Manufacturing method of nanoscale super resolution optical focusing device

An optical focusing and nanoscale technology, applied in the direction of nanotechnology, diffraction grating, etc., can solve the problems of low transmission efficiency and weak focal spot intensity, and achieve the effects of improved integration, simple structure and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the scope of protection of the present invention is not limited to the following examples, but should include all content in the claims.

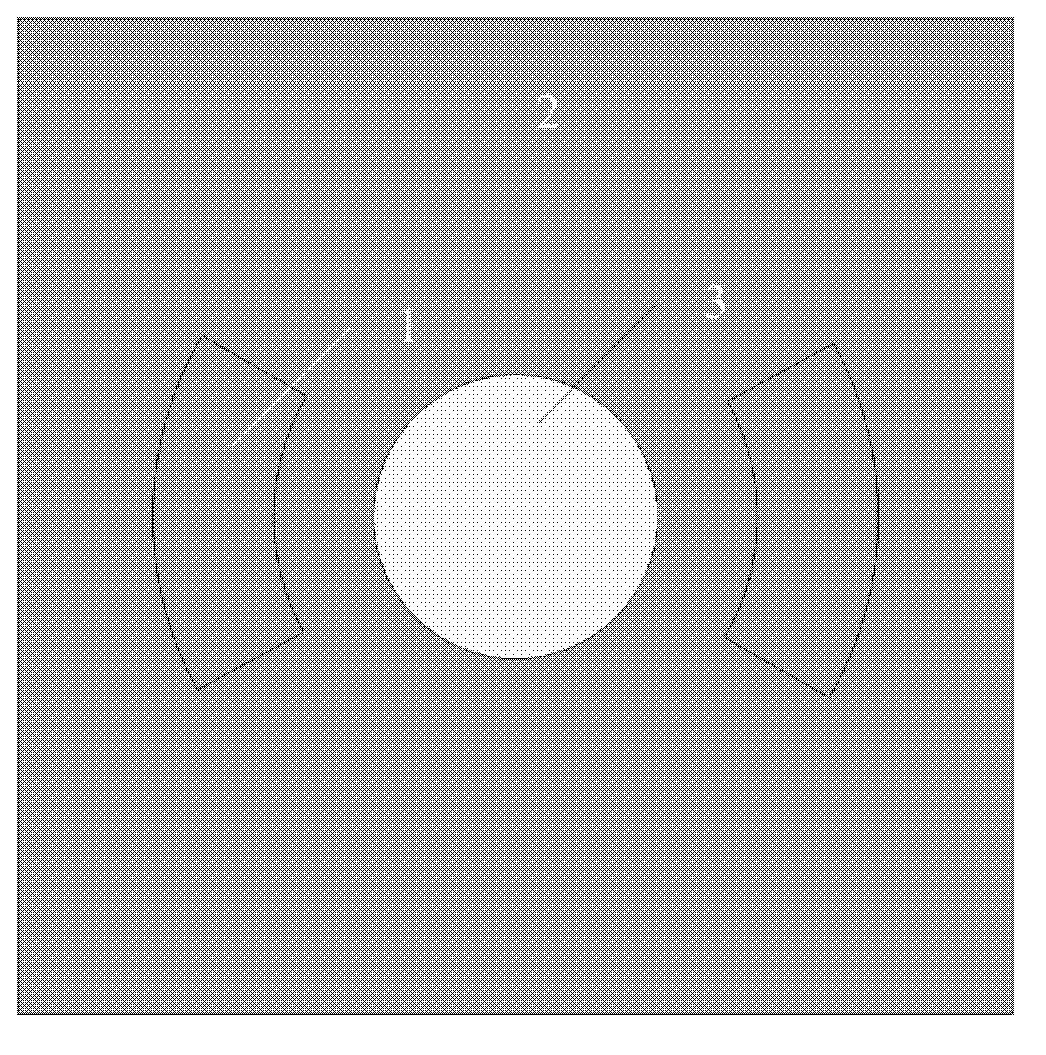

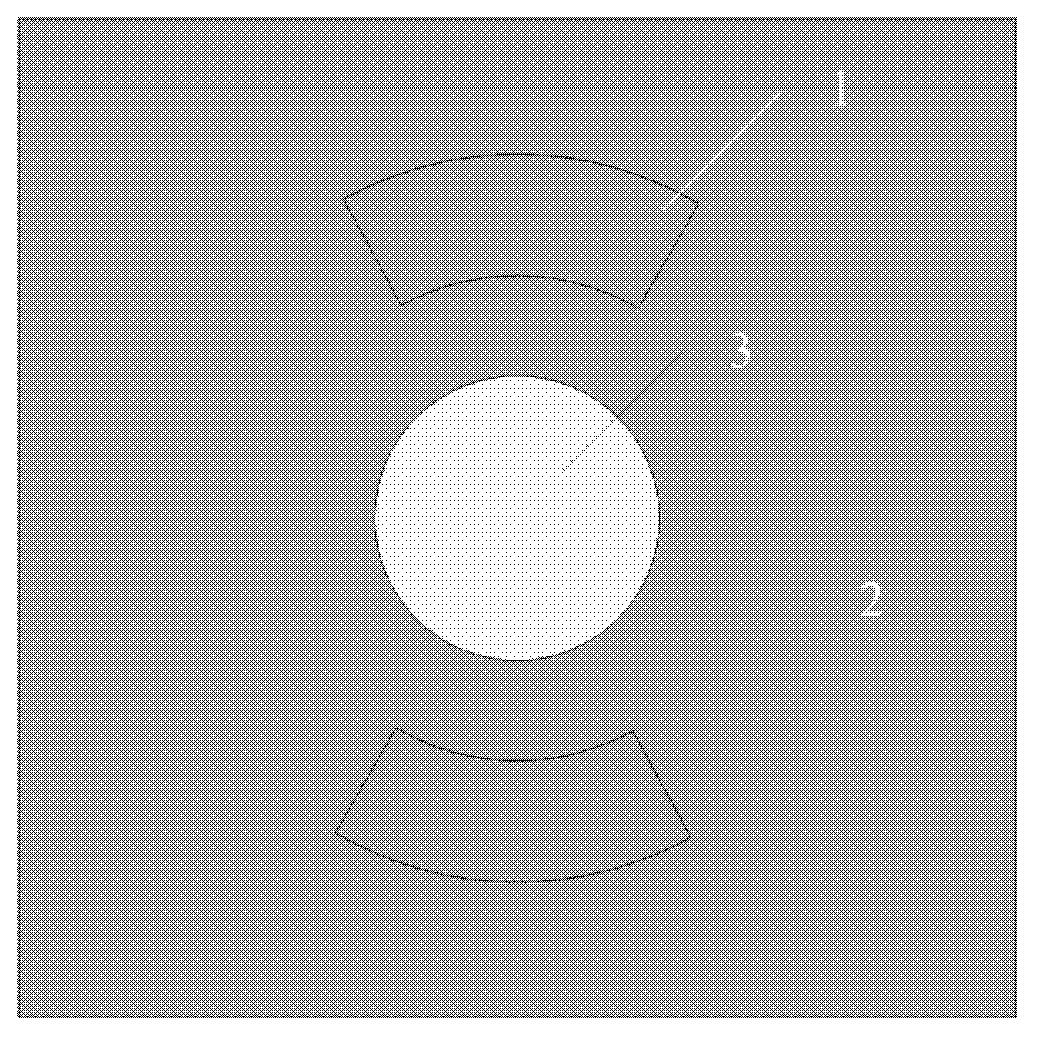

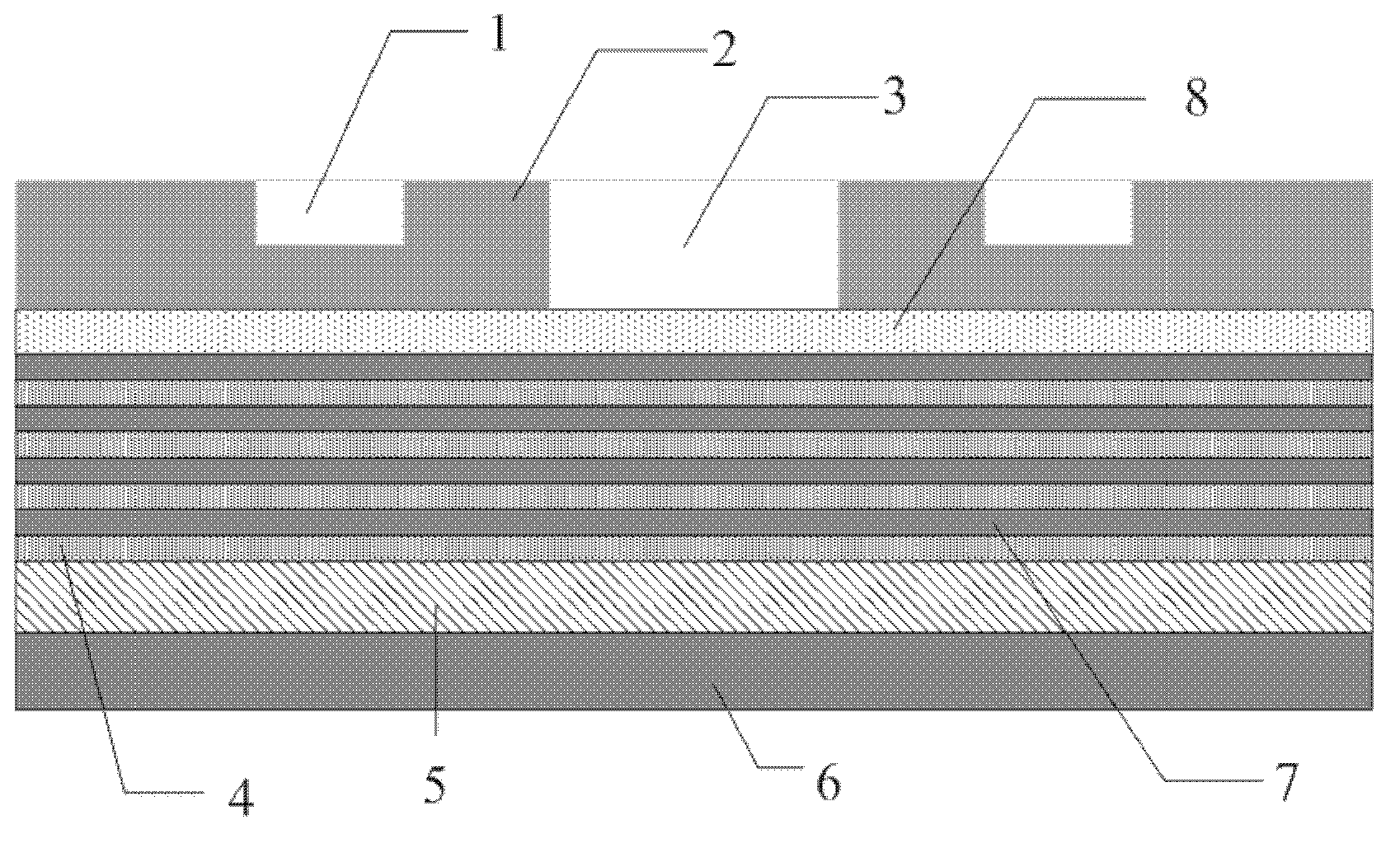

[0023] figure 2 shows the fabrication of nanoscale super-resolution optical focusing devices, figure 2 Among them, 1 is the groove annular zone, 2 is the metal film, 3 is the Fresnel first-order wave zone circular hole, 4 is the dielectric film, 5 is the photoresist, 6 and 7 are the metal film, and 8 is the substrate. The metal film 2, the dielectric film 4, the photoresist 5, the metal films 6 and 7, and the substrate 8 are all closely arranged up and down.

[0024] The present invention implements the fabrication method of the nanoscale super-resolution optical focusing device, comprising the following steps:

[0025] Step S1: select the working wavelength λ of the incident light, and select the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com