Detection system for continuous detection of molten steel temperature and composition for converter steelmaking

A technology of molten steel temperature and converter steelmaking, applied in the direction of manufacturing converters, etc., can solve the problems such as the inability to provide continuous molten steel temperature and the demand for important components for steelmaking operators, and the decline of economic and technical indicators, and achieve the goal of improving economic and technical indicators. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

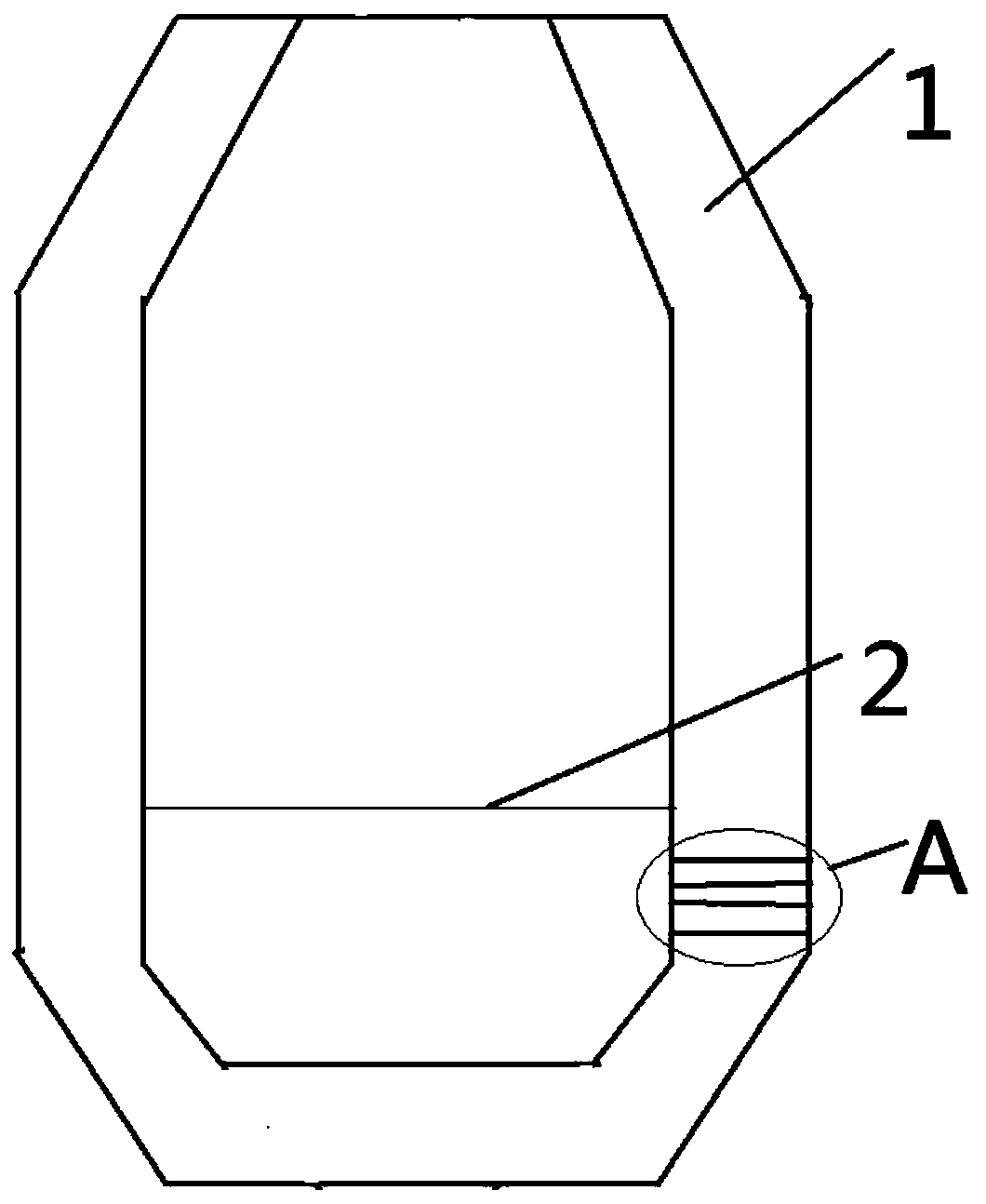

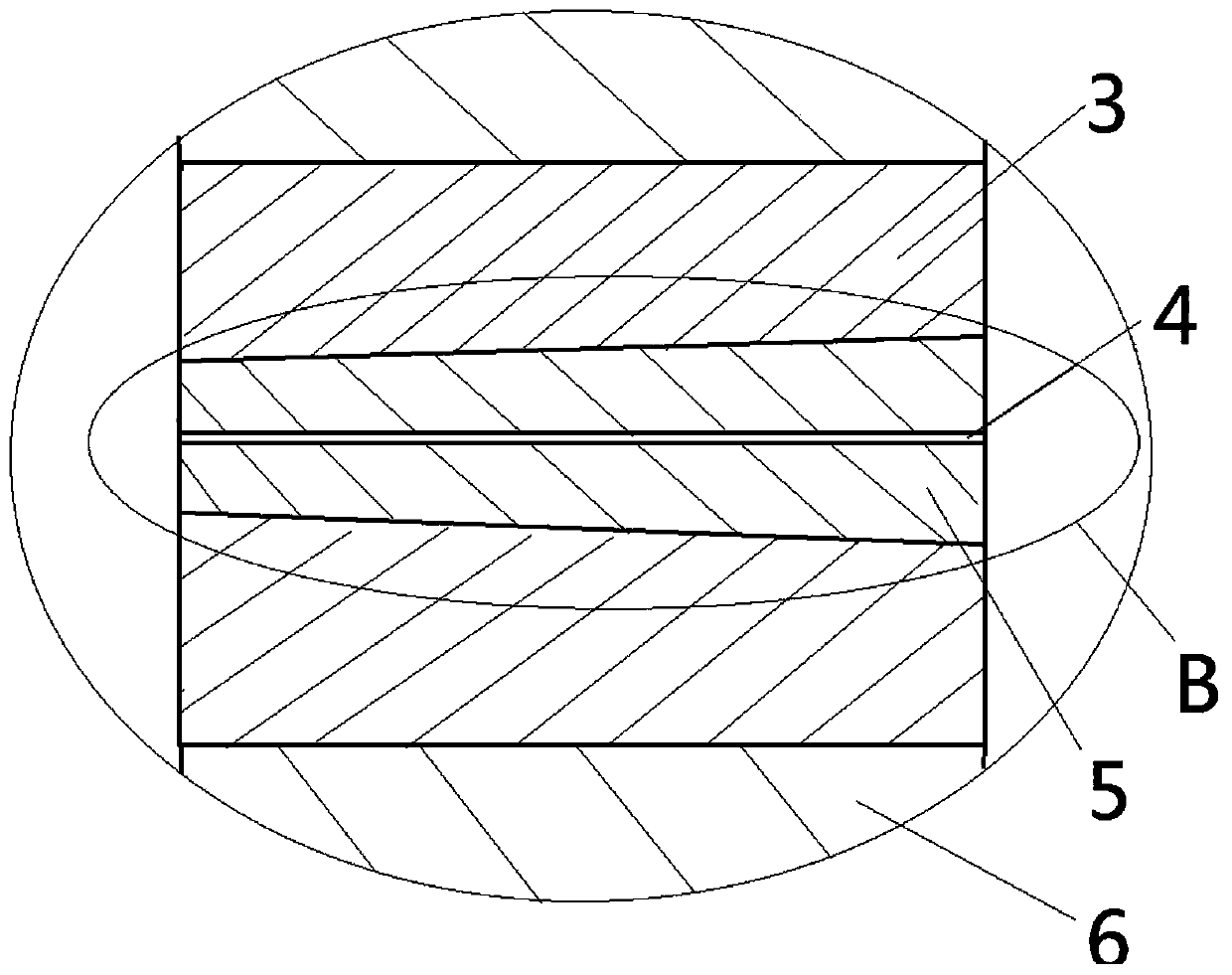

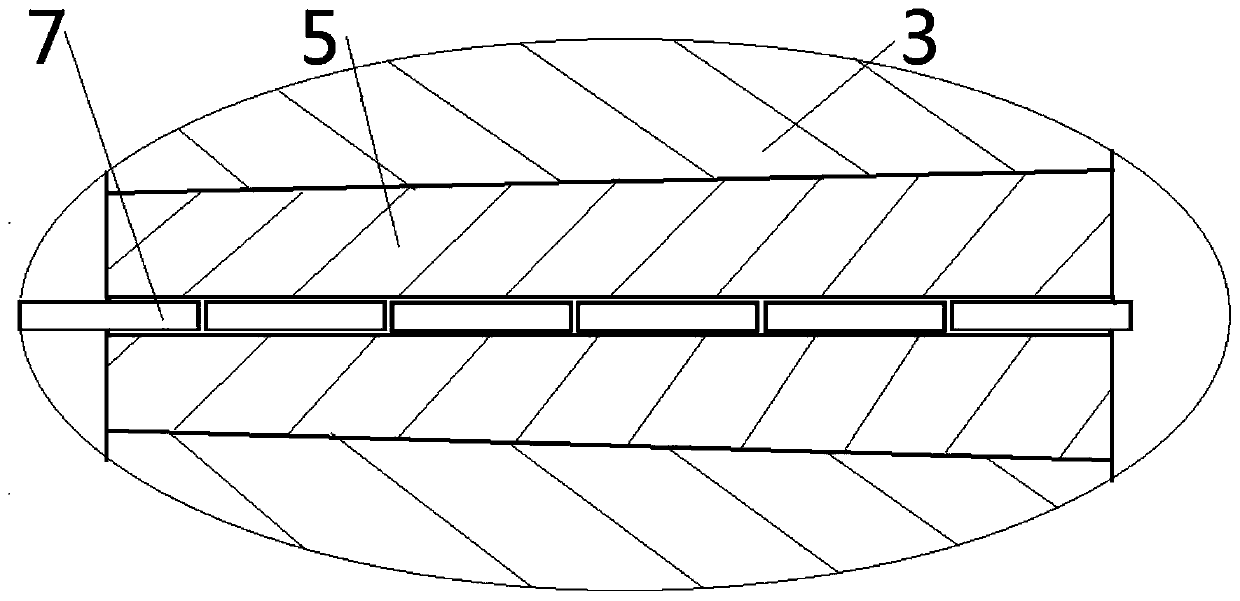

[0038] Such as figure 1 As shown, this embodiment provides a detection system for continuously detecting the temperature and composition of molten steel in converter steelmaking, including a block 3, a probe delivery pipe 5 and a detection probe 7; On the side wall, a mounting hole is provided in the middle of the block 3, and the diameter of the mounting hole facing the inside of the converter 1 is smaller; the probe delivery pipe 5 is arranged in the installation hole, and the probe delivery pipe 5 is provided with a There are a plurality of detection through holes 4, the number of detection through holes 4 is determined according to different detection items, generally three to five can be set, four detection through holes 4 are set in this embodiment, and the detection probe 7 includes a temperature measurement Probes, crystallization carbon determination probes, oxygen measurement probes and phosphorus measurement probes, each detection through hole 4 is provided with a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com