Novel silicon carbide (SiC) small-angle tilting table terminal structure and preparation method thereof

A technology of terminal structure and mesa structure, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of uniform photoresist reflow, limited blocking ability of photoresist mask, difficult terminal structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

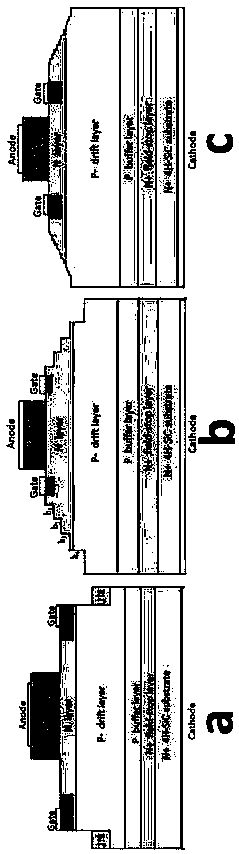

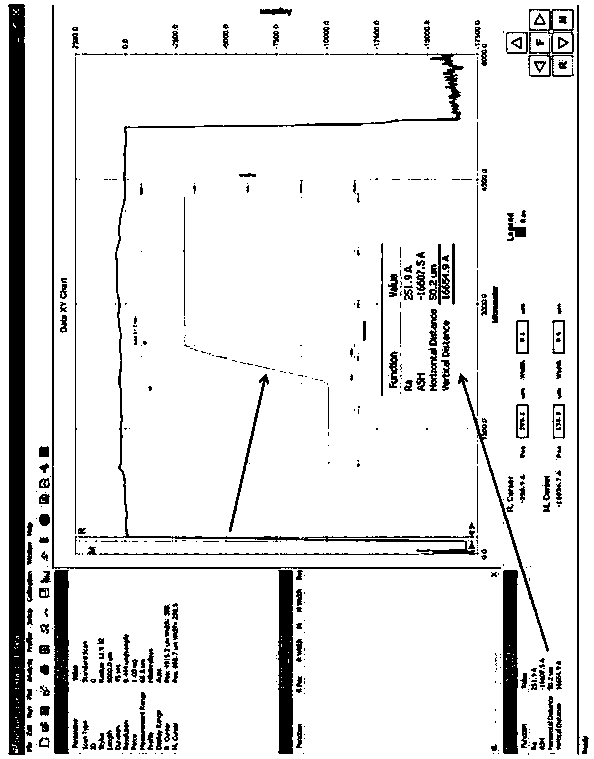

[0028] A new type of small-angle inclined mesa terminal applied to silicon carbide GTO devices. The epitaxial structure of the SiC sample material is a typical P+ / N / P- / P / N+ structure in GTO devices from top to bottom, and the epitaxial layers are in order P+ contact layer (thickness 2μm, doping concentration 1×10 19 cm -3 ), N base layer (thickness 2μm, doping concentration 2×10 17 cm -3 ), P-drift layer (thickness 60μm, doping concentration 2×10 14 cm -3 ), P buffer layer (thickness 2μm, doping concentration 2×10 17 cm -3 ), N+ field stop layer (thickness 1μm, doping concentration 5×10 18 cm -3 ), the bottom is the 4H-SiC intrinsic substrate of N+. The device mesa of the GTO device is a rounded rectangle of 5mm*2.5mm.

[0029] like Figure 5 As shown, it is a schematic diagram of the terminal structure of the silicon carbide GTO device. The terminal structure is prepared on the N+ type SiC intrinsic substrate 101. From the bottom to the top of the conductive N+ type...

Embodiment 2

[0032] A new type of small-angle inclined mesa terminal applied to silicon carbide PiN devices. The epitaxial structure of the SiC sample material is a P+ / N- / N+ structure from top to bottom, and each epitaxial layer is a P+ contact layer (thickness 2 μm, doped Concentration 1×10 19 cm -3 ), N-drift layer (thickness 60μm, doping concentration 2×10 14 cm -3 ), N+ field stop layer (thickness 1μm, doping concentration 5×10 18 cm -3 ), the bottom is the 4H-SiC intrinsic substrate of N+. The device mesa of the PiN device is a rounded rectangle of 5mm*2.5mm.

[0033] like Figure 6 As shown, it is a schematic diagram of the terminal structure of the silicon carbide PiN device. The terminal structure is prepared on the N+ type SiC intrinsic substrate 201. From the bottom to the top of the conductive N+ type SiC substrate 201, the N+ type SiC field stop Layer 202, N-type SiC drift layer 203, P+ type SiC contact layer 204; mesa inclination angle θ is less than 5 o , the etching ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com