Blow-in method for blast furnace to smelt high-titanium type vanadium titano-magnetite

A vanadium-titanium magnetite and blast furnace smelting technology, which is applied to blast furnaces, blast furnace details, furnace types, etc., can solve the problems of restricting blast furnace production and efficiency progress, slow material conversion speed, high consumption, etc., and improve economic and technical indicators , fast effect and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

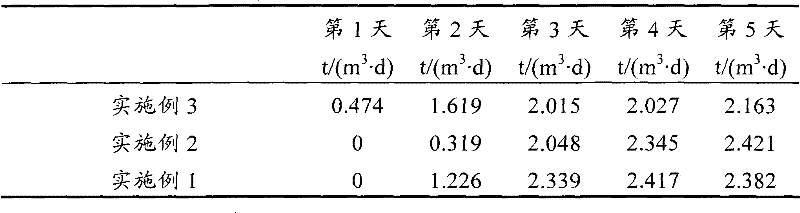

Embodiment 1

[0037] The furnace opening method of the present invention is used in a blast furnace for smelting high-titanium vanadium-titanium magnetite. The blast furnace capacity is 1200m 3 .

[0038] Iron-bearing lump ore is high-titanium vanadium-titanium magnetite lump ore, of which all iron (T Fe ) content is 44wt%, silicon dioxide (SiO 2 ) content can be 18wt%, and the particle size is in the range of 25-75mm. The particle size of the limestone is between 25mm and 75mm, and the effective calcium oxide (CaO) content is greater than 51wt%.

[0039] For the selection of tuyere area, except for the 4 tuyeres where furnace bottom ignition blowpipes are installed, φ90mm tuyere refractory ferrules are installed on the rest, and the air inlet area is 69.22% of the normal blast area. First, the hearth and the middle and lower parts of the bosh are filled with coke, the upper part of the bosh and the waist are filled with empty material, and then when the empty material and normal materi...

Embodiment 2

[0041] The furnace opening method of the present invention is used in a blast furnace for smelting high-titanium vanadium-titanium magnetite. The blast furnace capacity is 2000m 3 .

[0042] The lump ore is a high-titanium vanadium-titanium magnetite lump ore, of which all-iron (T Fe ) content is 44wt%, silicon dioxide (SiO 2 ) content can be 18wt%, and the particle size is in the range of 25-75mm. The particle size of the limestone is between 25mm and 75mm, and the effective calcium oxide (CaO) content is greater than 51wt%.

[0043] For the selection of tuyere area, except for the 4 tuyeres where furnace bottom ignition blowpipes are installed, φ90mm tuyere refractory ferrules are all installed, and the air inlet area is 68.72% of the normal blast area. Firstly, the hearth and the middle and lower parts of the bosh are filled with coke, the upper part of the bosh and the furnace waist are filled with empty material, and when the empty material and normal material are loa...

Embodiment 3

[0045] The furnace opening method of the present invention is used in a blast furnace for smelting high-titanium vanadium-titanium magnetite. The blast furnace capacity is 1280m 3 .

[0046] The lump ore is a high-titanium vanadium-titanium magnetite lump ore, of which all-iron (T Fe ) content is 46wt%, silicon dioxide (SiO 2 ) content can be 20wt%, and the particle size is in the range of 25-75mm. The particle size of the limestone is between 25mm and 75mm, and the effective calcium oxide (CaO) content is greater than 55wt%.

[0047] For the selection of tuyere area, except for the 4 tuyeres where furnace bottom ignition blowpipes are installed, φ90mm tuyere refractory ferrules are installed on the rest, and the air inlet area is 67.8% of the normal blast area. Firstly, the hearth and the middle and lower parts of the bosh are filled with coke, the upper part of the bosh and the furnace waist are filled with empty material, and when the empty material and normal material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com