Photoresist remover

A photoresist and remover technology, applied in optics, optomechanical equipment, detergent compositions, etc., can solve the problems of strong corrosiveness and insufficient cleaning ability of semiconductor wafer patterns and substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The reagents and raw materials used in the present invention are all commercially available. The cleaning solution of the present invention can be prepared by simply and uniformly mixing the above components.

[0020] The advantages of the present invention will be further elaborated below through specific embodiments. But the present invention includes, but is not limited to, the specific compositions of the following examples.

[0021] Preparation Example

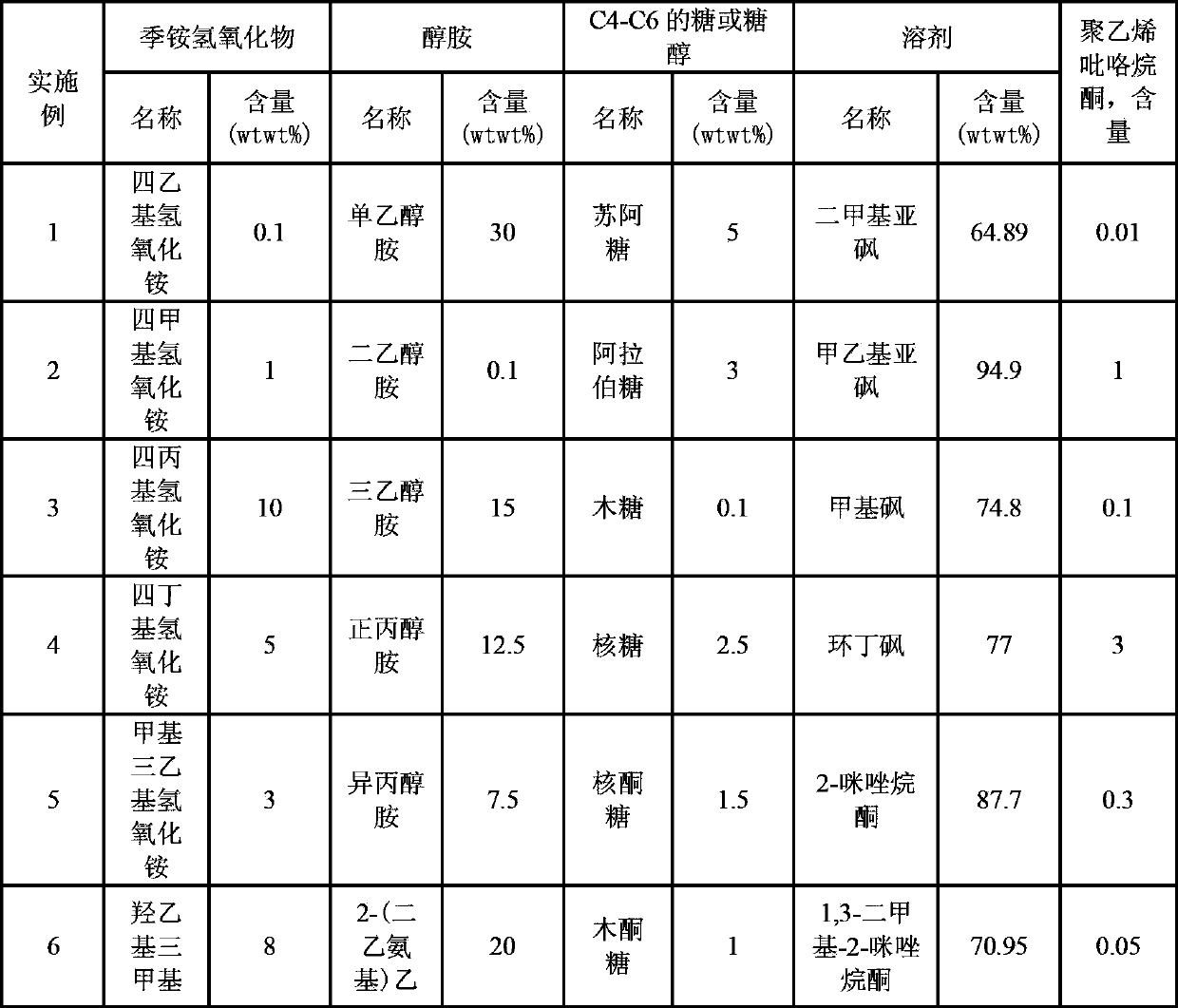

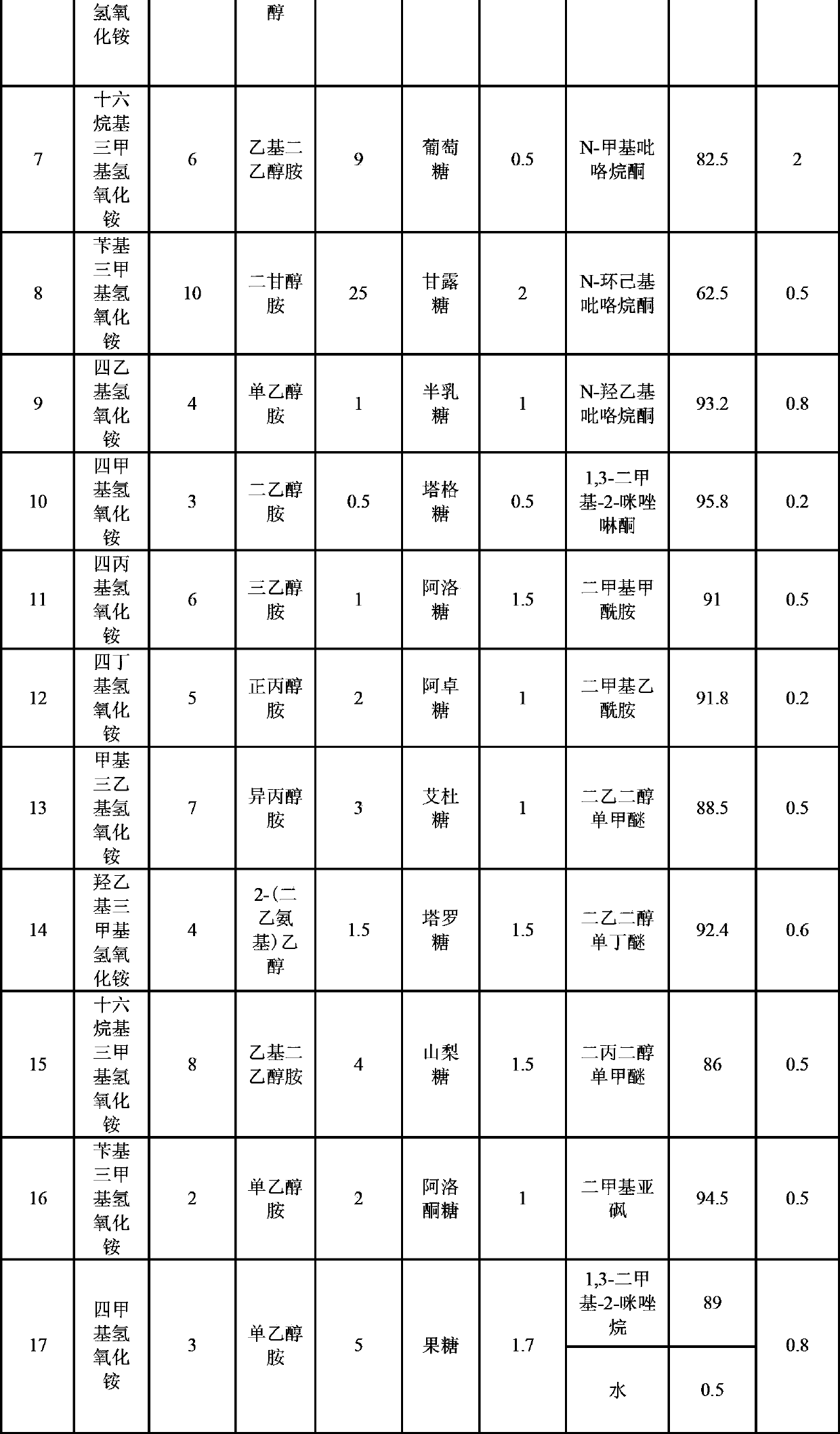

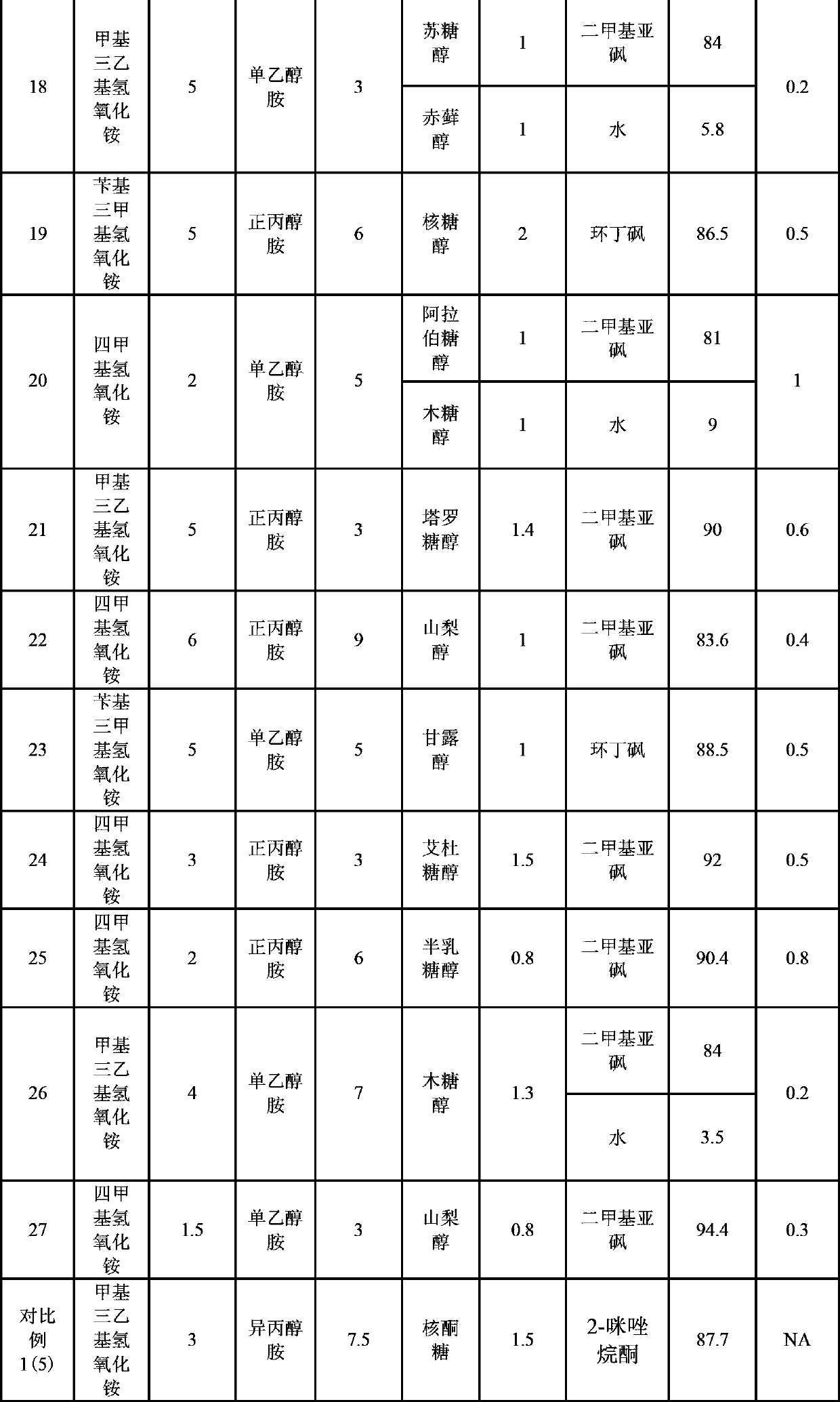

[0022] Table 1 provides the cleaning solution formula of the present invention. The percentages described below are all mass percentages.

[0023] Table 1 Components and contents of cleaning agents in Examples and Comparative Examples

[0024]

[0025]

[0026]

[0027]

[0028] In order to further investigate the cleaning situation of this type of cleaning solution, the present invention adopts the following technical means: immerse the wafer containing photoresist in the cleaning agent, and use a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com