Manufacturing method of large-power vertical light-emitting diode

A technology of light-emitting diodes and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as cracking of metal sapphire substrates, increase of production costs, and reduction of core particle yield, so as to facilitate separation, The effect of reducing warpage and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Method steps of the present invention are:

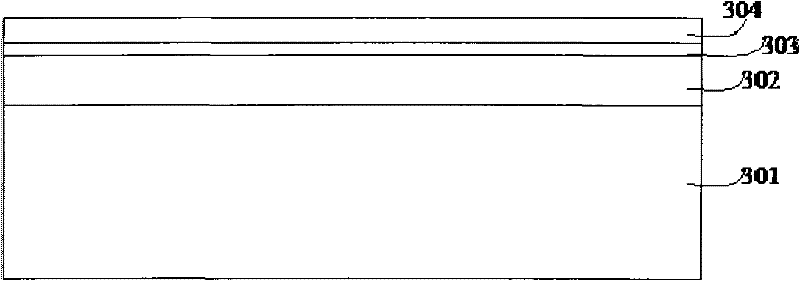

[0029] 1) see figure 1 , growing an N-type GaN-based semiconductor layer 302, a quantum well active region 303, and a P-type GaN-based semiconductor layer 304 sequentially on the sapphire substrate 301 by metal-organic chemical vapor deposition;

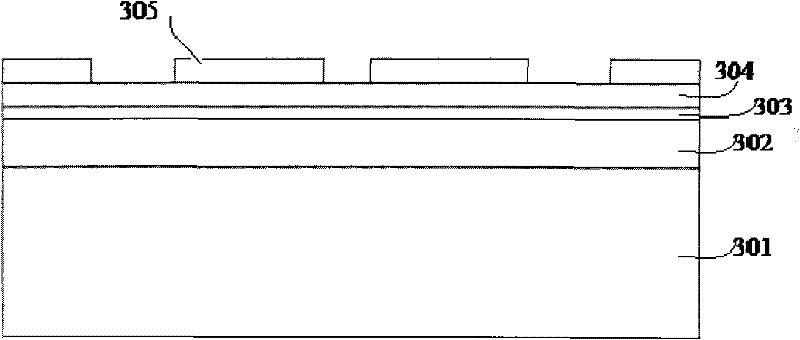

[0030] 2) see figure 2 , on the P-type GaN-based semiconductor layer 304, a reflective metal layer 305 is evaporated, with a thickness of Annealing at a high temperature for 10-30 minutes in a nitrogen environment, so that an ohmic contact is formed between the reflective metal layer 305 and the P-type GaN-based semiconductor layer 304, and the bonding force between the two is enhanced;

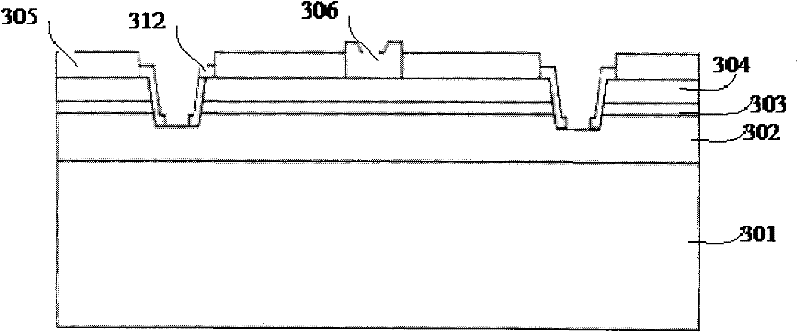

[0031] 3) see image 3 , using inductively coupled plasma ICP etching to form the mesa, using plasma enhanced chemical vapor deposition method PECVD to deposit a multi-layer dielectric film, and forming a current blocking layer 306 in the N electrode area by etching, which is used to uniforml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com