Burden distribution method for using small coke nuts by blast furnace

A cloth and blast furnace technology, applied in blast furnaces, blast furnace details, furnaces, etc., to achieve the effects of improving overall utilization, relieving coking pressure, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

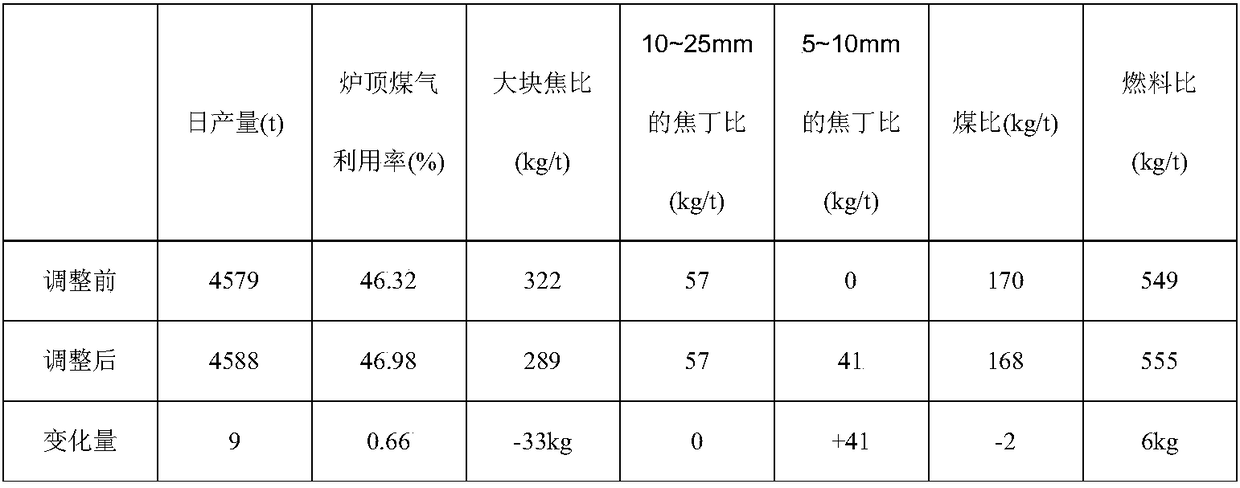

Embodiment 1

[0026] The coke consumed by the blast furnace before the experiment was bulk coke with a particle size ≥ 25mm and diced coke with a particle size of 10-25mm, and coke with a particle size of 10-25mm was mixed with iron ore. During the experiment, 2 circles of 5-10 mm small cokes were placed on the edge of the furnace throat to replace large pieces of coke. At the beginning, 2 circles of cokes were placed on the edge of the blast furnace for every 5 batches of materials, and the proportion of small cokes was gradually increased. When the final furnace condition was stable At the same time, each batch of material is clothed with 2 circles of small Jiao Ding on the edge. The loading system consists of tweak to (Where K stands for ore, J d and J s Respectively represent large coke and small coke with a particle size of 5-10mm, and the numbers and subscripts represent the unit and the number of cloth circles respectively). The monthly economic and technical indicators befor...

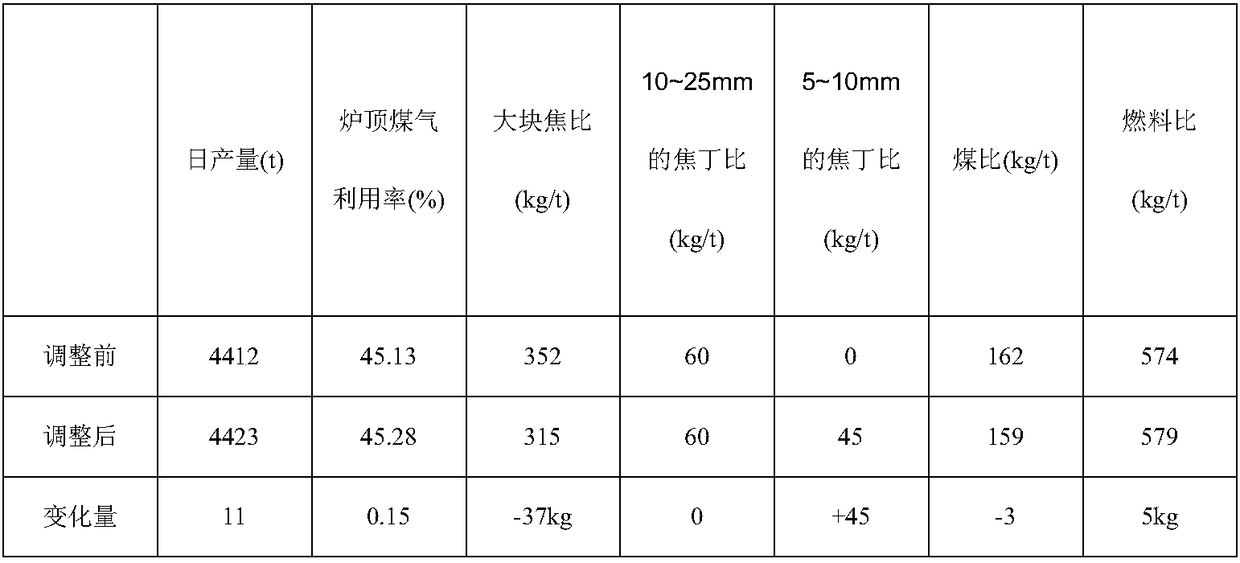

Embodiment 2

[0031] The coke consumed by the blast furnace before the experiment was bulk coke with a particle size ≥ 25mm and diced coke with a particle size of 10-25mm, and coke with a particle size of 10-25mm was mixed with iron ore. During the experiment, 2 circles of 5-10 mm small cokes were placed on the edge of the furnace throat to replace large pieces of coke. At the beginning, 2 circles of cokes were placed on the edge of the blast furnace for every 5 batches of materials, and the proportion of small cokes was gradually increased. When the final furnace condition was stable At the same time, each batch of material is clothed with 2 circles of small Jiao Ding on the edge. The loading system consists of tweak to (Where K stands for ore J d and J s Respectively represent large pieces of coke and small coke with a particle size of 5-10mm, and the subscripts and subscripts of the numbers represent the ring position and the number of fabric circles respectively). The monthly ec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com