Paper packaging machine

A paper bag and packaging technology, which is applied in the field of small-scale fresh noodle making and selling machines, can solve the problems of environmental pollution, unfavorable environmental sanitation, clean noodle products, and difficulty in degrading, etc., and achieve the effect of overcoming the non-automatic packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

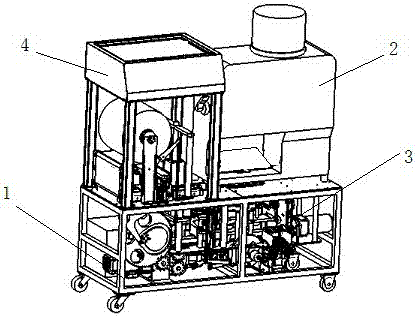

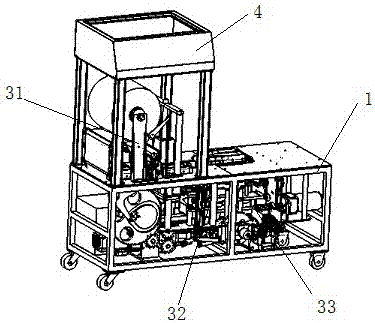

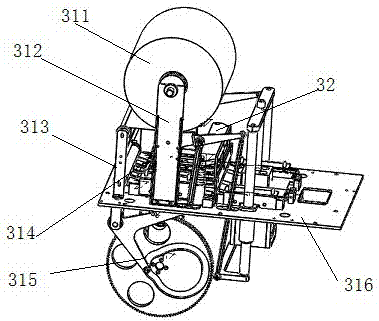

[0020] In order to further illustrate the technical scheme of the present invention, the specific implementation manner of the present invention is illustrated in conjunction with accompanying drawing now; Figure 5, in this example, the linear guide rail type conveying device commonly used in this industry is selected as the carton longitudinal conveying device 331, which is installed on the mounting bracket 334, and connected with the longitudinal conveying transmission device 339; in this example, the carton commonly used in packaging machinery is selected The sealing device on both sides of the upper part is used as the packaging device 332 on both sides of the paper shell, and the packaging device 332 on both sides of the paper shell is installed on the mounting bracket 334, and is located at the noodle inlet 3310, and is connected with the packaging transmission device 338; The general sealing device at both ends of the carton packaging upper cover is used as the packagin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com