A kind of recycling method of beryllium in beryllium waste liquid measured by beryllium loading method

A technology of waste liquid, beryllium hydroxide, applied in chemical instruments and methods, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc. and other problems, to achieve the effect of reducing pollution, saving laboratory costs, and saving reagent costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

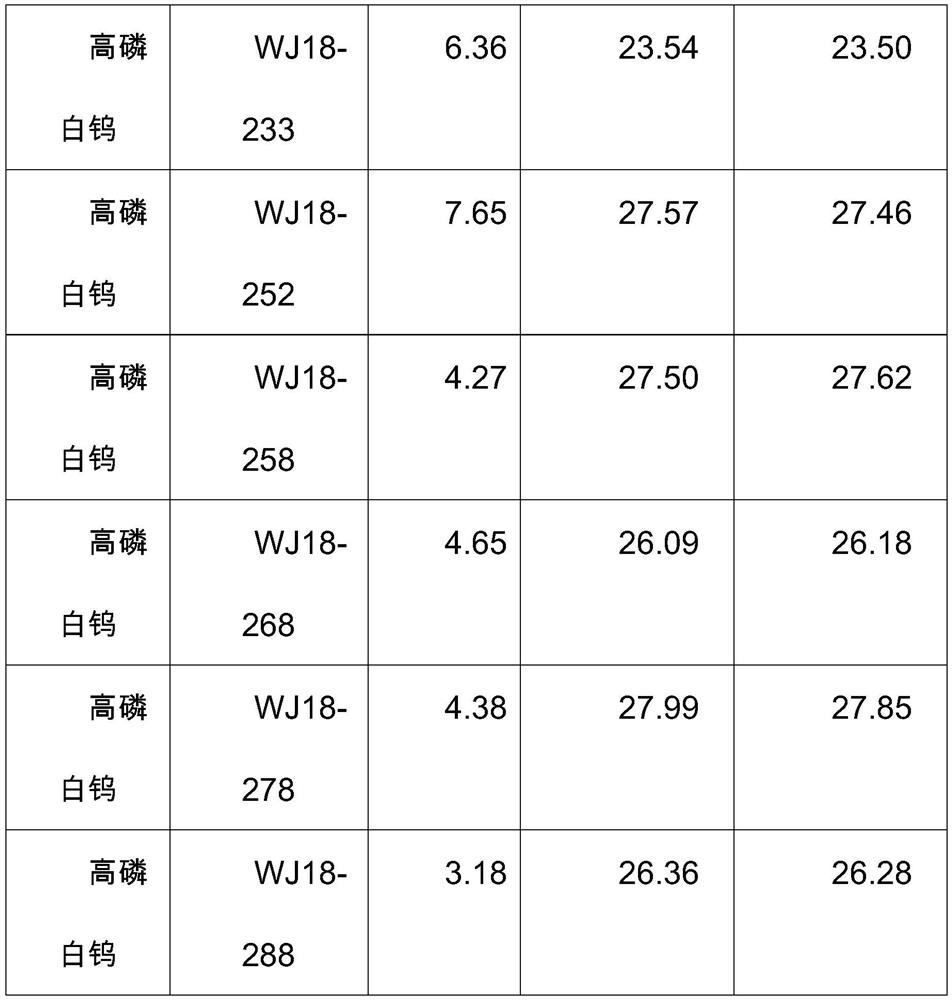

[0018] Take 2500mL of P waste solution (GB / T6150.3-2009) in a 3000mL beaker, heat it on an electric furnace to concentrate the volume to about 800-1000mL, take it out and cool it slightly, and add liquid alkali to pH approx. 6. Add ammonia water to pH 8.5-9 to completely precipitate beryllium hydroxide, heat to boiling, filter with a Buchner funnel while hot, wash the precipitate with hot ammonia water-ammonium nitrate mixture for 10 times, and transfer the precipitate into a beaker. Add 8mL nitric acid to dissolve, dilute to 200mL after dissolving, then add ammonia water to pH 8.5~9, make beryllium hydroxide precipitate completely, heat to boiling, filter with Buchner funnel while hot, and use hot ammonia water-ammonium nitrate mixture Wash the precipitate 10 times, transfer the precipitate into a beaker, add 8mL nitric acid to dissolve, and dilute to 400mL after dissolution, which is used for the phosphorus removal step of the determination of tungsten trioxide in high-phosph...

Embodiment 2

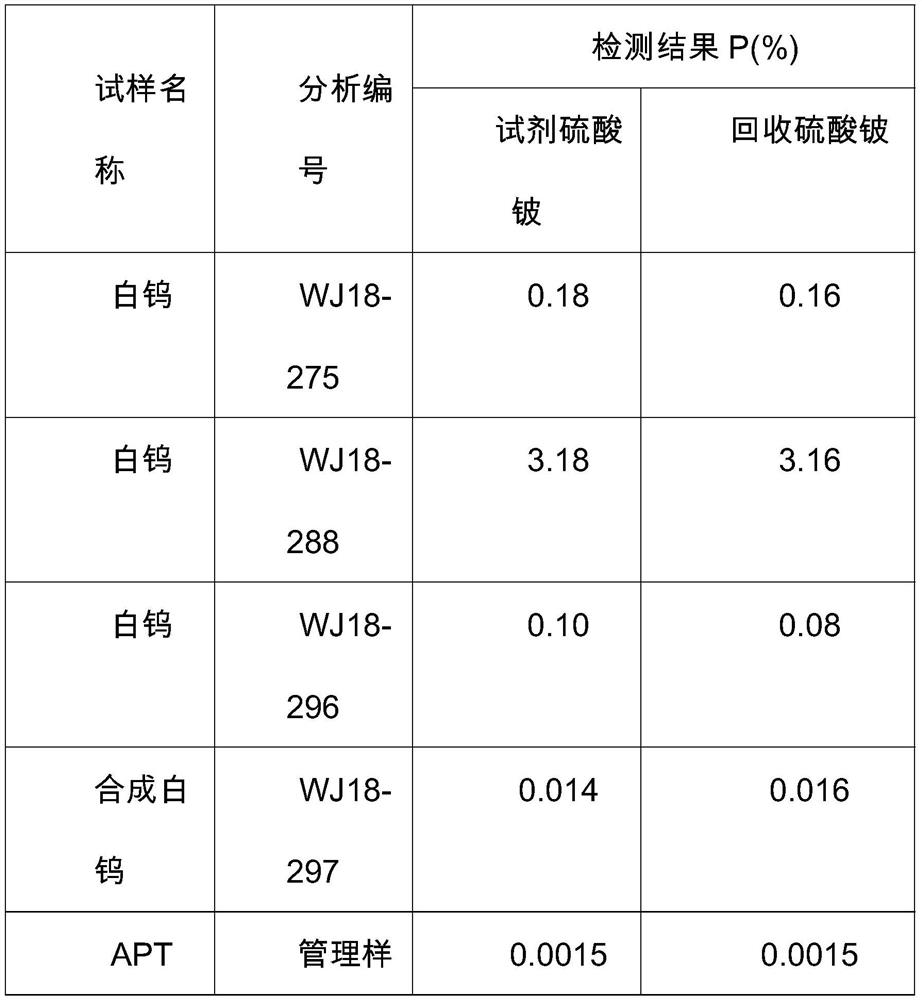

[0023] Take 2500mL of P waste solution (GB / T4324.24-2012) in a 3000mL beaker, heat it on an electric furnace to concentrate the volume to about 800-1000mL, take it out and cool it slightly, add NaOH solution (500g / L) to pH about 6, add ammonia water to pH 8.5-9, make the precipitation of beryllium hydroxide complete, heat to boiling, filter with Buchner funnel while hot, wash the precipitate 10 times with hot ammonia water-ammonium sulfate mixed solution, put Move the precipitate into a beaker, add 6mL sulfuric acid to dissolve, dilute to 200mL after dissolving, then add ammonia water to pH8.5~9, make the beryllium hydroxide precipitate completely, heat to boiling, filter with Buchner funnel while hot, and use hot ammonia water -Wash the precipitate with ammonium sulfate mixture 10 times, transfer the precipitate into a beaker, add 6mL of sulfuric acid to dissolve, dilute to 400mL after dissolving, transfer to a 500mL separatory funnel, add 25mL of ammonium molybdate solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com