Vapor deposition method used for anticorrosion pretreatment of permanent magnet

A technology of vapor deposition and permanent magnets, which is applied in the surface treatment of NdFeB permanent magnet materials and the pretreatment field of permanent magnet materials before coating. Al plating layer damage and other problems, to achieve the effect of improving corrosion resistance, overcoming the shortcomings of magnetic damage, and dense coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

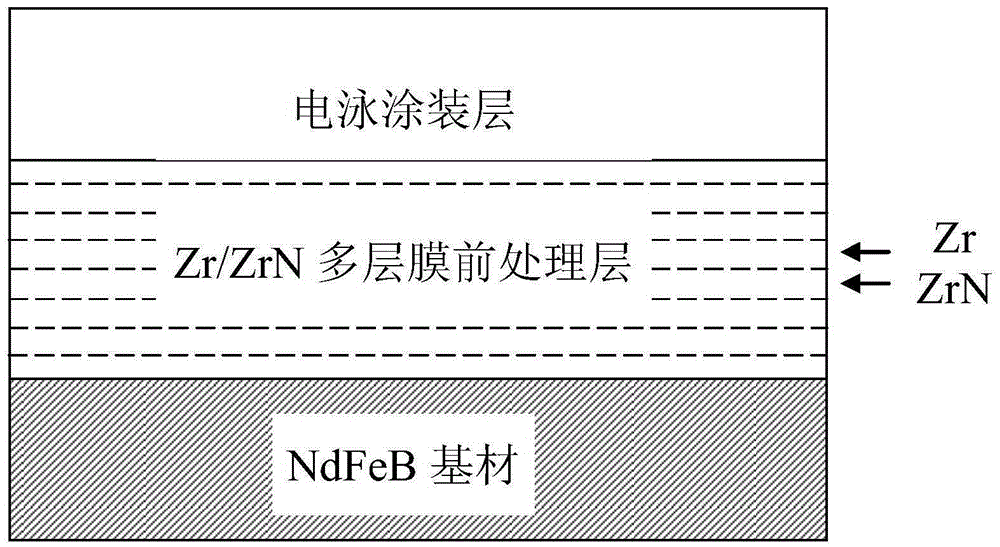

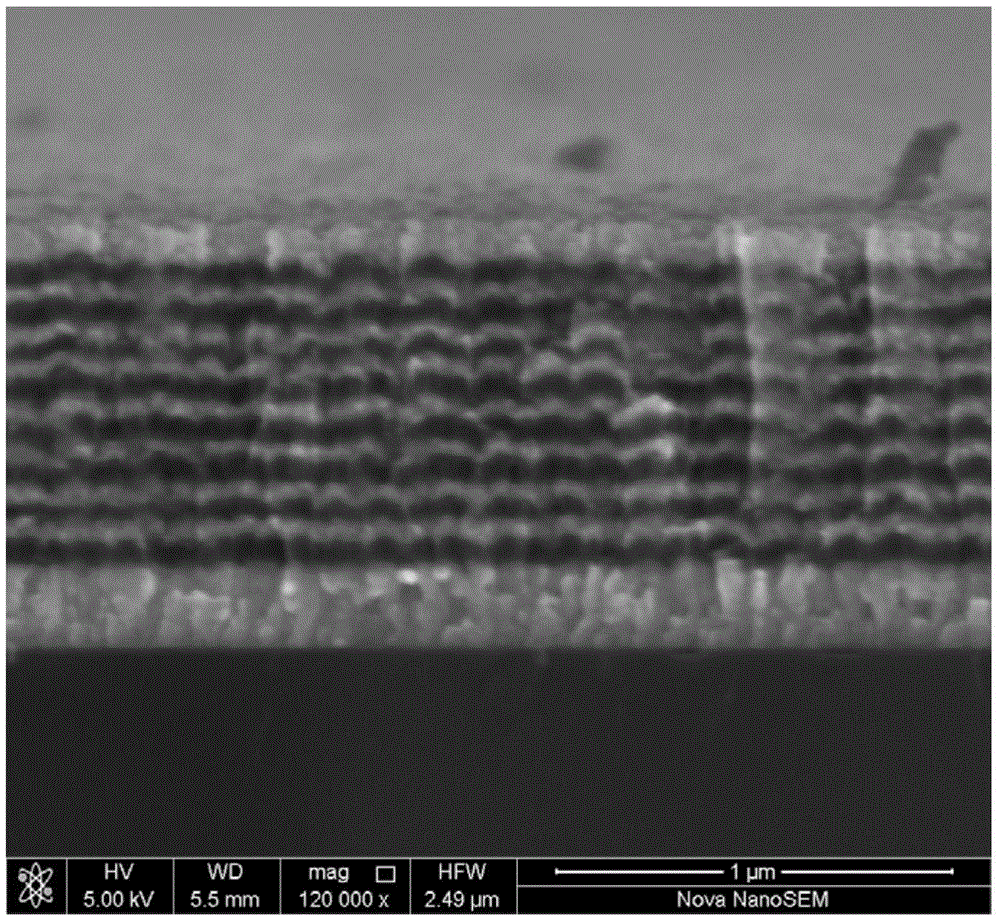

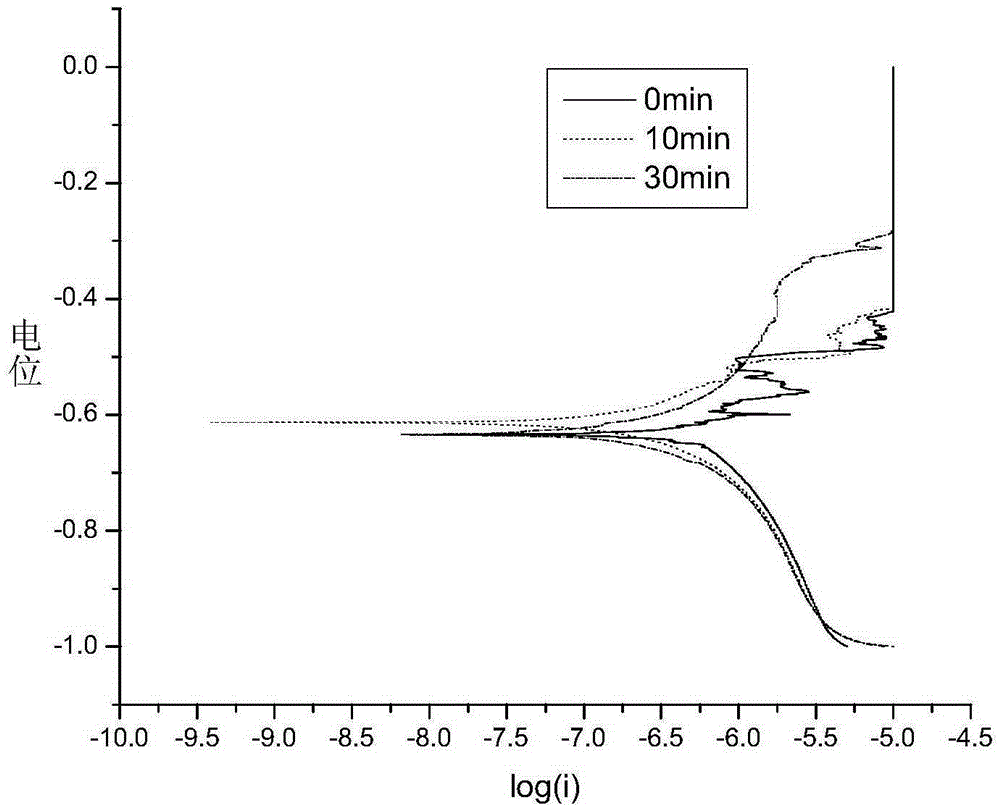

[0048]In this embodiment, the magnetron sputtering technology is used to sputter-deposit a nano-multilayer film of zirconium (Zr) and zirconium nitride (ZrN) with a NdFeB magnet as a substrate. Concrete preparation process is as follows:

[0049] (1) Pretreatment: Grinding the NdFeB permanent magnets; placing the polished NdFeB permanent magnets in an ultrasonic cleaner filled with degreasing liquid for ultrasonic-assisted degreasing treatment; The NdFeB permanent magnet after oil treatment is placed in an ultrasonic cleaner filled with derusting liquid for ultrasonic assisted derusting treatment; the NdFeB permanent magnet after ultrasonic assisted derusting treatment is placed in boiling deionized water for sealing Pore treatment; the time for the sealing treatment is 10 minutes.

[0050] (2) Put it into the vacuum chamber of the magnetron sputtering equipment after drying. Vacuum the membrane to a vacuum of 7×10 -3 Pa. Introduce argon (Ar) to a vacuum of 3Pa. Turn on...

Embodiment 2

[0065] In this embodiment, arc ion plating technology is used to deposit titanium (Ti) and titanium nitride (TiN) nanometer multilayer film with NdFeB magnet as the substrate. Concrete preparation process is as follows:

[0066] (1) Pretreatment: Grinding the NdFeB permanent magnets; placing the polished NdFeB permanent magnets in an ultrasonic cleaner filled with degreasing liquid for ultrasonic-assisted degreasing treatment; The NdFeB permanent magnet after oil treatment is placed in an ultrasonic cleaner filled with derusting liquid for ultrasonic assisted derusting treatment; the NdFeB permanent magnet after ultrasonic assisted derusting treatment is placed in boiling deionized water for sealing Pore treatment; the time for the sealing treatment is 20 minutes.

[0067] (2) After drying, put it into the vacuum chamber of the arc ion plating equipment. Vacuum the membrane to a vacuum of 7×10 -3 Pa. Argon (Ar) was introduced to a vacuum of 4Pa. Turn on the negative bia...

Embodiment 3

[0081] In this embodiment, magnetron sputtering technology is used to sputter-deposit a thin film of nanometer multilayer structure of chromium (Cr) and chromium nitride (CrN) with NdFeB magnet as the substrate. Concrete preparation process is as follows:

[0082] (1) Pretreatment: Grinding the NdFeB permanent magnets; placing the polished NdFeB permanent magnets in an ultrasonic cleaner filled with degreasing liquid for ultrasonic-assisted degreasing treatment; The NdFeB permanent magnet after oil treatment is placed in an ultrasonic cleaner filled with derusting liquid for ultrasonic assisted derusting treatment; the NdFeB permanent magnet after ultrasonic assisted derusting treatment is placed in boiling deionized water for sealing Pore treatment; the time for the sealing treatment is 20 minutes.

[0083] (2) Put it into the vacuum chamber of the magnetron sputtering equipment after drying. Vacuum the membrane to a vacuum of 7×10 -3 Pa. Argon (Ar) was introduced to a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com