Cleaning agent for thick-film photoresist

A cleaning agent and photoresist technology, applied in the processing of photosensitive materials, etc., can solve the problems of insufficient cleaning ability, strong corrosion of semiconductor wafer patterns and substrates, etc., and achieve the effect of low etching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below through specific embodiments.

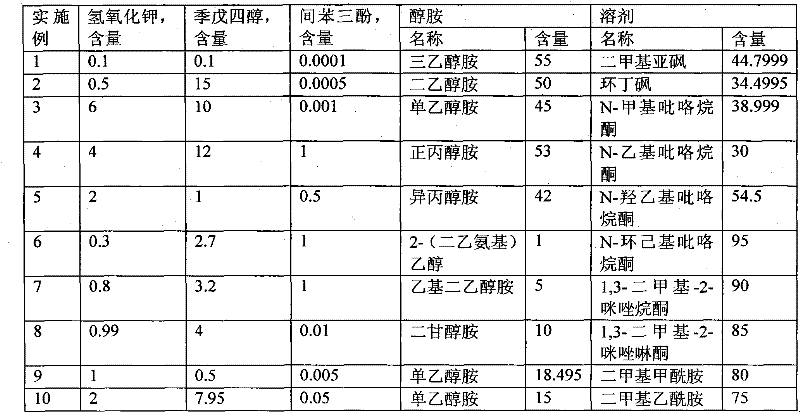

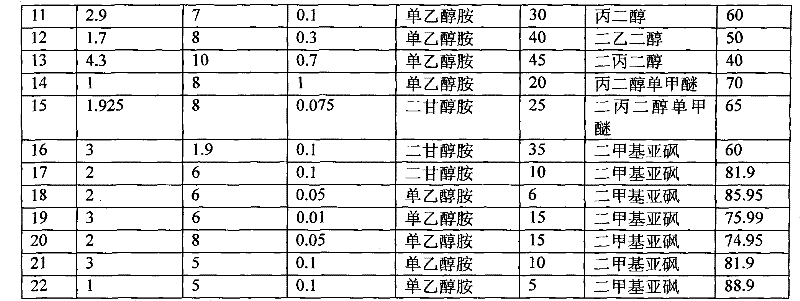

[0013] Component and content of cleaning agent in each embodiment (Examples) of table 1

[0014]

[0015]

[0016] Note: NA means that this component was not added.

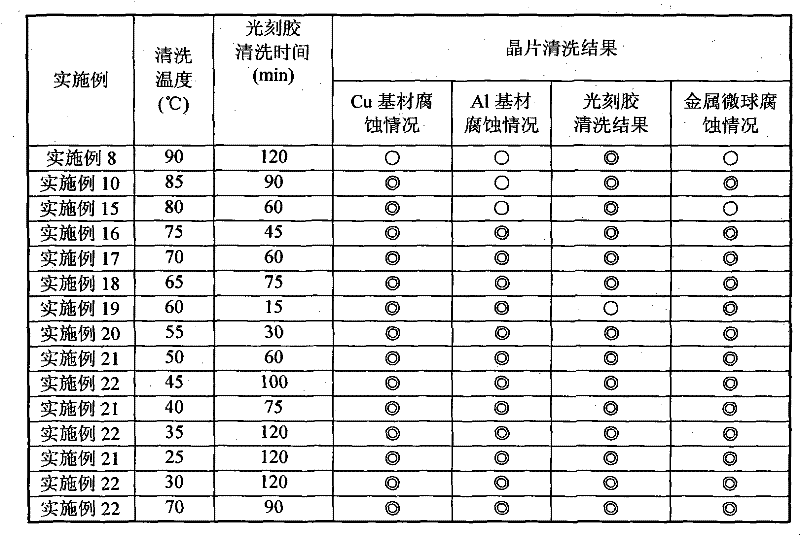

[0017] In order to further investigate the cleaning situation of this type of cleaning solution, the present invention adopts the following technical means: the semiconductor wafer (bump package) that will contain negative acrylic photoresist (thickness is about 120 microns, and through exposure and etching) (wafer) immersed in cleaning agent, vibrating with a constant temperature oscillator at a vibration frequency of about 60 rpm for 15 to 120 minutes at 25 to 90° C., then washed with deionized water and blown dry with high-purity nitrogen. The cleaning effect of the photoresist and the corrosion situation of the wafer by the cleaning solution are shown in Table 2.

[0018] Table 2 embodiment to wafer cleaning s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com