Method for improving filtration performance of zinc oxide leaching liquid

A filter performance and leaching solution technology, which is applied in the field of improving the filtration performance of zinc oxide leaching solution, to achieve the effects of reducing hazards, reducing overall costs, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

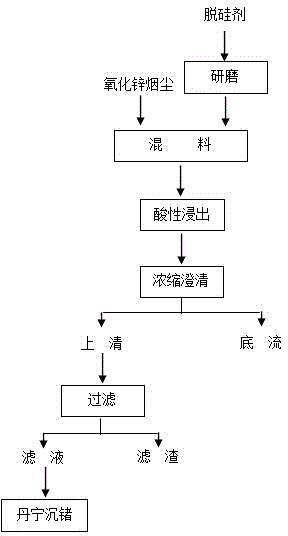

Method used

Image

Examples

Embodiment 1

[0023] (1) Add zinc oxide soot mixture containing 1% calcium-aluminum composite desiliconization agent into 1000mL dilute sulfuric acid solution, keep the temperature at 65-80°C, and leaching time for 2.5 hours. The terminal acidity at this time is 1.1g / L , keep the temperature at 70-75°C for natural concentration and clarification for 30 minutes, take the supernatant and filter: natural filtration rate 10mL / min;

[0024] (2) Add zinc oxide dust into 1000mL of dilute sulfuric acid solution, keep the temperature at 65-80°C, and leaching time for 2.5 hours. At this time, the end point acidity is 1.2g / L, keep the temperature at 70-75°C for 30 minutes to concentrate and clarify naturally, take the above Clear filtration: natural filtration rate 5mL / min.

Embodiment 2

[0026] (1) Add the zinc oxide soot mixture containing 2.5% calcium-aluminum composite desiliconization agent into 1000mL dilute sulfuric acid solution, keep the temperature at 65-80°C, and leaching time for 2.5 hours. The terminal acidity at this time is 1.0g / L , keep the temperature at 70-75°C for natural concentration and clarification for 30 minutes, take the supernatant and filter: the natural filtration rate is 16.4mL / min;

[0027] (2) Add zinc oxide dust into 1000mL dilute sulfuric acid solution, keep the temperature at 65-80°C, and leaching time for 2.5 hours. At this time, the end-point acidity is 1.1g / L, keep the temperature at 70-75°C for 30 minutes to concentrate and clarify naturally, take the above Clear filtration: natural filtration rate 5.3mL / min.

Embodiment 3

[0029] (1) Add the zinc oxide soot mixture containing 5% calcium-aluminum composite desiliconization agent into 1000mL dilute sulfuric acid solution, keep the temperature at 65-80°C, and leaching time for 2.5 hours. The terminal acidity at this time is 0.8g / L , keep the temperature at 70-75°C for natural concentration and clarification for 30 minutes, take the supernatant and filter: the natural filtration rate is 17.8mL / min;

[0030] (2) Add zinc oxide dust into 1000mL dilute sulfuric acid solution, keep the temperature at 65-80°C, and leaching time for 2.5 hours. At this time, the end point acidity is 1.0g / L, keep the temperature at 70-75°C for 30min to concentrate and clarify naturally, take the above Clear filtration: natural filtration rate 4.9mL / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com