Indium welded ball array preparing method based on electroplating technology

A solder ball array and electroplating technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of difficult process and little research, and achieve the effect of low cost and large scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

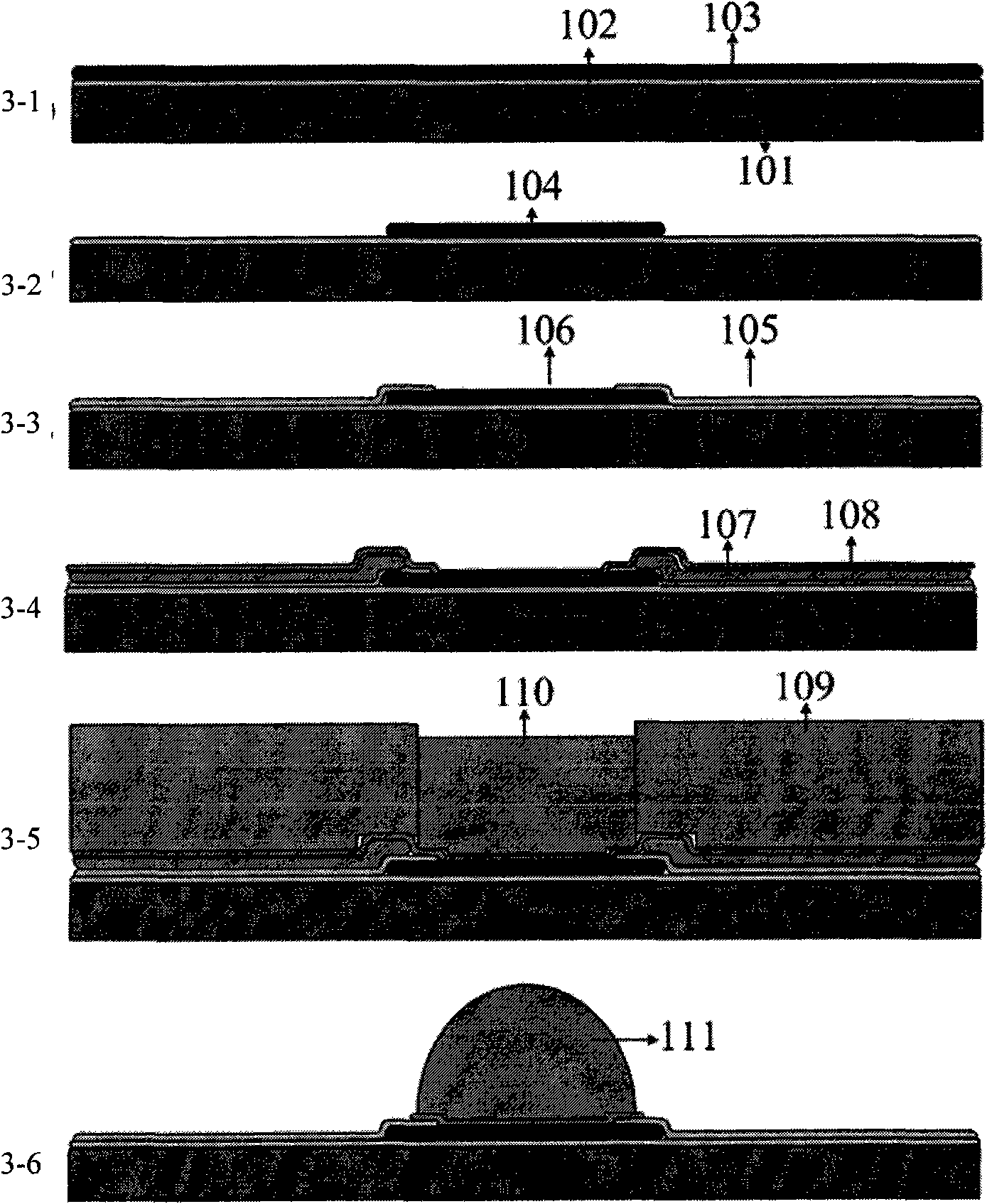

[0035] The concrete process step of embodiment 1 sees image 3 shown.

[0036] 1. With the silicon wafer 101 as the substrate, an oxide layer with a thickness of SiO 2 102 as an insulating layer, and then sputter a layer on it Thick Al layer 103; ( Figure 3-1 )

[0037] 2. Coating 1.7 μm of S1912 thin glue on the Al layer of the sputtering 103 and then photolithography, after the photolithography is completed, the pad 104 is etched out in the Al etching solution; ( Figure 3-2 )

[0038] 3. In order to protect the Al pad and prevent the indium solder ball from collapsing during reflow, it is necessary to use PECVD (ion-enhanced vapor deposition) to make a layer with a thickness of SiO 2 as the passivation layer 105. Then apply 1.7 μm S1912 thin glue again and photolithography, and then use RIE (reactive ion sputtering) to remove part of the SiO on the Al pad 104 2 To realize the passivation layer opening 106; ( Figure 3-3 )

[0039] 4. Apply S1912 thin glue agai...

Embodiment 2

[0043] The seed layer is Cr / Au or Ti / Ni / Au, and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com