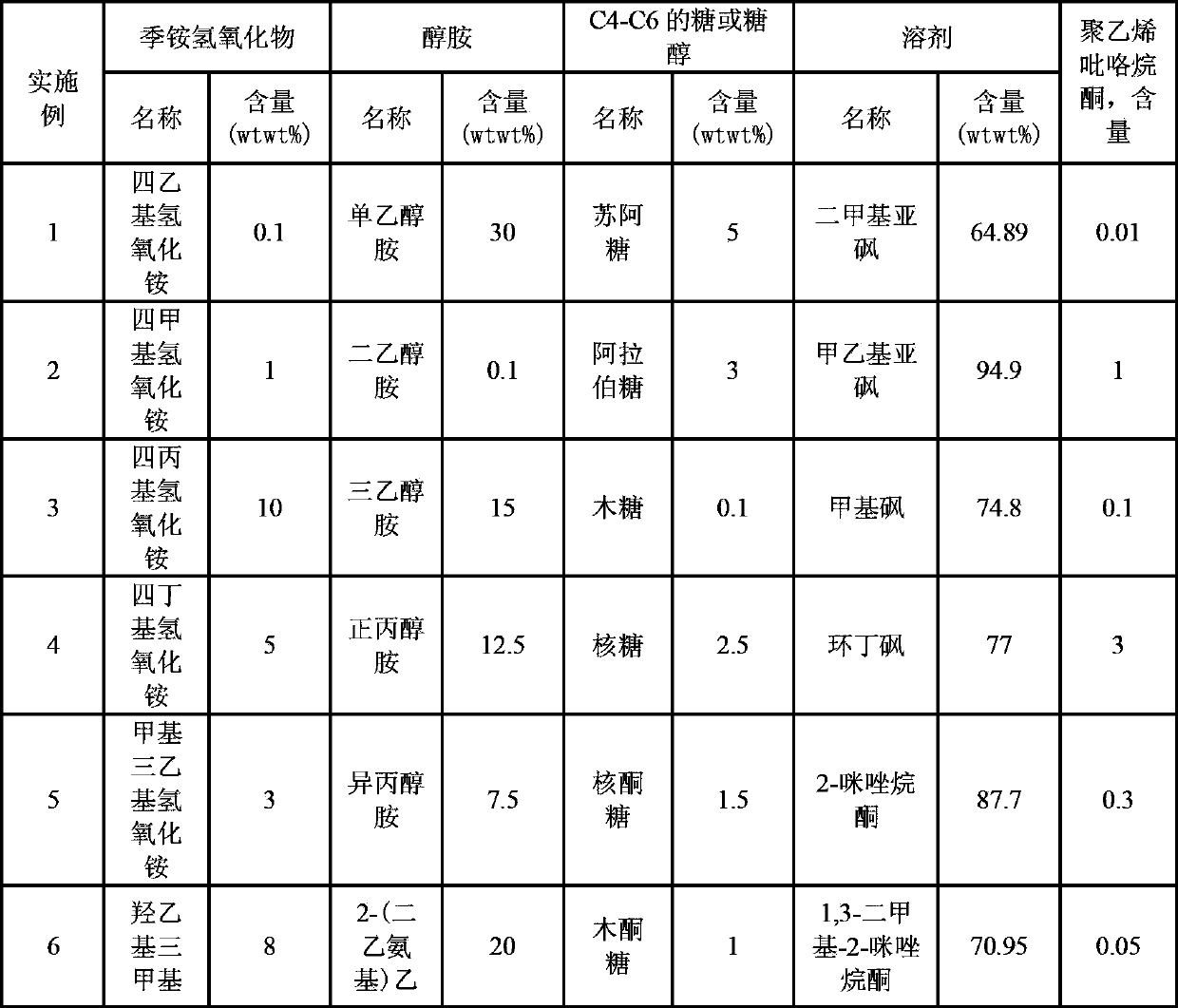

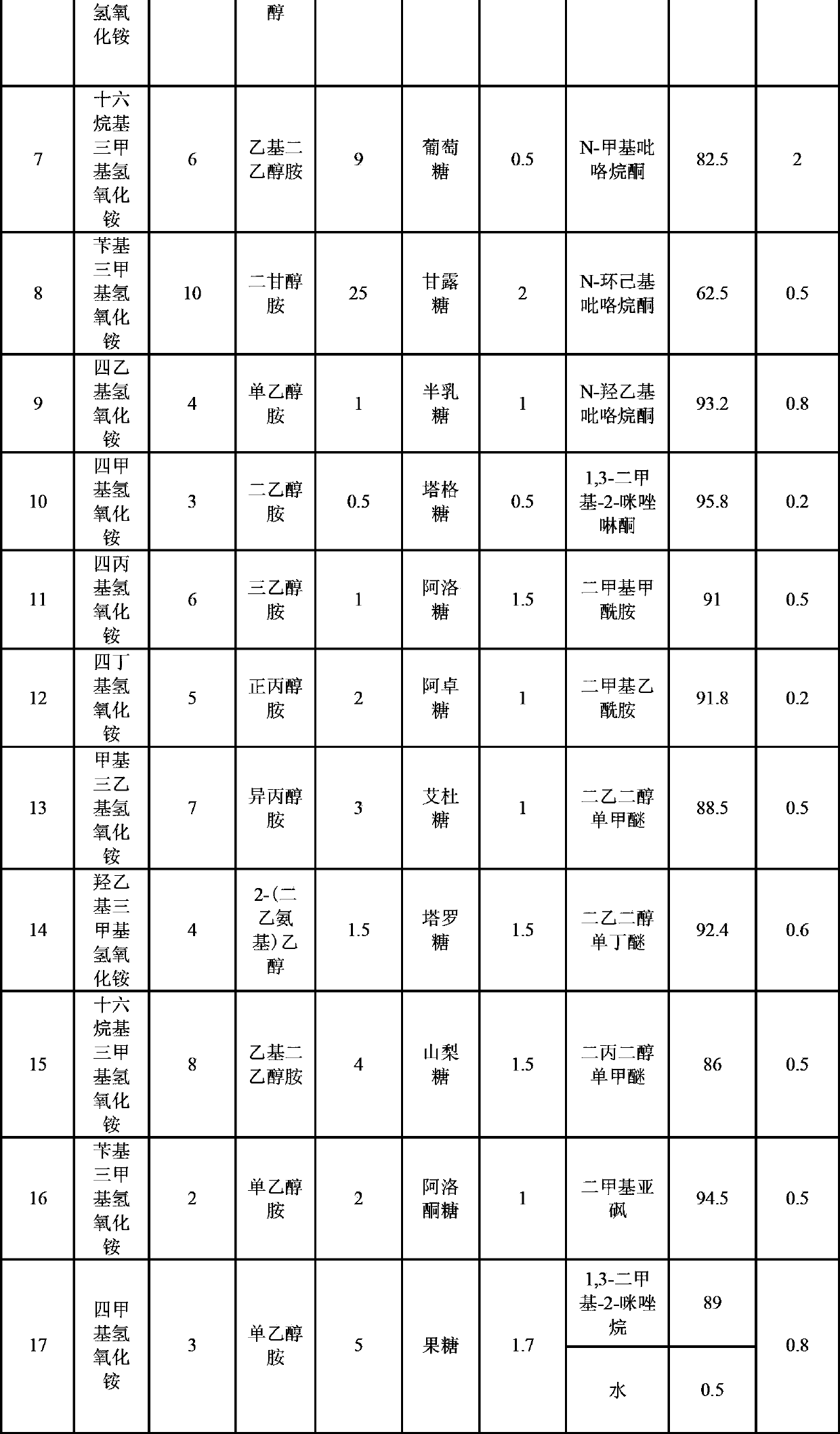

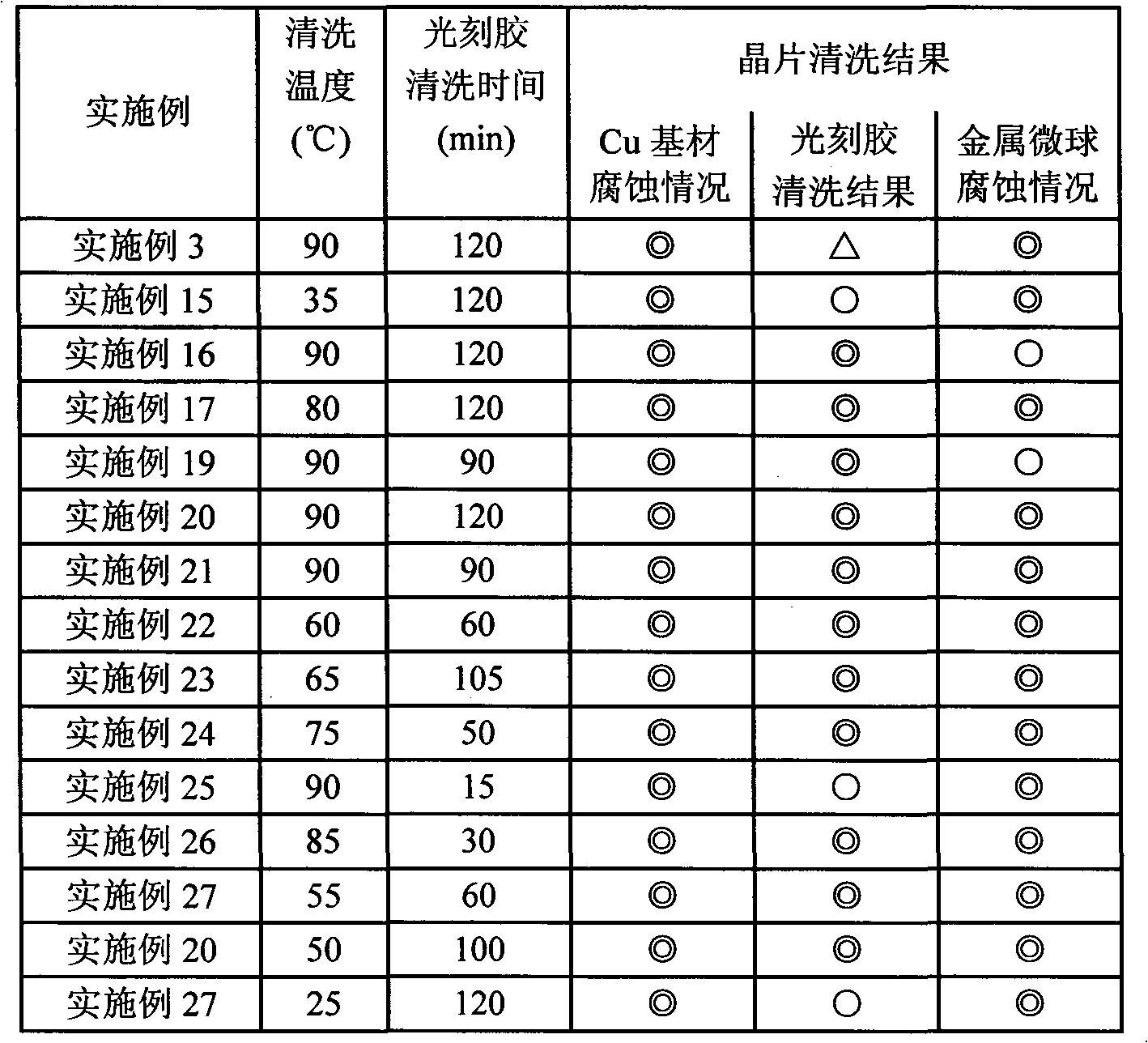

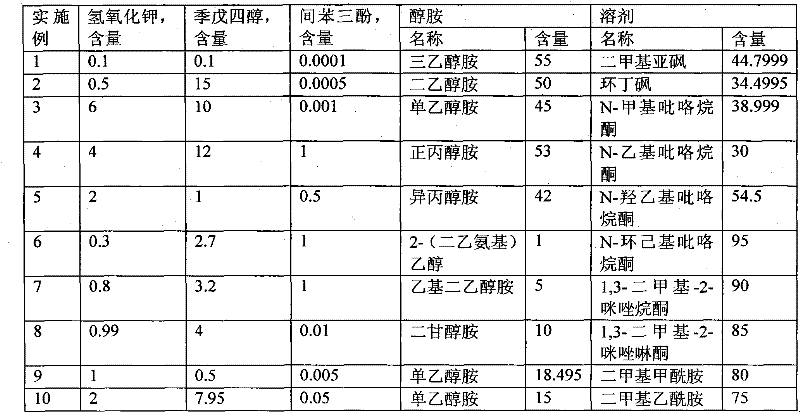

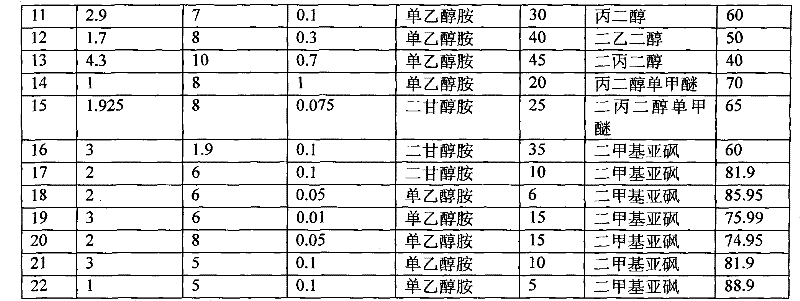

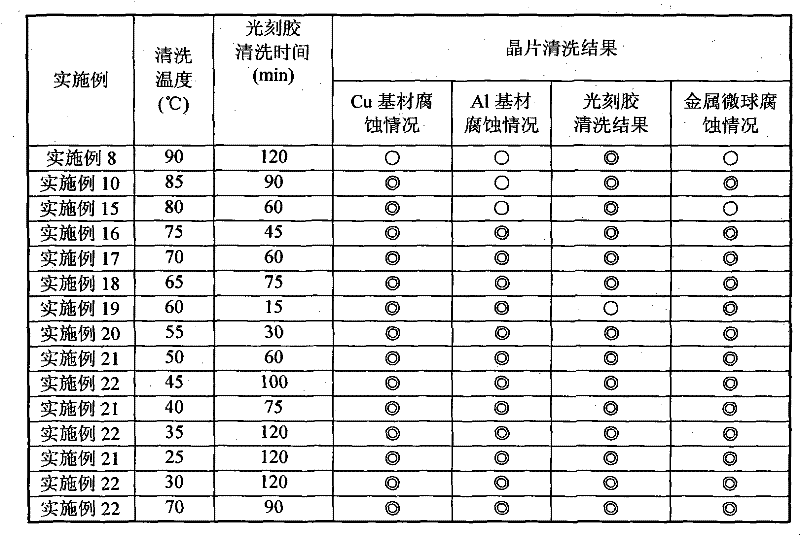

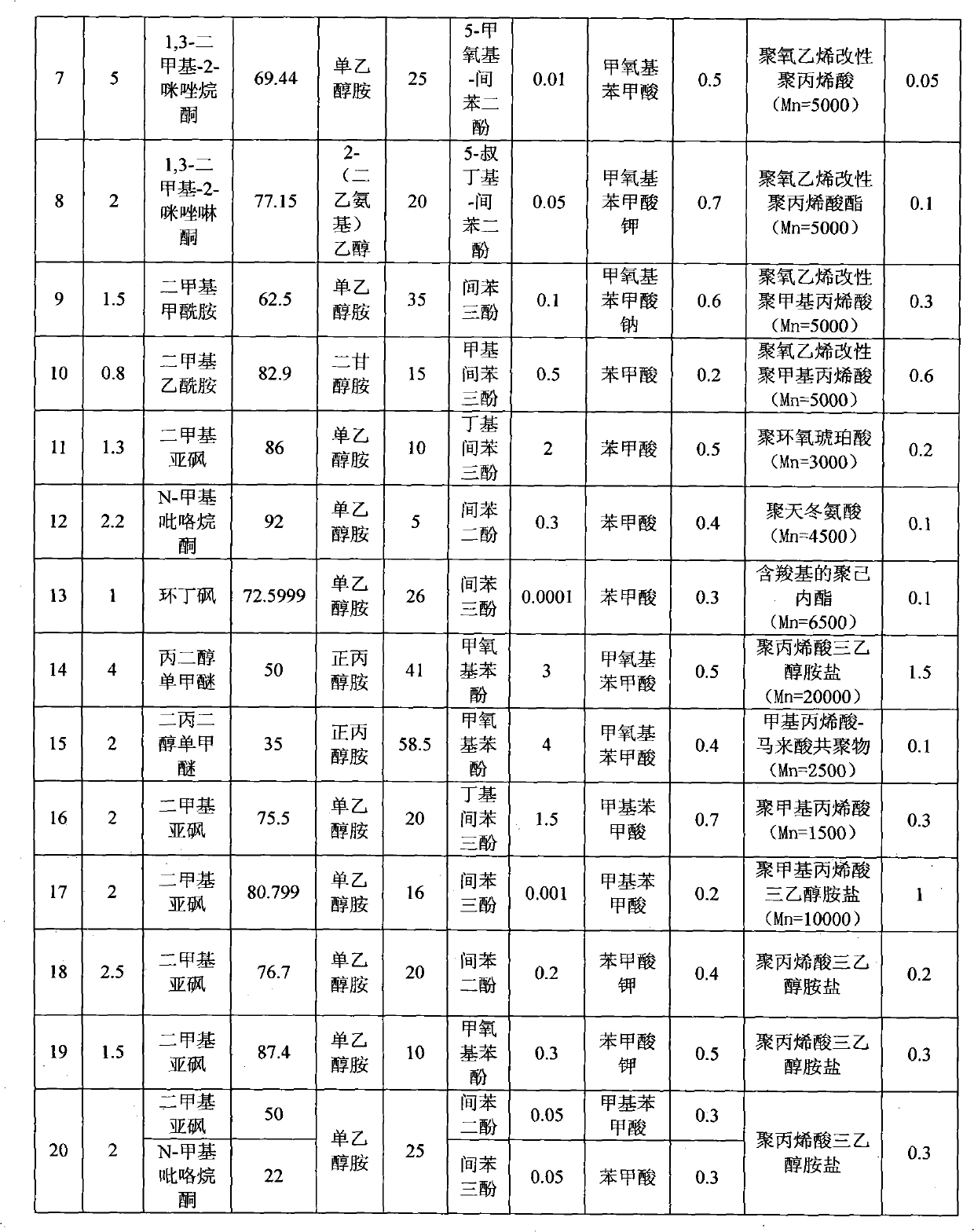

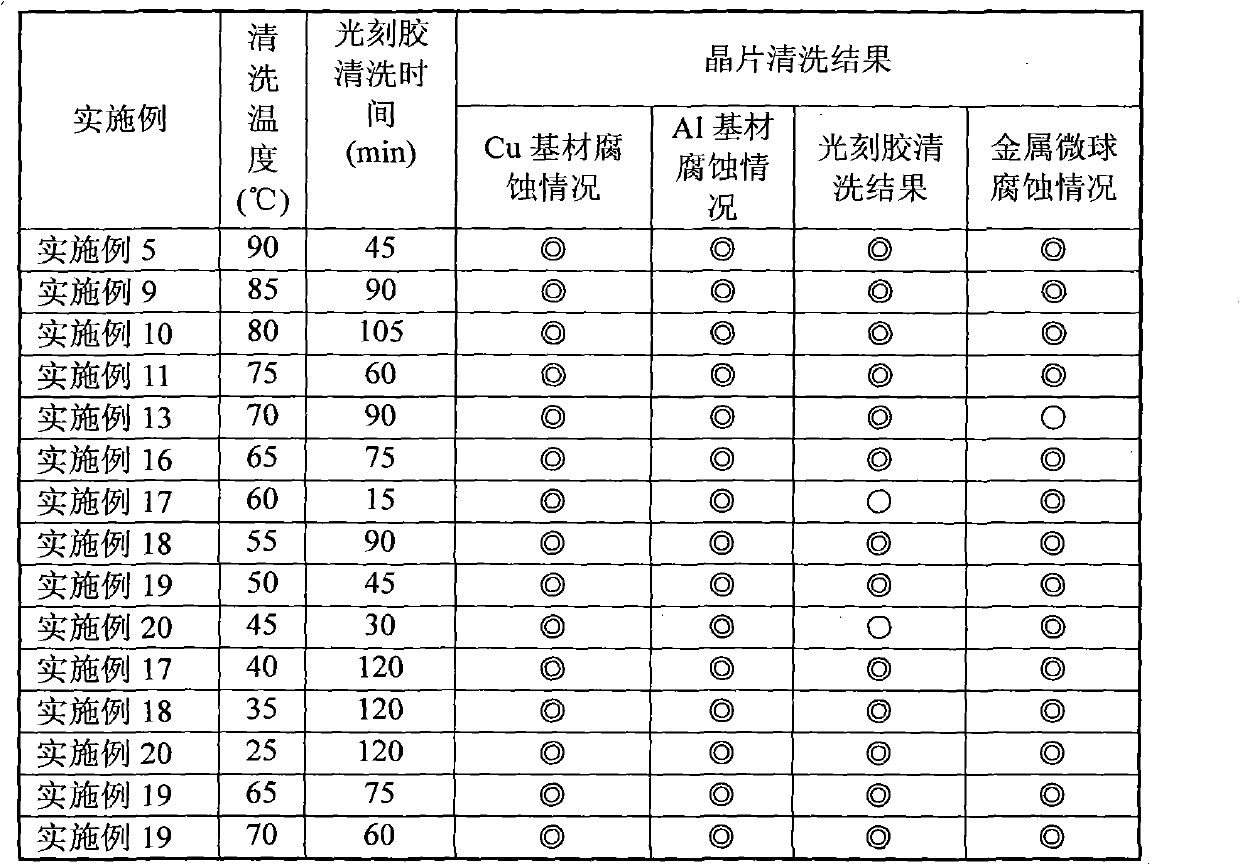

Photoresist remover

InactiveCN103869636AAvoid corrosionGood removal effectOrganic detergent compounding agentsDetergent mixture composition preparationEtchingAlcohol sugars

The invention discloses a low etching resist cleaning fluid suitable for cleaning of thicker photoresists. The low etching resist photoresist cleaning fluid comprises (a) a quaternary ammonium hydroxide, (b) an alkylol amine, (c) a sugar or a sugar alcohol, (d) a surfactant, and (e) a solvent. The low etching resist photoresist cleaning fluid is capable of removing the photoresists on semiconductor wafers with high efficiency; no attack on base materials, such as aluminium and copper, is caused; and the low etching resist photoresist cleaning fluid processing a promising application prospect in the field of semiconductor wafer cleaning.

Owner:ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

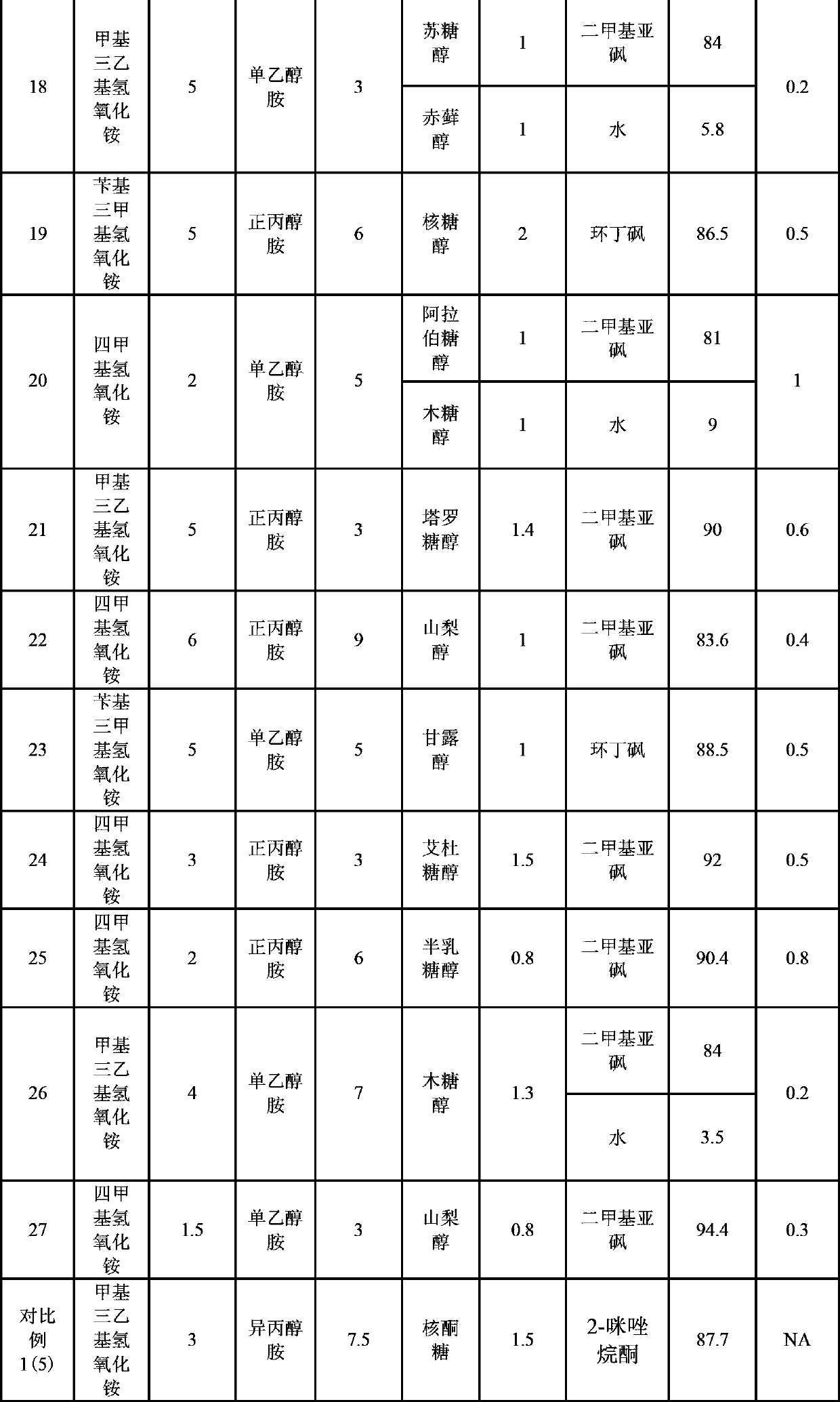

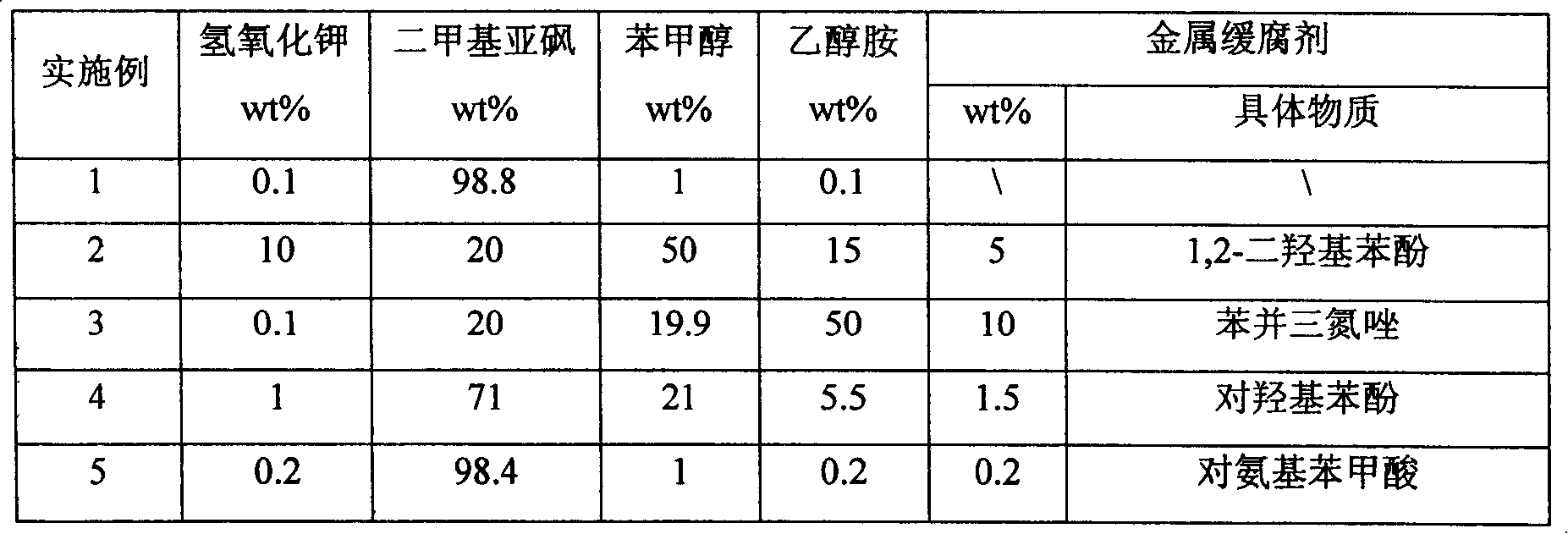

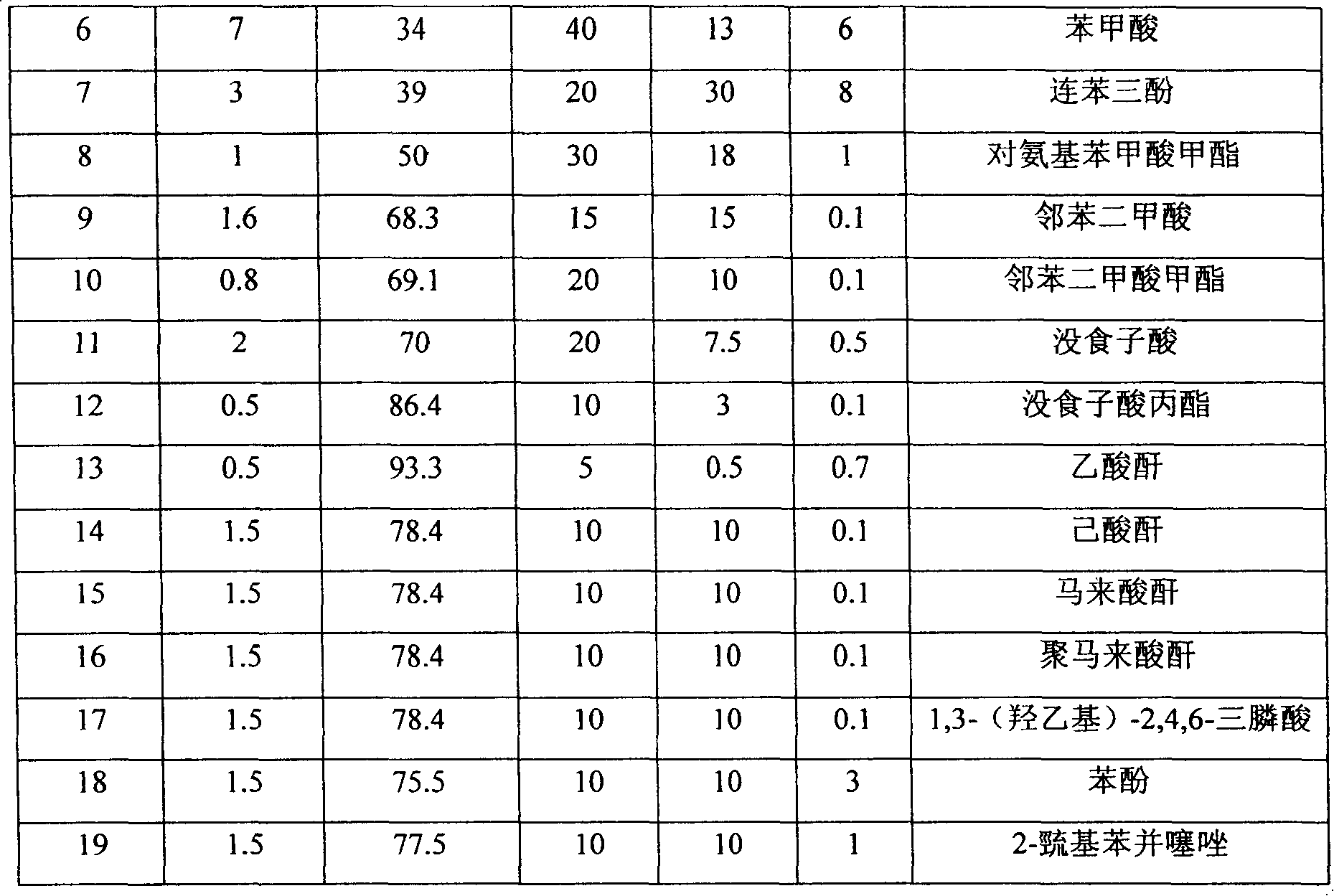

Low etching relative thick photoresist cleaning liquor

InactiveCN101187788AImprove protectionReduce corrosionDetergent mixture composition preparationPhotosensitive material processingResistDielectric substrate

The invention discloses a low-etching cleaning agent which is suitable for cleaning photoresist which is much thicker, which is characterized in that the invention comprises caustic potash, dimethyl sulfoxide, benzoic alcohol, and aminoethyl alcohol. The cleaning agent of the invention can be used for removing photo resist (light blockage) or other residues on metals, metal alloy, or dielectric substrate, which is especially suitable for cleaning the photoresist which is much thicker (the thickness is more than 100 mm), meanwhile, the invention has a lower etching speed for metals such as copper and the like. The invention has a good application prospect in the microelectron field such as the cleaning of semiconductor crystal and the like.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

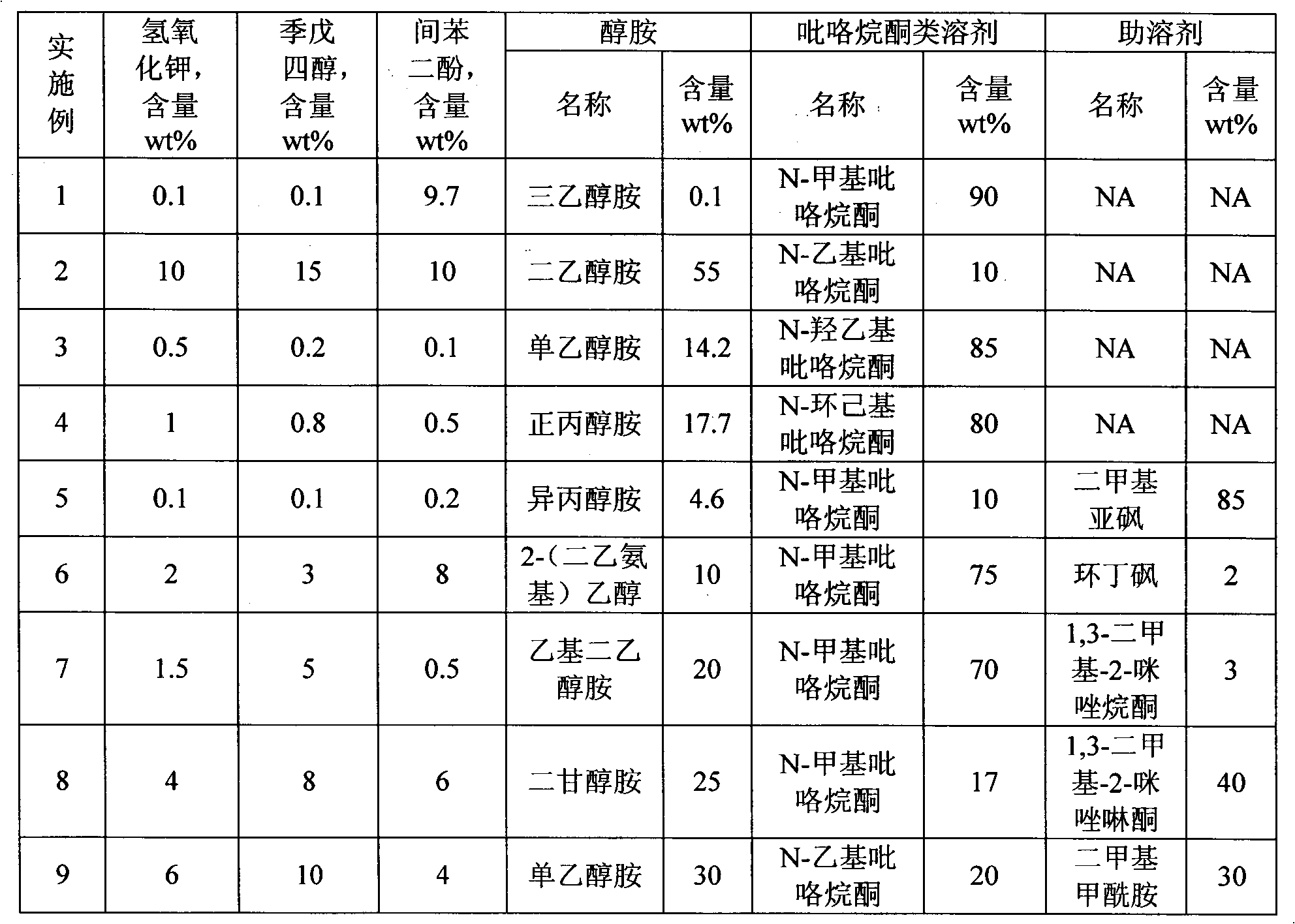

Cleaning solution for photoresist

ActiveCN102338994AImprove removal efficiencyReduce corrosionDetergent mixture composition preparationSemiconductor/solid-state device manufacturingDielectric substratePotassium hydroxide

The invention discloses a low etching cleaning solution for removing a thick photoresist. The low etching cleaning solution for a photoresist comprises (a) potassium hydroxide, (b) a pyrrolidone solvent, (c) pentaerythritol, (d)?alcohol amine, and (e) resorcinol. The low etching cleaning solution for a photoresist can be used for removing a photoresist and other residues on a metal, metal alloy or dielectric substrate, and also shows a low etching rate to Cu and other metals, thus boasting good application prospects in semiconductor wafer cleaning and other microelectronic fields.

Owner:宁波安集微电子科技有限公司

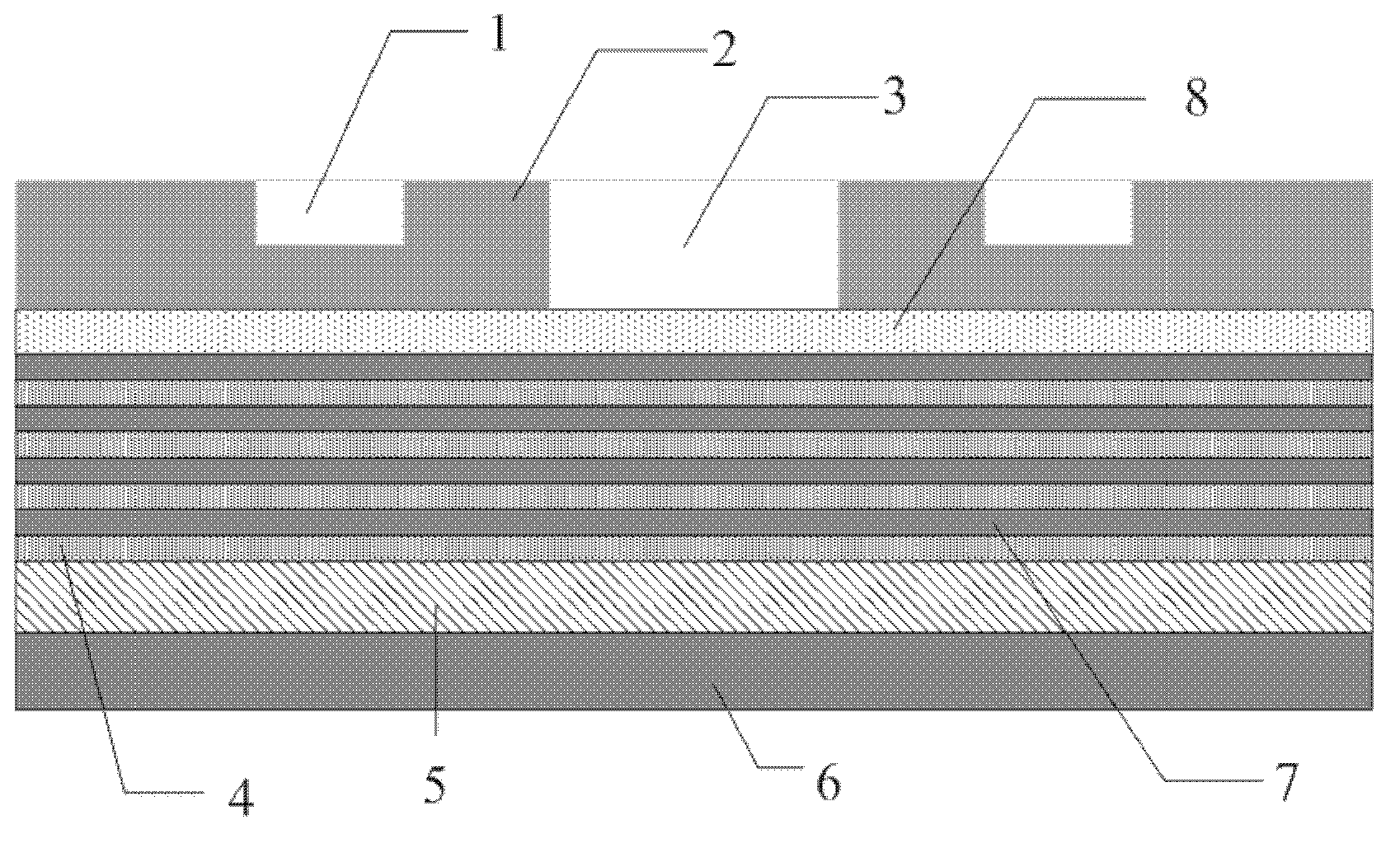

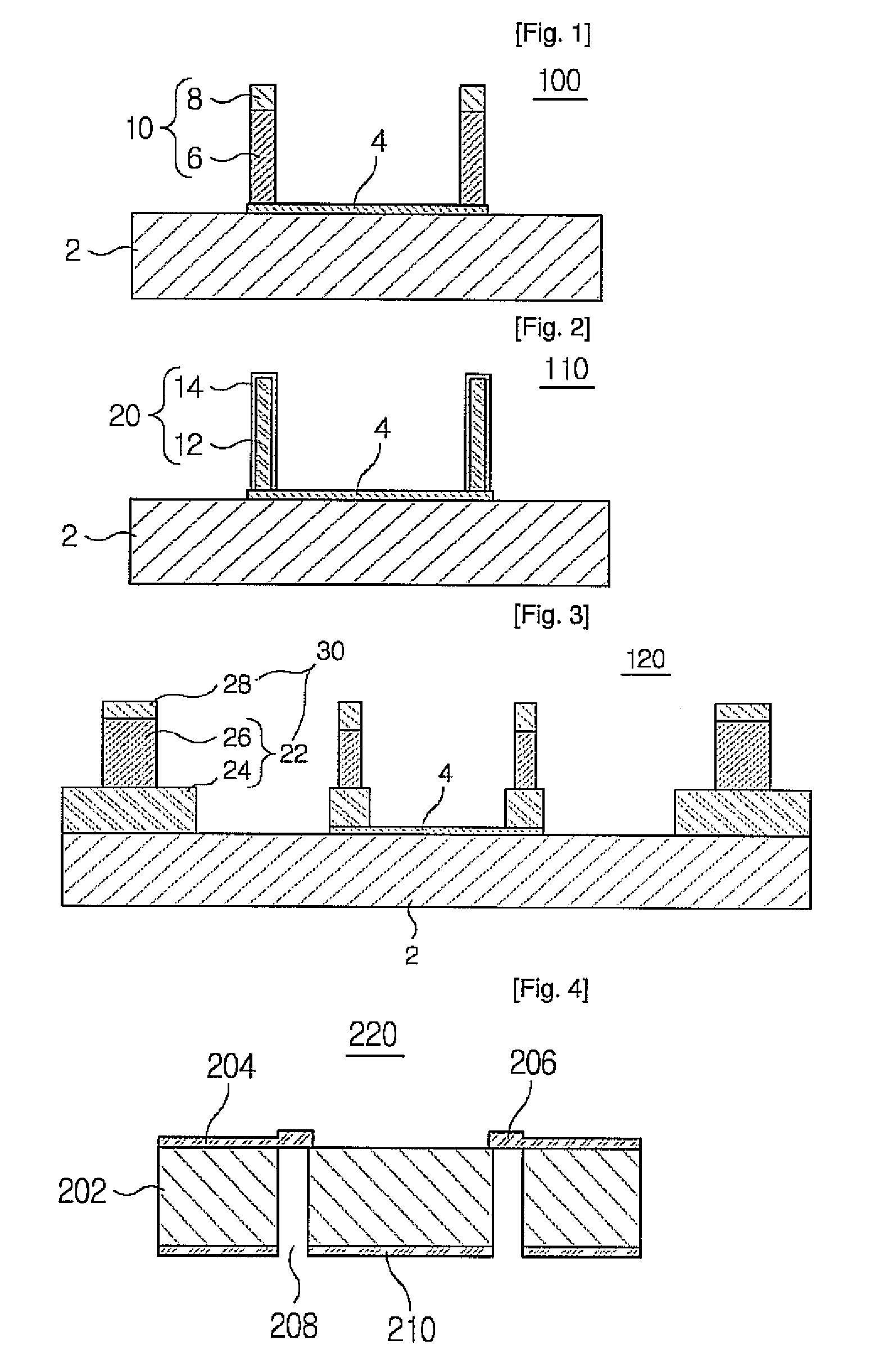

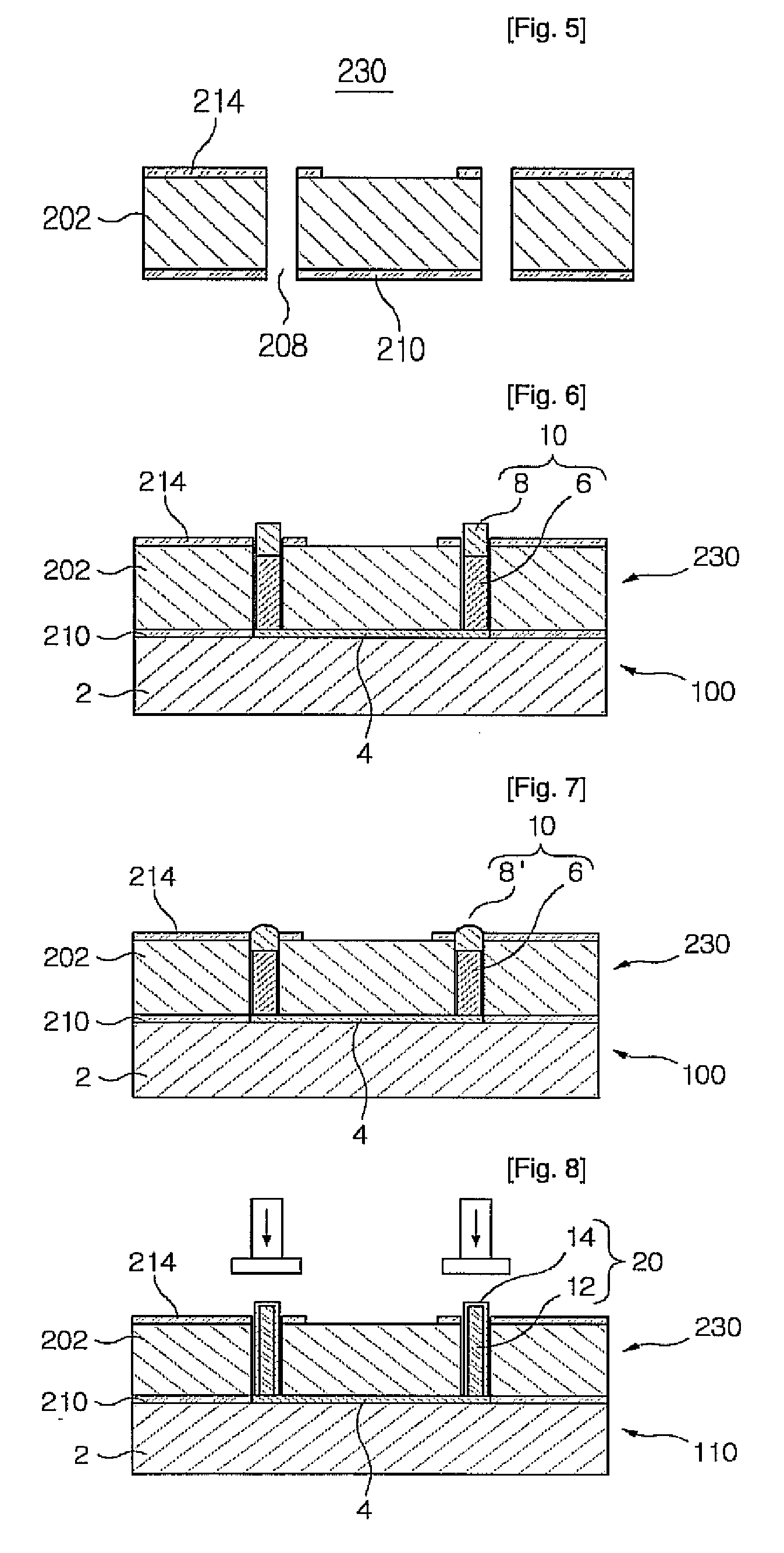

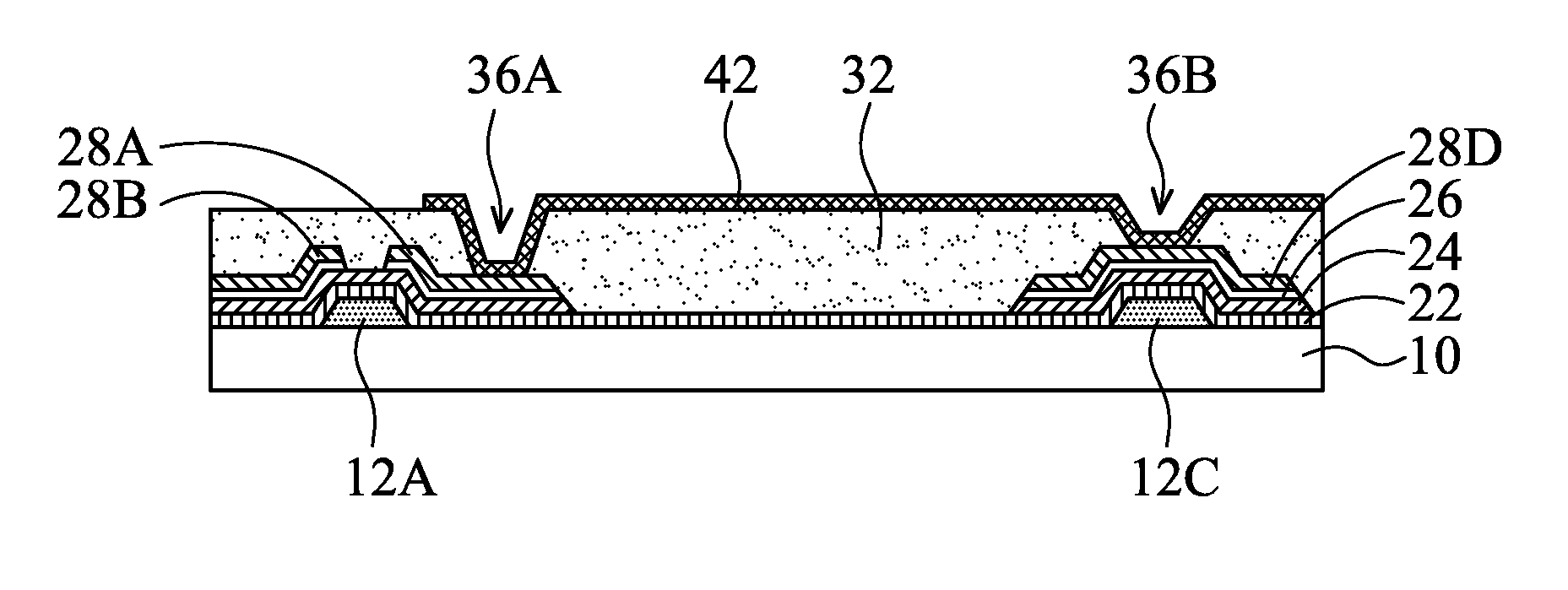

Multi-layer package structure and fabrication method thereof

InactiveUS20090175022A1Achieve structural stabilityStable structureLine/current collector detailsSemiconductor/solid-state device detailsEngineeringStructural stability

A method for allowing an easier electric connection between layers of a multi-layer package structure using a metal pin fabricated based on semiconductor device processes is provided. A metal pin having a high aspect ratio is formed on a lower substrate, while a via hole is formed in an upper substrate. The metal pin is inserted into the via hole and adhered together to make an electric connection between the lower and upper substrates. The metal pin is obtained by patterning a thick photoresist material and plating a material thereon. The metal pin may have a core member obtained by performing a plating process on the surface of a patterned polymer based pin. Solder or gold is used for adhesion and electric connection between the signal line and the metal pin. The above electric connection method can be simpler and have improved structural stability compared with the typical connection method.

Owner:WAVENICS +1

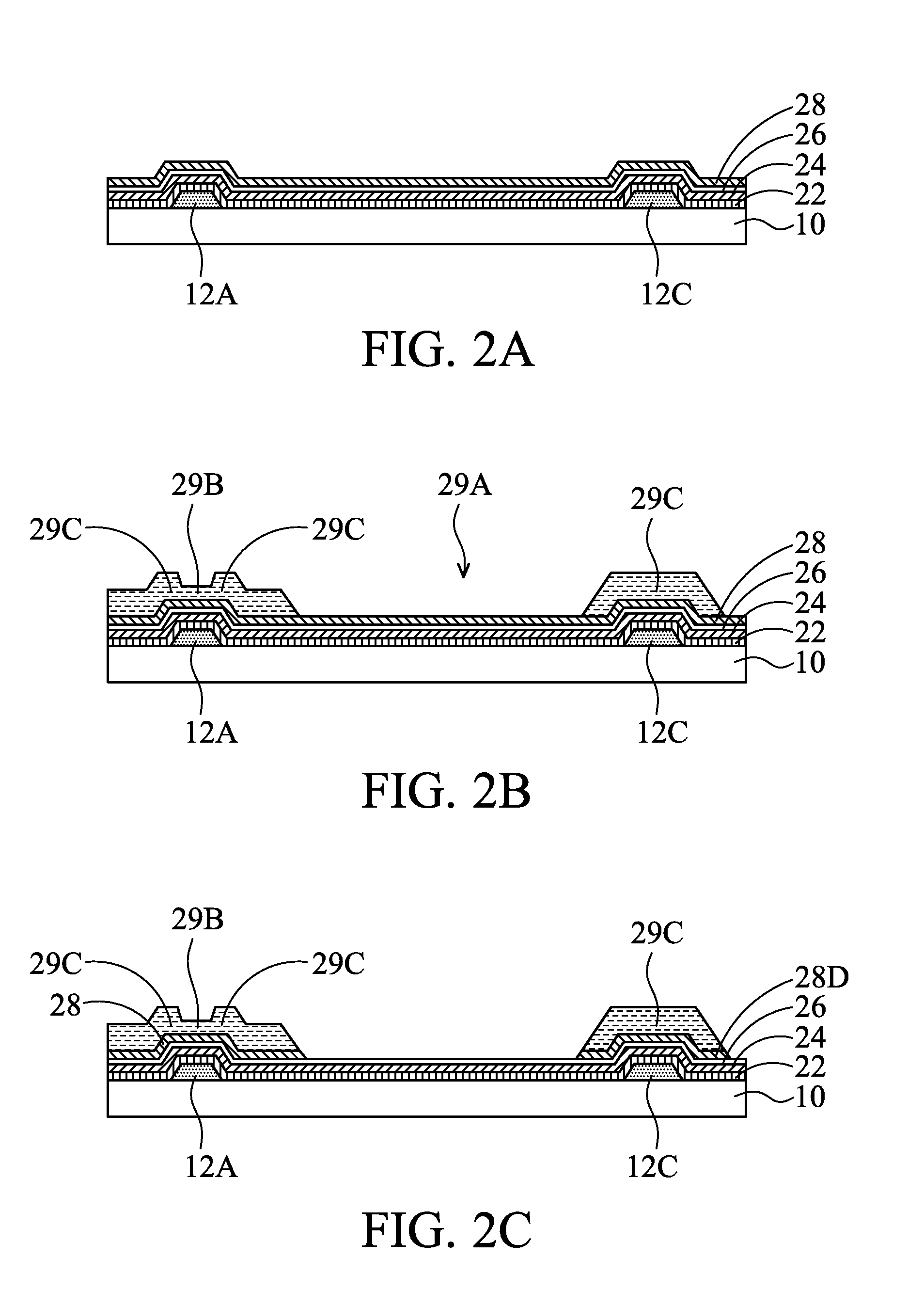

Methods for manufacturing array substrates

ActiveUS20120156834A1Solid-state devicesSemiconductor/solid-state device manufacturingLithography processThick photoresist

Disclosed is a patterned photoresist layer on a passivation layer, formed by a lithography process with a multi-tone photomask, having a non-photoresist region, a thin photoresist pattern, and a thick photoresist pattern. The passivation layer corresponding to the non-photoresist region is removed, thereby forming vias to expose a part of a drain electrode in a TFT and a part of a top electrode in a storage capacitor, respectively. The thin photoresist pattern is then ashed to expose the passivation layer in a pixel region. Thereafter, a conductive layer is selectively deposited on the exposed passivation layer and on the sidewalls / bottoms of the vias. Subsequently, the remaining thick photoresist pattern is ashed.

Owner:INNOLUX CORP

CMOS-MEMS process

ActiveUS7435612B2Avoid disadvantagesIncreased processing flexibilitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringCmos mems

A fully CMOS compatible MEMS multi-project wafer process comprises coating a layer of thick photoresist on a wafer surface, patterning the photoresist to define a micromachining region, and performing a micromachining in the micromachining region to form suspended microstructures.

Owner:NAT APPLIED RES LAB

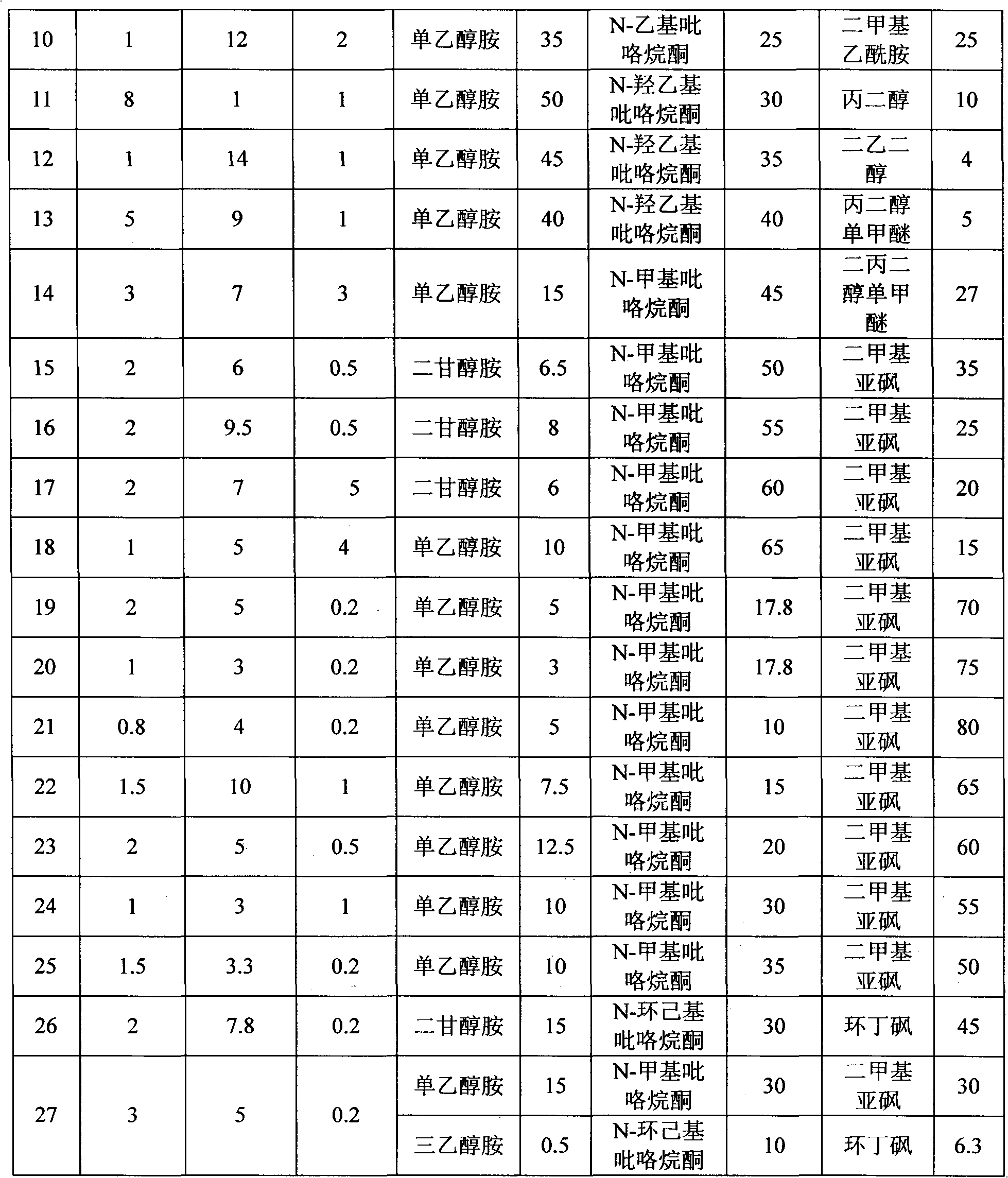

Cleaning agent for thick-film photoresist

InactiveCN102540774AReduce etch rateAvoid corrosionPhotosensitive material processingPentaerythritolMetal alloy

The invention discloses a cleaning agent suitable for cleaning thick photoresist and with low etching performance, which contains (a) potassium hydroxide, (b) dissolvent, (c) pentaerythritol, (d) alkylol amine and (e) phloroglucinol. The cleaning agent for the photoresist can also be used for removing the photoresist and other residues on metal, metal alloy or dielectric medium substrates, has low etch rate on metal including copper (Cu) and the like simultaneously, and has good application prospect in microelectronics fields including semiconductor chip cleaning and the like.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

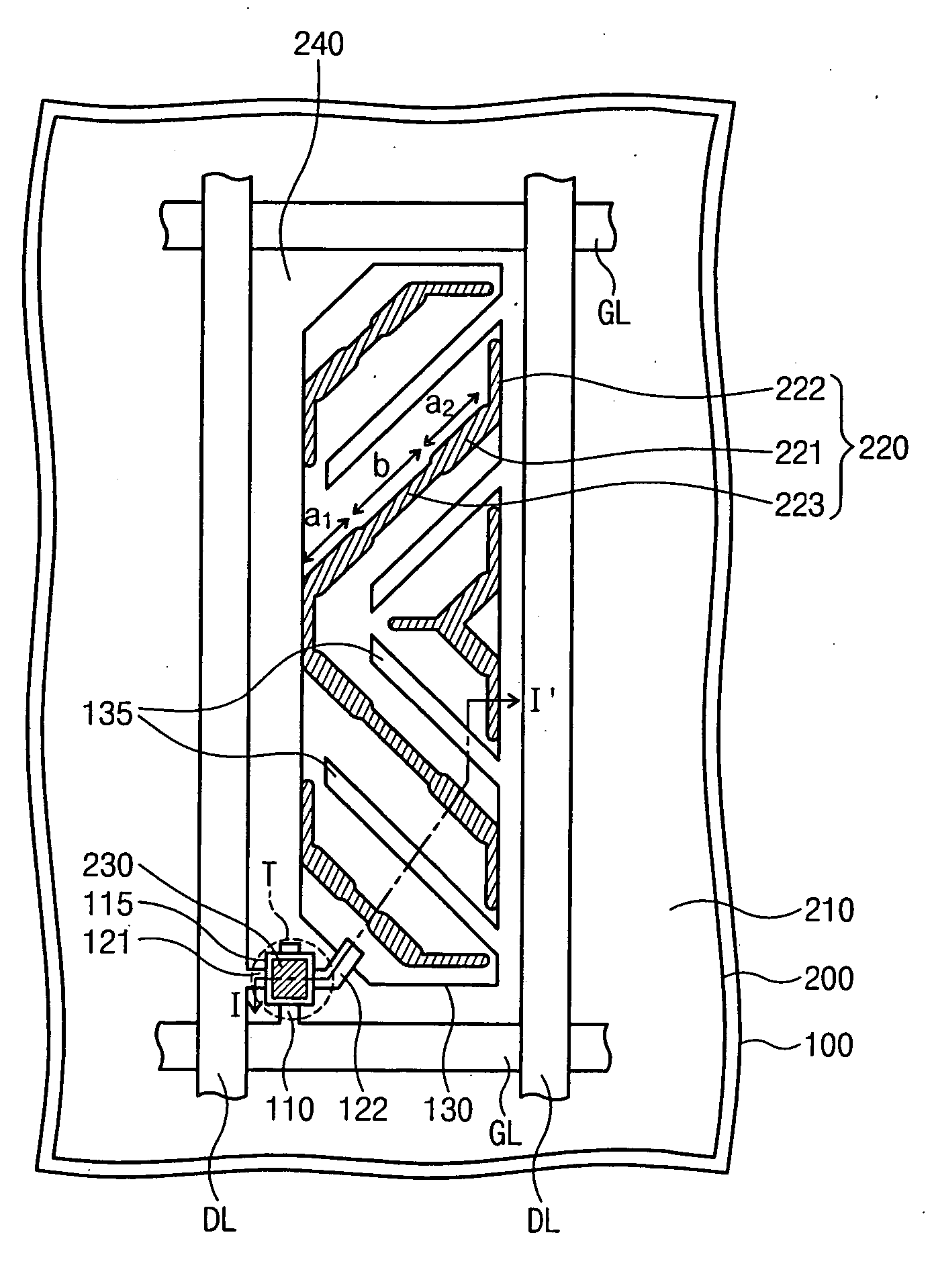

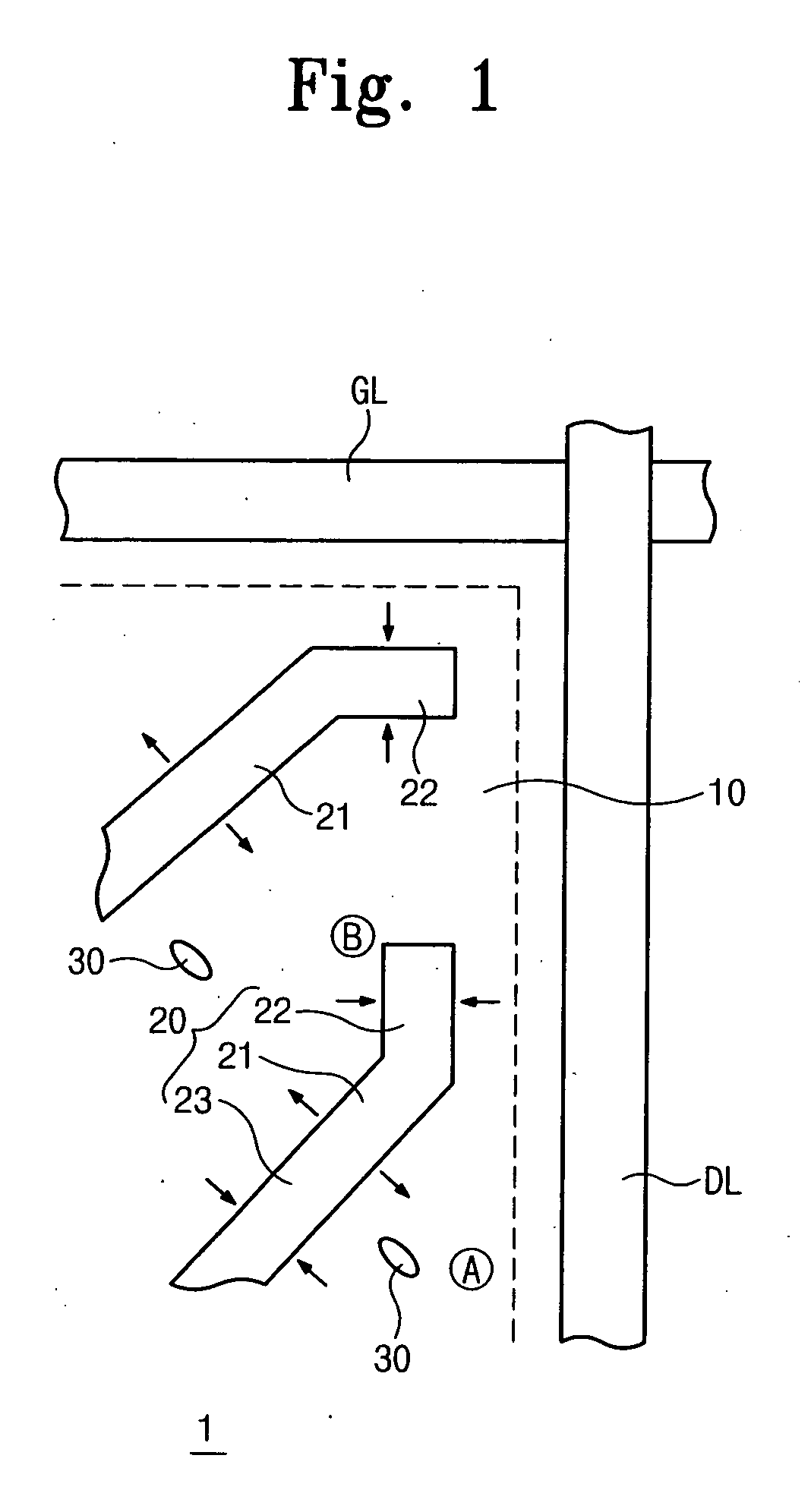

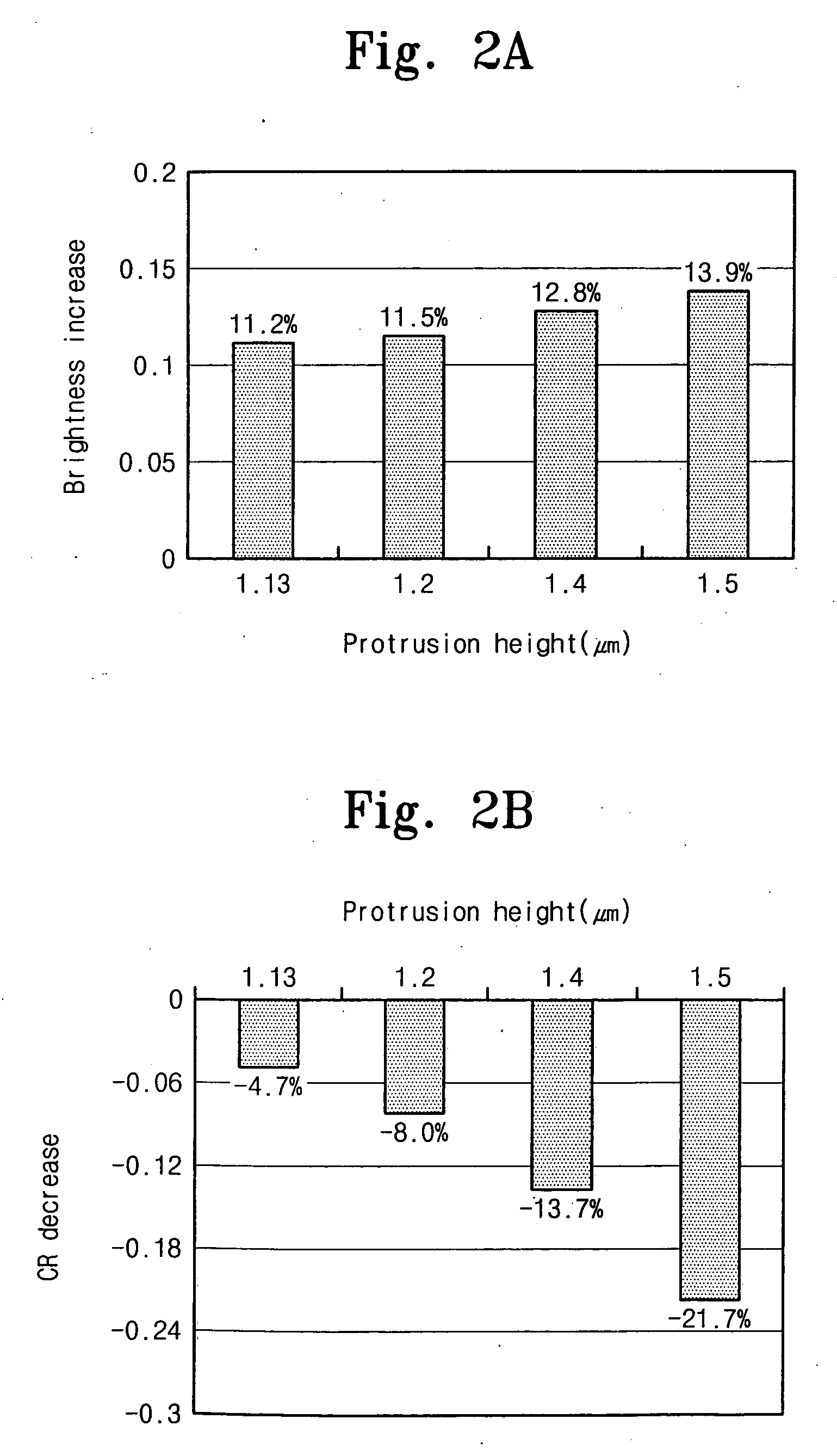

Liquid crystal display and method of manufacturing the same

A liquid crystal display device includes a substrate, liquid crystal disposed on the substrate, and a protrusion to influence on the alignment of the molecules of the liquid crystal to increase a viewing angle. The protrusion includes portions with different sizes, depending on the desired control power of the protrusion on the alignment of the molecules. That is, the portion size increases in the area where more control power is desired, and the portion size decreases in the area where less control power is desired. The protrusion is formed by depositing and pattering a thick photoresist. At the same time, a spacer can be formed.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for fabricating an integrated nozzle plate and multi-level micro-fluidic devices fabricated

A method for fabricating a multi-level micro-fluidic device for an micro-fluidic injection head equipped with symmetrical heaters. The method incorporates two thick photoresist deposition processes, a light-absorbing layer deposited in-between and a nickel-containing material electroplating process. The first thick photoresist deposition process is carried out to form a primary ink chamber in fluid communication with a funnel-shaped manifold and an injector orifice. The light-absorbing layer is deposited to prevent overheating of the first photoresist layer during a subsequent metal seed layer sputtering process. The second thick photoresist deposition process forms a mold for forming an injector passageway that leads to the injector orifice. The nickel-containing material electroplating process provides an orifice plate on top of the injection head through which an injector passageway that leads to the injector orifice is provided for injecting ink droplets.

Owner:IND TECH RES INST

Indium welded ball array preparing method based on electroplating technology

InactiveCN101847592ALow costSolid-state devicesSemiconductor/solid-state device manufacturingIndiumLithographic artist

The invention relates to an indium welded ball array preparing method based on an electroplating technology, which is characterized in that primary thin photoresist lithography is carried out before a seed layer is manufactured, then the seed layer is manufactured, thick positive photoresist is coated at places where indium needs to be deposited to photoetch a mold and form a thin photoresist / seed layer / thick photoresist structure, an indium column with required height is deposited in the mold by an electroplating method, the seed layer is stripped by ultrasound, and finally indium salient point backflow is realized in an annealing furnace with a controllable temperature so as to obtain an indium welded ball array. The invention provides a novel seed layer removing technology by which high-quality indium welded balls with small distance, small size and large array are prepared successfully.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

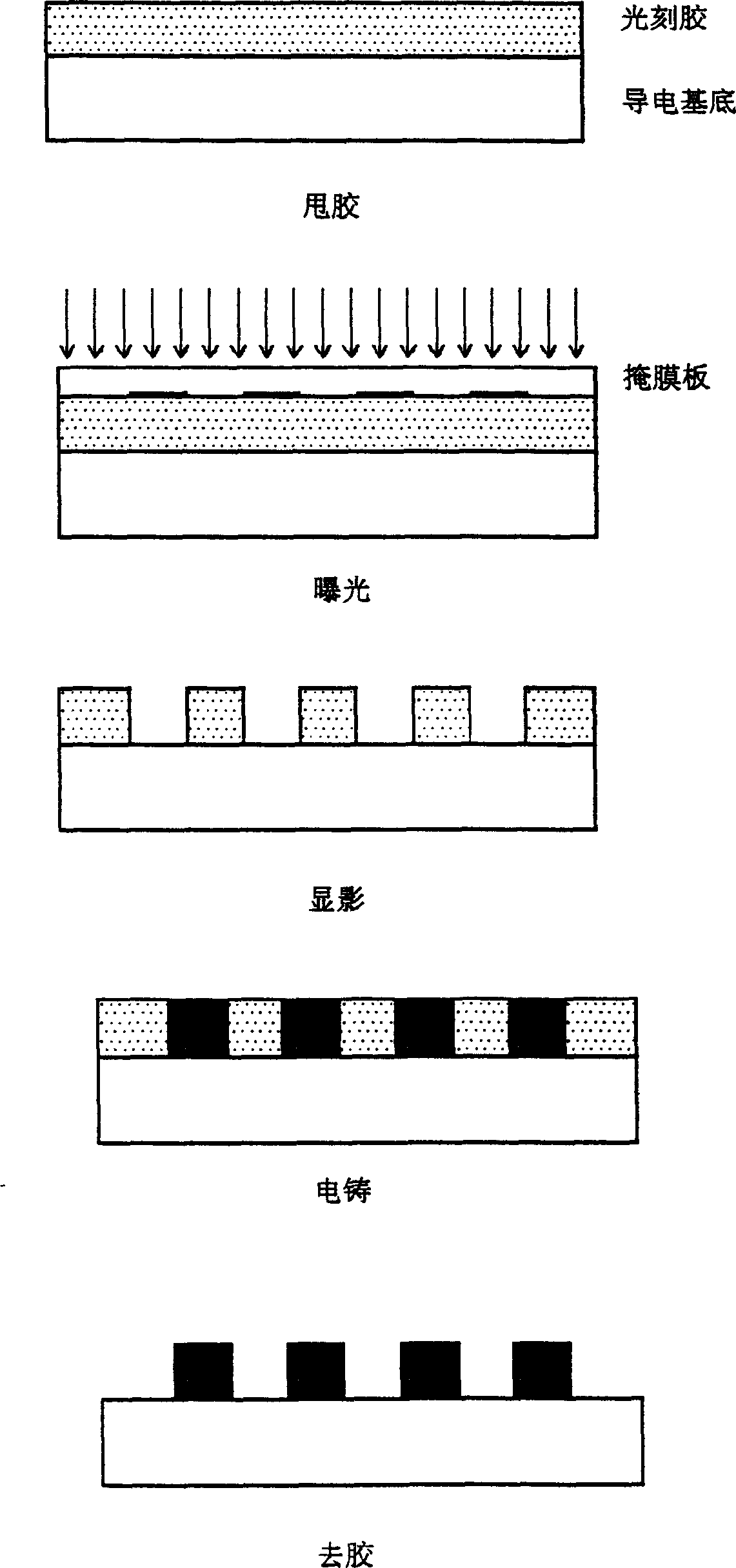

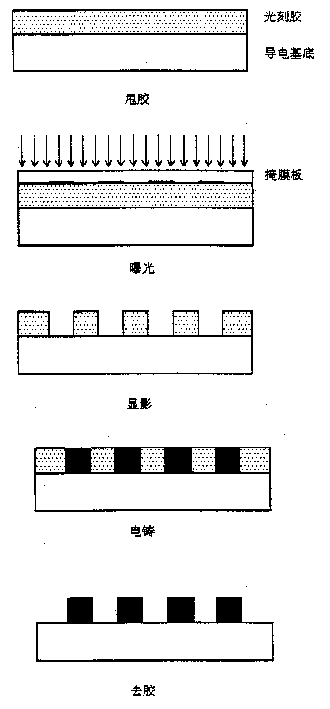

Process method of pore based on photolithograph

InactiveCN1482282ASolve processing problemsSolve the costSpinnerette packsElectroforming processesFiberHigh volume manufacturing

The present invention belongs to the field of chemical fiber producing technology, and is spinning jet capillary bore machining method based on photoetching. Mask is first made based on the shape ofspinning capillary bores, homogeneous thick photoresist layer is then formed on conducting substrate, and through further ultraviolet exposure and electroforming the metal structure is obtained, withthe photoresist in spinning capillary pores being finally eliminated. The said technological process can machine spinning board with complicated pores and pores in different shapes, and the technological process has high flexibility, high identity, high precision and low cost and is suitable for mass production. The present invention provides one new method for machining spinning jet capillary pores.

Owner:SHANGHAI JIAO TONG UNIV

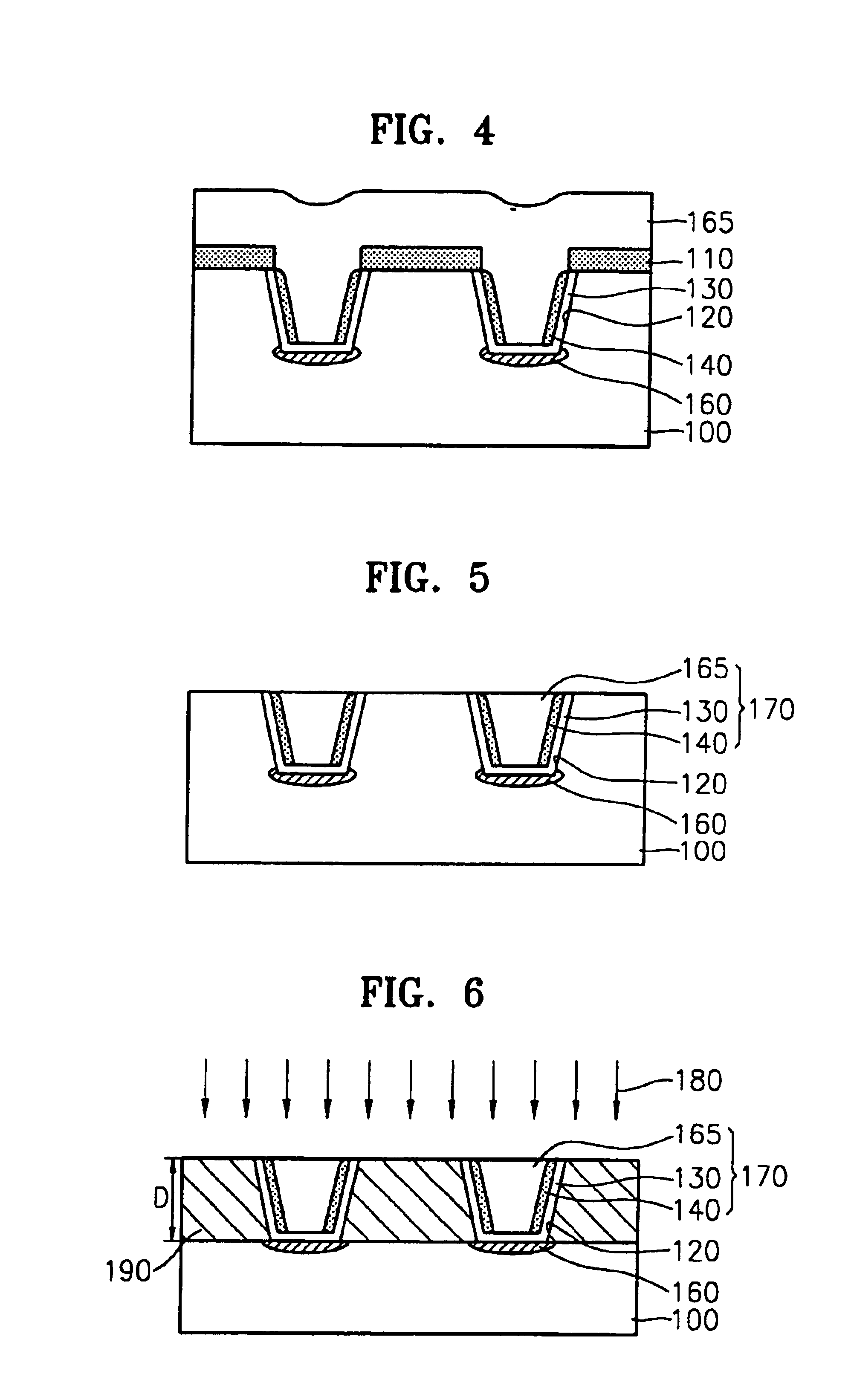

Method for forming shallow well of semiconductor device using low-energy ion implantation

InactiveUS6844239B2Reduce well resistanceLower resistanceTransistorSolid-state devicesDevice materialHigh doses

A method for forming a shallow well of a semiconductor device using low-energy ion implantation is described. A well region is formed to the depth of a trench isolation layer using a low-energy, high-dose ion implantation process. The method for forming a well using low-energy ion implantation can minimize well margin reduction caused by impurity spread and well margin reduction caused by shrinkage of a thick photoresist pattern.

Owner:SAMSUNG ELECTRONICS CO LTD

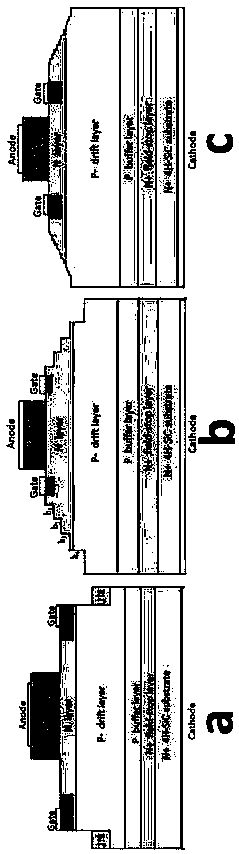

Novel silicon carbide (SiC) small-angle tilting table terminal structure and preparation method thereof

PendingCN107910360AEnhanced inhibitory effectSimple processSemiconductor devicesTerminal equipmentHigh pressure

The invention provides a novel silicon carbide (SiC) small-angle tilting table terminal structure applicable to SiC large-sized high-voltage device terminal structures and a preparation method thereof. Such high-voltage devices include SiC GTO, SiC PiN and other SiC devices that adopt the small-angle tilting table terminal structure; and an etching technology of the invention uses an AZ4620 thickphotoresist as a mask mode and achieves uniform reflux of the large-area photoresist, and based on different reflux conditions of the photoresist, a base angle of an etched SiC small-angle tilting table can be between 0 degree and 20 degrees. As different types of devices have different etching depths on the tilting table, the etching technology can be used to prepare a single tilting table etching terminal structure, or can be used for multiple times to form a multi-stage tilting table etching terminal structure. Compared with other multi-table terminal etching scheme processes, the scheme ofthe invention can be significantly simplified, and as the scheme is an ideal slope, the suppression effect of the scheme on the edge field intensity aggregation of the devices is theoretically superior to other approximation schemes.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

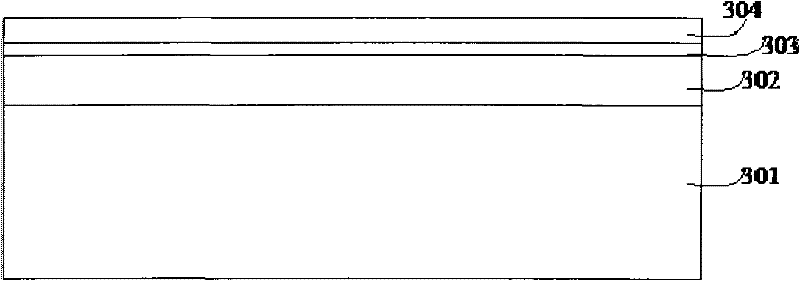

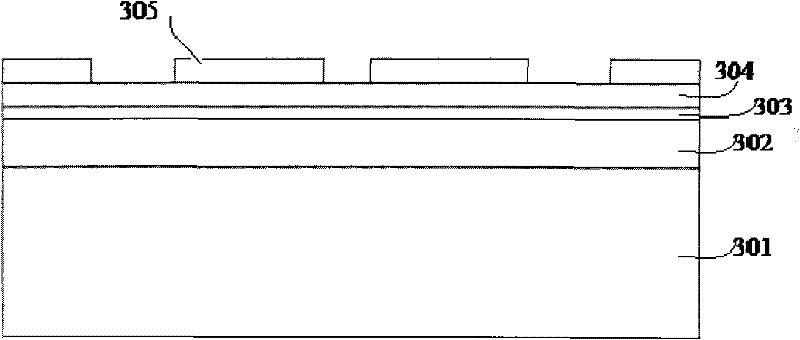

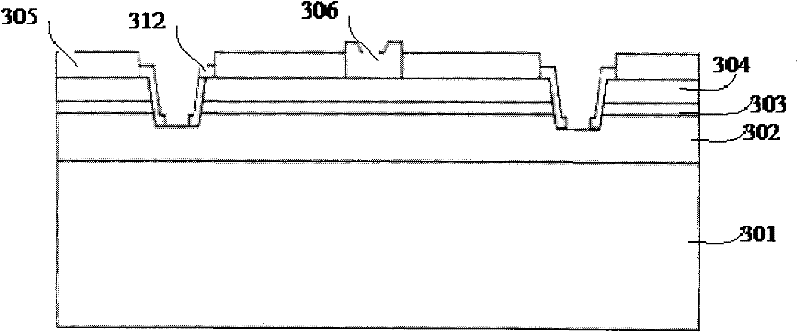

Production method of thin film transistor

InactiveCN107369715AReduce manufacturing costTransistorSemiconductor/solid-state device manufacturingThick photoresistSemiconductor

The invention provides a production method of a thin film transistor. The method comprises the following steps of sequentially depositing a semiconductor layer and a metal layer; coating a photoresist layer on the metal layer; exposing the photoresist layer, patterning the photoresist layer, wherein one part of the photoresist layer is formed into a thin photoresist layer, and the other part is formed into the thick photoresist layer or non-photoresist layer; etching primarily: etching the metal layer and the semiconductor layer to remove the part covered by the non-photoresist layer; graying the photoresist layer, and removing the thin photoresist layer to expose the metal layer positioned under the thin photoresist layer; etching secondarily: etching the metal layer to form a source, a drain and a channel area and expose the semiconductor layer positioned in the channel area; and removing the photoresist layer. According to the production method provided by the invention, one time of utilization of a photomask is reduced, production cost of the thin film transistor is reduced, and a technological process is optimized.

Owner:NANJING CEC PANDA FPD TECH CO LTD +2

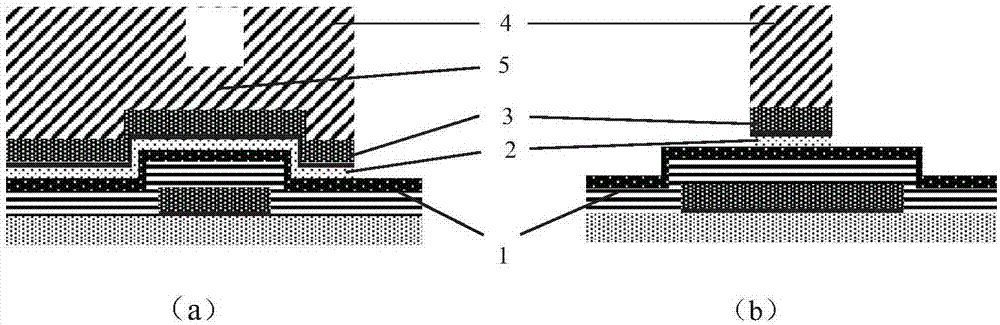

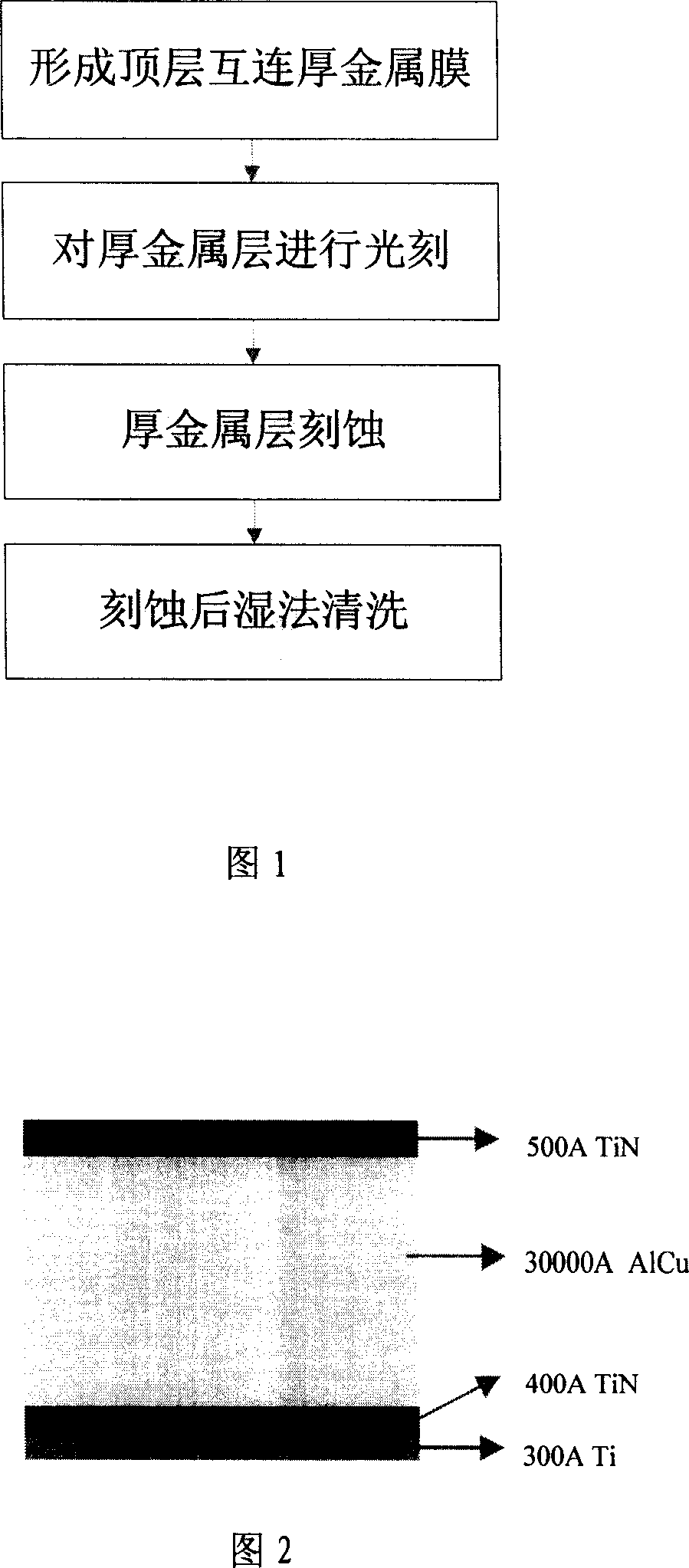

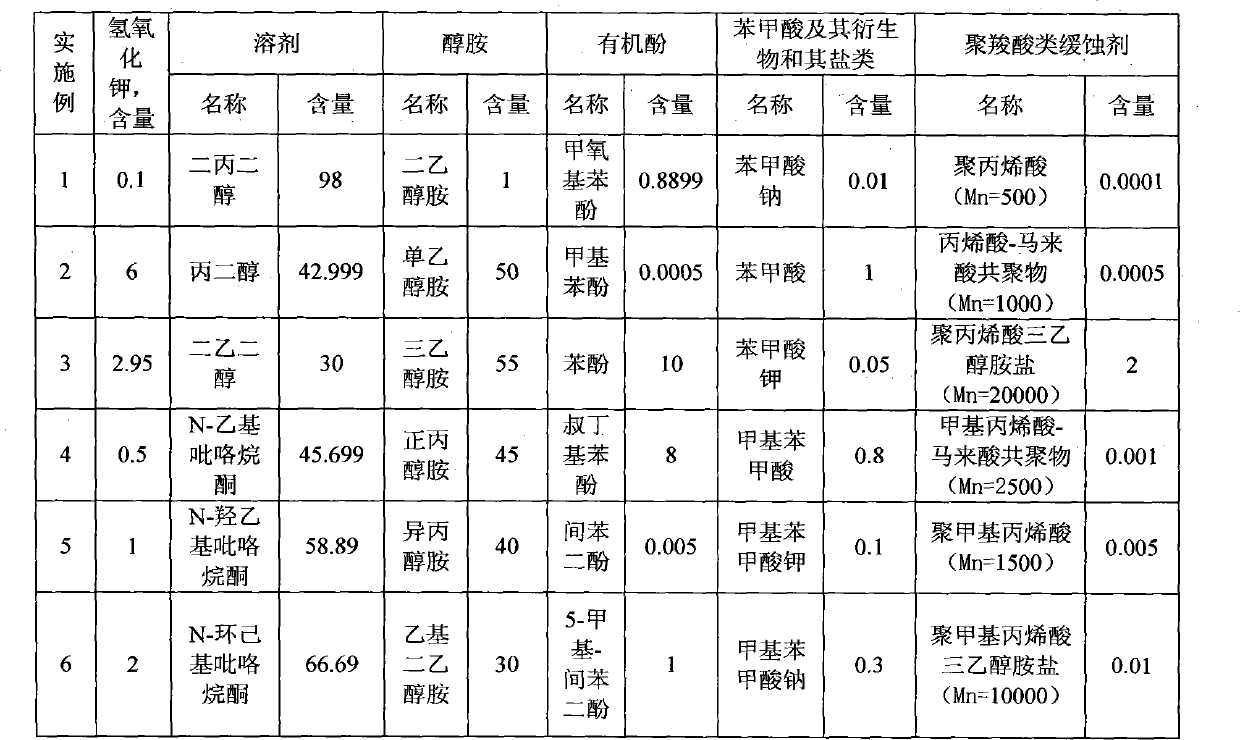

Method for making thick metal inductance in integrated circuit

ActiveCN1979800AInductive process stability is goodGood electrical propertiesSemiconductor/solid-state device manufacturingGas phaseProtection layer

The method includes steps: (1) using physical vapor deposition to deposit Ti, TiN, AlCu, and TiN in sequence to form thick metal films interlinked through top level; (2) using thick photoresist as metal graph protection layer in etching time to carry out photo etching for thick metal layers; (3) using Cl2 and BCl3 as main etching gases, the dry etching method carries out etching for thick metal layers; (4) using wet cleaning process to carry out cleaning step after etching. The invention is suitable to IC-manufacture area.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

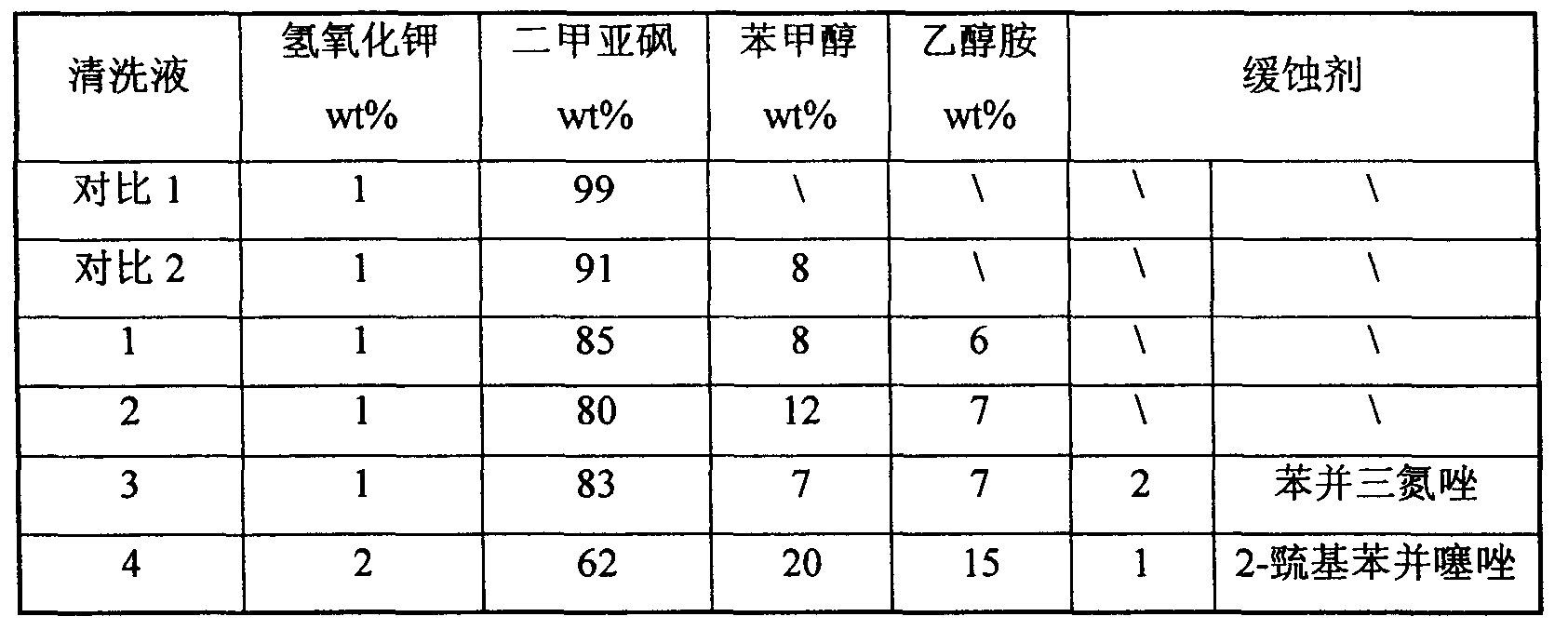

Thick film photoresist cleaning solution

ActiveCN102566332AAvoid corrosionReduce corrosionPhotosensitive material processingBenzoic acidPotassium hydroxide

The invention discloses a low-etching cleaning solution suitable for cleaning relatively thick photoresist. The low-etching photoresist cleaning solution contains potassium hydroxide, solvent, alkylol amine, organic phenol, benzoic acid and derivative thereof or salt thereof, and polycarboxylate corrosion inhibitor. The photoresist cleaning solution can be used for removing the photoresist or other residues on metal, metal alloy or dielectric substrate, has relatively low etching rate on the metals such as copper, aluminum, tin, lead and silver, and has good application prospect in the micro-electronics field such as semiconductor chip cleaning.

Owner:ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

Method for improving photoresist morphology through repetitive exposure

ActiveCN105334699ASolving the challenge of difficult to achieve topography with undercut structuresLow costPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistLength wave

The invention discloses a method for improving photoresist morphology through repetitive exposure. According to the method, problem that in a thick photoresist lithography technology, a morphology having an undercut structure is difficulty realized on the sidewall of the photoresist can be solved, and the method has the advantages of low cost and strong enforcement performance. The method comprises the following steps: coating a first photoresist and pre-baking the first photoresist, wherein the first photoresist only sensitizes to light of a first wavelength; coating a second photoresist and pre-baking the first photoresist, wherein the second photoresist only sensitizes the light of a second wavelength, and the second wavelength is different from the first wavelength; exposuring the first photoresist by using light of the first wavelength; exposuring the second photoresist by using light of the second wavelength; and developing the exposure first photoresist and the second photoresist, wherein, the exposure condition is set, so that the size of the developed first photoresist is smaller than the size of the second photoresist.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Manufacturing method of large-power vertical light-emitting diode

ActiveCN102544251AReduce the binding forceReduce difficultySemiconductor/solid-state device manufacturingSemiconductor devicesManufacturing technologyEngineering

The invention provides a manufacturing method of a large-power vertical light-emitting diode, relating to the technical field of a semiconductor photoelectric device. The manufacturing method disclosed by the invention comprises the following steps of: 1) generating an epitaxial wafer on a sapphire substrate; 2) evaporating a reflection metal layer on a P-type GaN-based semiconductor layer; 3) forming a current stopping layer on an N-electrode area and forming a protection type passivation layer on the side wall of a groove; 4) forming an isolation groove; 5) filling photoresist I into the isolation groove; 6) depositing a diffusion impervious layer on the surface of the device, electrically plating a seeding layer, etching to expose the diffusion impervious layer, and coating thick photoresist II; 7) forming a metal supporting layer above the device; 8) stripping the sapphire substrate from the device and cleaning; 9) roughening the surface and evaporating an N-type electrode; 10) cutting the device to from core particles; and 11) grinding and polishing the surface of the sapphire substrate. According to the manufacturing method disclosed by the invention, the stability of an LED (Light-Emitting Diode) in a vertical structure can be improved and the yield of the finished core particles is improved.

Owner:NANTONG TONGFANG SEMICON

Forming a ferromagnetic alloy core for high frequency micro fabricated inductors and transformers

ActiveUS20130062729A1Reduces eddy current lossTotal current dropSemiconductor/solid-state device detailsSolid-state devicesTransformerAlloy

A plurality of sequential electro-deposition, planarization and insulator deposition steps are performed over a patterned thick photoresist film to form a laminated ferromagnetic alloy core for micro-fabricated inductors and transformers. The use of a plurality of contiguous thin laminations within deep patterns on non-removable photoresist film provides sufficient volume of magnetic film in, for example, high frequency applications, and reduces eddy current loss at high frequency.

Owner:TEXAS INSTR INC

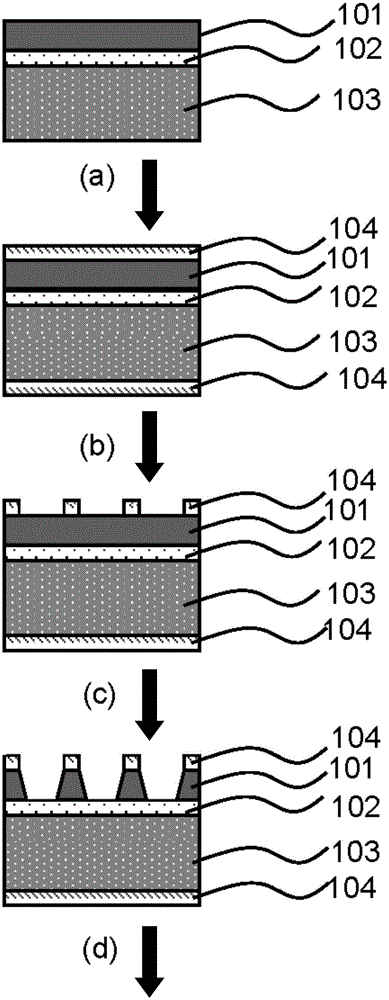

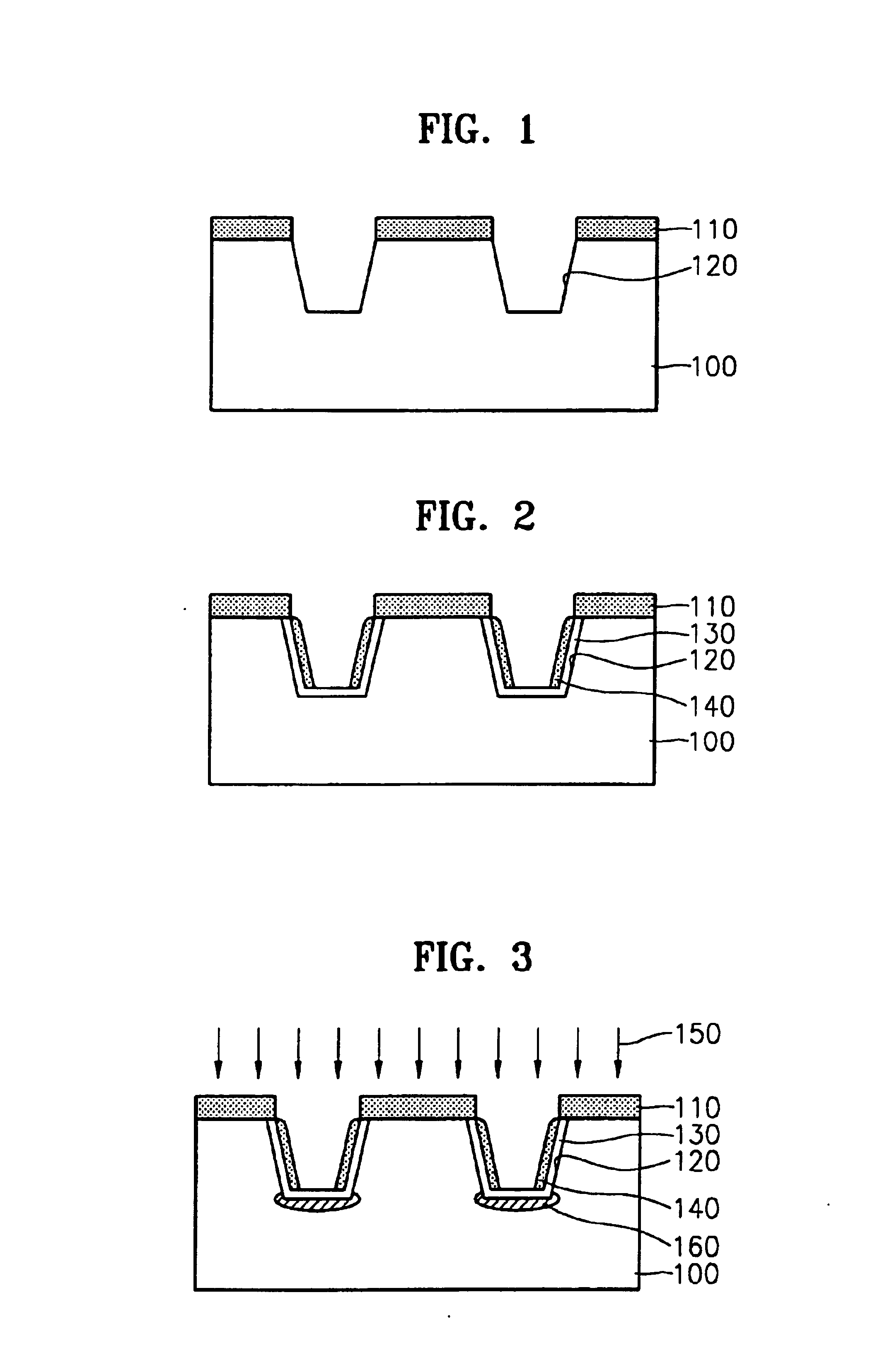

Fabrication method of a three-dimensional microstructure

InactiveUS20030215753A1Radiation applicationsSemiconductor/solid-state device manufacturingThree dimensional microstructureThick photoresist

A fabrication method of three-dimensional microstructures is to fabricate a real 3D microstructure. First, a substrate is coated with an anti-reflection layer to absorb reflected exposure light, and then the anti-reflection layer is overlaid with a first thick photoresist. After having been fully exposed by a first photo mask, a predetermined exposure depth of the first thick photoresist is achieved by a second photo mask and dosage-controlled UV exposure. If the unexposed areas of the first thick photoresist are released during a development step, a single-layer microstructure is created. Inversely, a multi-layered microstructure can be obtained simply by repeating the process described above. After all layers are laminated on the substrate, all unexposed areas of the all thick photoresist layers are released and connected to each other during a development step.

Owner:NATIONAL TSING HUA UNIVERSITY

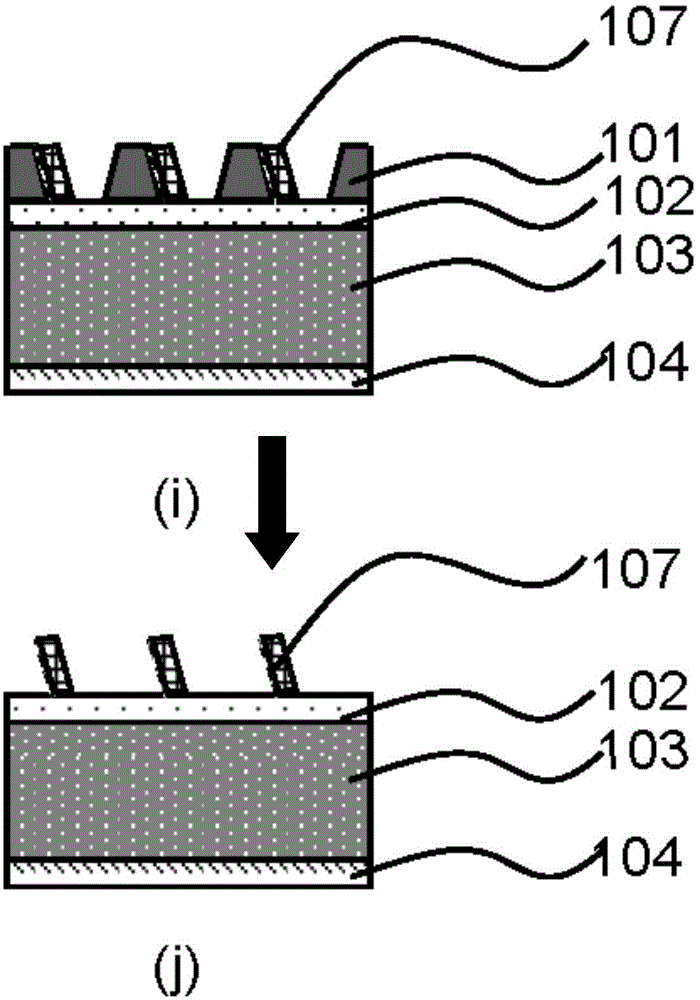

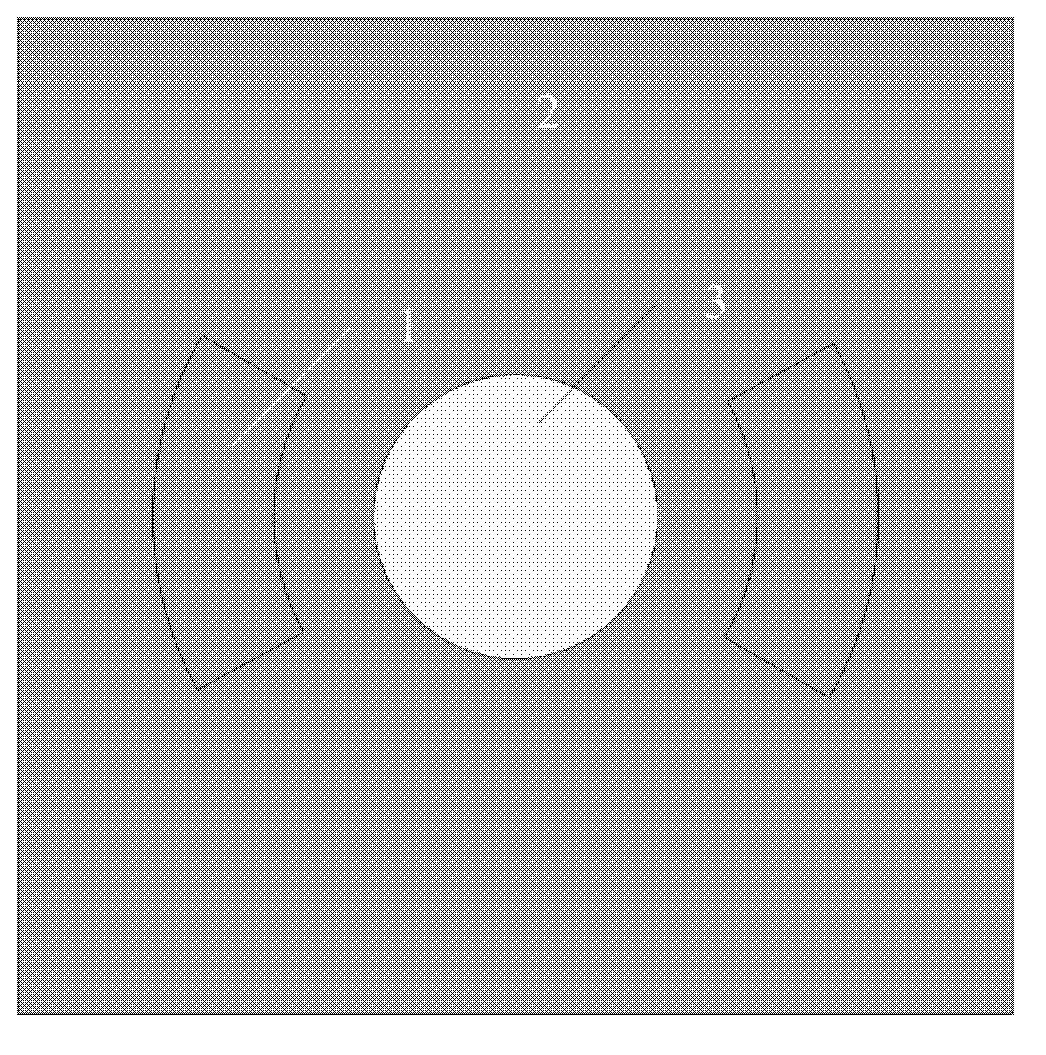

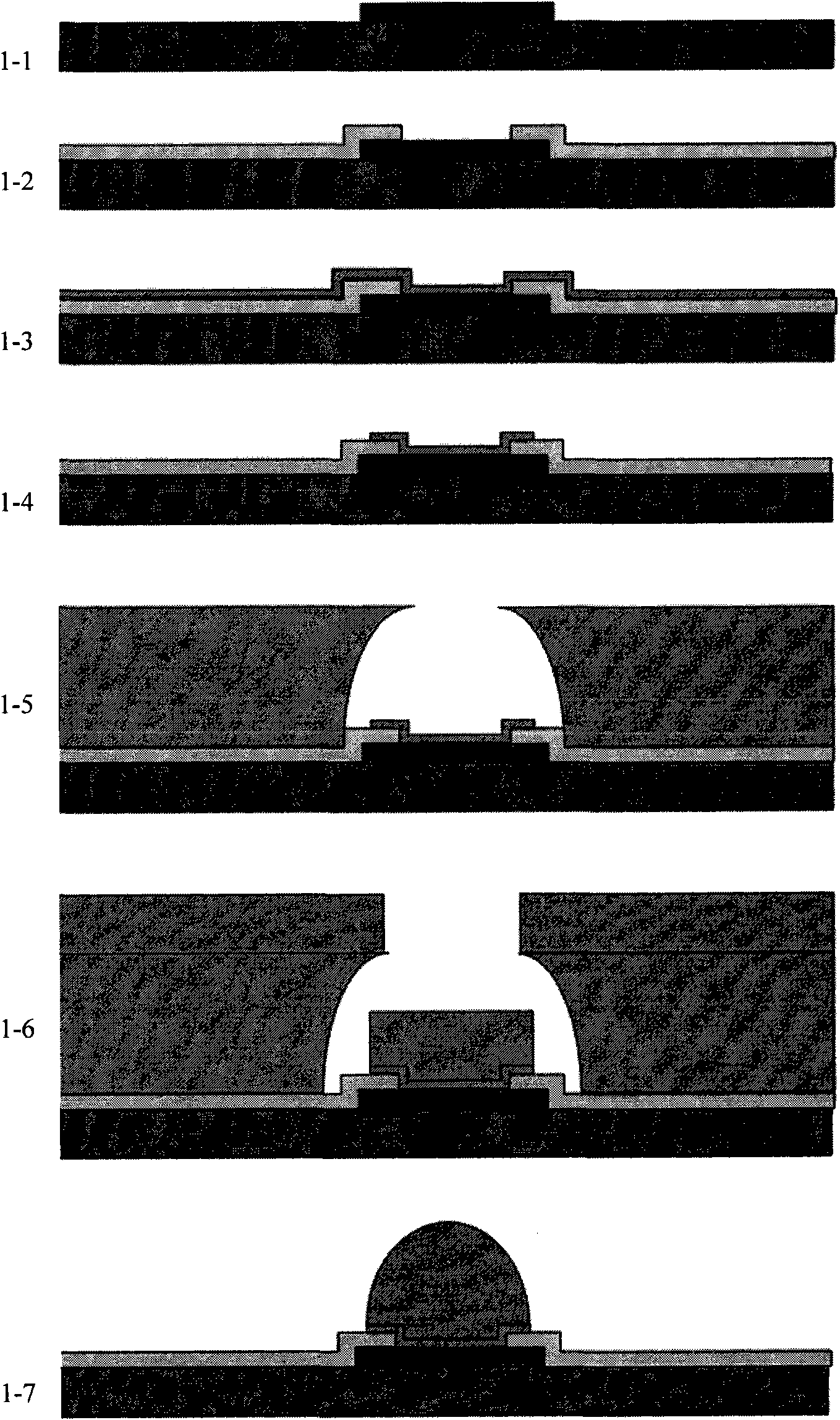

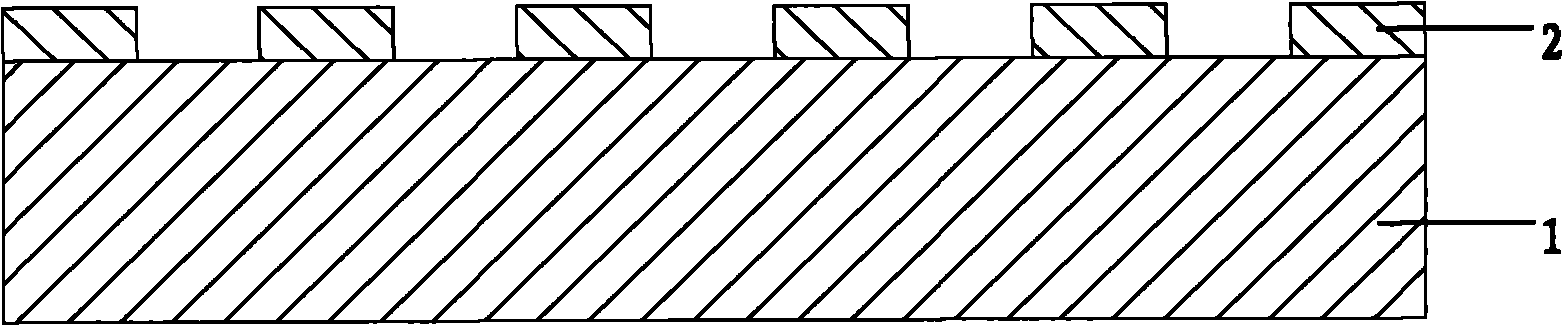

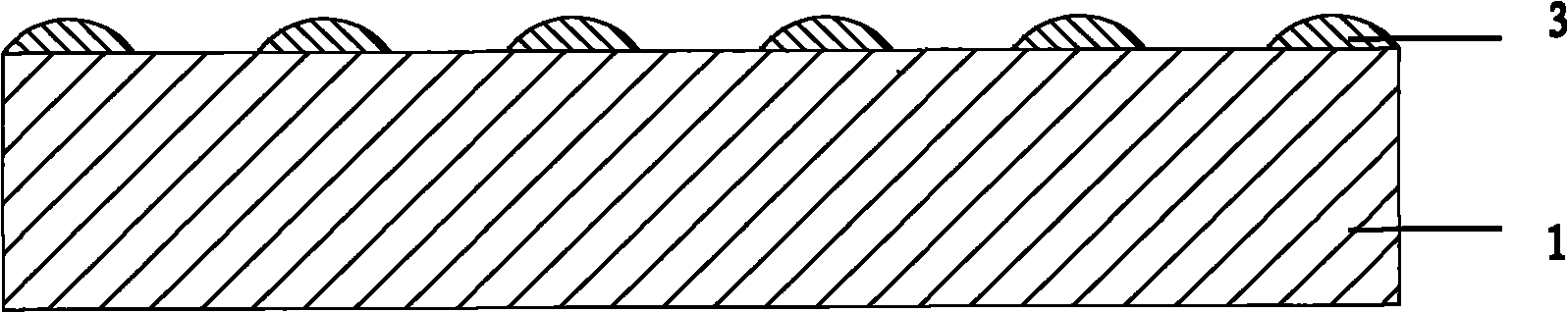

Self-aligned process for preparing convex graphical substrate

The invention discloses a method for preparing a convex graphical substrate used for the epitaxial growth of nitrides, namely, a self-aligned process for preparing the convex graphical substrate. The method comprises the following steps of: carbonizing a plurality of convex graphical microstructures which are made of thin photoresist and arranged on a sapphire substrate by high-temperature processing; coating a thick photoresist layer on the carbonized microstructures, and carrying out self-aligned exposure on the thick photoresist layer by using the carbonized convex graphical microstructures as a masking film; and fusing the carbonized convex graphical microstructures and the developed photoresist graphs to convex round balls by using high temperature hardening, and finally transferring the graphical structure to the substrate by using the dry etching technology so as to obtain the convex graphical substrate. By adopting the self-aligned process of the invention, the problem that the convex graph made of thick photoresist is easy to drop can be solved, a high-precision exposure requirement can be met by using a common exposure machine, and the uniformity of the graph can be greatly improved, so that the process for preparing the convex graphical substrate can realize industrialization.

Owner:EPILIGHT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com