Method and corresponding tool for automatically adjusting the screwing speed of a screwing tool on a continuous scale

A screw speed, automatic adjustment technology, applied in the field of tools, can solve the problems of productivity loss, error, torque overshoot, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

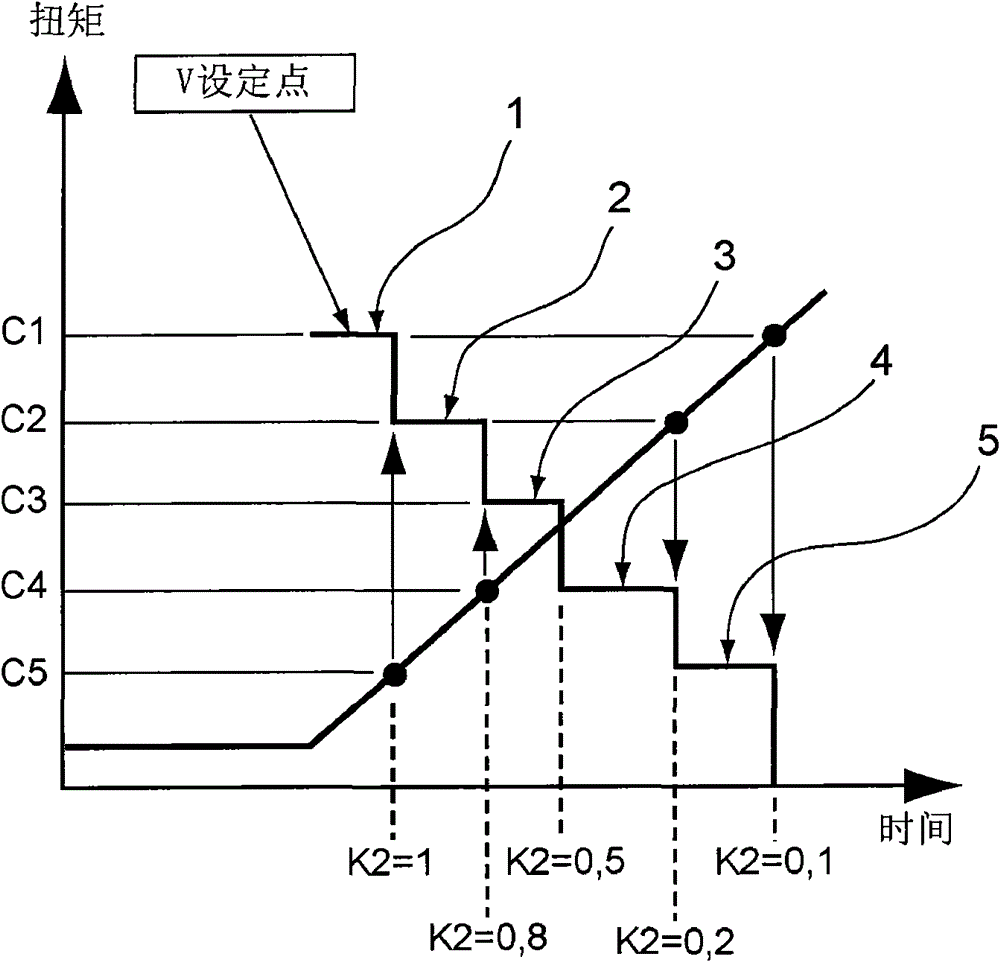

[0056] As indicated above, the principle of the present invention lies in the fact that a method is proposed for automatically adjusting the screwing speed as the torque changes, wherein the screwing speed is determined according to the upper and lower limits of the torque change as a function of time and Adjusted in successive levels defined by the percentage of the final torque to be achieved, where the screwing speed decreases from one level to the next and is calculated based on two coefficients:

[0057] a first coefficient K1, which is determined according to the rate of change dC / dT of the torque or in other words according to the torque change over time;

[0058]A second coefficient K2, which is determined from the torque level achieved (measured) relative to the final torque to be achieved.

[0059] For each level, the setpoint speed Vc is defined as follows:

[0060] Vc=V Max ×K1×K2,

[0061] where V Max = maximum speed of the tool (obtained from the characterist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com