Bubble breaking type thick waterborne elastic middle coating and preparation method thereof

A foam breaking, water-based technology, applied in the field of coatings, can solve the problems of high elongation at break, poor stain resistance, unstable shape, etc., and achieve the effects of high elongation at break, good temperature resistance and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

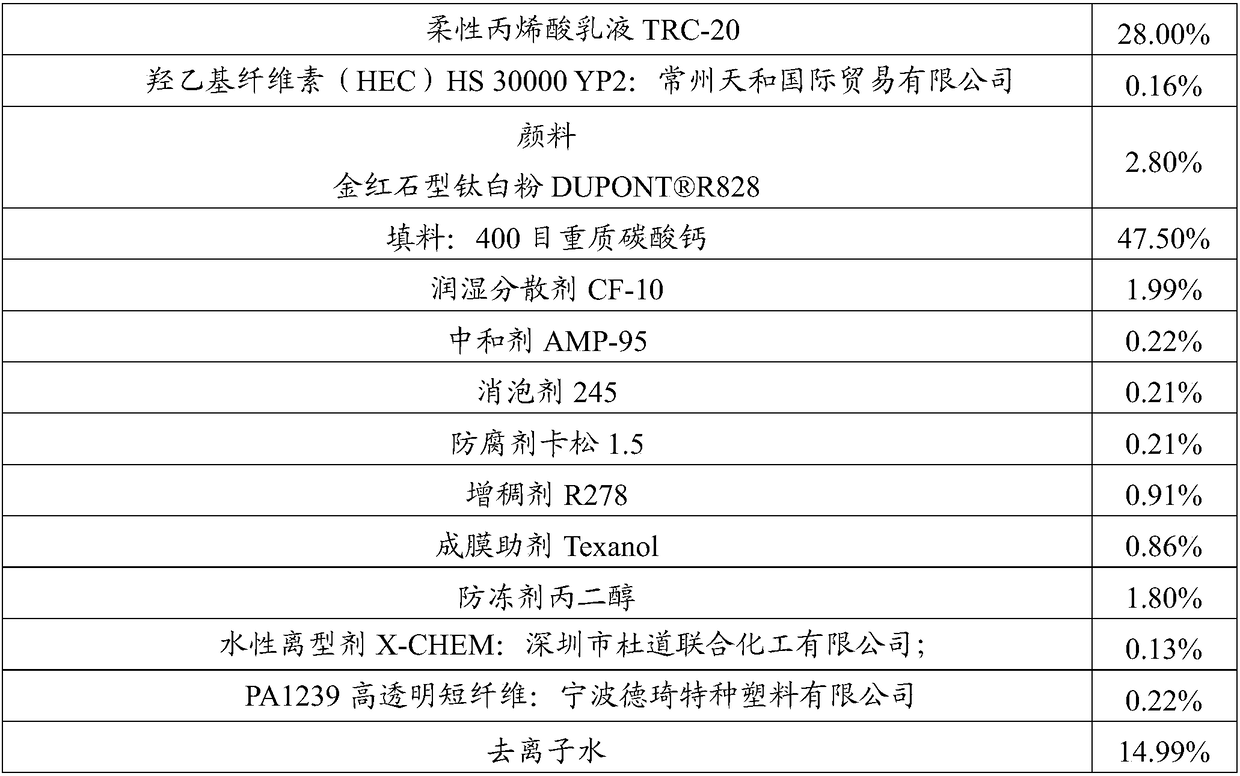

[0053] The proportion of each component of the thick foam-breaking type water-based elastic middle coating is (wt%):

[0054]

[0055] The preparation method of the thick foam-breaking type water-based elastic middle coating is as follows:

[0056] According to the above formula, hydroxyethyl cellulose (HEC), the wetting and dispersing agent, the neutralizing agent, the silicone defoamer accounting for 50% of the quality of the silicone defoamer, the quality of the preservative 50% of preservatives, the pigments, the fillers and 50% of the water mass are uniformly mixed at room temperature, and ground to below 40 μm, and the rest of the silicone defoamer is added under stirring at a speed of 500 rpm , the remaining preservative, the flexible acrylic emulsion, the film-forming aid, the antifreeze, the water-based release agent, the thickener and the remaining water, mix well, add PA short fiber 300rpm Stir at a rotating speed for 30 minutes, let it stand for 30 minutes, and...

Embodiment 2

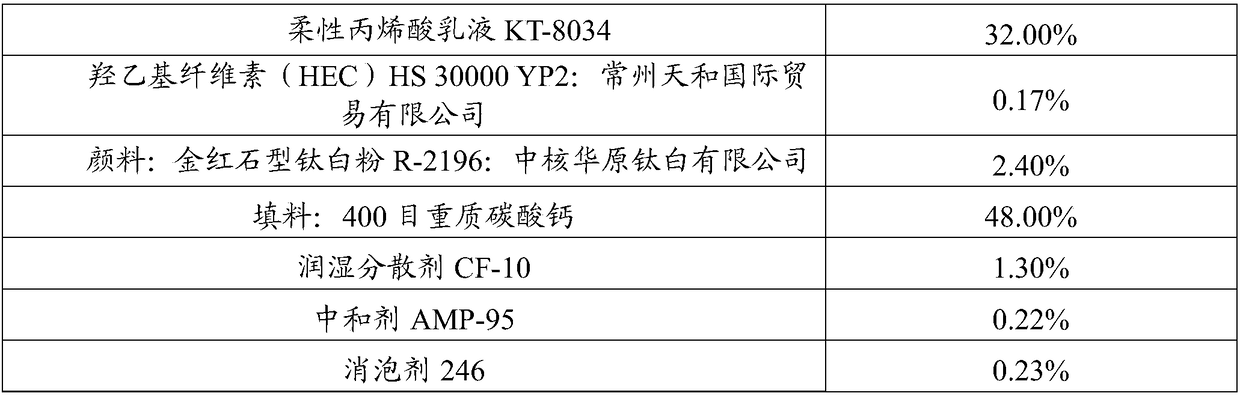

[0058] The proportion of each component of the thick foam-breaking type water-based elastic middle coating is (wt%):

[0059]

[0060] The preparation method of the thick foam-breaking type water-based elastic middle coating is as follows:

[0061] According to the above formula, hydroxyethyl cellulose (HEC), the wetting and dispersing agent, the neutralizing agent, the silicone defoamer accounting for 40% of the quality of the silicone defoamer, the quality of the preservative 40% of the preservative, the pigment, the filler, and 40% of the water mass are uniformly mixed at room temperature, and ground to below 40 μm, and the remaining silicone defoamer is added under stirring at a speed of 400 rpm , the remaining preservative, the flexible acrylic emulsion, the film-forming aid, the antifreeze, the water-based release agent, the thickener and the remaining water, mix well, add PA short fiber 300rpm Stir at a rotating speed for 25 minutes, let it stand for 30 minutes, and...

Embodiment 3

[0063] The proportion of each component of the thick foam-breaking type water-based elastic middle coating is (wt%):

[0064]

[0065]

[0066] The preparation method of the thick foam-breaking type water-based elastic middle coating is as follows:

[0067] According to the above formula, hydroxyethyl cellulose (HEC), the wetting and dispersing agent, the neutralizing agent, the silicone defoamer accounting for 30% of the quality of the silicone defoamer, the quality of the preservative 30% of the preservative, the pigment, the filler and 30% of the water mass are uniformly mixed at room temperature, and ground to below 40 μm, and the remaining silicone defoamer is added under stirring at a speed of 300 rpm , the remaining preservative, the flexible acrylic emulsion, the film-forming aid, the antifreeze, the water-based release agent, the thickener and the remaining water, mix well, add PA short fiber 200rpm Stir at a rotating speed for 20 minutes, let it stand for 30 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com