Method for preparing microwave power device by composite mask plate

A microwave power and reticle technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of microwave performance deterioration of microwave power devices, unequal distance between the emission area and the base ohmic contact area, etc., to achieve Improves microwave performance and eliminates the effect of unequal spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

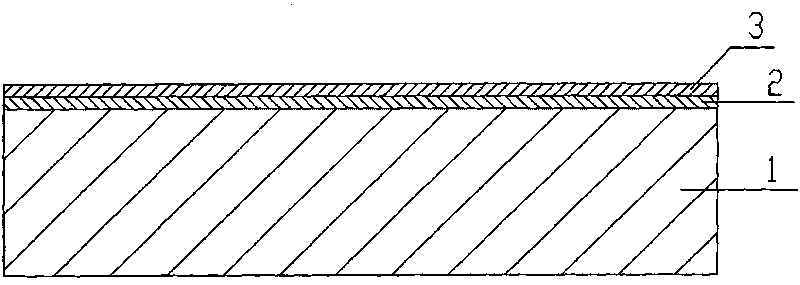

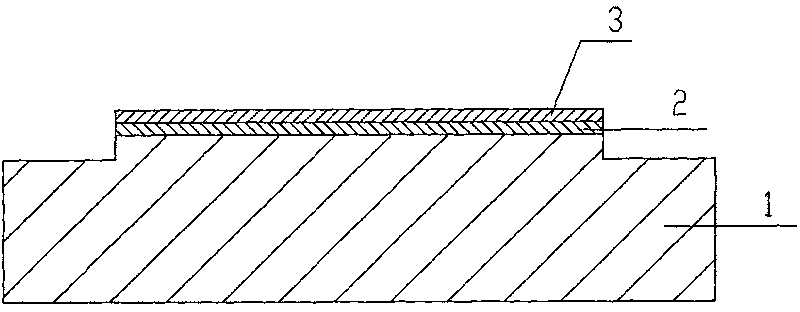

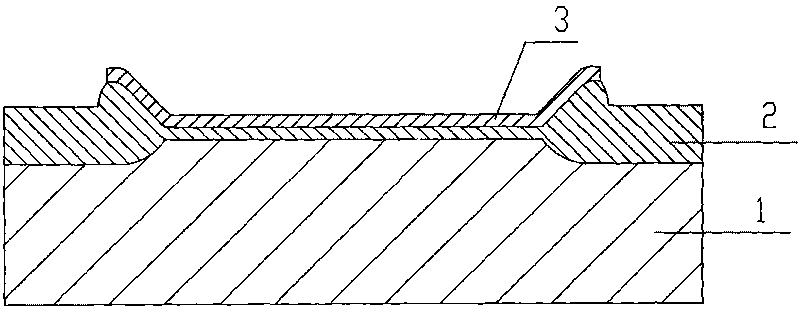

[0023] A method for preparing a microwave power device using a composite mask provided by the present invention includes: depositing a protective layer of silicon oxide 2 and silicon nitride 3 on a silicon wafer 1, and forming an emission region 10 and base ohmic contact region 13, and then deposit metal layer to prepare metal lead-out electrodes to form emitter 14 and base 15; in this method, composite mask plate 6 is used to complete photolithography at one time, and etch to form emission region window and base Very ohmic contact region window; selectively cover the base ohmic contact region window or emission region window by coating photoresist 7, continue etching and ion implantation to form emission region 10 or Base ohmic contact region 13; cover the emitter region 10 or base ohmic contact region 13 formed after the above-mentioned ion implantation wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com