Shutter device for exposure subsystem of photoetching machine

A technology of sub-system and lithography machine, applied in microlithography exposure equipment, photolithography process exposure device and other directions, can solve the problems of slow start-up speed of rotating motor, unsuitable for thin glue process, low exposure yield, etc. Heat resistance, improved exposure yield, effect of high shutter speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

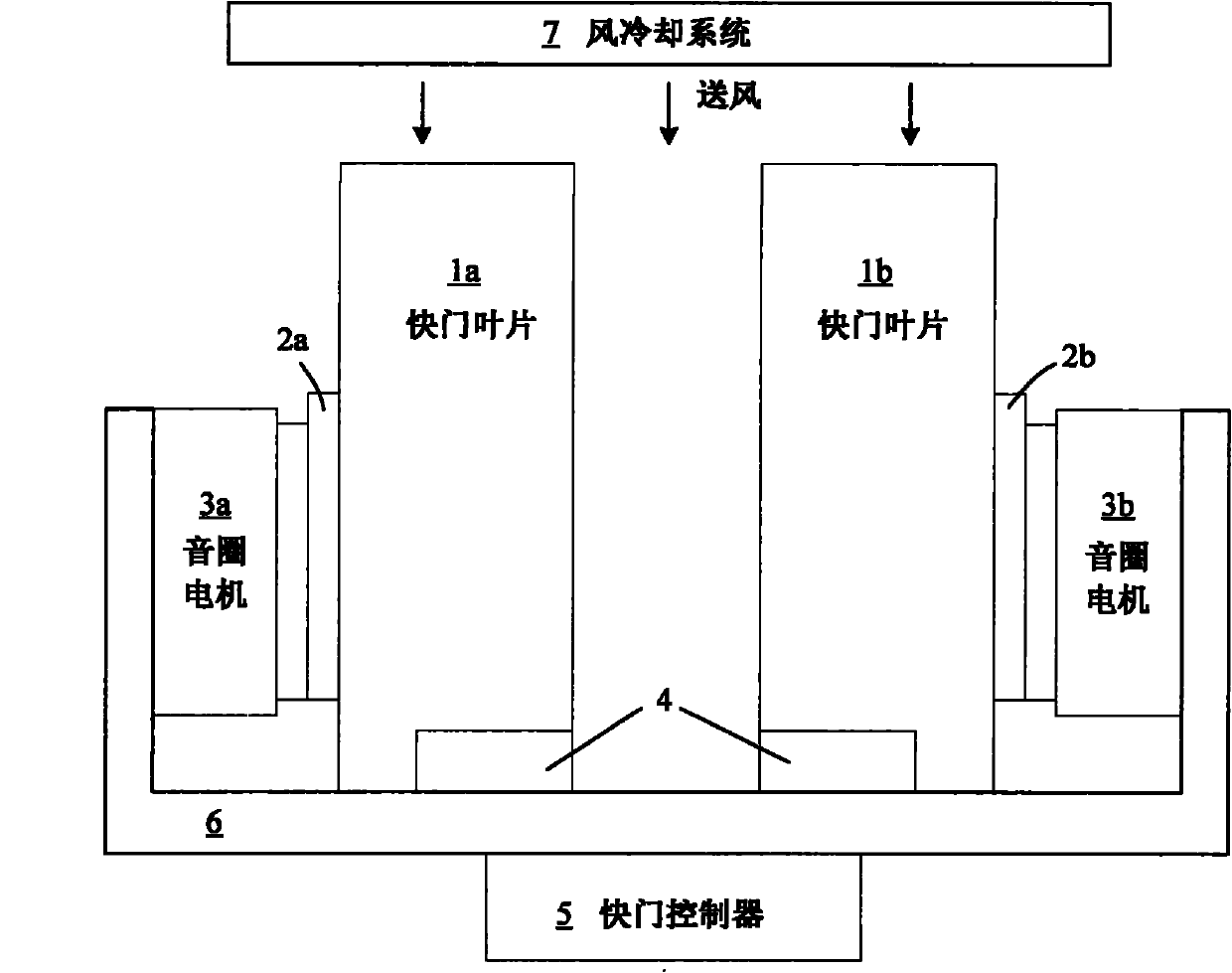

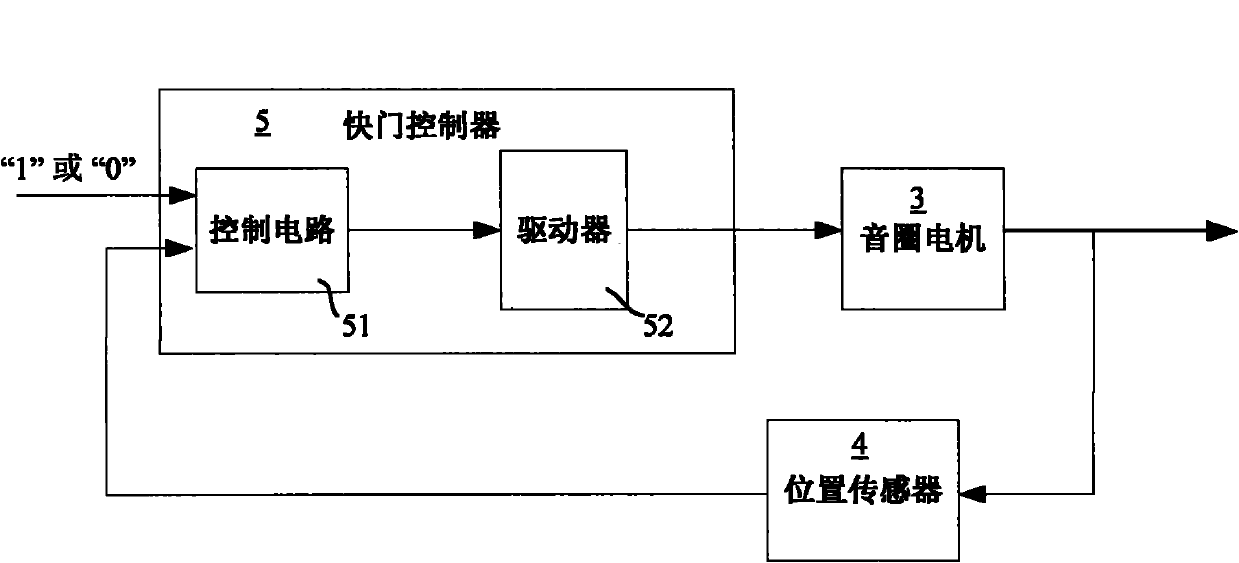

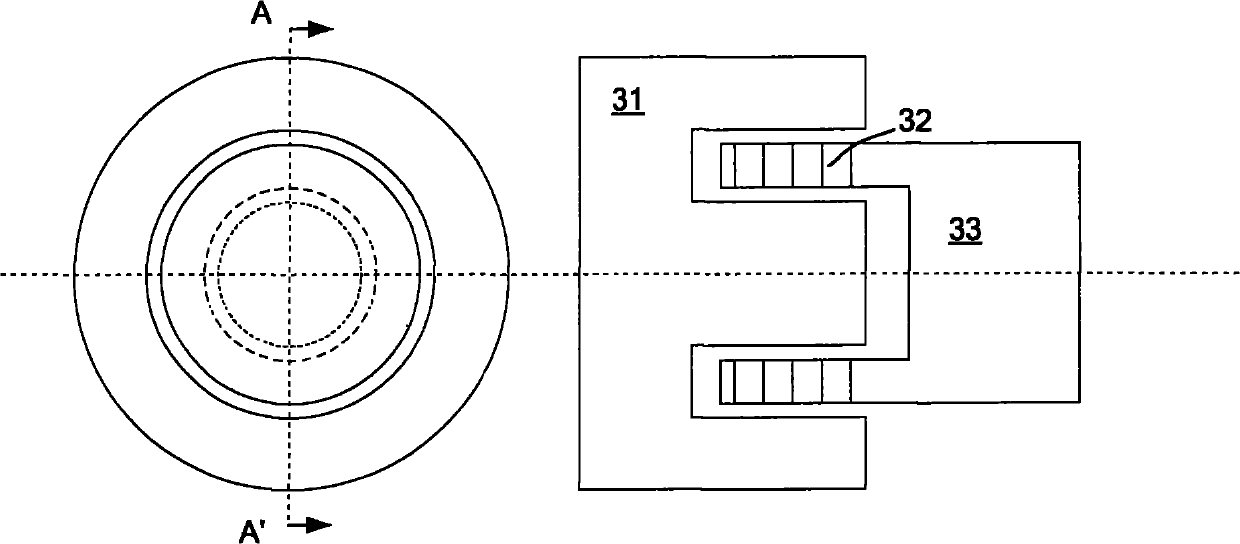

[0022] Such as figure 1 Shown is a top view of the shutter device of the exposure subsystem provided in this embodiment. The shutter device in this embodiment includes two shutter blades 1 a and 1 b , corresponding heat shields 2 a and 2 b , voice coil motors 3 a and 3 b , position sensors 4 a and 4 b and a shutter controller 5 . The voice coil motors 3a and 3b, the position sensors 4a and 4b and the shutter controller 5 are all located on the bracket. Such as figure 2 As shown, the shutter controller forms a closed-loop control loop with the voice coil motor and the position sensor. The shutter blades are used to block the exposure light and are symmetrically distributed on both sides of the exposure light path. It should be added that the shutter blades in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com