Process method of pore based on photolithograph

A processing method and technology of capillary holes, which are applied in spinneret assemblies, textiles and papermaking, electrolysis processes, etc., can solve the problems of adhesion between injection molding materials and molds, loss of precision of spinneret capillaries, etc., and achieve good consistency, Suitable for mass production, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

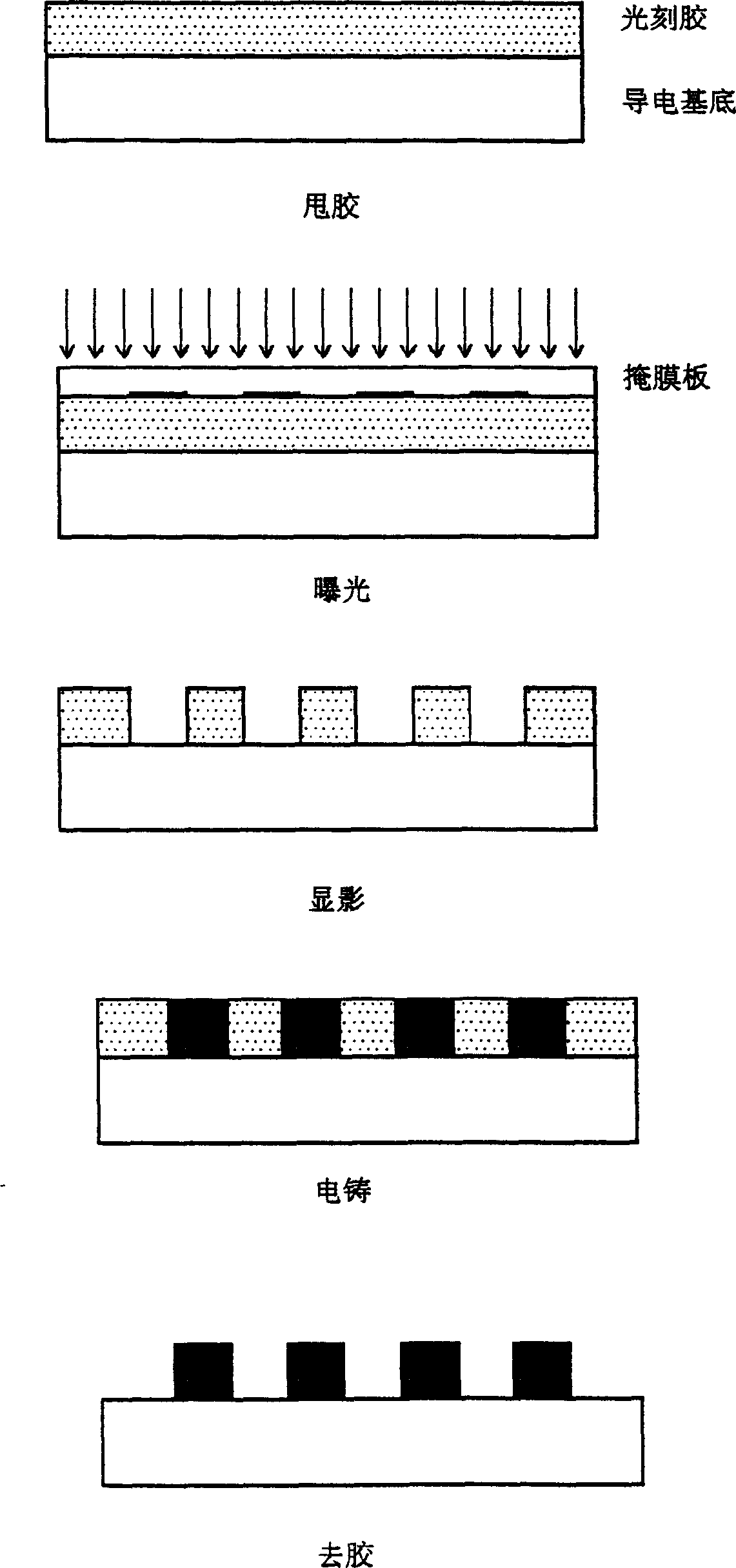

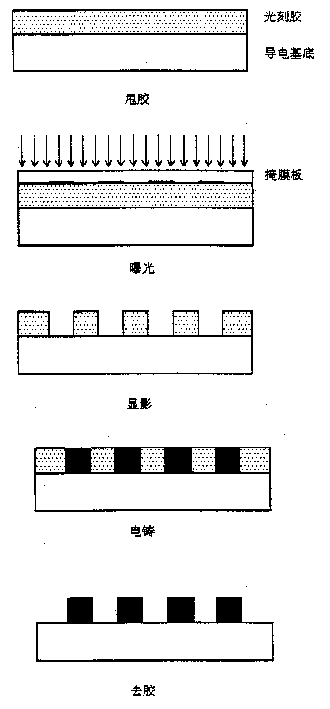

[0016] Such as figure 1 Shown, provide following embodiment in conjunction with the content of the inventive method:

[0017] (1) Draw a plan view of the cross-sectional shape of the spinneret capillaries on the entire spinneret, and determine the shape of the spinneret capillaries (can have a variety of hole shapes), quantity, and positional relationship, and make a mask according to this plan plate;

[0018] (2) The spinneret with the guide holes processed is filled with paraffin wax, and the surface is cleaned. A layer of 800-1000 angstrom metal copper film is sputtered on the surface of the spinneret. Throw a thin layer of photoresist (AZ4330) 1-2 microns, and leave a photoresist film 5-10 microns larger than the guide hole at the guide hole by photolithography. Use wet etching (ferric chloride solution) to remove the metal copper film that is not protected by photoresist, and then use acetone to remove the photoresist protective layer to obtain a metal copper film, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com