Method for improving content of ferrous iron in leaching liquid during zinc oxide smoke and dust leaching process

A zinc oxide and leaching solution technology, applied in the field of zinc hydrometallurgy, can solve the problems of large fluctuation in content, difficult to control, affecting the production of the subsequent process, etc., and achieve the effects of improving economic and technical indicators, simple process and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

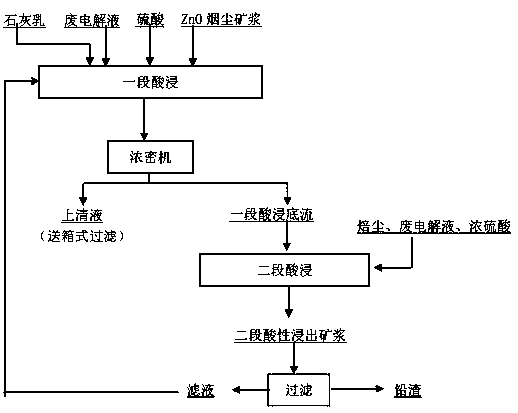

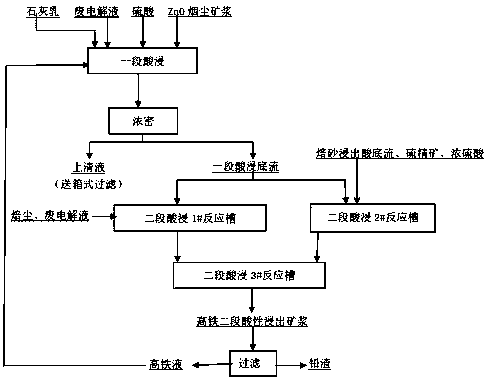

Image

Examples

Embodiment 1

[0027] 1) In the zinc oxide fume two-stage acid leaching process, the one-stage acid leaching underflow with a liquid-to-solid ratio of 2 to 3:1 obtained by the one-stage acid leaching is respectively introduced into the second-stage acid leaching 1# reaction tank and the second-stage acid leaching 2 # In the reaction tank, the underflow of the first stage of acid leaching into the second stage of acid leaching 1# reaction tank is 10 m 3 / h, the underflow of the first stage of acid leaching into the second stage of acid leaching 2# reaction tank is 30 m 3 / h, add roasting dust and waste electrolyte into the second stage acid leaching 1# reaction tank, the main components of roasting dust are Zn 45-50 wt%; Fe 8-11 wt%; S 2.5-4.5 wt%, and the added amount is 1 t / h, the electrolyte contains H + 160~170 g / L, containing Zn 2+ 50~55 g / L, fully agitate the reaction; add calcine to the second stage acid leaching 2# reaction tank to extract acid underflow, pyrite concentrate and concentr...

Embodiment 2

[0033] 1) In the zinc oxide fume two-stage acid leaching process, the one-stage acid leaching underflow with a liquid-to-solid ratio of 2 to 3:1 obtained by the one-stage acid leaching is respectively introduced into the second-stage acid leaching 1# reaction tank and the second-stage acid leaching 2 # In the reaction tank, the underflow of the first stage of acid leaching into the second stage acid leaching 1# reaction tank is 30 m 3 / h, the underflow of the first stage of acid leaching into the second stage of acid leaching 2# reaction tank is 50 m 3 / h, add roasting dust and waste electrolyte into the second stage acid leaching 1# reaction tank, the main components of roasting dust are Zn 45-50 wt%; Fe 8-11 wt%; S 2.5-4.5 wt%, and the added amount is 3 t / h, the electrolyte contains H + 160~170 g / L, containing Zn 2+ 50~55 g / L, fully agitate the reaction; add calcine to the second stage acid leaching 2# reaction tank to extract acid underflow, pyrite concentrate and concentrate...

Embodiment 3

[0039] 1) In the zinc oxide fume two-stage acid leaching process, the one-stage acid leaching underflow with a liquid-to-solid ratio of 2 to 3:1 obtained by the one-stage acid leaching is respectively introduced into the second-stage acid leaching 1# reaction tank and the second-stage acid leaching 2 # In the reaction tank, the underflow of the first stage of acid leaching into the second stage of acid leaching 1# reaction tank is 40 m 3 / h, the underflow of the first stage of acid leaching into the second stage of acid leaching 2# reaction tank is 60 m 3 / h, add roasting dust and waste electrolyte into the second stage acid leaching 1# reaction tank, the main components of roasting dust are Zn 45-50 wt%; Fe 8-11 wt%; S 2.5-4.5 wt%, and the added amount is 4 t / h, the electrolyte contains H + 160~170 g / L, containing Zn 2+ 50~55 g / L, fully agitate the reaction; add calcine to the second stage acid leaching 2# reaction tank to extract acid underflow, pyrite concentrate and concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com