Comprehensive treatment process for silver-bearing material in silver nitrate production

A technology for comprehensive treatment and silver nitrate is applied in the field of comprehensive treatment technology of silver-containing materials, which can solve the problems of complex comprehensive treatment process, high silver content, long process, etc., and achieves high economic and technical indicators, low treatment cost, and simplified treatment. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

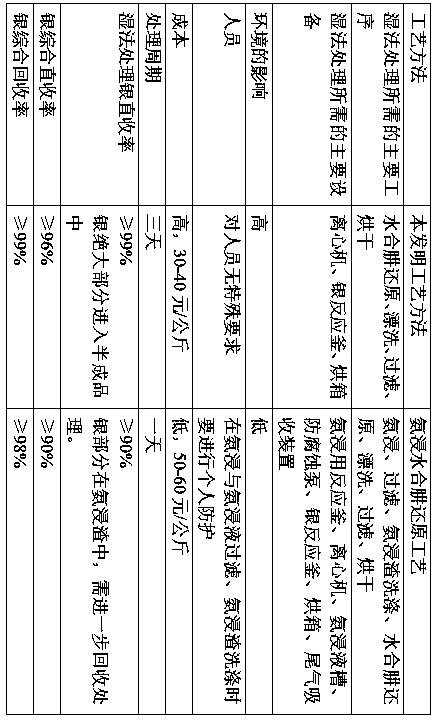

Problems solved by technology

Method used

Image

Examples

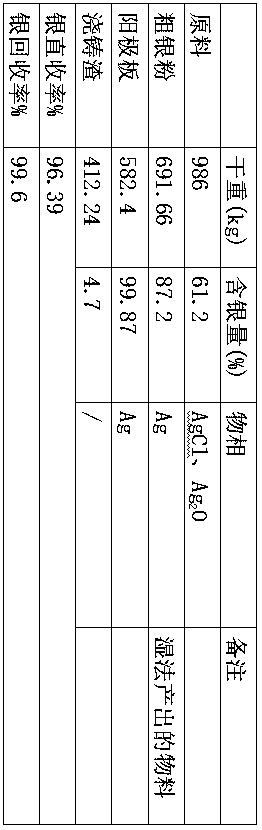

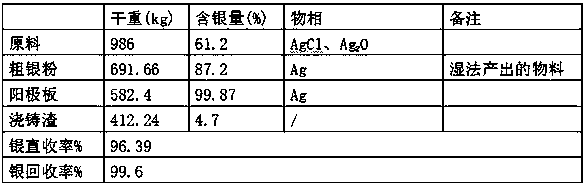

Embodiment 1

[0015] Embodiment 1, (1) batching: the silver-containing material in the production of silver nitrate is carried out pretreatment, removes the sundry greater than 5mm in diameter, gets 100 kilograms of materials and puts into reaction kettle, adds 500 liters of water and stirs evenly, adds 30 kilograms of hydrogen Add sodium oxide and heat up to 60°C; add 20 kg of 80% hydrazine hydrate aqueous solution to the batching kettle, add 40 liters of water and stir evenly.

[0016] (2) Reaction: When the temperature of the reaction kettle reaches the specified value, the solution in the batching kettle is slowly and evenly added to the reaction kettle, and the reaction process is continuously and evenly stirred, and the cumulative liquid discharge time is 30 minutes. When the pH value is less than or equal to 10, add a small amount of solid sodium hydroxide, and keep the temperature at 60°C for 30 minutes after the addition;

[0017] (3) Rinse: put the material into the centrifuge for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com