Stagnation pressure measuring device and method of oxygen lance system

A technology of stagnation pressure and measuring device, which is applied in the field of stagnation pressure measurement device of oxygen lance system, can solve the problems of unknown design requirements and the stagnation pressure of nozzles cannot be directly measured, and achieves the effect of optimizing the system and improving economic and technical indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

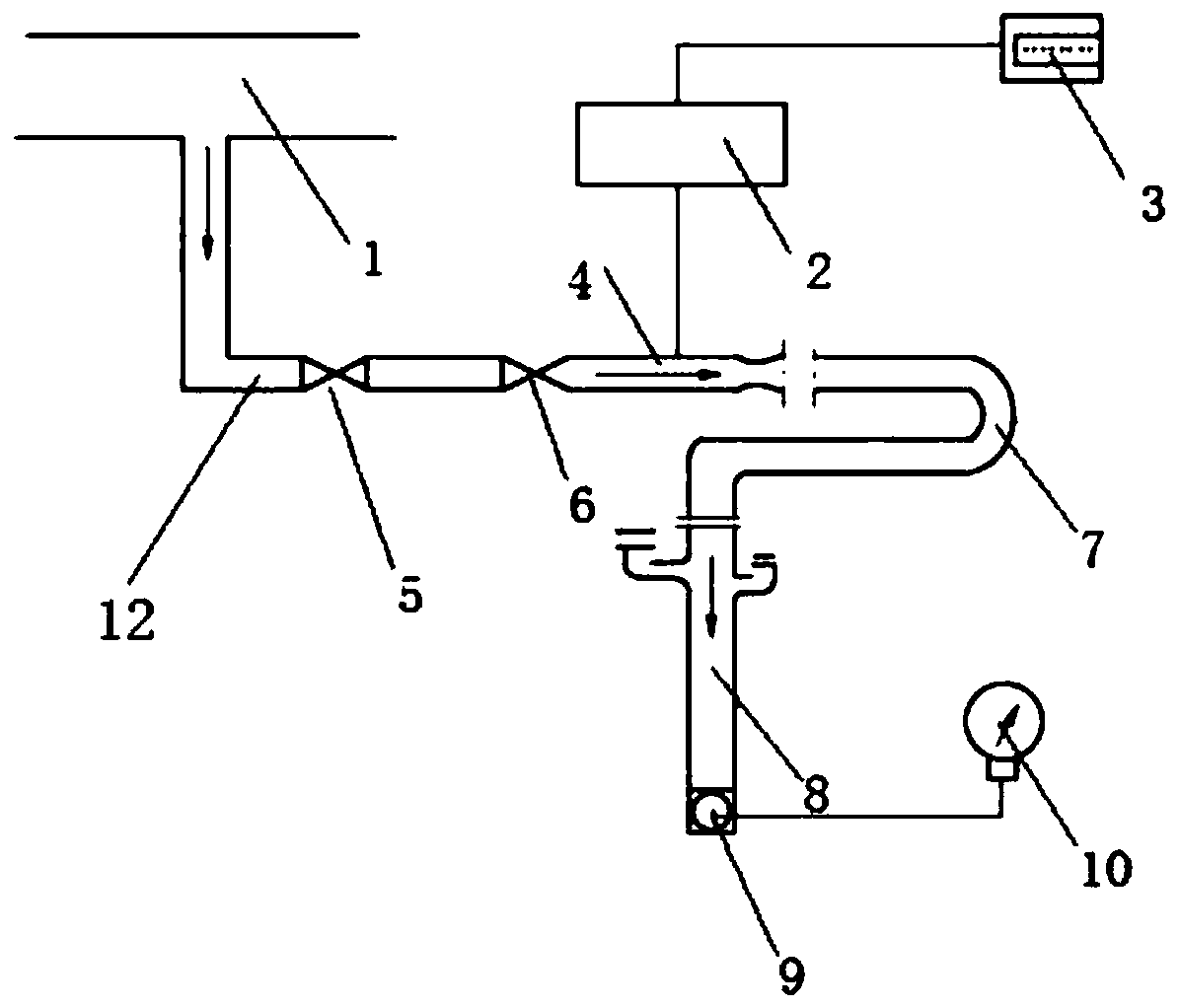

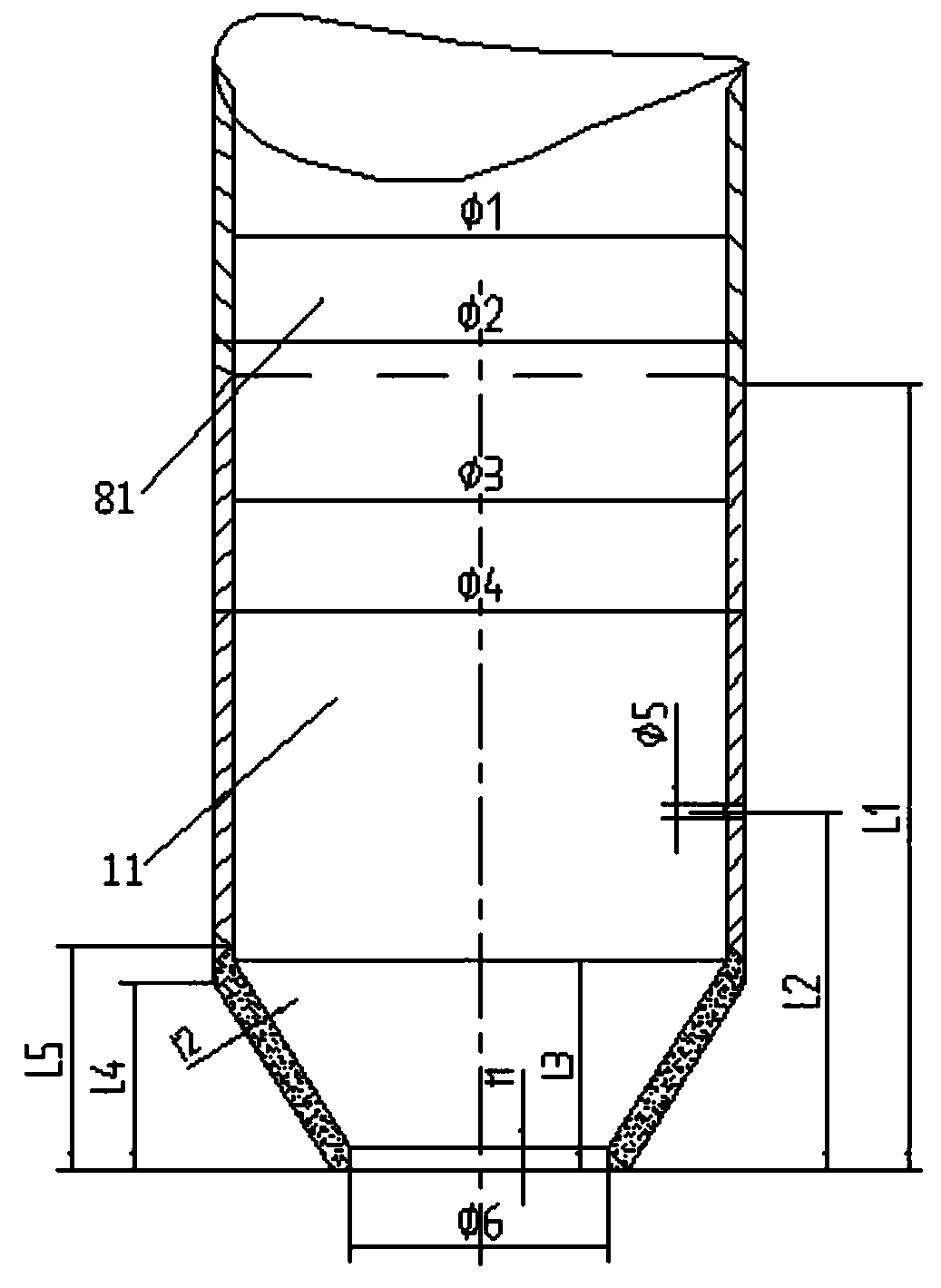

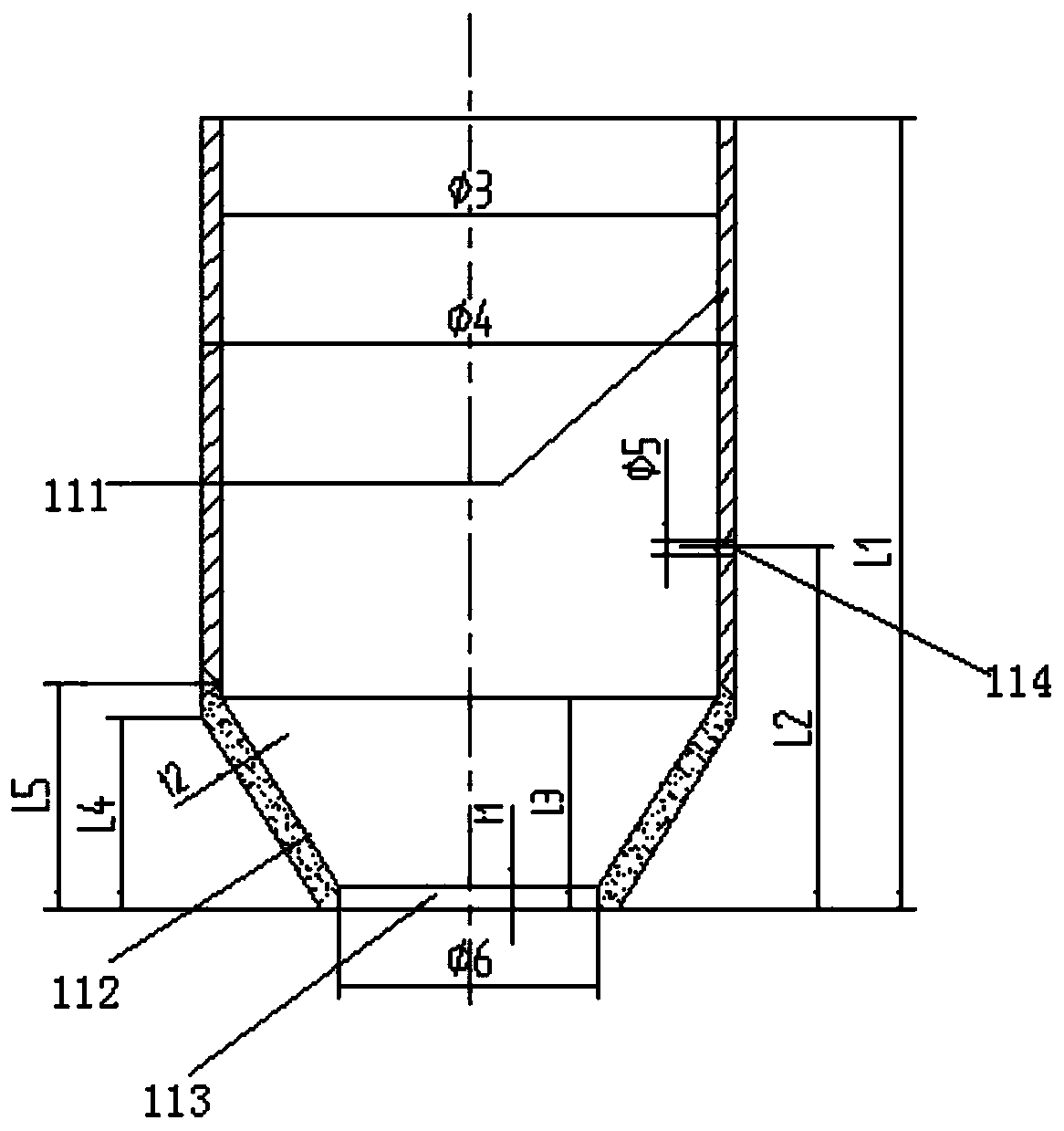

[0027] From figure 1 It can be seen that a stagnation pressure measurement device for an oxygen lance system in this embodiment includes an oxygen main pipe 1, the output end of the oxygen main pipe 1 is connected with an oxygen branch pipe 12, and the pipeline of the oxygen branch pipe 12 is sequentially provided with a regulating valve 5, a fast Shut-off valve 6 and pressure-taking point 4, pressure-taking point 4 is connected with branch pipe pressure transmitter 2, one end of branch pipe pressure transmitter 2 is connected with branch pipe pressure gauge 3, and the output end of oxygen branch pipe 12 is connected with oxygen The hose 7, the regulating valve 5 on the oxygen main pipe 1 and the oxygen branch pipe 12, the quick cut-off valve 6 and the oxygen hose 7 are connected in series in sequence. The lance end 9 and the oxygen lance end 9 are equipped with an equivalent throat 11. The equivalent throat 11 is composed of a cylindrical body 111 and a conical constriction s...

specific Embodiment

[0038] Specific examples are as follows, select 300 tons converter oxygen lance system,

[0039] Oxygen lance 8 has an outer diameter of 355.6mm, a throat diameter of 47.0mm, 6 holes, a Mach number of 2.05, a design stagnation pressure of P0=0.8572MPa, an inner tube 81 of the oxygen lance with an inner and outer diameter of 220mm and 236mm, and a cylinder body 111, The outer diameter is determined according to the inner tube 81 of the oxygen lance, Ф1=Ф3=220mm, Ф2=Ф4=236mm; the diameter Ф6 of the outlet 113 is calculated and determined according to the parameters of the oxygen lance 8 nozzle through the formula: Ф6=2×(A / π) 1 / 2 =2×(6×47×47 / 4×π / π) 1 / 2 =115mm; the height L4 of the tapered constriction section 112 is 84mm; the thickness t2 is 12mm; the total length L1 of the equivalent throat 11 is 350mm; Port 11 is made of Q235.

[0040] Measure the stagnation pressure P0 at the pressure-taking hole 114 through the standard pressure gauge 10, measure the pressure P1 at the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Mach number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com