Semiconductor made thick photoresist film coating device and application method thereof

A coating device and semiconductor technology, which is applied in the manufacture of semiconductor/solid-state devices, devices for coating liquids on surfaces, spray devices, etc. Thick and uniform, easy to use and flexible, to eliminate the effect of wafer edge protrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

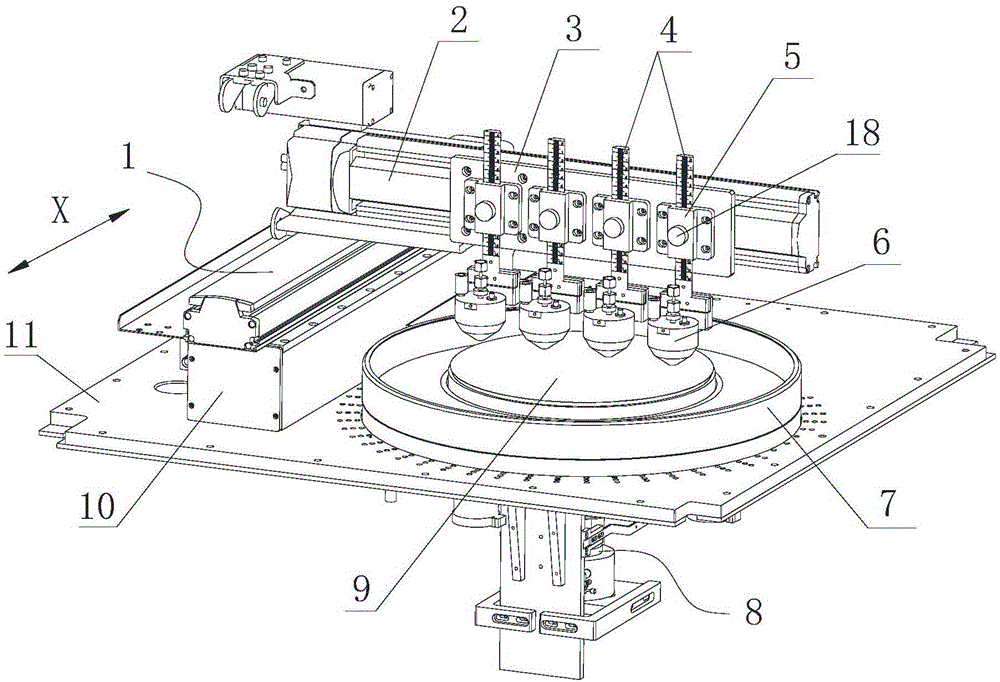

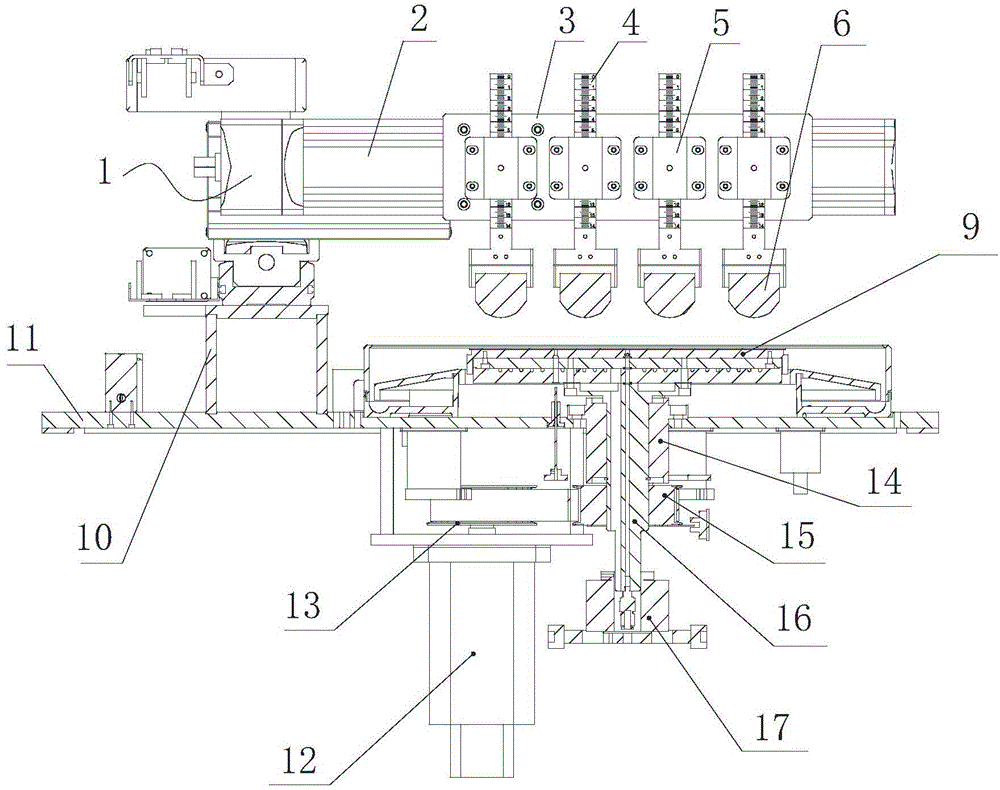

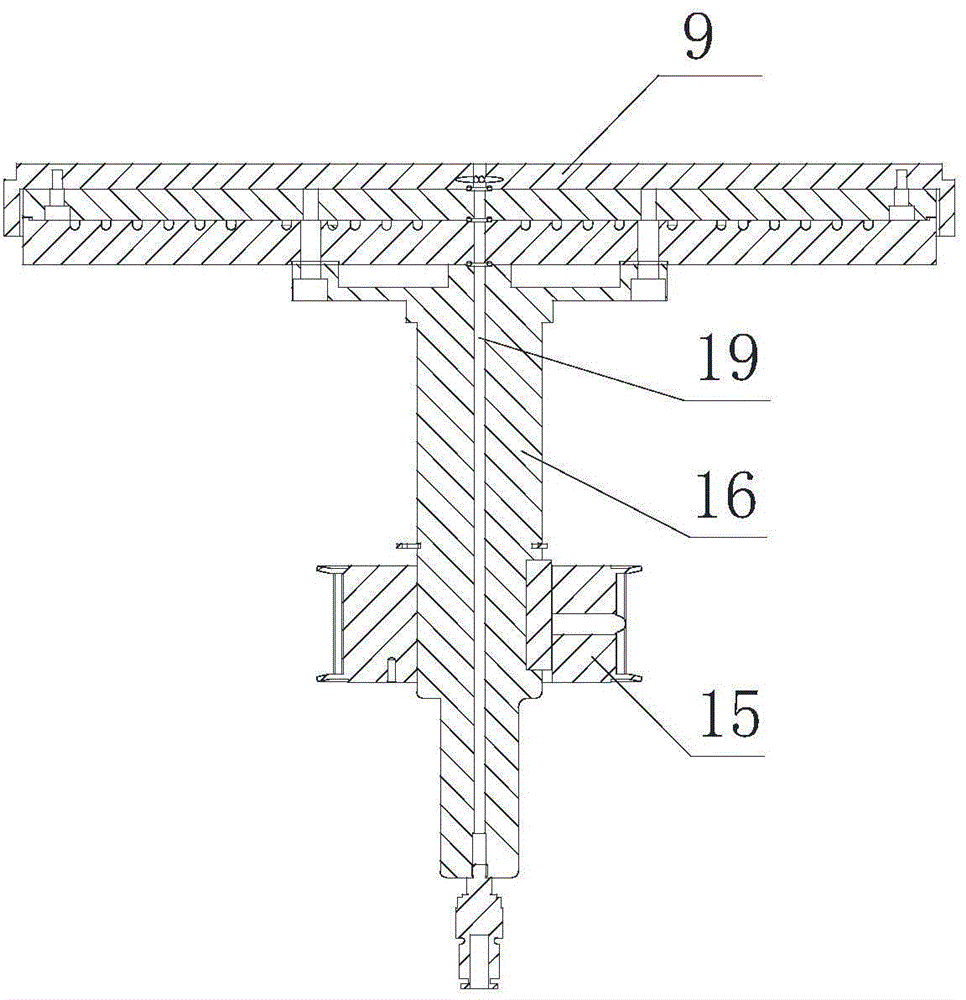

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] Such as Figure 1~2 As shown, the present invention includes an electric cylinder 1, a fixed plate 3, a scale 4, a spray head 6, a plastic cup assembly 7, a rotary adsorption mechanism 8 and a base plate 11, wherein the base plate 11 is fixed on the external equipment frame of the present invention, and the electric cylinder 1 is installed on the base plate 11 through a supporting frame 10, the electric cylinder 1 is provided with a moving beam 2, and the moving beam 2 is vertically arranged relative to the length direction of the supporting frame 10, and the moving beam 2 is A fixed plate 3 is provided, and a plurality of scales 4 are installed on the fixed plate 3 through the mounting frame 5 respectively, and a nozzle 6 is fixedly installed at the lower end of each scale 4, and all the nozzles 6 are driven by the electric cylinder 1 Translate synch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com