Aluminum liquid horizontal measurement method and tool

A technology of level measurement and measurement tools, which is applied in the direction of liquid level indicators for physical variable measurement, can solve the problems of electrolytic cell interference, heavy workload, and cathode carbon block peeling off and bursting layers, etc., to improve economic and technical indicators, guide Enhanced effect and convenient measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

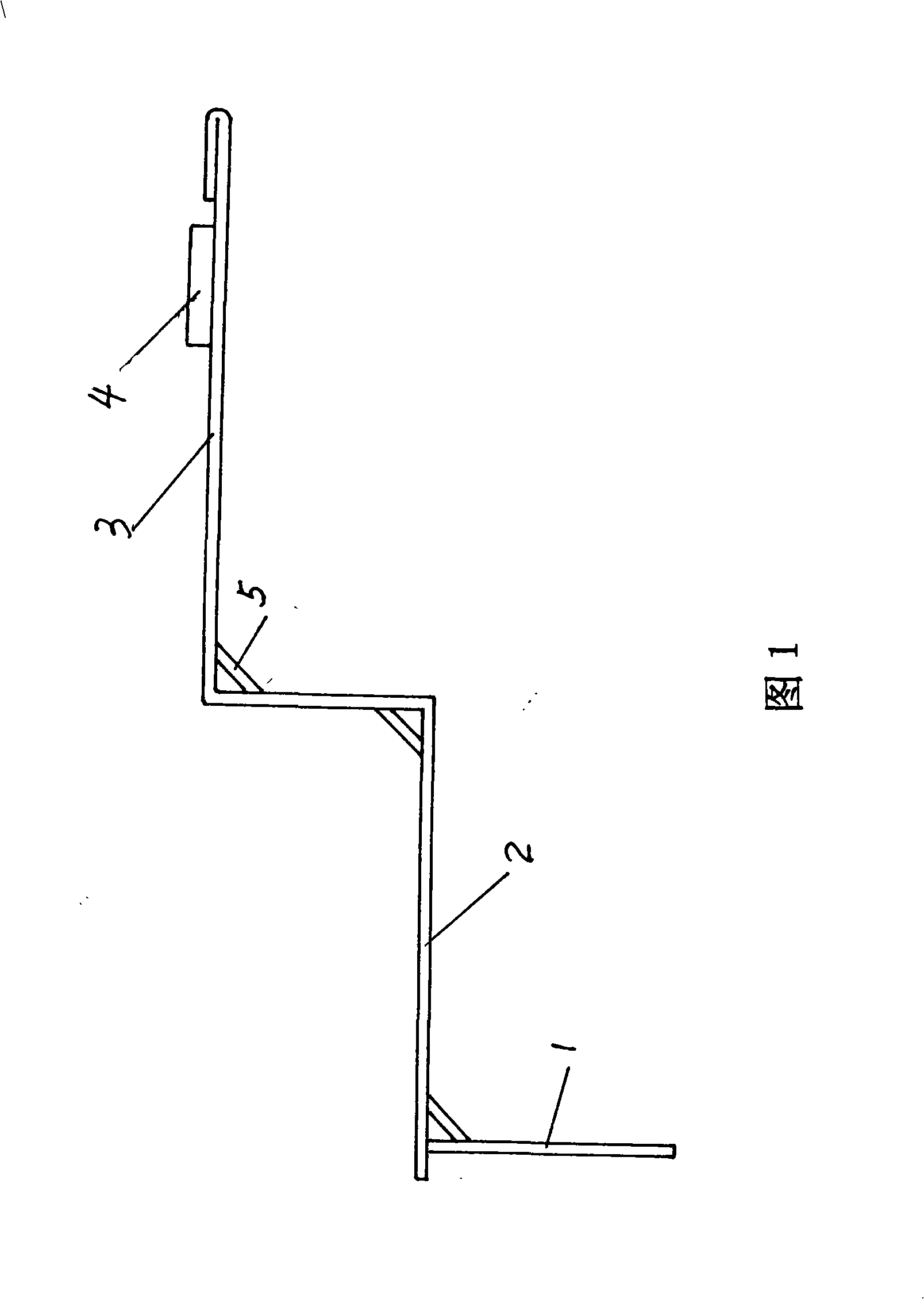

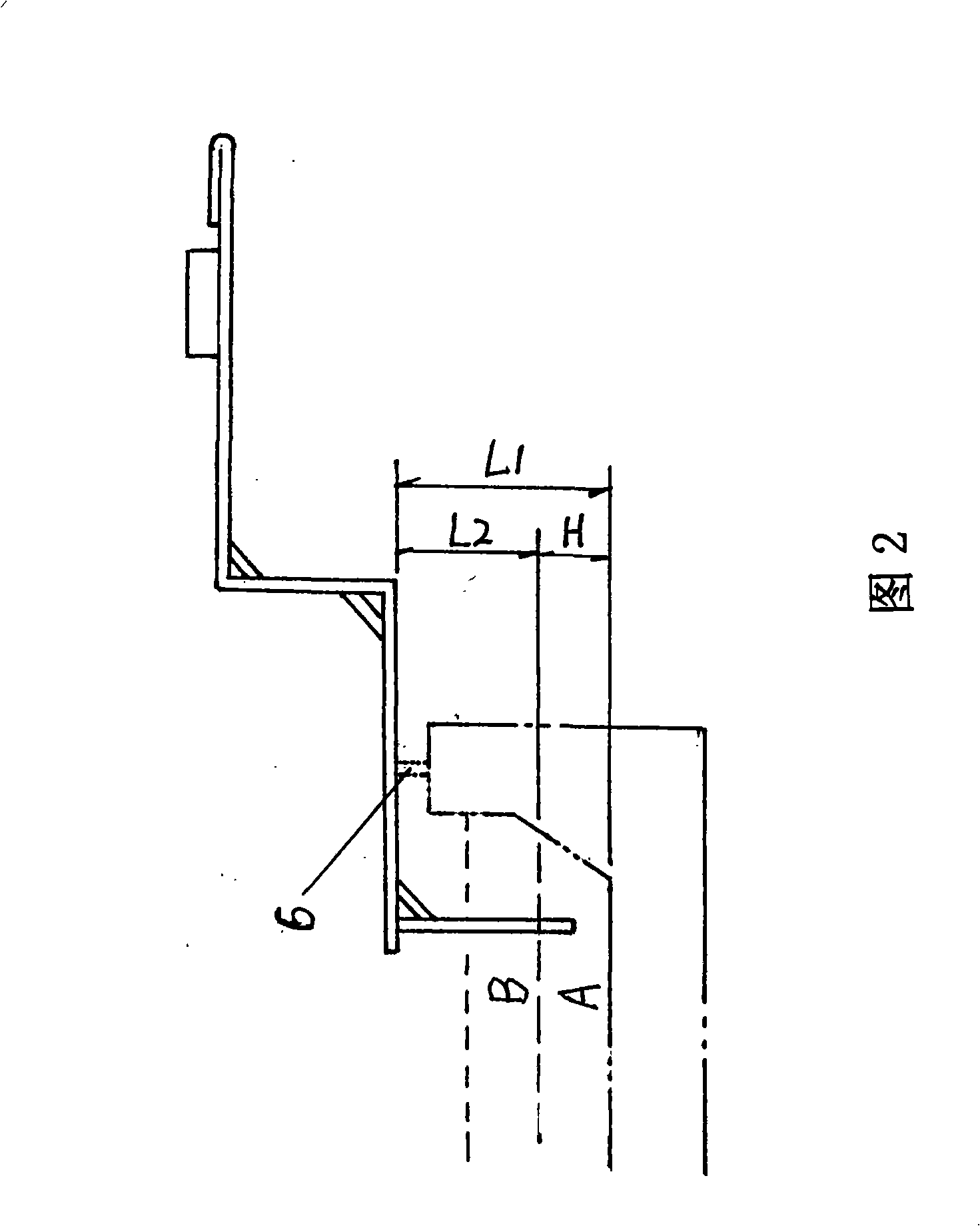

[0017] Embodiment 1: Take the vertical edge plate top of a certain electrolytic cell as the measurement reference zero point, and the distance L1 from the reference zero point to the upper surface of the cathode carbon block in the electrolytic cell is 58cm. Using the measuring tool of the present invention, its measured iron brazing length H1 is 53cm. According to the measurement method of the present invention, the measuring iron 1 of the measuring tool is vertically inserted into the aluminum electrolytic cell, and the reference level bar 2 of the measuring tool is placed on the vertical edge plate of the aluminum electrolytic cell, and the measurement of the iron can be guaranteed by observing the level ruler 4 vertical insertion. Then pull out the measuring tool. Because the heat dissipation speed of the electrolyte liquid and the aluminum liquid is different, at this time, a clear boundary mark between the two is left on the measuring iron braze 1 of the measuring tool....

Embodiment 2

[0018] Embodiment 2: Taking the top of the vertical edge plate of a certain electrolytic cell as the reference zero point of measurement, the distance L1 from the reference zero point to the upper surface of the cathode carbon block in the electrolytic cell is 62cm. Using the measuring tool of the present invention, its measured iron brazing length H1 is 50cm. According to the measuring method of the present invention, the measuring iron brazing 1 of the measuring tool is vertically inserted into the aluminum electrolytic cell, and the reference horizontal bar 2 of the measuring tool is placed on the vertical edge plate of the aluminum electrolytic cell. Then pull out the measuring tool. Because the heat dissipation speed of the electrolyte liquid and the aluminum liquid is different, at this time, a clear boundary mark between the two is left on the measuring iron braze 1 of the measuring tool. In this way, the value L2 measured from the reference zero point to the boundary ...

Embodiment 3

[0019] Embodiment 3: Take the vertical edge plate top of a certain electrolytic cell as the reference zero point of measurement, and the distance L1 from the reference zero point to the upper surface of the cathode carbon block in the electrolytic cell is 68cm. Using the measuring tool of the present invention, its measured iron brazing length H1 is 55cm. According to the measurement method of the present invention, the measuring iron 1 of the measuring tool is vertically inserted into the aluminum electrolytic cell, and the reference level bar 2 of the measuring tool is placed on the vertical edge plate of the aluminum electrolytic cell, and the measurement of the iron can be guaranteed by observing the level ruler 4 vertical insertion. Then pull out the measuring tool. The numerical value L2 measured from the reference zero point to the boundary point of the electrolyte and the aluminum liquid level according to the boundary mark left on the measuring iron brazing 1 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com