Papermaking wastewater recycling device and method based on electrochemical and electrodialysis technology

A technology of papermaking wastewater and electrodialysis, which is applied to chemical instruments and methods, processing process wastewater treatment, water/sewage treatment, etc., can solve the problems of no advanced treatment and recycling, wastewater is mostly discharged, waste of water resources, etc., to reduce Membrane cleaning and regeneration costs, eradication of biological pollution, and the effect of reducing wastewater discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

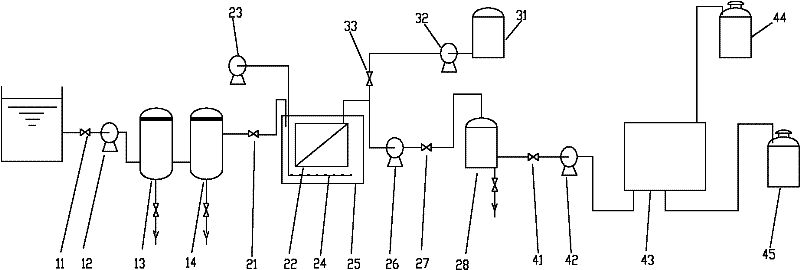

[0055] A method for purification, regeneration and recycling of 150 tons / day papermaking advanced treatment wastewater.

[0056] The measured indicators of the papermaking advanced treatment wastewater are shown in Table 1.

[0057] Table 1

[0058] serial number

project

unit

measured value

serial number

project

unit

measured value

1

COD Cr

mg / L

186

4

Chroma

80

2

SS

mg / L

90

5

pH

7.5

3

NTU

6

6

μS / cm

3200

[0059] After 150 tons of printing and dyeing advanced treatment wastewater is extracted by the water supply pump 12 at a flow rate of 7.5T / h, it is input into the nano-catalytic electrolysis machine 13, and the nano-catalytic electrolyzed water directly enters the sedimentation tank 14, and after precipitation, it enters the submerged ultrafiltration membrane system to remove solid...

Embodiment 2

[0069] Purification and recycling method of 3000 tons / day papermaking advanced treatment wastewater.

[0070]Described papermaking advanced treatment waste water is measured, and index is as shown in table 4:

[0071] Table 4

[0072] serial number

project

unit

measured value

serial number

project

unit

measured value

1

COD Cr

mg / L

109

4

Chroma

120

2

SS

mg / L

75

5

pH

7.5

3

NTU

6

6

μS / cm

2300

[0073] After the papermaking advanced treatment wastewater is extracted by the water supply pump 12 at a flow rate of 150T / h, it is input into the nano-catalysis electrolysis tank 13, and the nano-catalysis electrolysis water directly enters the precipitation tank 14, and after neutralization and precipitation, the ultrafiltration membrane system 22 removes solid impurities in the water, Plankt...

Embodiment 3

[0083] Purification and recycling method of 5000 tons / day papermaking advanced treatment wastewater.

[0084] The papermaking advanced treatment wastewater has been measured, and the indicators are as shown in Table 7:

[0085] Table 7

[0086] serial number

project

unit

measured value

serial number

project

unit

measured value

1

COD Cr

mg / L

265

4

Chroma

110

2

SS

mg / L

33

5

pH

7.9

3

NTU

7

6

μS / cm

7700

[0087] After the papermaking advanced treatment wastewater is extracted by the water supply pump 12 at a flow rate of 250T / h, it is input into the nano-catalytic electrolysis machine 13, and the nano-catalytic electrolyzed water directly enters the sedimentation tank 14, and after precipitation, the ultrafiltration membrane system 22 removes solid impurities and plankton in the water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com