Quantification blow-in method for blast furnace

A blast furnace and air volume technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of different opening times, slow improvement of economic and technical indicators, and damage to blast furnace longevity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

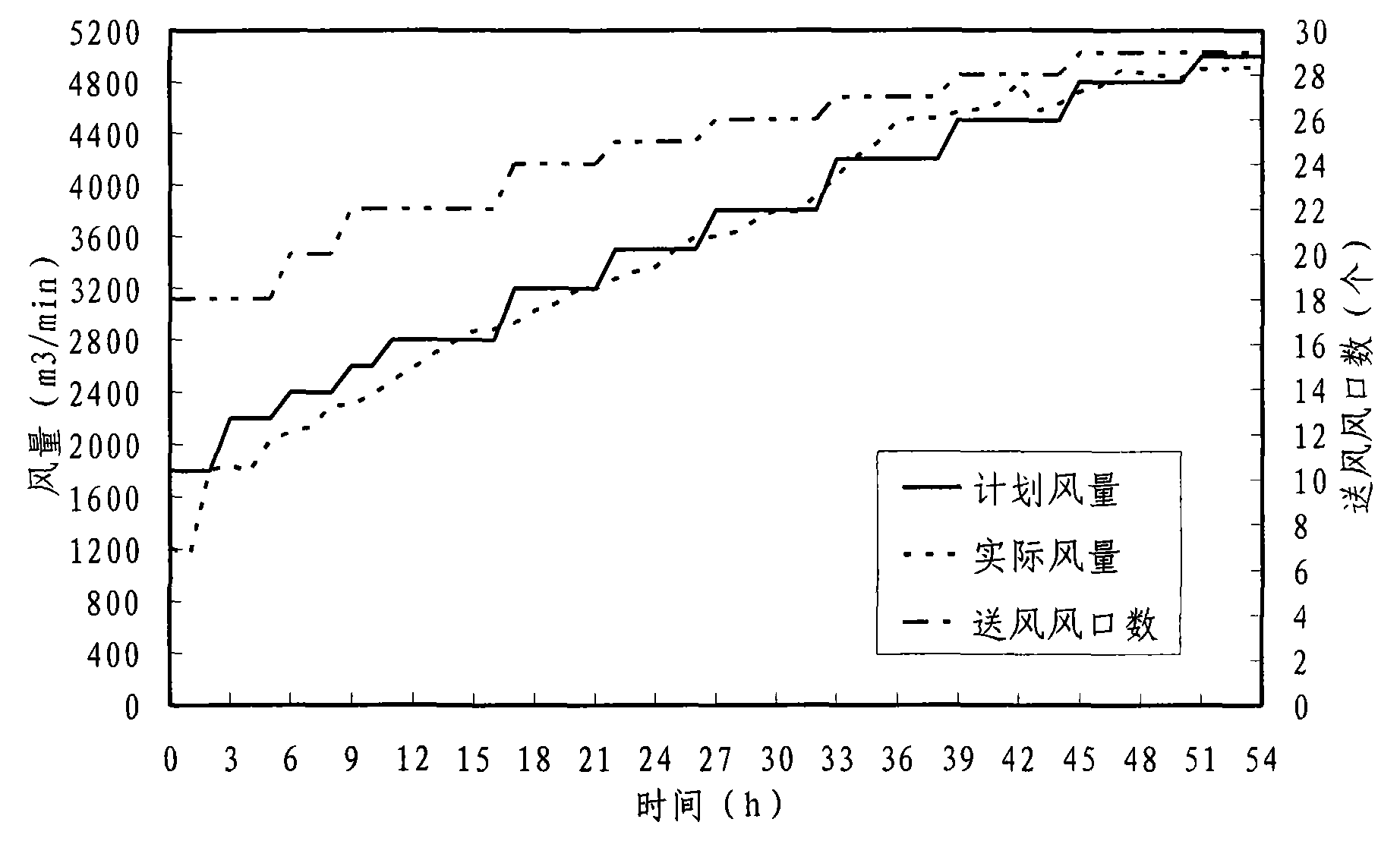

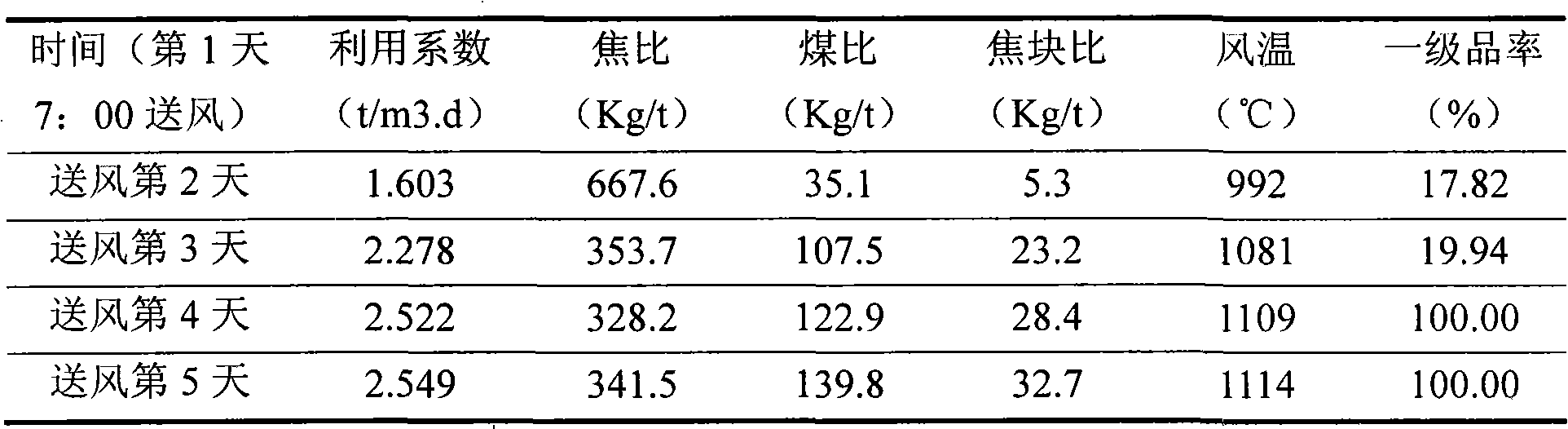

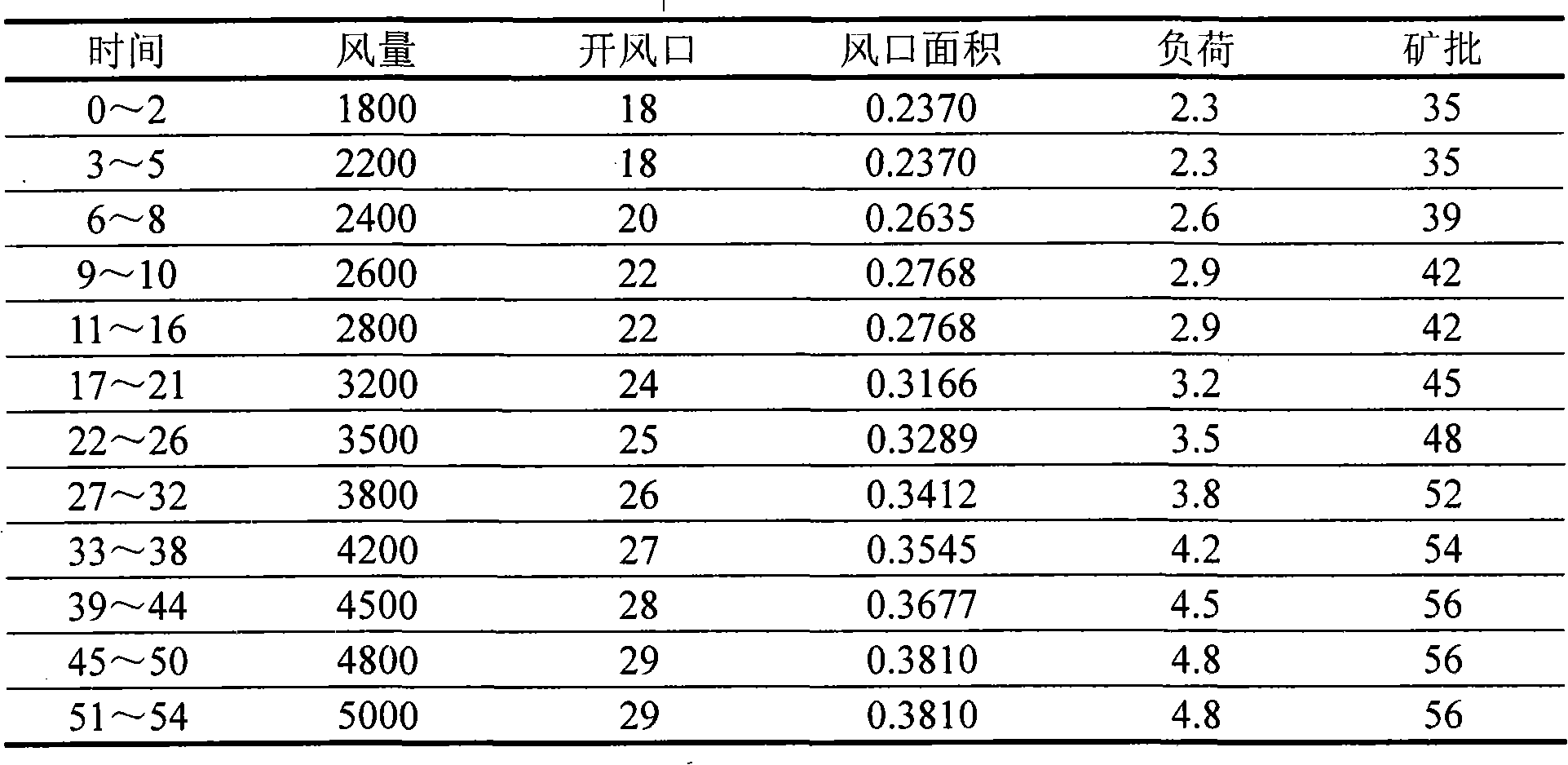

[0047] Effective volume of Shougang No. 1 blast furnace 2536m 3 , 30 tuyere and 3 iron ports, the furnace was opened on August 9, 1994. In recent years, the blast furnace has continuously strengthened smelting, and the main economic and technical indicators are close to the domestic advanced level. On March 21, 2009, the No. 1 blast furnace was shut down with the empty material line lowering surface, and a 5-day maintenance was carried out. The top airtight box was replaced, and the inner tuyere belt of the blast furnace was sprayed to the lower edge of the furnace throat steel tile. lining. Before opening the furnace, based on the quantitative principle of the opening technology, combined with the specific conditions of the opening of the blast furnace, the nodes and control principles at each stage of the opening process were calculated and planned, and various parameters of the opening process were refined.

[0048] Table 2 Quantitative control parameters of blast furnace star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com