Method and device for continuously detecting ingredients and temperature of molten steel

A technology of molten steel and composition, applied in the direction of measuring devices, electric devices, thermometer parts, etc., to achieve reliable detection results, no doubts about steel leakage, and low cost of probes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

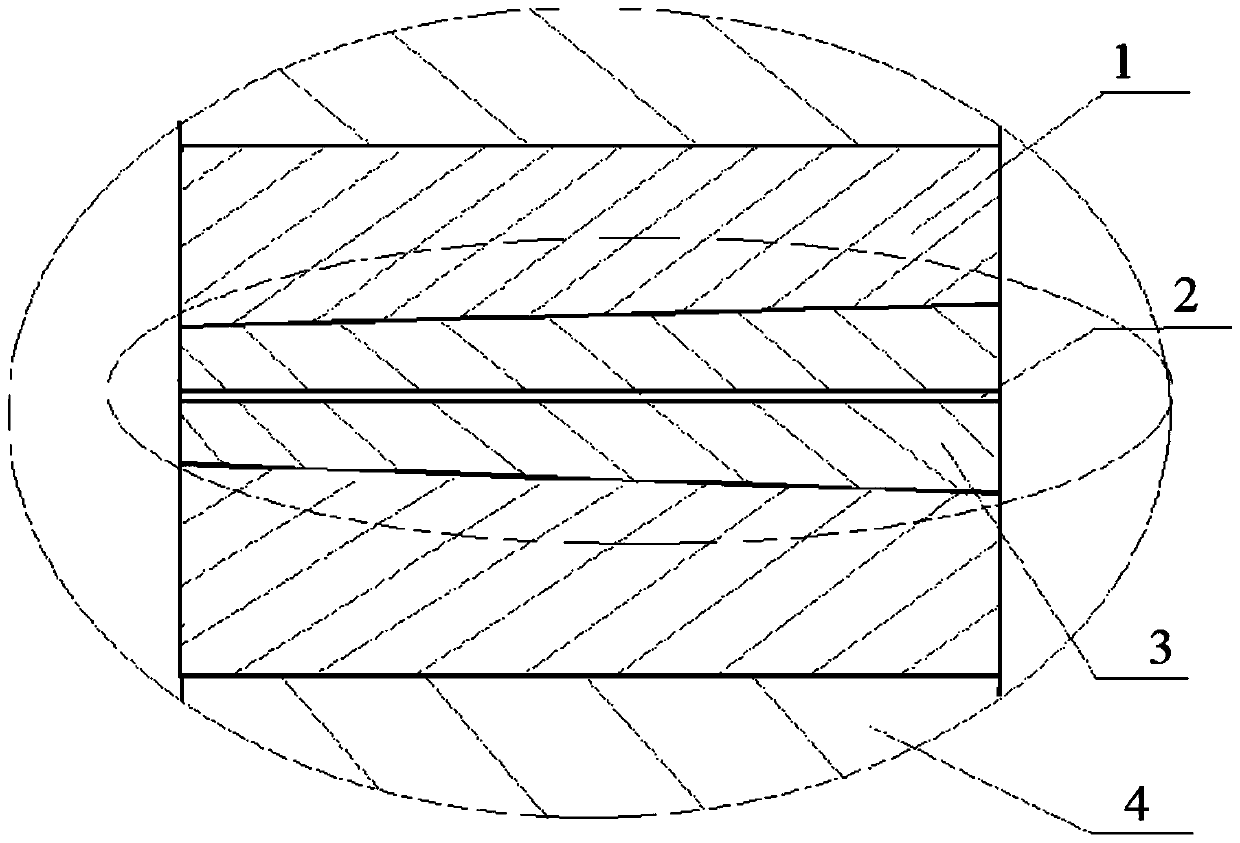

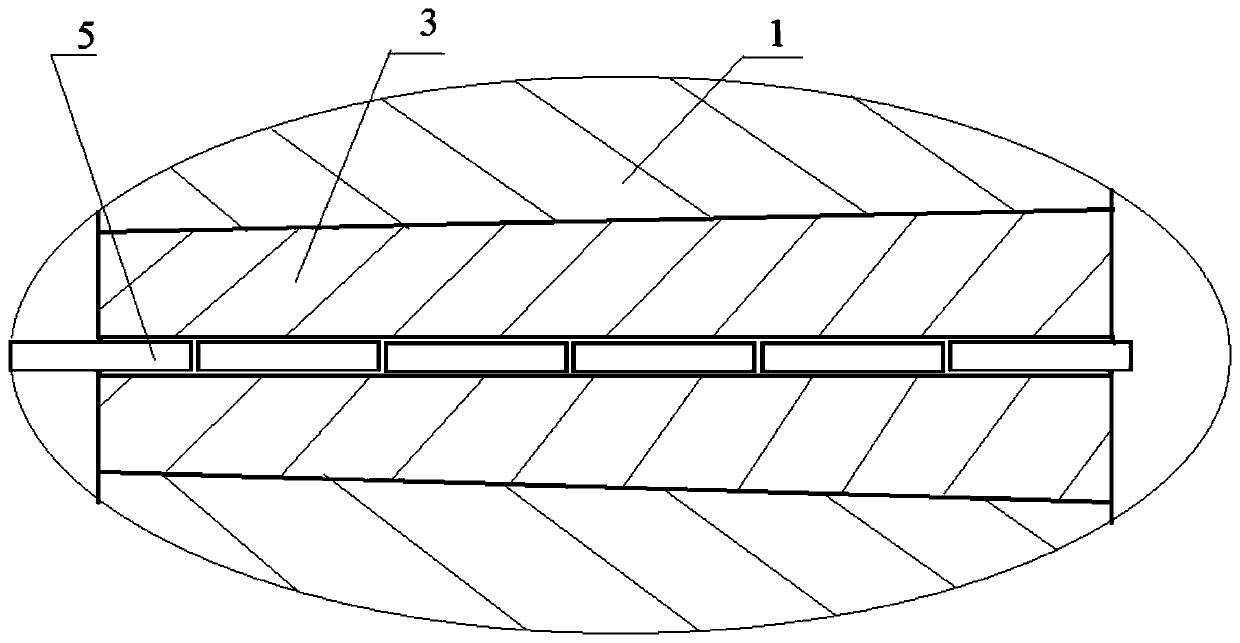

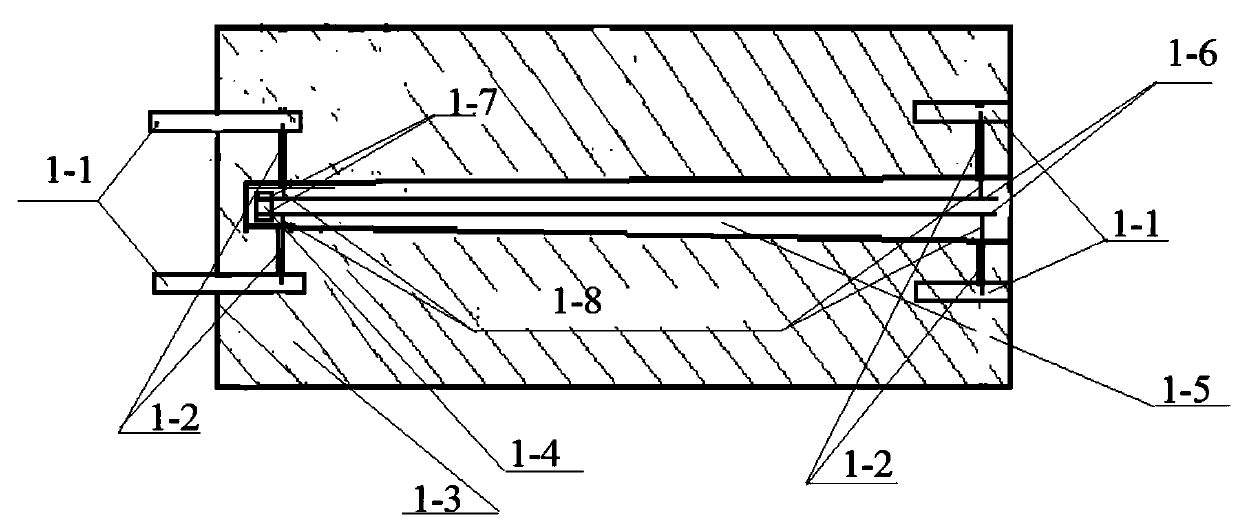

[0043] like Figure 1-4As shown, this embodiment provides a method for continuously detecting the composition and temperature of molten steel. A probe delivery pipe 3 is arranged in the furnace lining 4 of the side wall of the converter; a plurality of detection through holes 2 are arranged on the probe delivery pipe 3 , the detection probes 5 are linearly arranged in the detection through holes 2, a detection probe 5 is arranged in each detection through hole 2, and adjacent detection probes 5 are connected by plugging, so that adjacent detection probes A detachable connection and a test signal circuit are formed between the probes 5; the detection probe 5 in the detection through hole 2 is sent into the converter through a hydraulic cylinder, and the detection probe 5 is directly in contact with the molten steel to directly measure the temperature of the molten steel and composition; the detection probe 5 entering the molten steel is washed away by the molten steel, separate...

Embodiment 2

[0045] like Figure 1-4 As shown, this embodiment provides a device for continuously detecting the composition and temperature of molten steel, including a block 1 arranged in the hearth lining 4 on the side of the electric furnace. Three detection through holes 2 are provided, and a detection probe 5 is respectively placed in each detection through hole 2, and adjacent detection probes 5 in the same detection through hole 2 are connected by plugging. Direct contact with the molten steel in the electric furnace to detect the temperature or composition of the molten steel. When the detection probe 5 at the front end completes the detection, the cylinder pushes the detection probe 5 into the electric furnace so that the detection probe 5 at the front end completely enters the steel. In the water, under the scouring of molten steel, the detection probe 5 at the front end falls into the molten steel.

[0046] In order to prevent molten steel from flowing out along the gap between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com