Three-core photoelectric composite submarine cable with 220kV rated voltage

A rated voltage, photoelectric composite technology, applied in submarine cables, power cables, power cables with shielding layers/conducting layers, etc. Achieve the effect of improving the effective utilization rate and reducing the sea area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

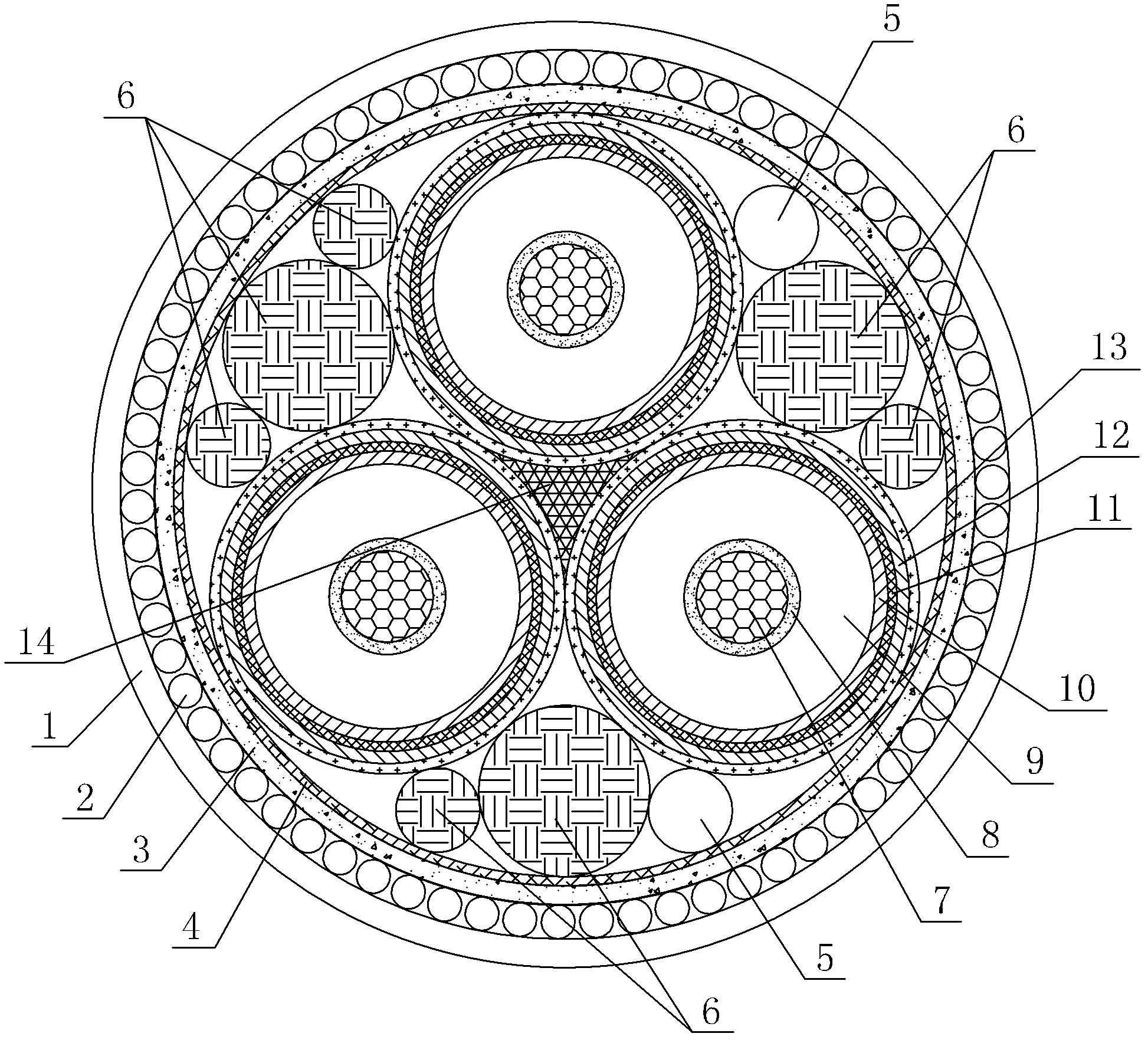

[0014] As shown in the figure, the rated voltage 220kV three-core photoelectric composite submarine cable includes an outer covering layer 1, an armor layer 2 and an inner lining layer 3 distributed in order from the outside to the inside. The inner lining layer 3 is provided with three two-phase outer Cut the electric unit, the electric unit includes the conductor 7, the conductor shielding layer 8, the insulating layer 9, the insulating shielding layer 10, the water blocking buffer layer 11, the lead alloy sleeve 12 and the inner sheath 13, which are distributed in sequence from the inside to the outside. The three gaps enclosed by the inner lining layer 3 are filled with multiple filling units, the central gap surrounded by the three electrical units is filled with a parallel strand filling rope 14, three electrical units, and a parallel strand filling r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com